High-strength graphite product produced by adding pitch coke, and preparation method thereof

A technology of graphite products and pitch coke, applied in the field of graphite product preparation, can solve the problems such as insufficient use of excellent characteristics, cracks in graphite products, and excessive amount of binder, and achieves dense structure, cracks and other unqualified products. , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

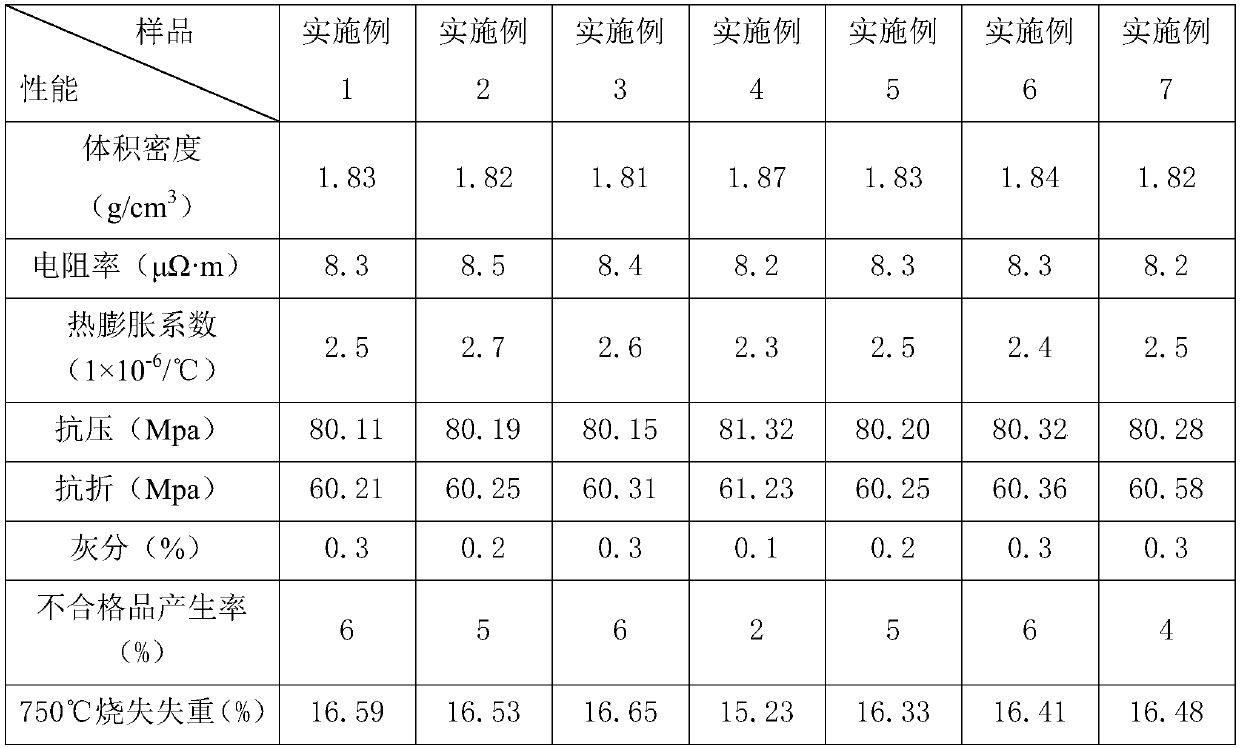

Examples

Embodiment 1

[0071] 1) Ingredients: Raw materials are prepared according to 0.30 tons of pitch coke with a particle size greater than 0mm and less than or equal to 0.8mm, 0.50 tons of calcined coke with a particle size greater than 0mm and less than or equal to 0.8mm, and 0.20 tons of coal tar pitch; wherein, the particle size is greater than 0mm and less than or equal to 0.8 The particle size distribution of pitch coke in mm is as follows:

[0072] 0.5mm

[0073] 0

[0074] 2) Kneading: Pour the prepared pitch coke and calcined coke into a kneading pot and stir for dry mixing. The dry mixing temperature is 130°C and the dry mixing time is 30 minutes; then put the coal tar pitch into the kneading pot and stir for wet mixing. The mixing temperature is 160°C, and the wet mixing time is 25 minutes;

[0075] 3) Drying: Cool the kneaded paste to 100°C for drying, and the drying time is 20 minutes;

[0076] 4) Vibration molding: Pour the air-dr...

Embodiment 2

[0082] 1) Ingredients: Raw materials are prepared according to 0.28 tons of pitch coke with a particle size greater than 0mm and less than or equal to 0.8mm, 0.52 tons of calcined coke with a particle size greater than 0mm and less than or equal to 0.8mm, and 0.20 tons of coal tar pitch; wherein, the particle size is greater than 0mm and less than or equal to 0.8 The particle size distribution of pitch coke in mm is as follows:

[0083] 0.5mm

[0084] 0

[0085] 2) Kneading: Pour the prepared pitch coke and calcined coke into a kneading pot and stir for dry mixing. The dry mixing temperature is 120°C and the dry mixing time is 30 minutes; then put the coal tar pitch into the kneading pot and stir for wet mixing. The mixing temperature is 130°C, and the wet mixing time is 25 minutes;

[0086] 3) Drying: Cool the kneaded paste to 120°C for drying, and the drying time is 20 minutes;

[0087] 4) Vibration molding: Pour the air-dr...

Embodiment 3

[0093] 1) Ingredients: Raw materials are prepared according to 0.32 tons of pitch coke with a particle size greater than 0 mm and less than or equal to 0.8 mm, 0.48 tons of calcined coke with a particle size greater than 0 mm and less than or equal to 0.8 mm, and 0.20 tons of coal tar pitch; wherein, the particle size is greater than 0 mm and less than or equal to 0.8 The particle size distribution of pitch coke in mm is as follows:

[0094] 0.5mm

[0095] 0

[0096] 2) Kneading: Pour the prepared pitch coke and calcined coke into a kneading pot and stir for dry mixing. The dry mixing temperature is 140°C and the dry mixing time is 30 minutes; then put the coal tar pitch into the kneading pot and stir for wet mixing. The mixing temperature is 160°C, and the wet mixing time is 25 minutes;

[0097] 3) Drying: Cool the kneaded paste to 100°C for drying, and the drying time is 30 minutes;

[0098] 4) Vibration molding: Pour the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com