A thermal insulation pipe for oil transportation

A technology for oil transportation and thermal insulation pipes, which is applied in the direction of protecting pipelines, pipes, and rigid pipes through thermal insulation. Thermal performance and anti-corrosion performance, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

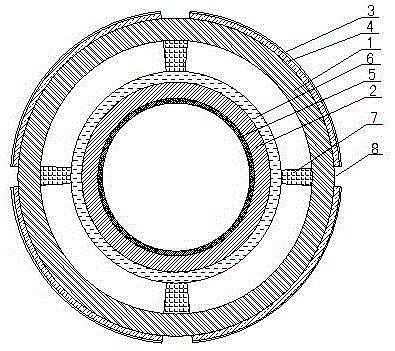

[0011] Such as figure 1 As shown, the new oil transportation insulation pipe according to the embodiment of the present invention includes an outer pipe body 1 and an inner pipe body 2, the inner pipe body 2 is arranged at the center of the inner cavity of the outer pipe body 1 and the inner pipe body 2 A layer of anti-corrosion layer 5 is set on the inner surface of the inner pipe body 2. At the same time, a layer of glass wool heat insulation layer 6 structure is set on the outer surface of the inner pipe body 2, and the thickness of the glass wool heat insulation layer 6 is equal to three times the thickness of the inner pipe body 2. The outer tube body 1 is evenly provided with four outer bosses 3 with arcs along the outer wall surface, and each outer boss 3 is wrapped with a layer of aluminum foil reflective layer 4, and every two adjacent outer Grooves 8 are provided between the bosses 3 to facilitate the embedding of lines. In addition, the stainless steel fastening ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com