Mortar

A technology of mortar and parts by weight, applied in the field of concrete, can solve problems such as difficult operation, viscosity of mortar, and reduced strength, and achieve the effects of reducing difficulty, improving adhesion and good impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

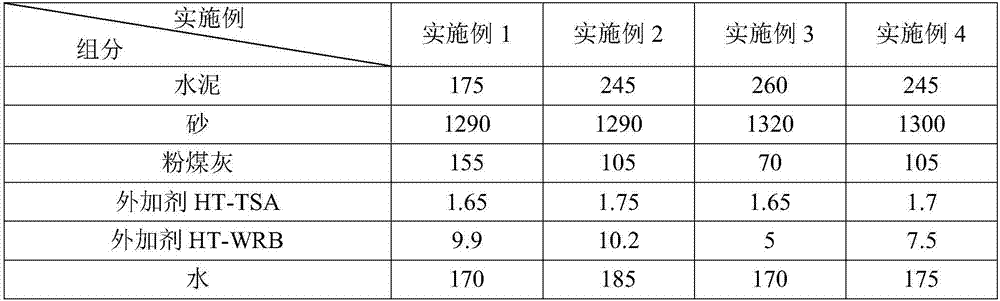

[0049] Example 1: A mortar, wherein the components and their corresponding parts by weight are shown in Table 1. The mixture includes three materials: fly ash, admixture HT-TSA, and admixture HT-WRB. During construction, the mixing ratio of cement, sand, admixture, and water is cement, sand, admixture, and water. 1:7.37:0.89:0.97, the fineness modulus of sand is 2.7. And the mortar is prepared through the following steps:

[0050] S1, adding the admixture HT-TSA and the admixture HT-WRB into the water and mixing uniformly to form a first mixture;

[0051] S2, fully mixing cement, sand and fly ash to form a second mixture;

[0052] S3: The first mixture obtained in step S1 is slowly added to the second mixture obtained in step S2, and the mixture is fully stirred and mixed to prepare.

[0053] Table 1 Each component in Examples 1-4 and their corresponding parts by weight

[0054]

Embodiment 2

[0055] Example 2: A mortar. The difference from Example 1 is that the components and their corresponding parts by weight are shown in Table 1. The mixing ratio of cement, sand, admixture, and water is 1:5.27:0.43 : 0.76.

Embodiment 3

[0056] Example 3: A mortar, which is different from Example 1 in that the components and their corresponding parts by weight are shown in Table 1. The mixing ratio of cement, sand, admixture, and water is 1:5.08:0.27 : 0.65.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com