Transmission, double linkage and anti-sway anti-fall device, crane system and wafer handling method

A transmission device and double-linkage technology, applied in the transmission device, safety device, transportation and packaging, etc., can solve the problems of aggravating the burden of the aerial track keel, occupying a large space, and complicated auxiliary mechanisms in the crane system, so as to save Effects of motor-related drivers, equipment weight reduction, and mechanism space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

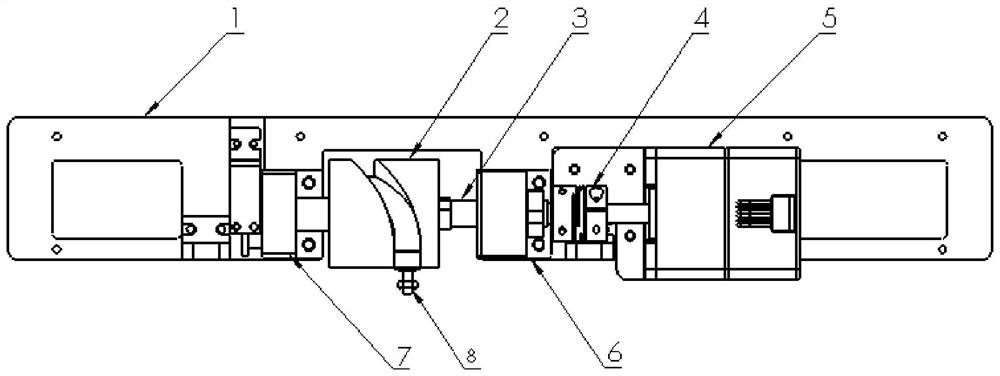

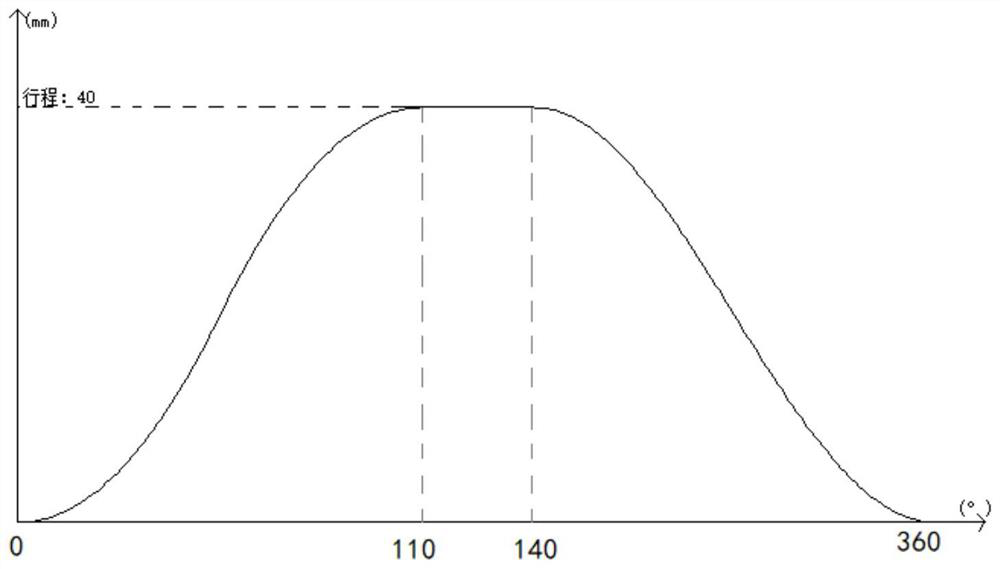

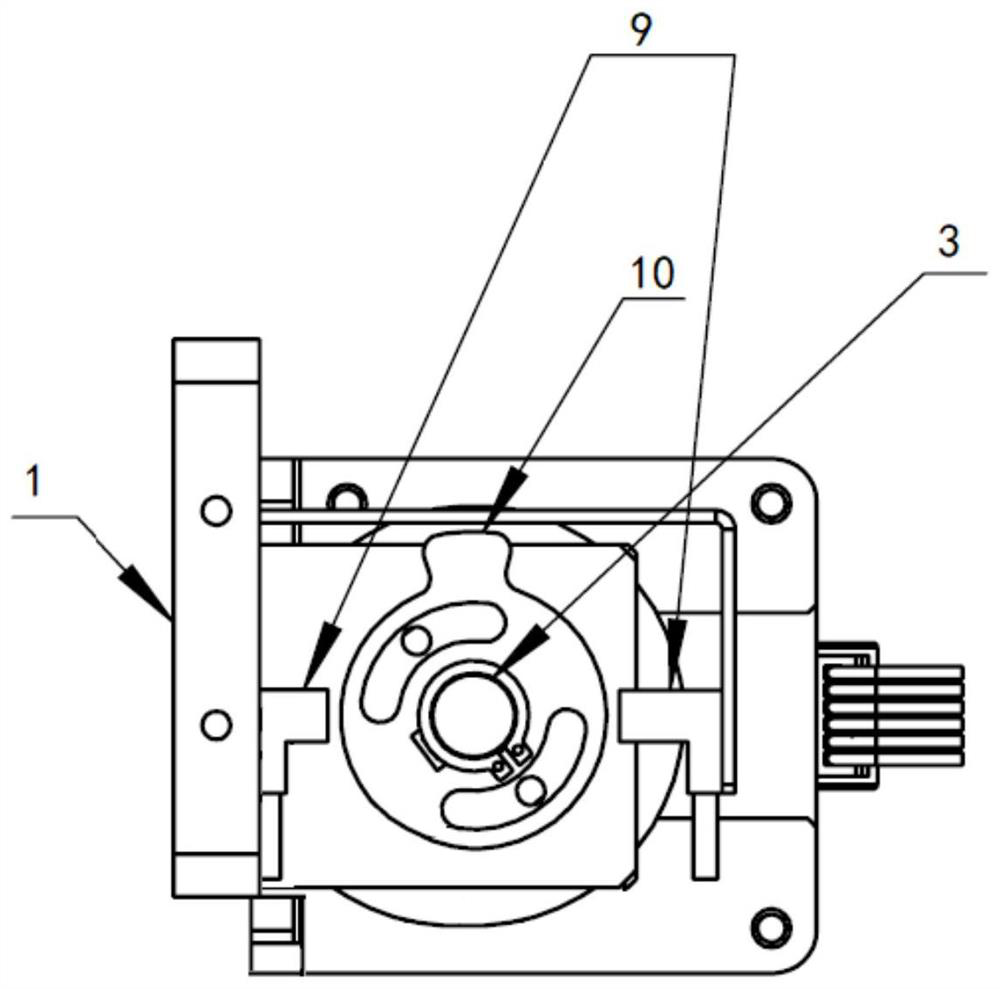

[0069] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

[0070] Based on the present application one skilled in the art should appreciate that an aspect described herein may be implemented independently of any other aspects and that two or more of these aspects may be combined in various ways. For example, any number and aspect set forth herein may be used to implement an apparatus and / or practice a method. In addition, such an apparatus may be implemented and / or such a method practiced using other structure and / or functionality than on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com