Shell and tube type heat exchanger

A technology of shell-and-tube heat exchangers and outer tubes, which is applied in the direction of heat exchangers, indirect heat exchangers, tubular elements, etc., can solve problems such as poor effect, limited load capacity, and inability to use, so as to reduce equipment and Load capacity, good effect, and the effect of controlling flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

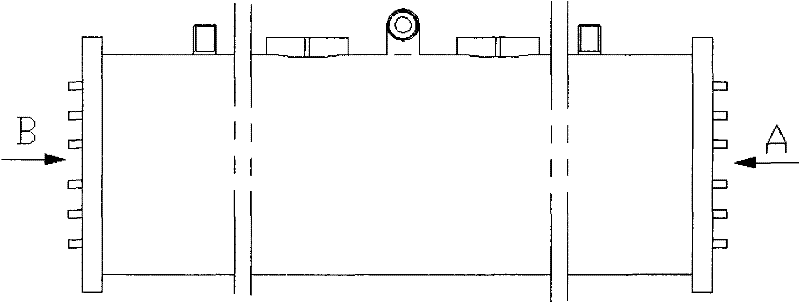

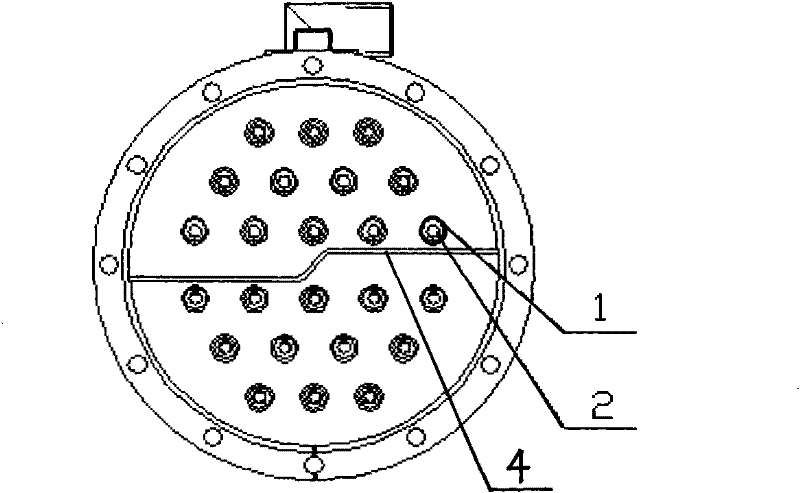

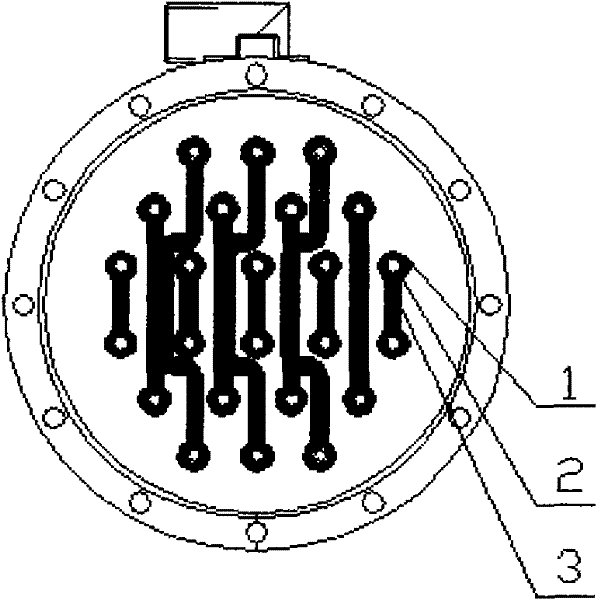

[0021] See attached figure 1 , 2 , 3 and 4.

[0022] The improved shell-and-tube heat exchanger of the present invention is mainly used as an adsorption bed in adsorption refrigeration. Unlike ordinary shell-and-tube heat exchangers, the tubes placed in the shell are not single tubes but a group of The set consists of two high-efficiency heat exchange tubes. The outer tube 1 is shorter than the inner tube 2, one end of the outer tube 1 is closed, and the outer tube 1 has a small opening near the closed port, and the openings of the two outer tubes 1 that are symmetrical up and down are connected by a tube 3; the other end of the outer tube 1 is not closed , as the inlet and outlet of the heating fluid. Both ends of the inner tube 2 are not closed, and the inner cross-sectional area of the inner tube 2 is larger than the annular area between the inner and outer tubes 1. Under the condition that the flow resistance is not too large, the larger the ratio, the more conducive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com