Yawing mechanism for wind driven generator, yawing control system and control method

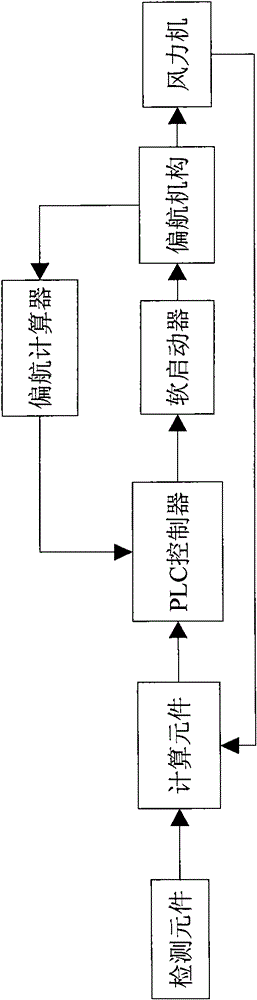

A wind turbine and yaw mechanism technology, applied in the control of wind turbines, wind turbines, wind power generation, etc., can solve problems such as nonlinearity, large impact, and inability to control yaw systems, and achieve overshoot and fluctuations, structure The effect of simple shape and smooth working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

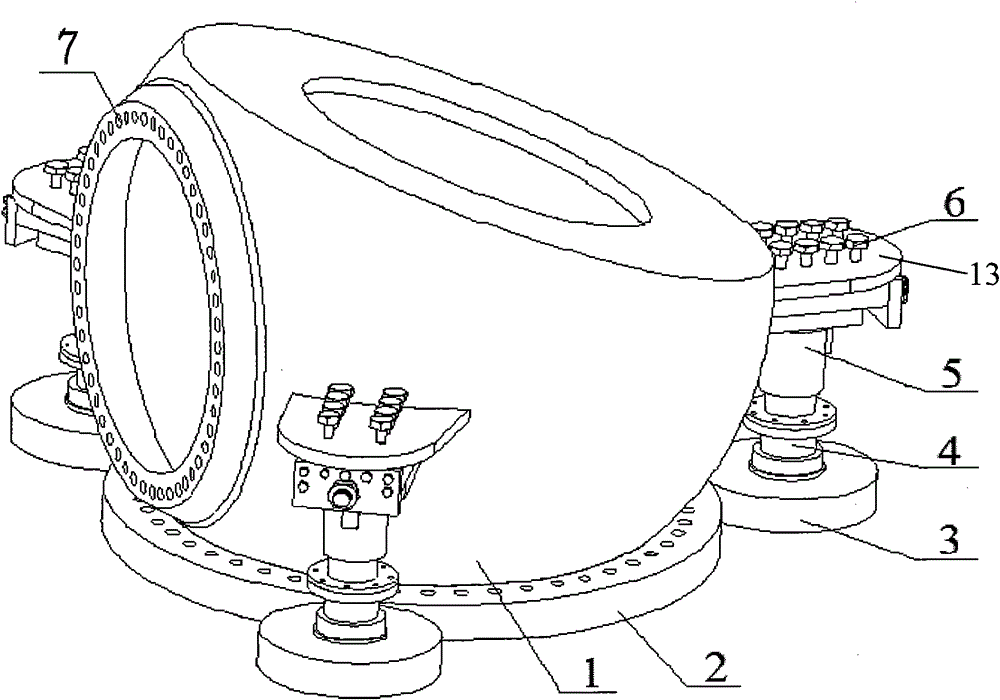

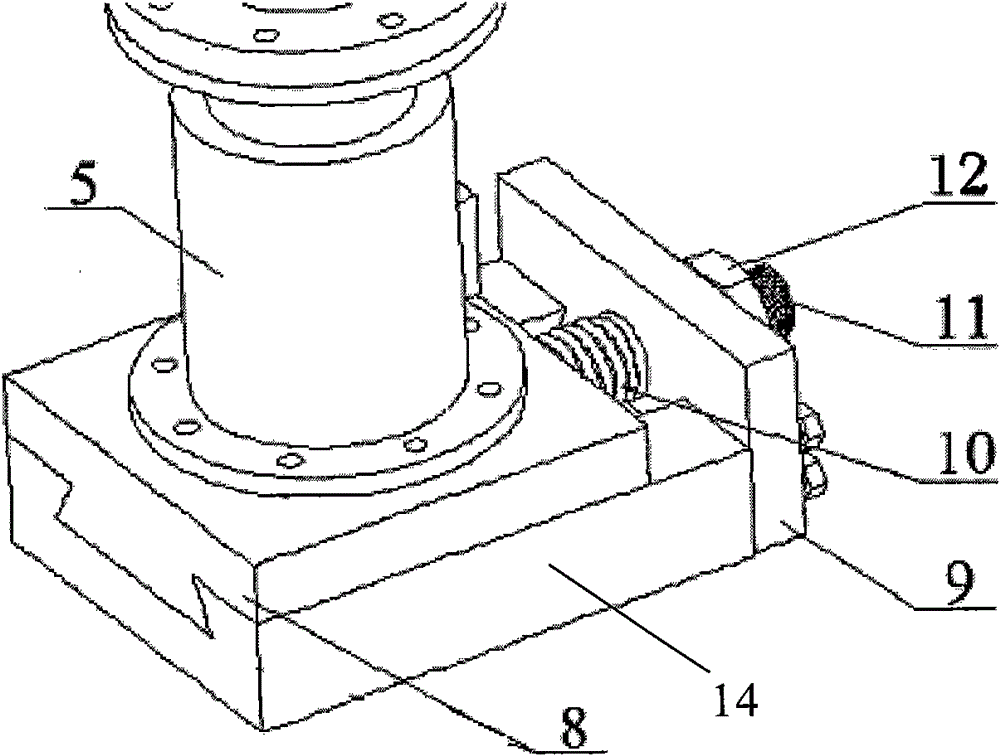

[0027] The present invention firstly provides a yaw mechanism of a wind power generator, please refer to figure 1 and figure 2 As shown, it includes a hemispherical base 1 connected to the generator assembly. The base 1 is connected to the generator assembly through the threaded hole 7 on the left end face. On the outer wall of the base 1 are evenly distributed three outward The side plate 13 is protrudingly arranged; a pre-tightening pressure adjustment device is fixed under each side plate 13 by bolts 6; One end of the yaw motor 5 is connected and fixed, the dovetail concave block 14 is connected and fixed with the baffle plate 9, and there is an interval space between the dovetail bump 8 and the baffle plate 9; one end of the stud 11 is fixedly connected with the dovetail bump 8 by threads, and the other One end passes through the baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com