Patents

Literature

42results about How to "Extended construction season" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt warm-mix agent and asphalt mixture mixed by same as well as preparation methods thereof

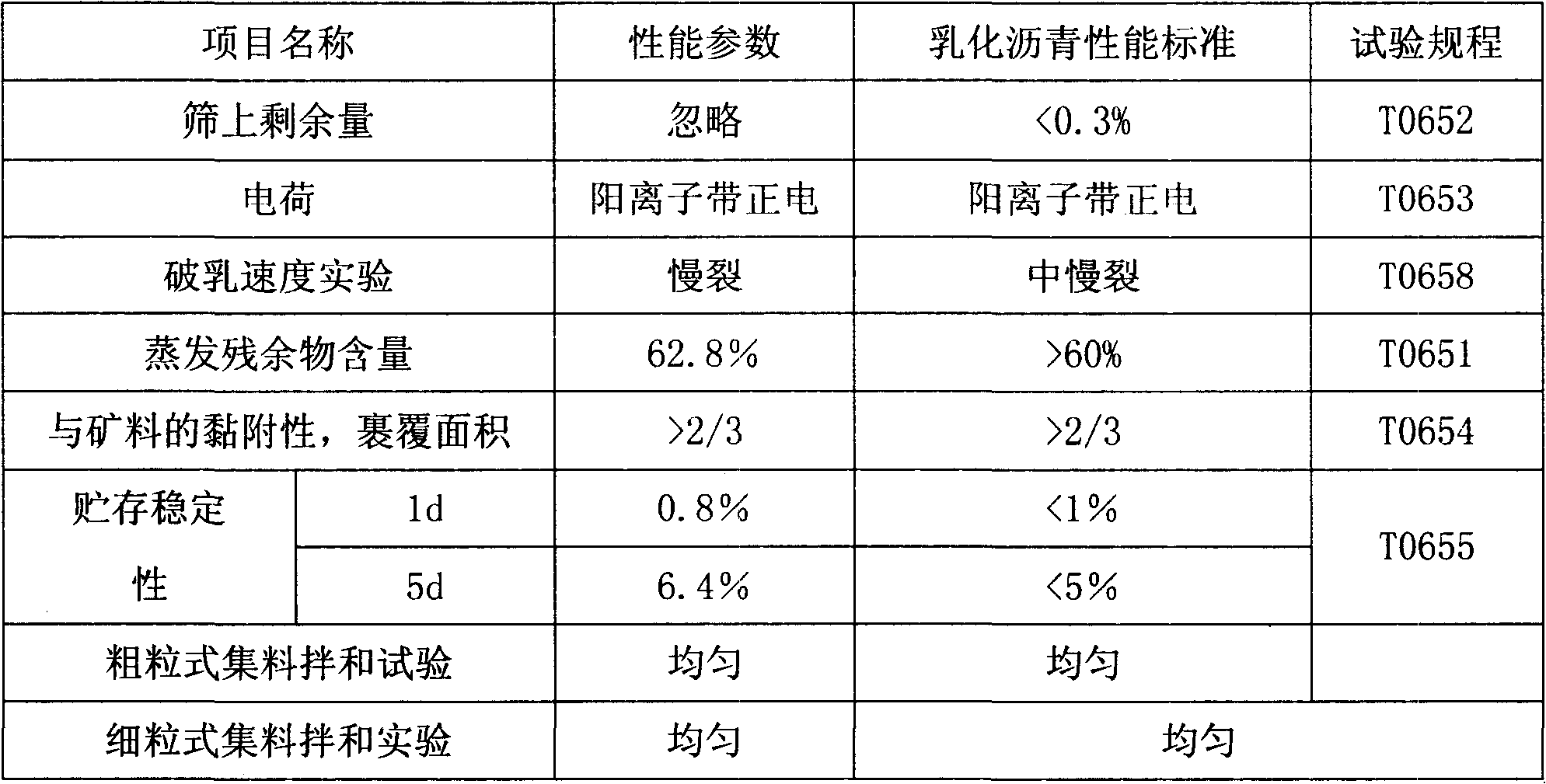

