A Concrete Wall Direct Buried Power Distribution Switch Box Installation Construction Technology

A technology for concrete walls and power distribution switches, which is applied to walls, buildings, building components, etc., can solve the problems affecting the stability and safety of power distribution switch boxes, damage to the structural strength and aesthetics of the wall, and the combination of the periphery and the wall. The problem of poor tightness, etc., can reduce wall cracks, improve installation and operation stability, and reduce the effect of opening formwork construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

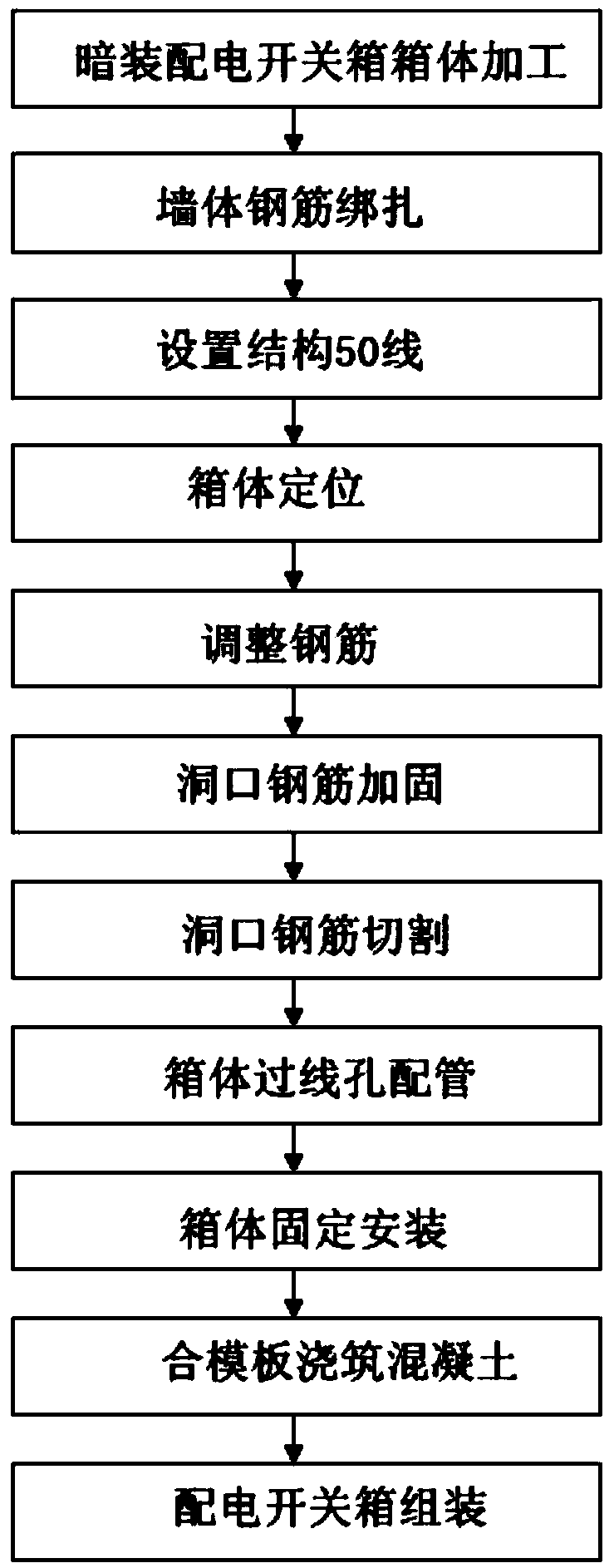

[0025] Such as figure 1 The installation and construction process of a concrete wall directly buried power distribution switch box shown includes the following steps:

[0026] The first step is to process the box body of the concealed assembly electric switch box, select the power distribution switch box of the corresponding specification according to the design and model of the pipeline on the drawing, and slot the wire hole on the side wall of the power distribution switch box, and the edge of the wire hole The distance from the edge of the box is 10mm, and then the cable hole is sealed with an elastic sealing plug, and a reinforced support rib is set in the power distribution switch box, and each side surface of the power distribution switch box is supported and positioned by the reinforced support rib. After the installation and positioning of the reinforced support ribs is completed, another layer of engine oil is applied to the inner surface of the distribution switch bo...

Embodiment 2

[0038] Such as figure 1 The installation and construction process of a concrete wall directly buried power distribution switch box shown includes the following steps:

[0039] The first step is to process the box body of the concealed assembly electric switch box, select the power distribution switch box of the corresponding specification according to the design and model of the pipeline on the drawing, and slot the wire hole on the side wall of the power distribution switch box, and the edge of the wire hole The distance from the edge of the box is 5mm, and then the cable hole is sealed with an elastic sealing plug, and a reinforced support rib is set in the power distribution switch box, and each side surface of the power distribution switch box is supported and positioned by the reinforced support rib. After the installation and positioning of the reinforced support ribs is completed, another layer of engine oil is applied to the inner surface of the distribution switch box, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com