Building curtain wall three-dimensional transporting system

A technology of three-dimensional transportation and curtain wall, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems that the work efficiency cannot be further improved, the number of tower cranes is limited, and the tower cranes are heavy, so as to achieve light equipment weight , Improve wind resistance, flexible layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

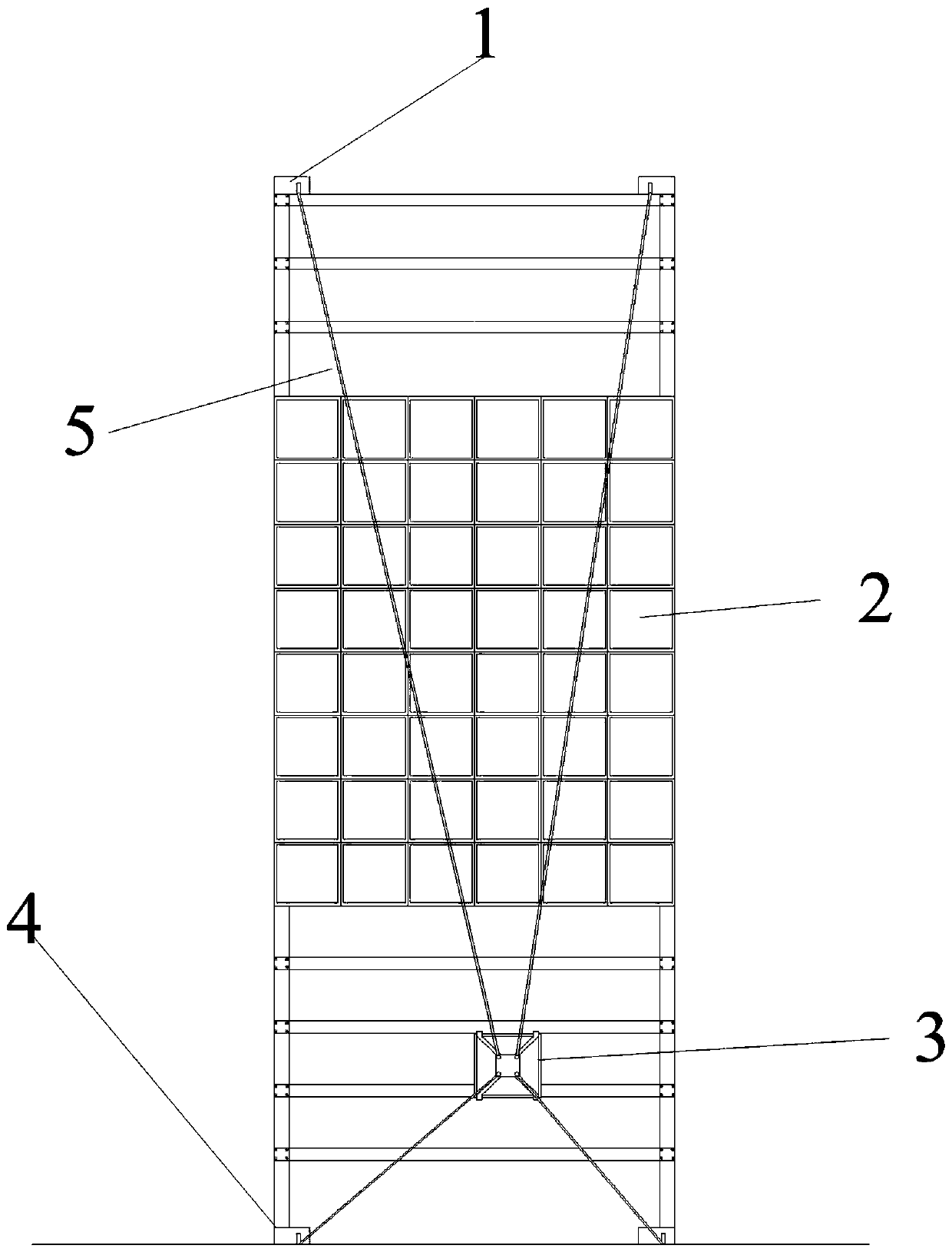