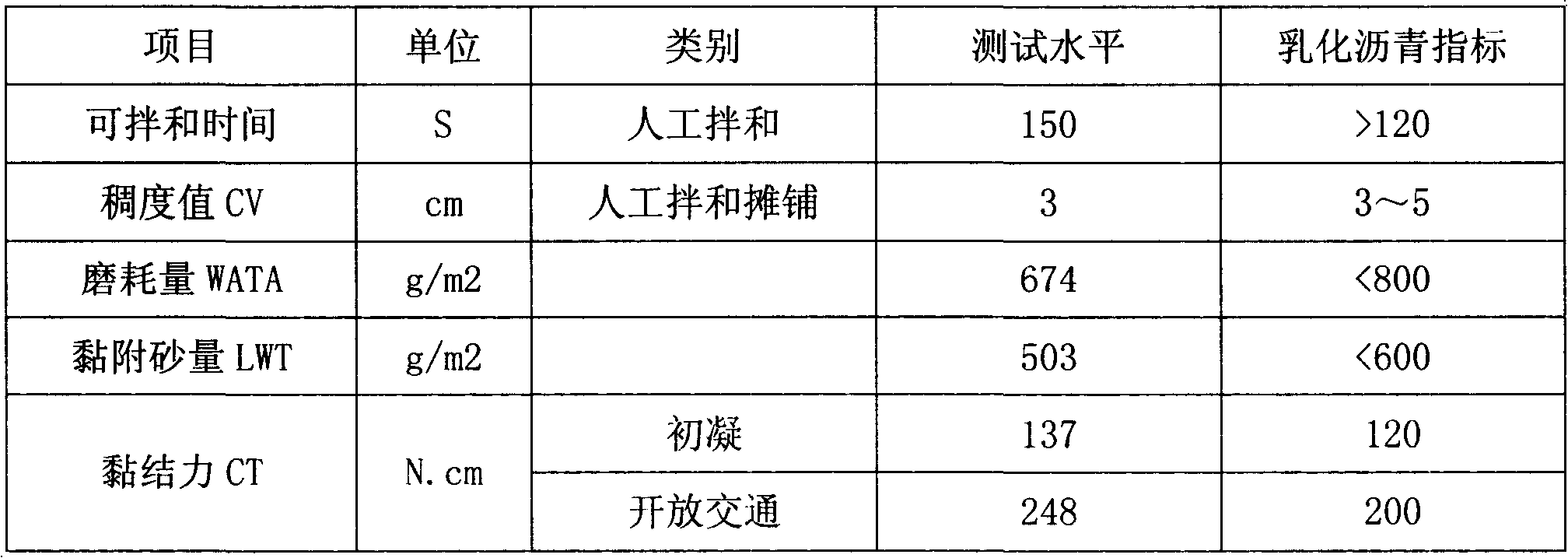

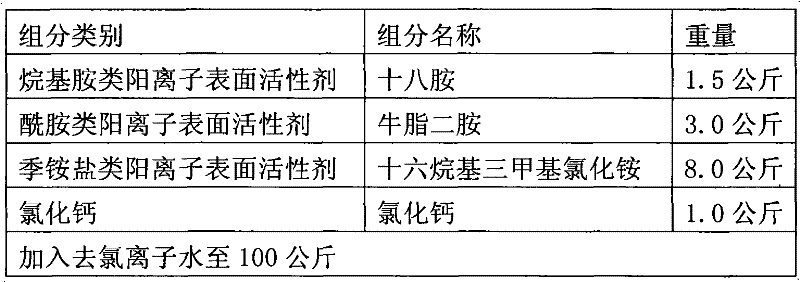

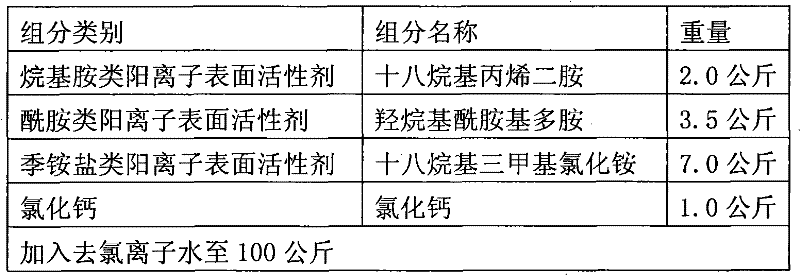

ActiveCN101899218AWith viscosity reductionWith foamClimate change adaptationBuilding insulationsChlorideRoad surface

