Noise-reducing and energy-saving EPDM polyrib belt

A technology of EPDM rubber and V-ribbed belts, applied in V-belts, fiber types, belts/chains/gears, etc., can solve the problem of reducing the contact area between the V-belt and the pulley, and the large contact area between the V-belt and the pulley , large friction between wedge and pulley, etc., to achieve the effect of reducing wire rope breakage, low production cost, and increased tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

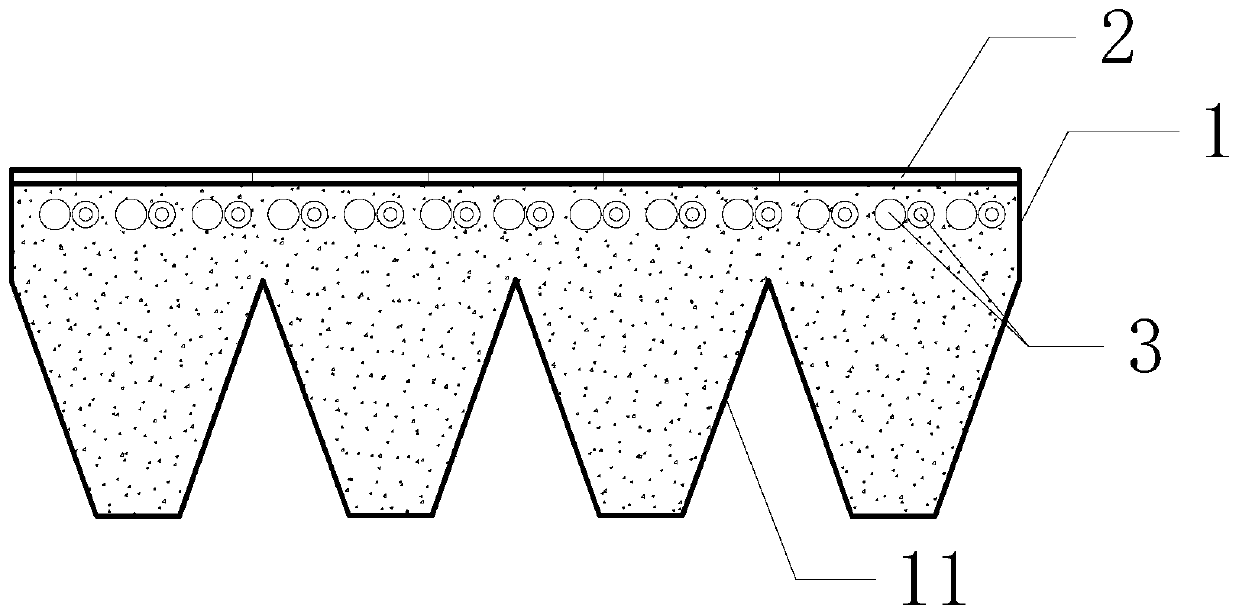

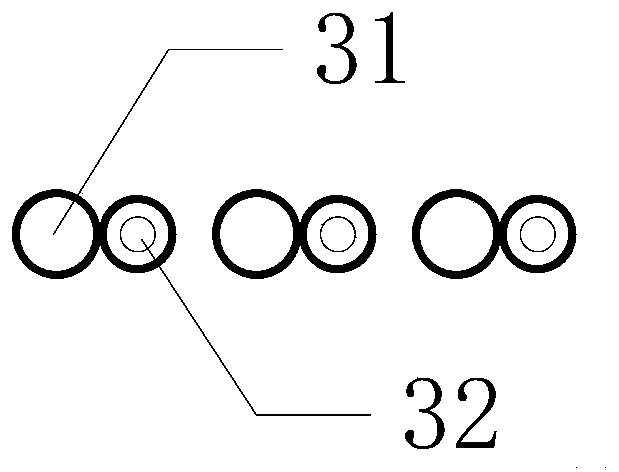

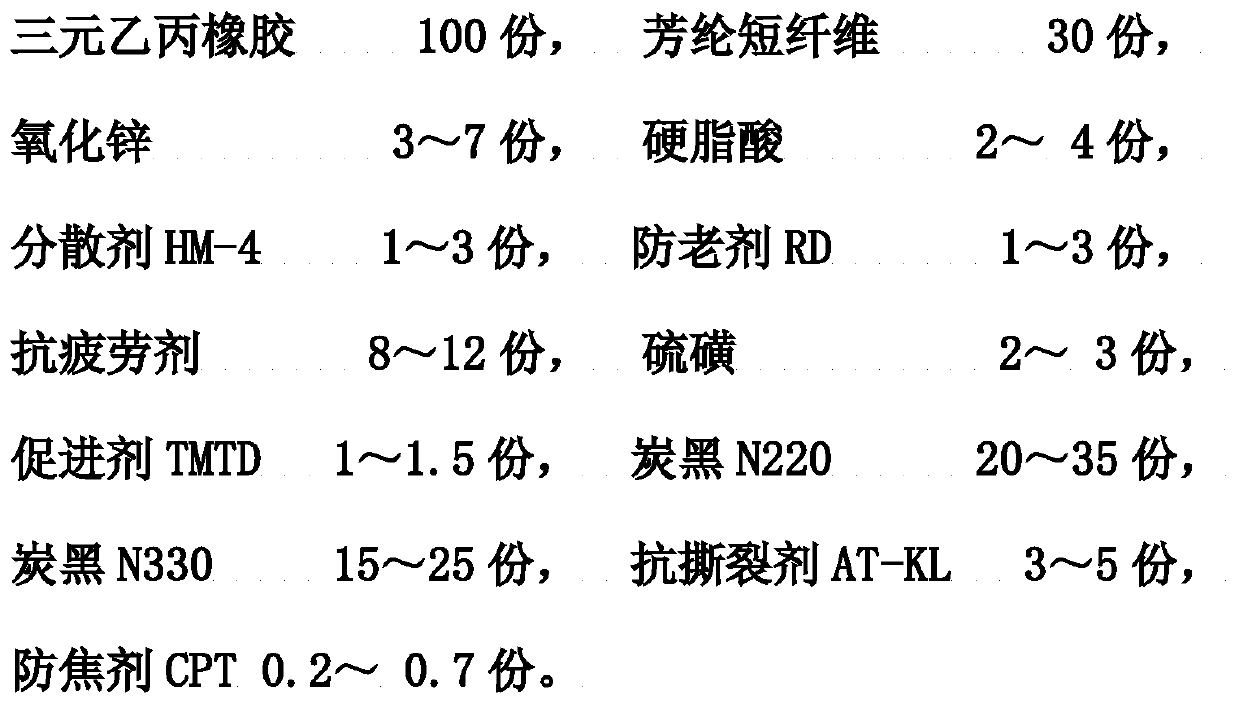

[0034] see figure 1 with figure 2 , the EPDM noise reduction and energy-saving aramid short fiber multi-ribbed belt of the present invention comprises a belt body, including a belt body 1 made of EPDM rubber material, and a group of trapezoidal wedges 11 are arranged on the inner side of the belt body 1, and the wedge height is 2.05mm. mm, the wedge distance of the trapezoidal wedge 11 is 3.56mm, and the wedge angle of the trapezoidal wedge 11 is 40 degrees; The transmission direction of the V-ribbed belt is parallel; the inside of the belt body 1 is provided with a skeleton formed by winding the skeleton rope group 3 along the transmission direction of the V-ribbed belt. An aramid thread 31 and a hollow fiber thread 32; the diameter of the said aramid thread 31 is 0.8mm, the diameter of the hollow fiber thread 32 is 0.6mm, the winding of the skeleton rope group 3 The manufacturing density is 4 groups / cm (winding density: the total number of turns of the skeleton rope group...

Embodiment 2

