High-voltage insulation bus and coating process

A high-voltage insulation and bus bar technology, applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems of increased maintenance, inspection difficulty, lack of installation conditions, and unsuitable for large-scale promotion, etc., to ensure anti-corrosion and insulation performance, improve Effect of insulation safety and durability, excellent chemical stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

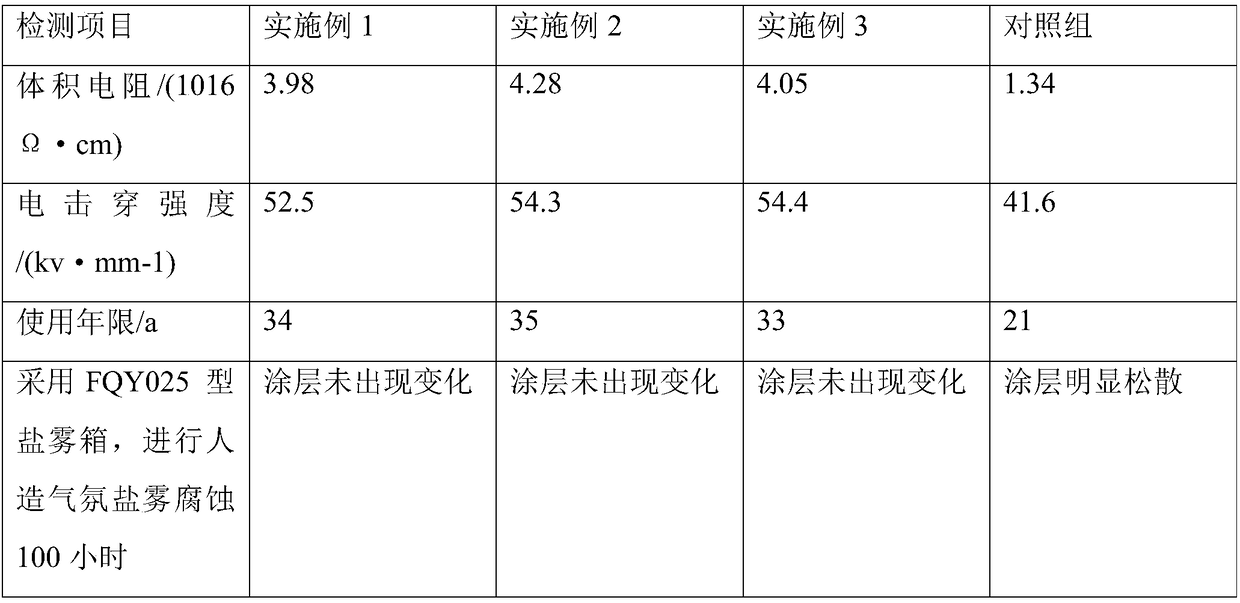

Examples

Embodiment 1

[0017] Embodiment 1: A high-voltage insulated busbar, including a busbar body, which is coated with an anti-corrosion layer at the bottom layer and an insulating layer at the outer layer. The anti-corrosion layer is coated with organic silicon paint, and the insulating layer includes The following components counted: 60 parts of silicone resin, 40 parts of acrylate rubber, 5 parts of titanate coupling agent, 3 parts of zirconia, 20 parts of silicon dioxide, 3 parts of naphthenic oil, 4 parts of calcium stearate 3 parts, 3 parts of alum stone, 5 parts of vinyltrimethoxysilane, 2 parts of alkali-free glass fiber, 9 parts of EPDM glue.

[0018] Among them, the preparation process of the insulating layer is as follows: disperse the silicone resin and acrylate rubber in naphthenic oil, the dispersion speed is 1200-1400 rpm, the dispersion temperature is 100-110 °C, and the dispersion time is 20-30 minutes. Then add titanate coupling agent and EPDM glue in turn, stir and mix for 20-...

Embodiment 2

[0025] Embodiment 2: A high-voltage insulated busbar, including a busbar body, the busbar body is coated with an anti-corrosion layer at the bottom layer, and an insulating layer at the outer layer, the anti-corrosion layer is coated with organic silicon paint, and the insulating layer includes The following components counted: 67 parts of silicone resin, 42.5 parts of acrylate rubber, 6 parts of titanate coupling agent, 3.5 parts of zirconia, 22 parts of silicon dioxide, 5 parts of naphthenic oil, 5 parts of calcium stearate 3.5 parts of alum stone, 6 parts of vinyltrimethoxysilane, 4 parts of alkali-free glass fiber, and 13 parts of EPDM glue.

[0026]Among them, the preparation process of the insulating layer is as follows: disperse the silicone resin and acrylate rubber in naphthenic oil, the dispersion speed is 1200-1400 rpm, the dispersion temperature is 100-110 °C, and the dispersion time is 20-30 minutes. Then add titanate coupling agent and EPDM glue in turn, stir and...

Embodiment 3

[0033] Embodiment 3: A high-voltage insulated busbar, including a busbar body, which is coated with an anti-corrosion layer at the bottom layer and an insulating layer at the outer layer. The anti-corrosion layer is coated with organic silicon paint, and the insulating layer includes The following components counted: 75 parts of silicone resin, 45 parts of acrylate rubber, 7 parts of titanate coupling agent, 4 parts of zirconia, 24 parts of silicon dioxide, 7 parts of naphthenic oil, 6 parts of calcium stearate 4 parts, 4 parts of alum stone, 7 parts of vinyltrimethoxysilane, 6 parts of alkali-free glass fiber, 17 parts of EPDM glue.

[0034] Among them, the preparation process of the insulating layer is as follows: disperse the silicone resin and acrylate rubber in naphthenic oil, the dispersion speed is 1200-1400 rpm, the dispersion temperature is 100-110 °C, and the dispersion time is 20-30 minutes. Then add titanate coupling agent and EPDM glue in turn, stir and mix for 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com