Recycled concrete with added polypropylene fibers and preparation method of recycled concrete

A polypropylene fiber and recycled concrete technology, which is applied in the field of green concrete preparation, can solve the problems of low mechanical properties of recycled concrete, low utilization rate of recycled concrete, and low strength of recycled concrete, so as to reduce open-air stacking and landfill Effects of treatment and prevention of subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

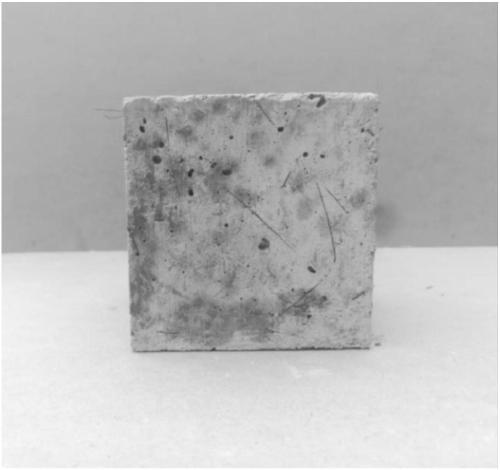

Image

Examples

preparation example Construction

[0032] The preparation method of the regenerated concrete that adds polypropylene fiber mainly comprises the following steps:

[0033] Step 1. According to the above mixing ratio, pour the recycled coarse aggregate, recycled fine aggregate, cement, and polypropylene fiber into the mixer, and mix evenly; the specific mixing time is 60-90s, and the mixing rate is 30 rpm;

[0034] Step 2. Pour the water into the concrete mixer in batches, and mix evenly to obtain recycled concrete added with polypropylene fibers.

[0035] Further, pour the water into the concrete mixer three times, the mixer continues to stir during the pouring process, the stirring rate is 20 rpm, the pouring interval is 30-50s, and the water pouring volume for the three times is 50%, 30% and 20% of the total amount in turn. %; To avoid the problem that the concrete cannot be fully absorbed by adding water at one time. Adding water in stages can allow the concrete to fully absorb during the mixing process, which...

Embodiment 1

[0043] A new type of concrete proposed in this embodiment, the concrete raw materials are proportioned by mass and include the following components: 226 parts of water, 240 parts of cement, 860 parts of recycled coarse aggregate with a particle size of 5 mm, and a fineness modulus of 3.0 525 parts of recycled fine aggregate, 0.75 parts of polypropylene fiber with a diameter of 0.2 mm and a length of 20 mm.

[0044] Among them, the recycled coarse aggregate is obtained by crushing and screening waste sintered bricks, and the recycled fine aggregate is obtained by crushing and screening waste concrete.

Embodiment 2

[0046] A new type of concrete proposed in this embodiment, the concrete raw materials are proportioned by mass and include the following components: 220 parts of water, 230 parts of cement, 850 parts of recycled coarse aggregate with a particle size of 10 mm, and a fineness modulus of 3.0 525 parts of recycled fine aggregate, 1.5 parts of polypropylene fiber with a diameter of 0.3 mm and a length of 50 mm.

[0047] Among them, the recycled coarse aggregate is obtained by crushing and screening waste sintered bricks, and the recycled fine aggregate is obtained by crushing and screening waste concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com