Efficient filling mining method for extra-thick coal seam

A technology of extra-thick coal seam and mining method, which is applied in the direction of filling, special mining, mining equipment, etc., can solve the problems of increasing the technical difficulty of filling and mining, and the production capacity advantages of difficult and extra-thick coal seams, so as to achieve full-volume rapid filling and reduce The weight of the equipment and the effect of simplifying the filling process system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

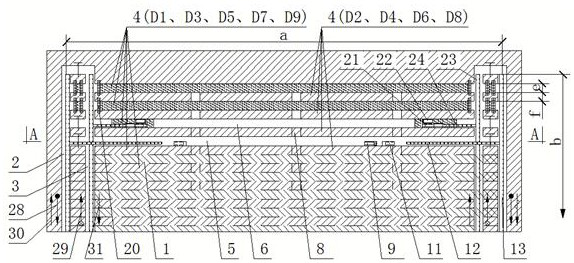

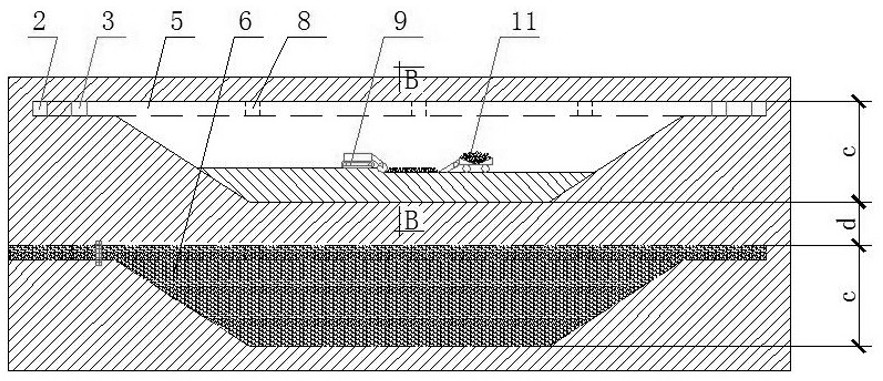

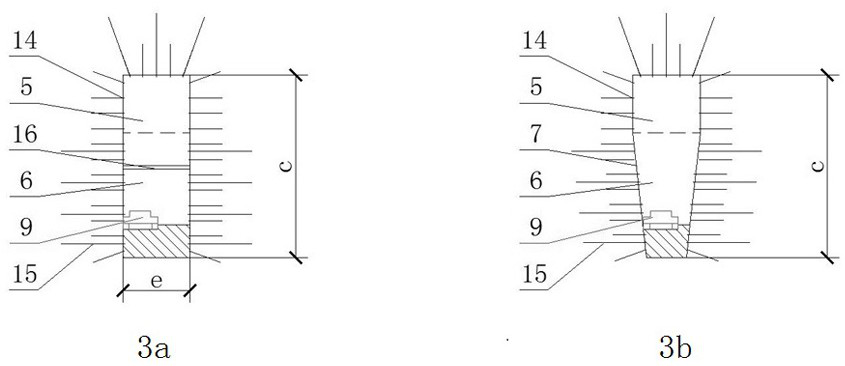

[0044] Such as Figure 1 to Figure 6 As shown, when the ultra-thick coal seam high-efficiency filling mining method is matched with gangue mechanized filling process system, the following steps shall be followed:

[0045] The first step is to determine the key technical parameters of mining and filling: according to the occurrence conditions such as the thickness, burial depth, overlying rock, and shape of the extra-thick coal seam, combined with the characteristics of the mining area, surrounding rock control requirements, and technical characteristics of mining and filling equipment, reasonably determine the mining and filling. The length, advance and thickness of the working face, the length, width and depth of the mining and filling trenches, the width of the protective coal pillars between the trenches, the thickness of the protective coal pillars between layers, the width of the protective coal pillars between the roadways and other key technical parameters of mining and ...

Embodiment 2

[0053] Such as Figure 1 to Figure 5 , Figure 7 ~ Figure 8 As shown, when the high-efficiency filling mining method of extra-thick coal seam is matched with paste or paste-like filling process system, the following steps shall be followed:

[0054] The first step is to determine the key technical parameters of mining and filling: according to the occurrence conditions such as the thickness, burial depth, overlying rock, and shape of the extra-thick coal seam, combined with the characteristics of the mining area, surrounding rock control requirements, and technical characteristics of mining and filling equipment, reasonably determine the mining and filling. The length, advance and thickness of the working face, the length, width and depth of the mining and filling trenches, the width of the protective coal pillars between the trenches, the thickness of the protective coal pillars between layers, the width of the protective coal pillars between the roadways and other key techni...

Embodiment 3

[0062] Such as Figure 1 to Figure 5 , Figure 9 ~ Figure 11 As shown, when the ultra-thick coal seam high-efficiency filling mining method is equipped with gangue and cement slurry independent transportation, natural mixing, and alluvial filling process system, the following steps are followed:

[0063] The first step is to determine the key technical parameters of mining and filling: according to the occurrence conditions such as the thickness, burial depth, overlying rock, and shape of the extra-thick coal seam, combined with the characteristics of the mining area, surrounding rock control requirements, and technical characteristics of mining and filling equipment, reasonably determine the mining and filling. The length, advance and thickness of the working face, the length, width and depth of the mining and filling trenches, the width of the protective coal pillars between the trenches, the thickness of the protective coal pillars between layers, the width of the protectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com