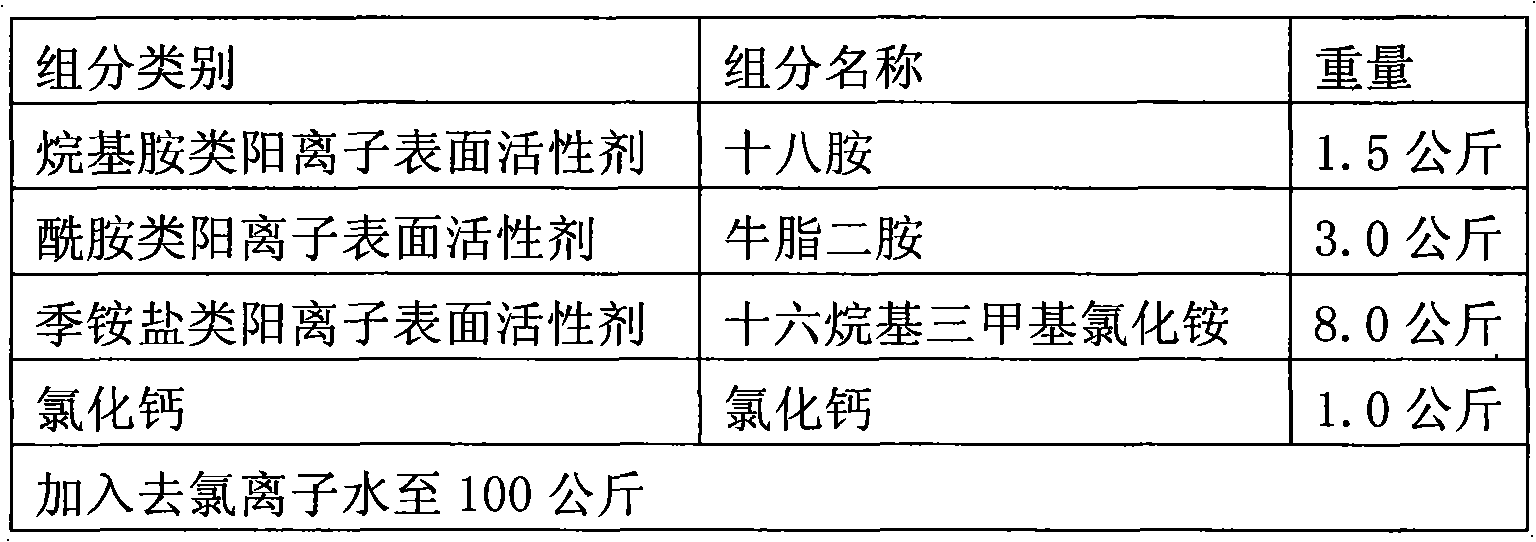

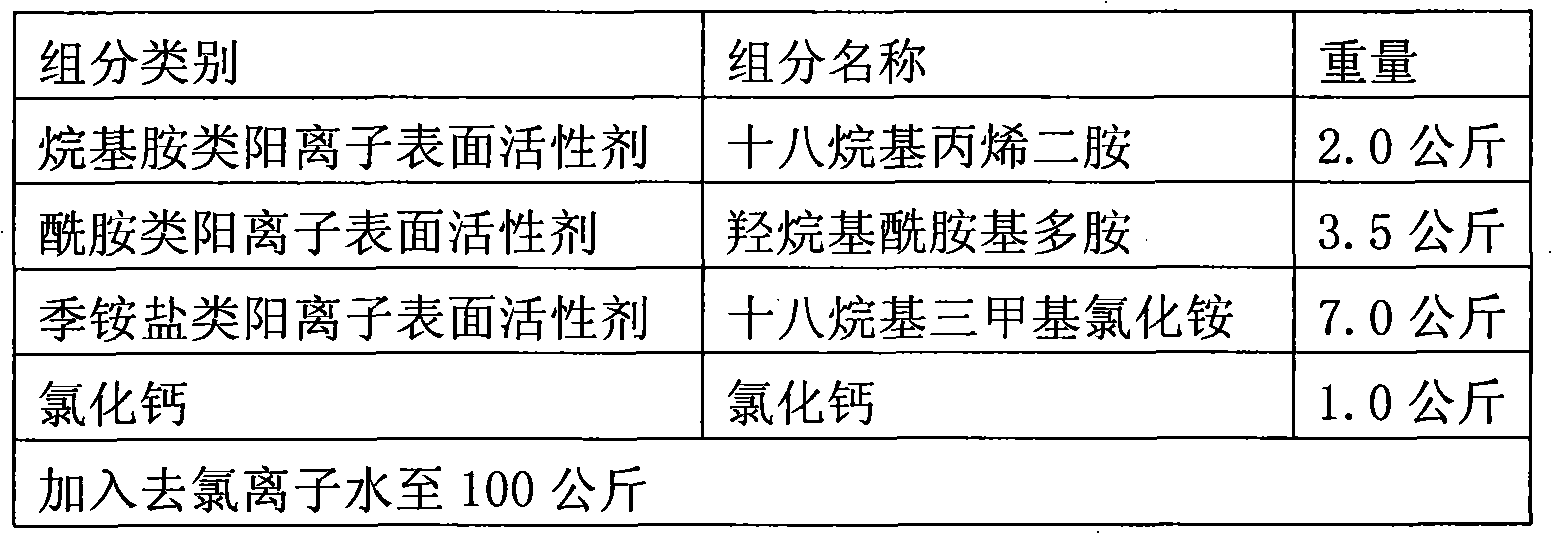

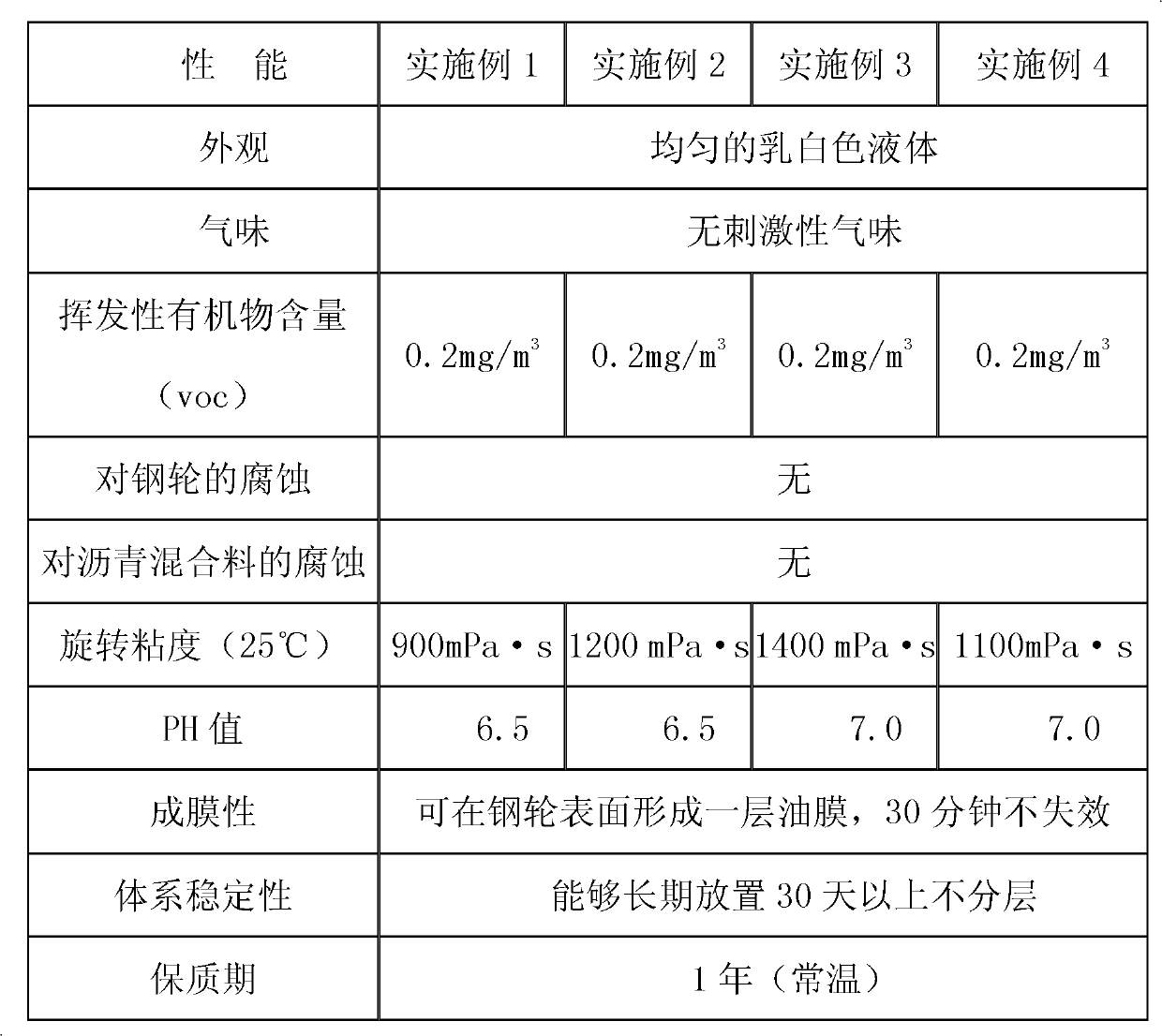

The invention relates to an asphalt warm-mix agent, comprising the following components in percentage by weight: 1.0-2.0% of alkylamine type cationic surfactant, 3.0-5.0% of amide type cationic surfactant, 5.0-10.0% of ammonium salt type cationic surfactant, 1.01.5% of calcium chloride, and water with residual percentage. The invention also relates to an asphalt mixture with the pavement applicability basically same as the traditional hot-mix asphalt mixture and the mixing and construction temperature lower than 20-50 DEG C; the purposes of energy saving, emission reduction, longer construction season, asphalt aging reduction and easier compaction are realized by reducing the mixing temperature; the indexes of the compaction degree, the water stability, the high-temperature performance, the low-temperature performance and the like of the pavement after paving the asphalt are not lower than those of hot-mix asphalt mixture at the same stage; and the service life of the asphalt pavement is efficiently guaranteed.

Owner:天津市市政工程研究院 +1

Epoxy static conducting anti-corrosive paint

InactiveCN101358099AFast curingExtended construction seasonAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyDiluent

