Washable waterproof moisture-permeable foam adhesive laminated fabric and preparation method thereof

A fabric-fitting, waterproof and moisture-permeable technology, which is applied in the field of fabric processing, can solve the problems of inconvenient practical application, poor water resistance performance, and decreased waterproof and moisture-permeable effect, and achieve high practicability, excellent water-resistance performance, excellent waterproof and moisture-permeable The effect of wet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

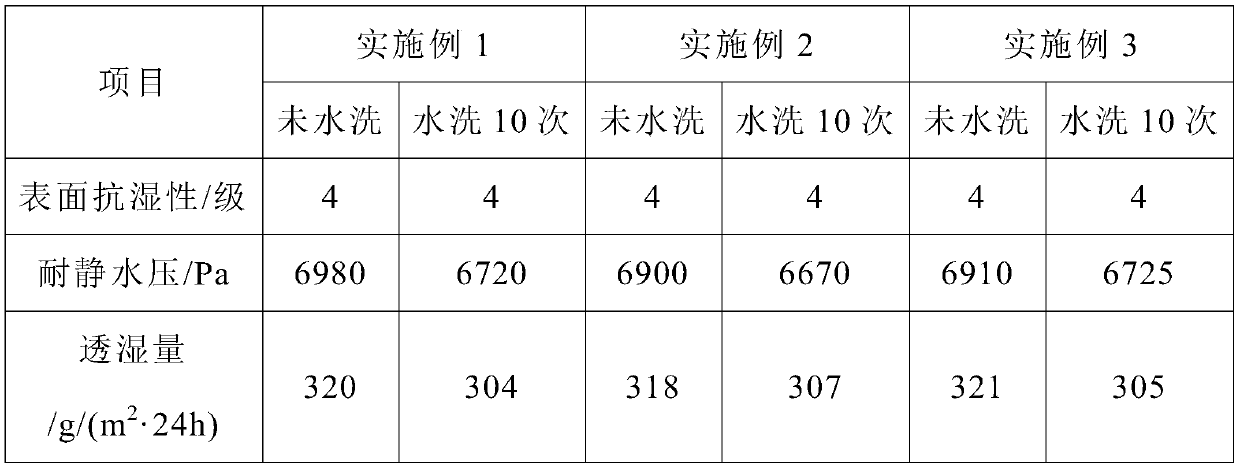

Examples

Embodiment 1

[0056] S1: Prepare materials;

[0057] S2: Preparation of the first modifier:

[0058] Take chitosan, dissolve in acetic acid, stir for 1 hour, then add sodium periodate, and stir for 45 hours in the dark, then add absolute ethanol to stop the reaction, filter with suction, wash, and dry at 40°C to obtain oxidized chitosan;

[0059] Take oxidized chitosan, dissolve it in deionized water, add sericin powder, mix and stir for 10 minutes, and use ultrasonic treatment for 10 minutes. During ultrasonic treatment, intermittent ultrasonic treatment is used, and the ultrasonic treatment is stopped for 1 minute every 1 minute. The ultrasonic power is 80W, and the first modification is obtained. agent;

[0060] S3: Preparation of modified fabric:

[0061] Take cotton fabric, put it in sodium hydroxide solution at 80°C, soak for 0.8h, wash with deionized water, put it in oxalic acid solution at 70°C, soak for 25min, wash with deionized water, ultrasonically wash for 15min, and dry to g...

Embodiment 2

[0073] S1: Prepare materials;

[0074] S2: Preparation of the first modifier:

[0075] Take chitosan, dissolve it in acetic acid, stir for 1.5 hours, then add sodium periodate, and stir for 47 hours in the dark, then add absolute ethanol to stop the reaction, filter with suction, wash, and dry at 42°C to obtain oxidized chitosan;

[0076] Take oxidized chitosan, dissolve it in deionized water, add sericin powder, mix and stir for 13 minutes, and ultrasonically treat for 11 minutes. During ultrasonication, intermittent ultrasonic treatment is used, and the ultrasonic treatment is stopped for 1 minute every minute. The ultrasonic power is 80W, and the first modification is obtained. agent;

[0077] S3: Preparation of modified fabric:

[0078] Take the cotton fabric, put it in sodium hydroxide solution at 82°C, soak for 0.9h, wash it with deionized water, put it in oxalic acid solution at 73°C, soak it for 28min, wash it with deionized water, wash it ultrasonically for 19min, a...

Embodiment 3

[0090] S1: Prepare materials;

[0091] S2: Preparation of the first modifier:

[0092] Take chitosan, dissolve it in acetic acid, stir for 2 hours, then add sodium periodate, avoid light and stir for 48 hours, then add absolute ethanol to stop the reaction, filter with suction, wash, and dry at 45°C to obtain oxidized chitosan;

[0093]Take oxidized chitosan, dissolve it in deionized water, add sericin powder, mix and stir for 15 minutes, and ultrasonically treat for 12 minutes. Intermittent ultrasonic treatment is used during ultrasonic treatment, and the ultrasonic power is 80W to obtain the first modification. agent;

[0094] S3: Preparation of modified fabric:

[0095] Take the cotton fabric, put it in 85°C sodium hydroxide solution, soak for 1 hour, wash it with deionized water, put it in 75°C oxalic acid solution, soak it for 30 minutes, wash it with deionized water, wash it ultrasonically for 20 minutes, and dry it to get the pre- processing fabrics;

[0096] Take c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com