[0037] The difference from Embodiment 1 is that in this embodiment, the height of the trapezoidal wedge 11 of the V-ribbed belt is 2.0 mm; the wire diameter of the aramid fiber 3 is 0.7 mm, the wire diameter of the hollow fiber wire 4 is 0.5 mm, and the skeleton rope group The winding density of 3 is 3 groups / cm; the content of aramid staple fiber is 20 parts, and the length of aramid staple fiber is 2 mm. The belt body 1 is prepared from the following raw material components in parts by weight: 100 parts of EPDM rubber, 20 parts of aramid short fiber, 3 parts of zinc oxide, 2 parts of stearic acid, dispersant HM-4 1 1 part, 1 part of anti-aging agent RD, 8 parts of anti-fatigue agent, 2 parts of sulfur, 1 part of accelerator TMTD, 20 parts of carbon black N220, 15 parts of carbon black N330, 3 parts of anti-tearing agent AT-KL, 3 parts of anti-scorch agent CPT 0.2 parts.

Embodiment 3

[0039]Different from Embodiment 1, in this embodiment, the height of the trapezoidal wedge 11 of the V-ribbed belt is 2.1mm; the wire diameter of the aramid fiber 3 is 0.9mm, the wire diameter of the hollow fiber wire 4 is 0.8mm, and the skeleton rope group The winding density of 3 is 5 groups / cm; the content of aramid staple fiber is 40 parts, the length of aramid staple fiber is 4mm, and the belt body 1 is made from the following raw material components in parts by weight: ternary 100 parts of ethylene propylene rubber, 40 parts of aramid staple fiber, 7 parts of zinc oxide, 4 parts of stearic acid, 3 parts of dispersant HM-4, 3 parts of anti-aging agent RD, 12 parts of anti-fatigue agent, 3 parts of sulfur, accelerator 3 parts of TMTD, 35 parts of carbon black N220, 25 parts of carbon black N330, 5 parts of anti-tear agent AT-KL, 0.7 parts of anti-scorch agent CPT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com