The present invention discloses a static electricity-conducting anti-corrosive epoxy coating, which comprises a component A and a component B; wherein, the component A is composed of epoxide resin, epoxy active diluent, epoxy-terminated modified urethane resin, flaky conductive mica powder and granular conductive titanium pigment; the component B is composed of modified fatty amine, modified alicyclic amine and curing accelerator; the component A and the component B are mixed according to a proportion to prepare the double-component, non-carbon static electricity-conducting anti-corrosive epoxy coating without solvent. Because the static electricity-conducting anti-corrosive epoxy coating does not use volatile liquid solvent, adopts 100 percent of solid ingredients and uses the technical scheme of polyfunctional flexibilizer and the flaky and granular composite conductive media, the static electricity-conducting anti-corrosive epoxy coating has the advantages of high safety, energy saving, environment-friendliness, good static electricity-conducting property, good anti-corrosive property, one-step spraying and filming and convenient construction, so the static electricity-conducting anti-corrosive epoxy coating is widely applicable to the field of the static electricity conduction and corrosion prevention of oil storage tanks and has a wide market prospect.

Owner:BEIJING RADIATION APPL RES CENT

Insulator for low-temperature construction of asphalt pavement road roller and method for preparing same

ActiveCN102167939ANo pollution in the processNo chemical reactionClimate change adaptationCoatingsGreenhouseEngineering

The invention belongs to the technical field of preparation of insulators for the construction of asphalt pavement road rollers and relates to an insulator for the low-temperature construction of road rollers and a method for preparing the same. The insulator is mainly prepared by mixing silicone oil, compound emulsifier, glycerin, pH regulator, preserving agent and water. The insulator has the advantages of high chemical stability, high high-low temperature resistance, no corrosion to steel wheels, small amount of coating, lasting insulating effect, environment friendliness and the like. By using the insulator, the asphalt mixture pavement is guaranteed to be constructed at the ultralow temperature (15 DEG C below zero), so that the working season is greatly prolonged; and during normal-temperature construction, by using the insulator, the mixing temperature of the asphalt mixture is reduced to 15 to 20 DEG C under the condition of unchanging the compaction degree and the emitted greenhouse gases are reduced in the mixing process and the environment-friendly and energy saving requirements are met.

