Concrete steam curing method in subway construction

A steam curing and concrete technology, which is applied in the field of engineering construction, can solve the problems of reduced hydration products, reduced concrete performance, insufficient hydration of cementitious materials, etc., to reduce peeling and cracks, reduce costs, and improve maintenance efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

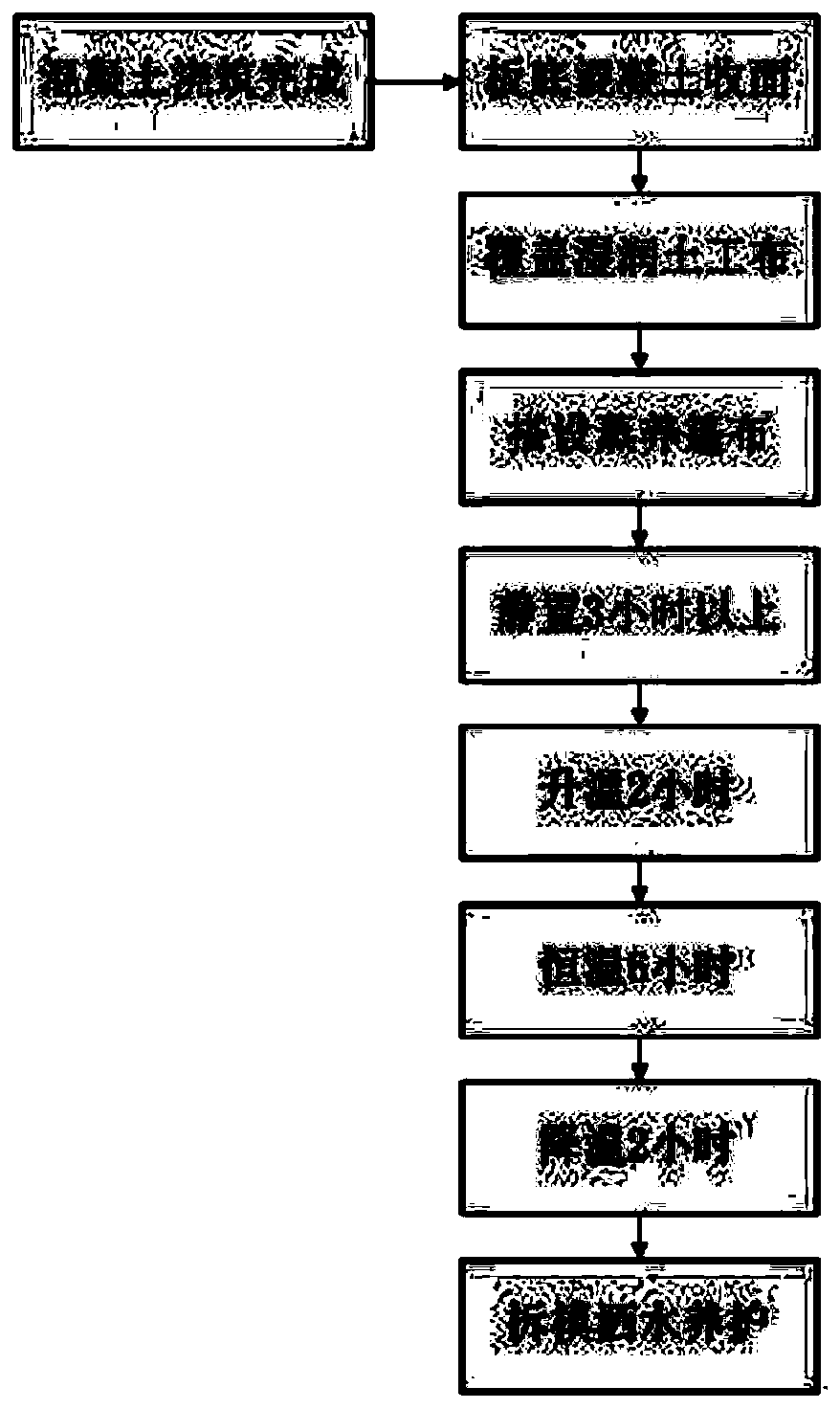

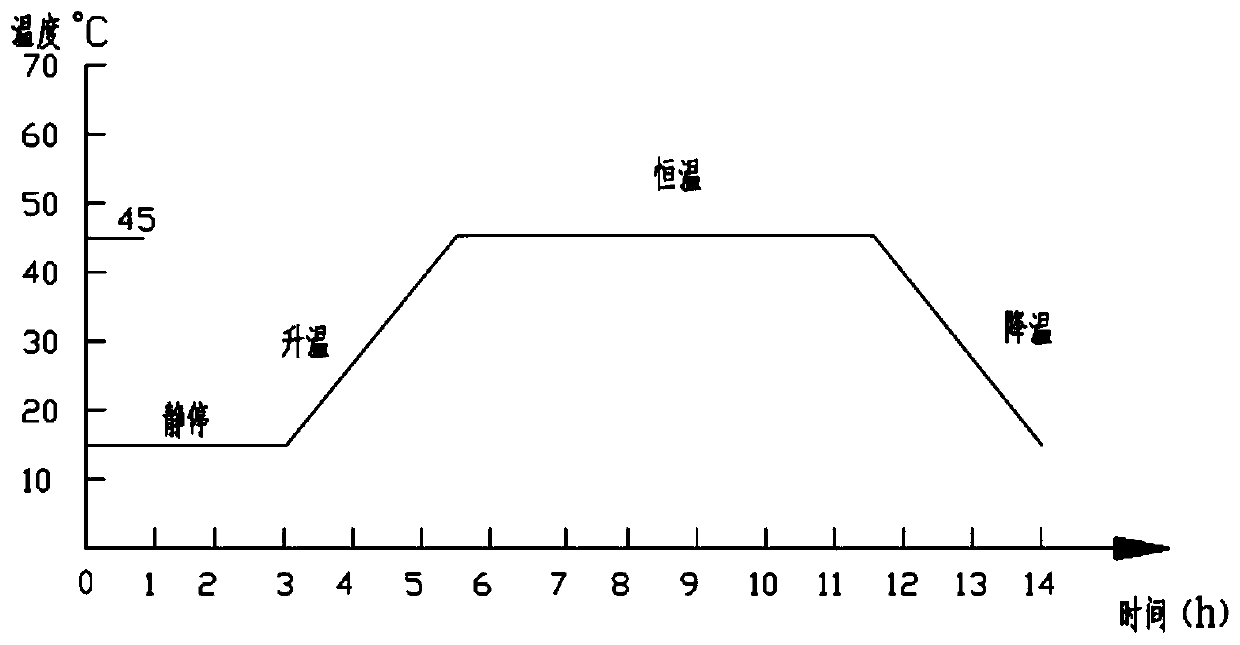

[0045] In the winter subway construction in a certain place in the south, the steam curing of the concrete of the main structure of the subway construction station is carried out according to the following procedures:

[0046] 1. Concrete finish

[0047] After vibrating and stopping for 3 minutes, the concrete surface at the bottom of the slab should be closed, and the edges and corners should be filled. When the concrete slump is large, spread clean gravel with a diameter of 1cm-2cm in the longitudinal anchor hole and the lifting position and smooth it into the concrete. After the concrete at the bottom of the slab is closed, it is necessary to take protective measures on the concrete slab, and it is strictly forbidden to step on it before the final setting.

[0048] After the concrete is vibrated for 20-30 minutes, cover the concrete surface with a geotextile moistened with water; then cover with a tarpaulin and sprinkle water to prevent the concrete from dispersing too qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com