High-strength regenerated concrete doped with waste cable and preparation method thereof

A technology of recycled concrete and waste cables, which is applied in the preparation of high-strength recycled concrete and the field of high-strength recycled concrete preparation, can solve problems affecting the mechanical properties and durability of concrete, achieve good recycling, reduce incineration and landfill treatment, and improve The effect of durability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

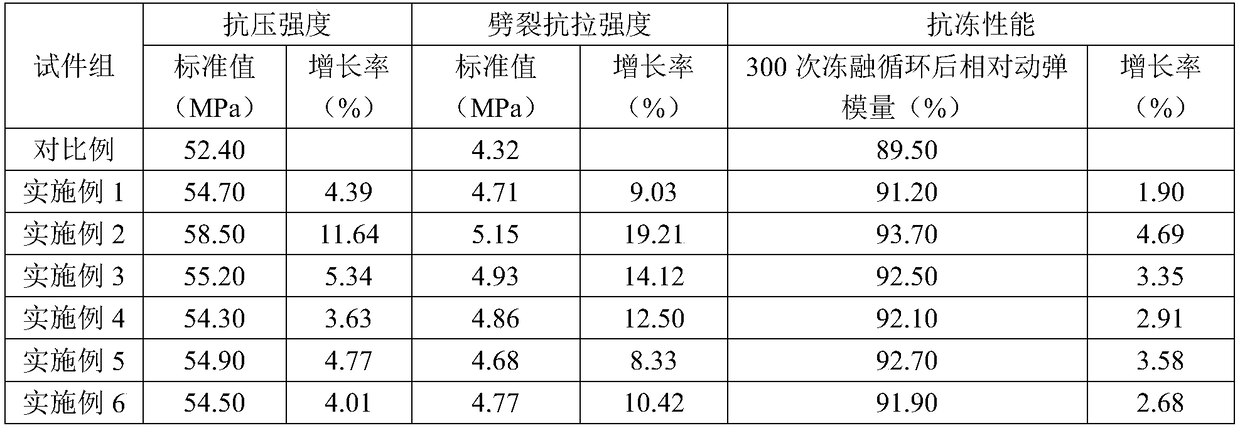

Examples

preparation example Construction

[0038] The present invention also provides a preparation method for the above-mentioned high-strength recycled concrete mixed with waste cables, comprising the following steps:

[0039] Step 1, prepare materials according to the ratio of the following raw materials,

[0040] Each cubic meter of high-strength recycled concrete consists of the following raw materials:

[0041] Water 168~180kg, cement 300~330kg, ultrafine mineral powder 63~70kg, fly ash 63~70kg, fine aggregate 860~900kg, recycled coarse aggregate 560~600kg, natural coarse aggregate 560~600kg, water reduction Agent 4.3~9.4kg, air-entraining agent 85.2~141g, waste cable 4.3~7.1kg;

[0042] Step 2. Pour 50% of the total amount of tap water, recycled coarse aggregate, natural coarse aggregate, fine aggregate and waste cables into the concrete mixer in sequence, and stir for 15s to 20s to make the surface of the recycled coarse aggregate wet;

[0043] Step 3. Pour ultrafine mineral powder and fly ash into the mixer,...

Embodiment 1

[0051]Crushing the waste concrete into recycled coarse aggregate, ensuring that the particle size of the recycled coarse aggregate is 5-20mm; screening the recycled coarse aggregate to remove the regenerated ones with many edges and corners, strips and triangles Coarse aggregate, try to ensure that the recycled coarse aggregate is approximately circular. Cut the waste cable to a length of 2cm.

[0052] Step 1, prepare materials according to the ratio of the following raw materials,

[0053] Each cubic meter of high-strength recycled concrete consists of the following raw materials:

[0054] 170kg of water, 320kg of cement, 65kg of superfine mineral powder, 65kg of fly ash, 880kg of fine aggregate, 580kg of recycled coarse aggregate, 580kg of natural coarse aggregate, 5kg of water reducing agent, 100g of air-entraining agent, and 5kg of waste cables;

[0055] Step 2. Pour 50% of the total amount of tap water, recycled coarse aggregate, natural coarse aggregate, fine aggregate...

Embodiment 2

[0061] Crushing the waste concrete into recycled coarse aggregate, ensuring that the particle size of the recycled coarse aggregate is 5-20mm; screening the recycled coarse aggregate to remove the regenerated ones with many edges and corners, strips and triangles Coarse aggregate, try to ensure that the recycled coarse aggregate is approximately circular. Cut the waste cable to a length of 5cm.

[0062] Step 1, prepare materials according to the ratio of the following raw materials,

[0063] Each cubic meter of high-strength recycled concrete consists of the following raw materials:

[0064] 170kg of water, 320kg of cement, 65kg of superfine mineral powder, 65kg of fly ash, 880kg of fine aggregate, 580kg of recycled coarse aggregate, 580kg of natural coarse aggregate, 5kg of water reducing agent, 100g of air-entraining agent, and 5kg of waste cables;

[0065] Step 2. Pour 50% of the total amount of tap water, recycled coarse aggregate, natural coarse aggregate, river sand an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com