Owner:山西省交通科技研发有限公司

Warm mixing shape memory alloy (SMA) asphalt mixture and preparation method thereof

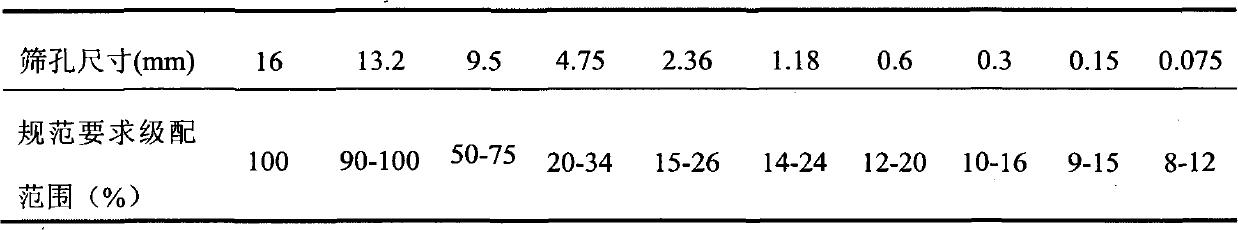

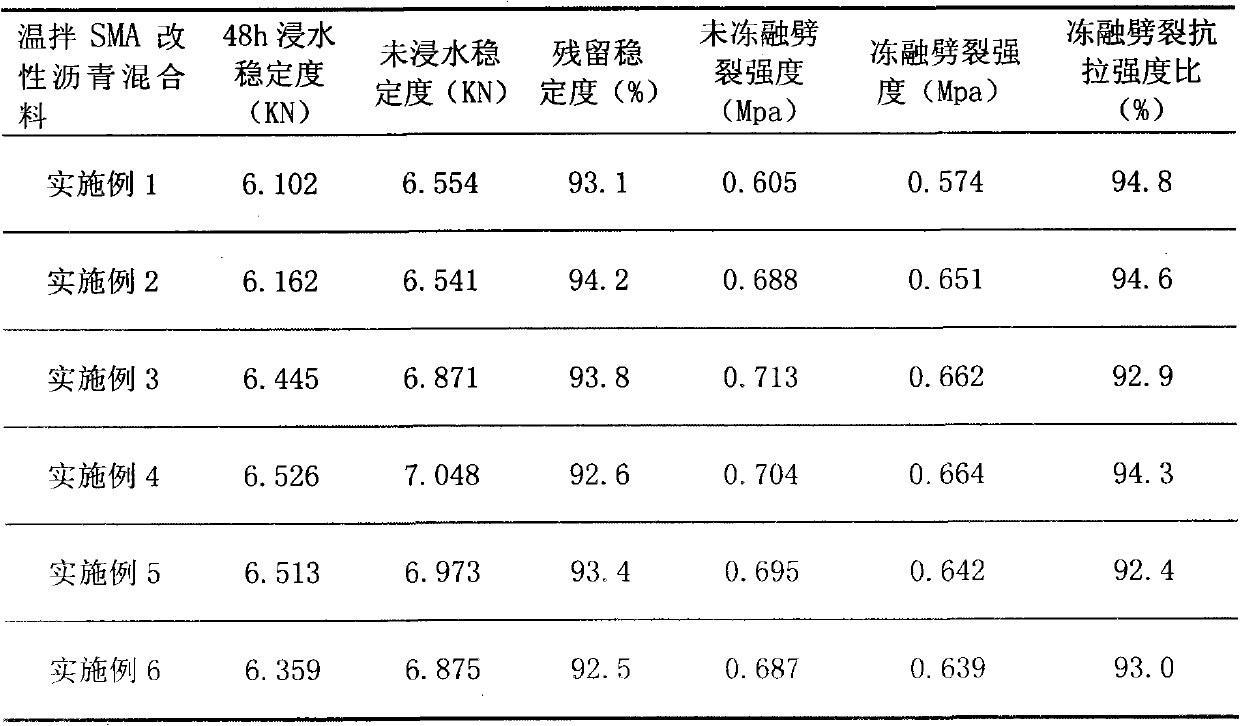

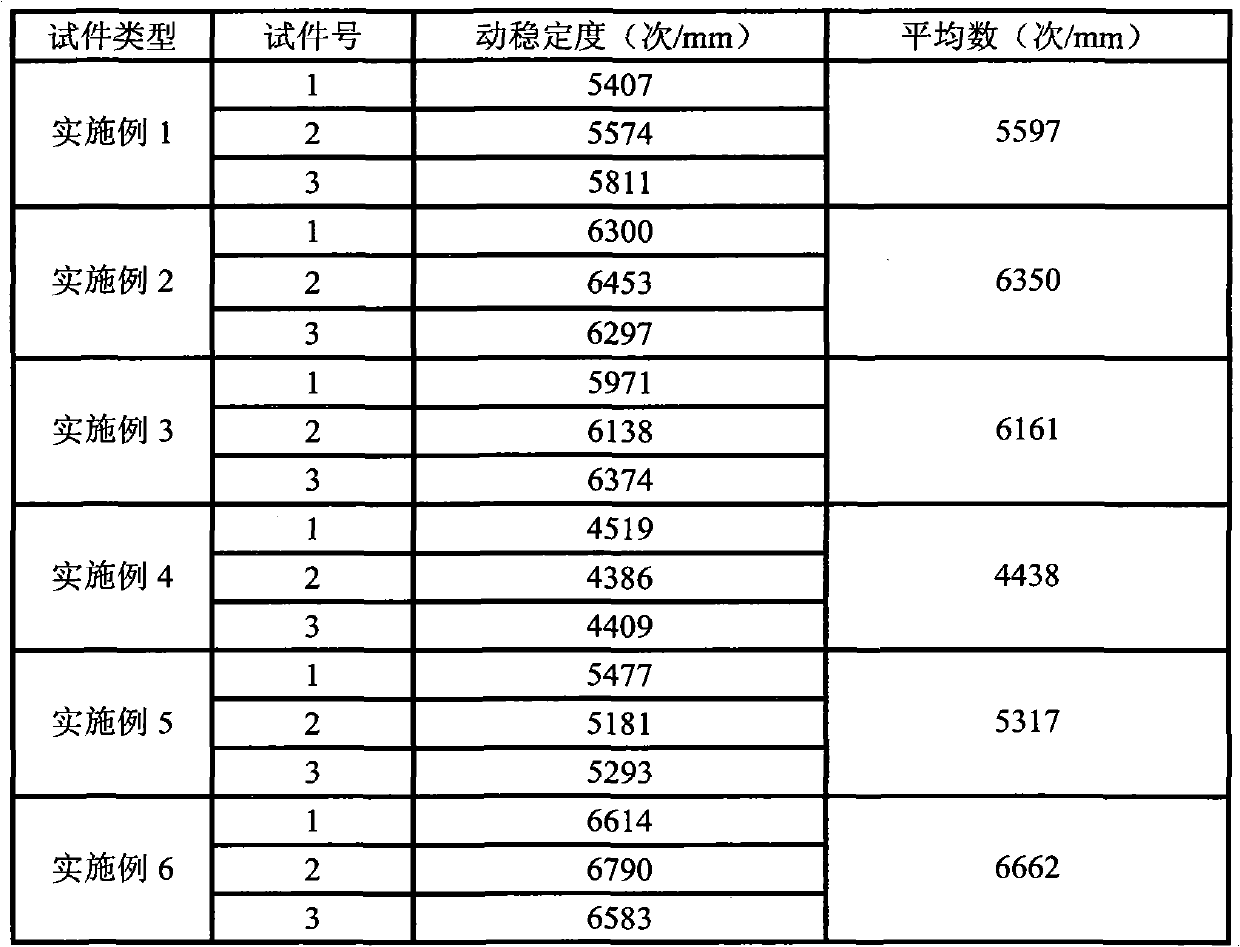

The invention discloses a warm mixing shape memory alloy (SMA) asphalt mixture. The warm mixing SMA asphalt mixture comprises styrene-butadiene-styrene (SBS) modified asphalt, aggregate, fiber, mineral powder and warm mixing agent, wherein the warm