Stainless steel PCM (Pre-Coated Metal Steel) plate and production process thereof

A technology of stainless steel and the other side, which is applied in the direction of coating, polyester coating, anti-corrosion coating, etc., can solve the problems of low aesthetics, poor touch, and the appearance of PCM board is not soft enough, so as to improve the aesthetics, reduce gloss, The effect of reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

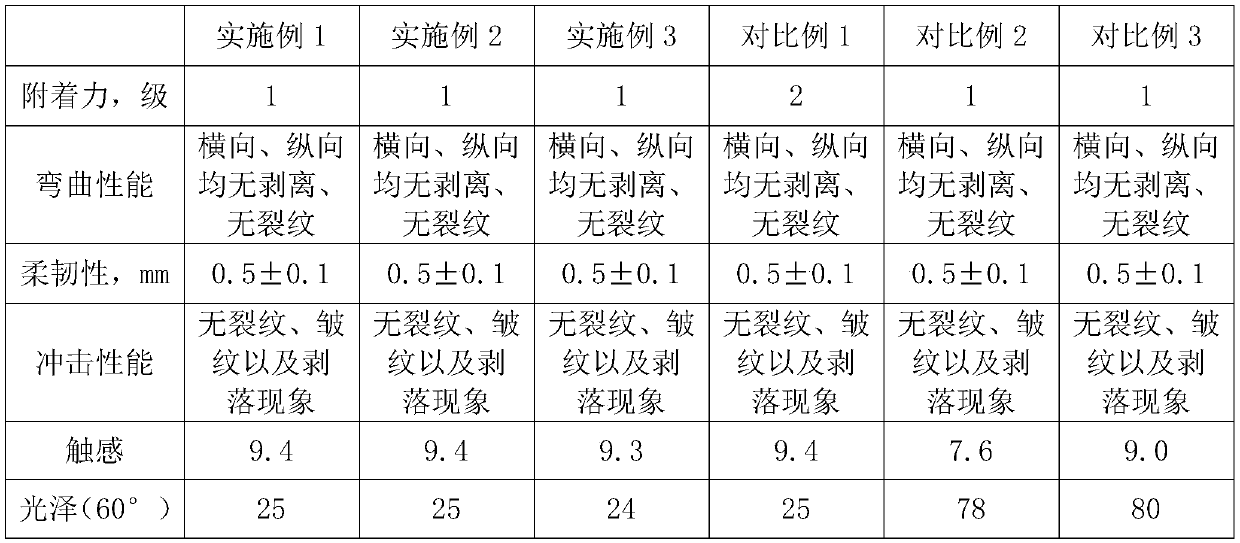

Examples

preparation example 1

[0036] Preparation example 1 of the primer: Take 20kg of methyl etherified water-based amino resin, 10kg of epoxy acrylate, 2kg of triethanolamine, 1kg of γ-glycidyl etheroxypropyltrimethoxysilane, and stir for 10min at a speed of 400r / min. Then add 0.2 kg of silicone leveling agent and 5 kg of isopropanol, and stir for 30 min at a speed of 1000 r / min to obtain a primer.

preparation example 2

[0037] Preparation example 2 of the primer: Take 25kg of methyl etherified water-based amino resin, 15kg of epoxy acrylate, 3kg of triethanolamine, 1.5kg of γ-glycidyl etheroxypropyltrimethoxysilane, and stir for 13min at a speed of 500r / min , and then add 0.6kg of silicone leveling agent and 7.5kg of isopropanol, and stir for 35min at a speed of 1300r / min to obtain a primer.

preparation example 3

[0038] Preparation example 3 of the primer: Take 30kg of methyl etherified water-based amino resin, 20kg of epoxy acrylate, 4kg of triethanolamine, 2kg of γ-glycidyl etheroxypropyltrimethoxysilane, and stir for 15min at a speed of 600r / min. Then add 1 kg of silicone leveling agent and 10 kg of isopropanol, and stir for 40 min at a speed of 1500 r / min to obtain a primer.

[0039] Two, the preparation example of matting agent

[0040] Preparation example 1 of matting agent: Take 40kg of talc powder, 20kg of silica powder and 10kg of zeolite powder, grind and mix them to obtain a mixture with a fineness of 2000 mesh; add 1kg of silane coupling agent KH550 to the mixture, Stir at a speed of 200r / min for 1h at a temperature of 200r / min, and obtain a matting agent after cooling.

[0041] Preparation example 2 of matting agent: get 50kg talcum powder, 25kg silica powder and 15kg zeolite powder, grind and mix to obtain a mixture with a fineness of 2500 meshes; add 1.5kg of silane cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com