Installation and construction method of heat preservation layer and outer protective plate of high-temperature high-pressure pipeline

A technology of pipeline thermal insulation layer, high temperature and high pressure, applied in pipeline protection, thermal insulation, pipeline protection through thermal insulation, etc., can solve problems such as poor thermal insulation performance, thick pipeline thermal insulation layer, tight pipeline layout space, etc., to save space and reduce thickness. Insulation thickness, reducing the effect of reserved holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

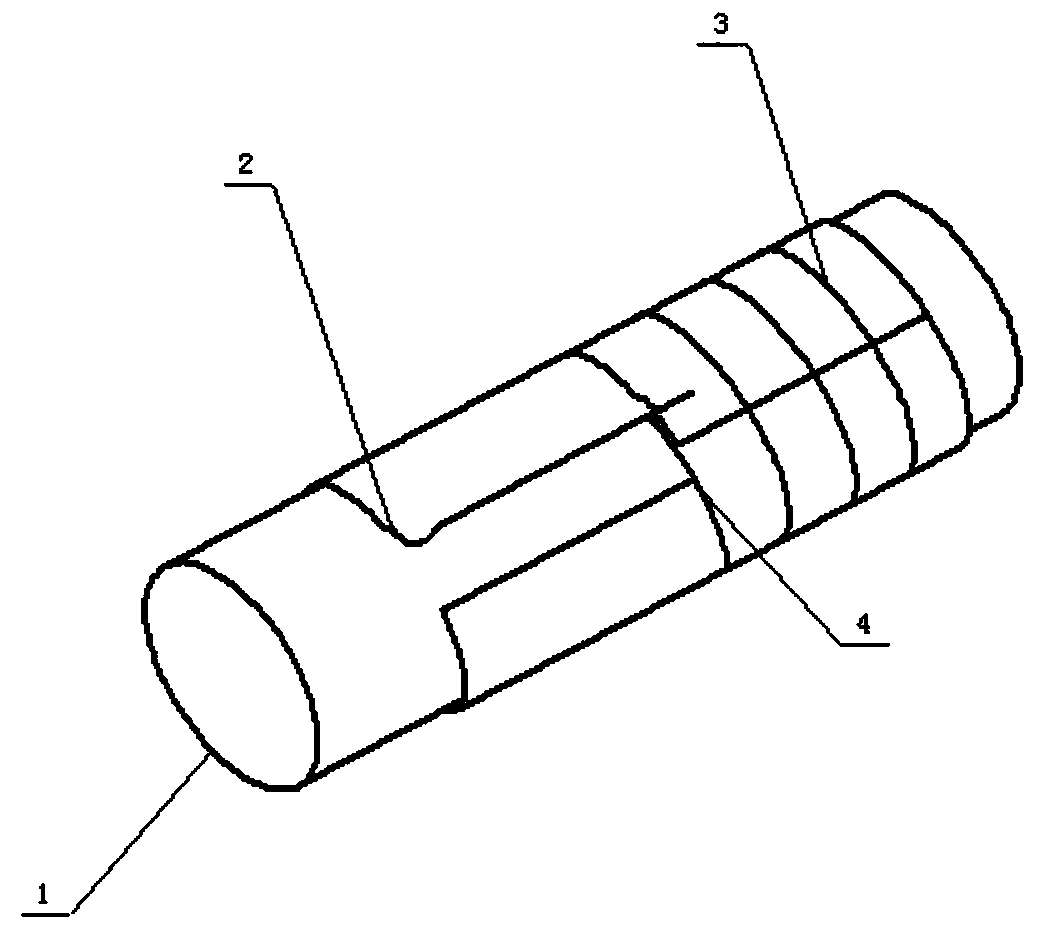

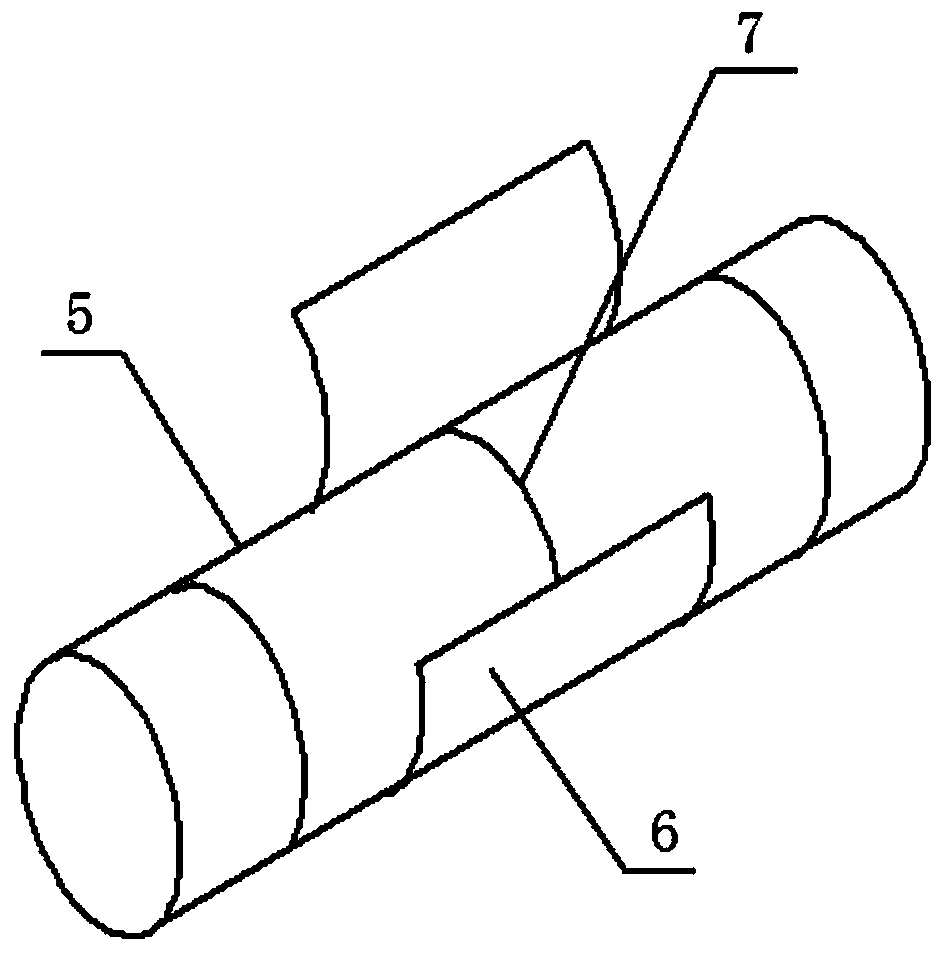

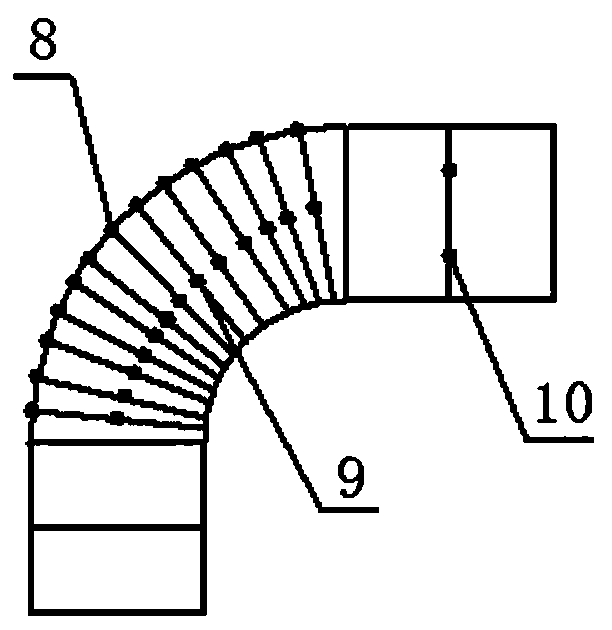

[0051] Below in conjunction with accompanying drawing, the present invention will be further explained and illustrated:

[0052] see Figure 1-Figure 3 , an installation and construction method of a high-temperature and high-pressure pipeline insulation layer and an outer guard plate, the specific steps are as follows:

[0053] Preparations include:

[0054] 1) Prepare the airgel thermal insulation blanket, metal plate, galvanized iron wire, plate connecting strip, lining strip, self-tapping screw required for construction;

[0055] 2) According to the diameter of the pipe and the size of the elbow, measure and calculate the position of the hole in the wall;

[0056] 3) Determine the length of the airgel insulation blanket required for each insulation layer of the pipeline by direct wrapping measurement;

[0057] Specific steps:

[0058] 1) Laying of pipeline airgel thermal insulation blanket insulation layer:

[0059] 1. Laying of airgel thermal insulation felt insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com