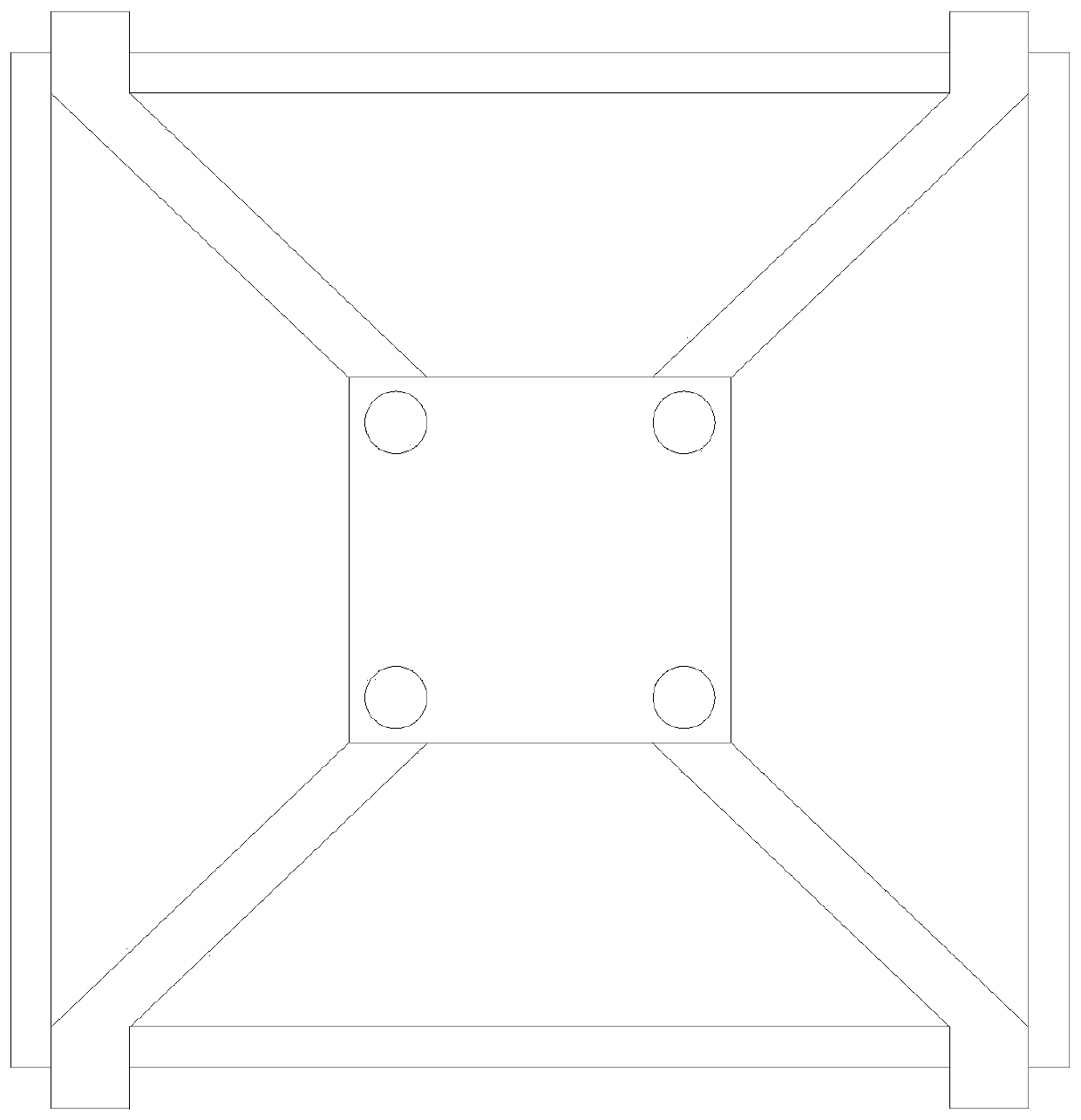

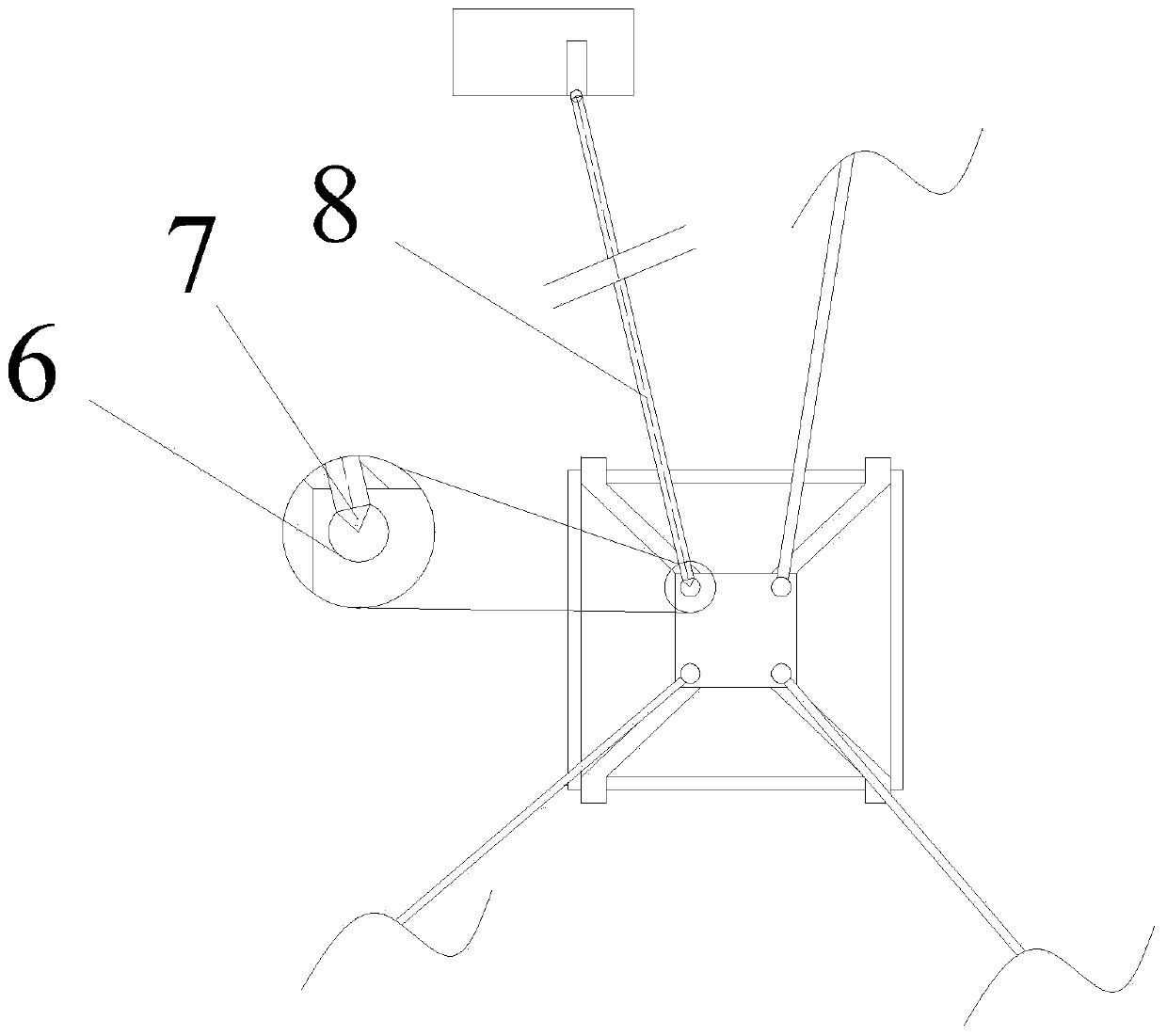

[0020] like Figure 1-Figure 3 It can be seen that a three-dimensional transportation system for building curtain walls in the present invention consists of an upper anchor base 1, a winch, a curtain wall 2, a curtain wall mounting system 3, a lower anchor base 4, a tension control system and steel cables 5. Wherein the upper anchor point base 1 is installed on two corners above the external force surface of the building, and the lower anchor point base 4 is installed on the two corners below the external force surface of the building. The curtain wall mounting system 3 is connected to the steel cable 5 through four joint bearings, the upper two steel cables 5 are connected to the upper anchor point base 1 and the winch, and the lower two anchor points are connected to the lower anchor point base 4 and the tension control system , the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com