Construction method of warm mix asphalt concrete pavement of municipal road

A technology of concrete pavement and warm asphalt, which is applied to roads, roads, on-site coagulation pavement, etc., which can solve the problem of excessive temperature drop of the mixture during transportation distance, restriction of transportation, paving and rolling time, and unfavorable energy saving Issues such as emission reduction and environmental protection, to achieve the effect of prolonging the daily construction time, prolonging the compaction time, and expanding the scope of product use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment.

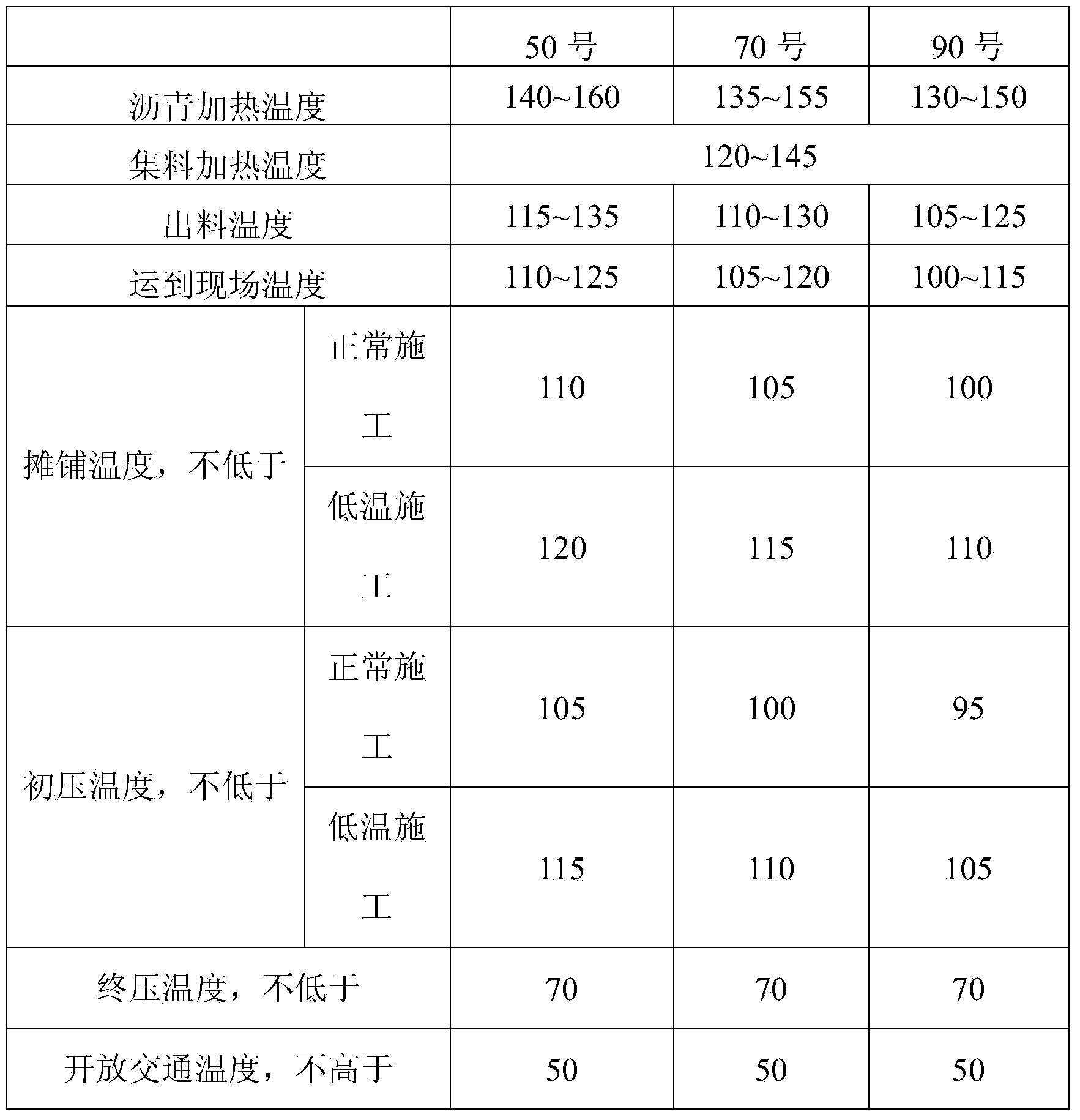

[0035] Warm mix asphalt concrete technology refers to the asphalt mixture mixing technology between hot mix asphalt mixture and normal temperature mix mixture. Under the same raw material conditions, the mixing temperature and compaction temperature of warm mixing are generally 20-40°C lower than that of hot mixing. The core of warm mix technology is to use physical or chemical means to increase the construction operability of asphalt mixture. After the mixture is formed, these physical or chemical additives will not have a negative impact on the performance of the pavement.

[0036] The key construction process of this project: During the asphalt mixture mixing process, the surface active additive aqueous solution is added in the form of external mixing, and it works with hot asphalt to achieve uniform dispersion and improve the coating ability and adhesion of asphalt and stone. , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com