mixing agent is inorganic silico-aluminate of which the water content is 18 to 23 percent; based on 1 weight part of SBS modified asphalt, the mixture contains 10 to 18 parts of aggregate, 0.01 to 0.08 part of fiber, 0.5 to 1.5 parts of mineral powder and 0.02 to 0.08 part of warm mixing agent; and the invention discloses a preparation method for the warm mixing SMA asphalt mixture, and adding sequence, control temperature and mixing time of the materials are described in the method. According to the warm mixing SMA asphalt mixture, the mixing temperature of the SMA asphalt is effectively reduced, the problem that the SMA asphalt mixture is difficult to compact is solved, emission of toxic gases such as 'asphalt fume' is reduced to a great extent, damage to the environment and harm to health of constructors are reduced, and storage type production is facilitated.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

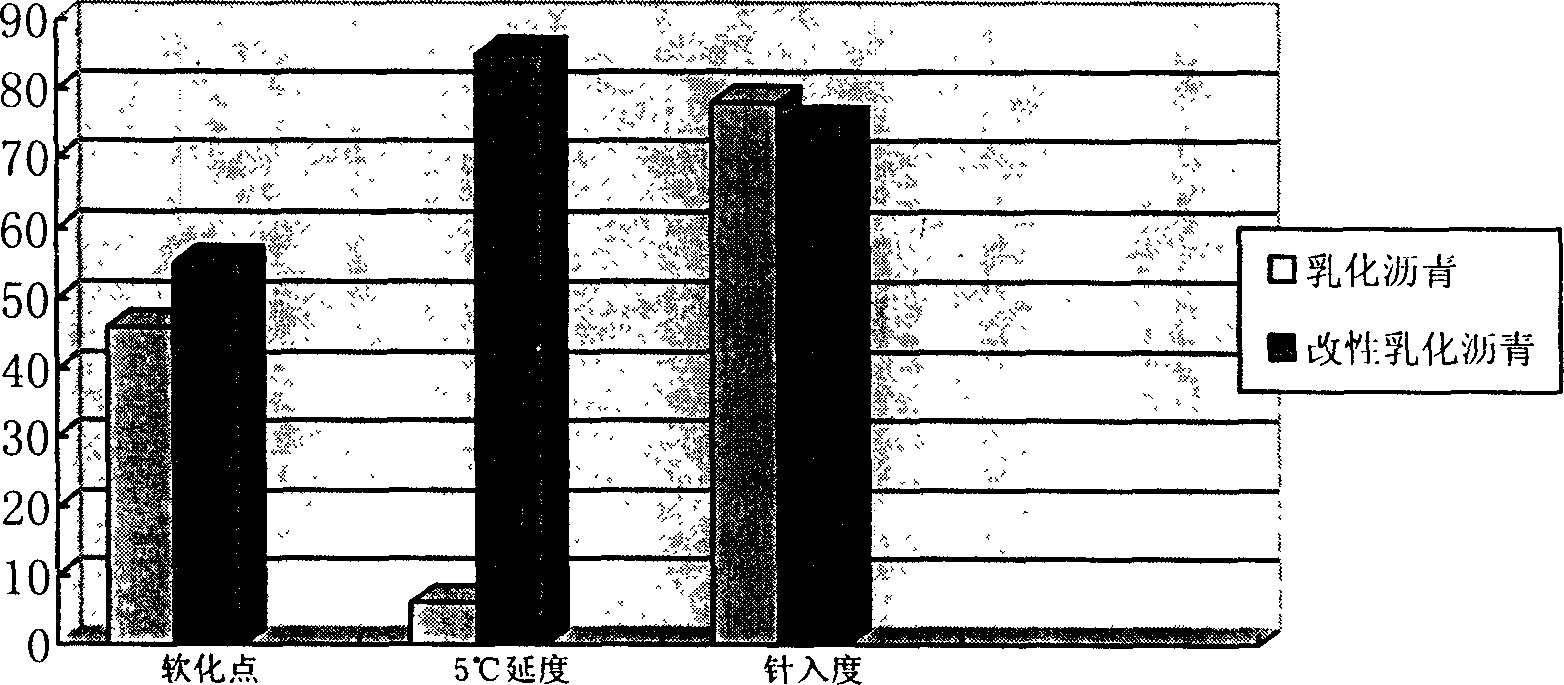

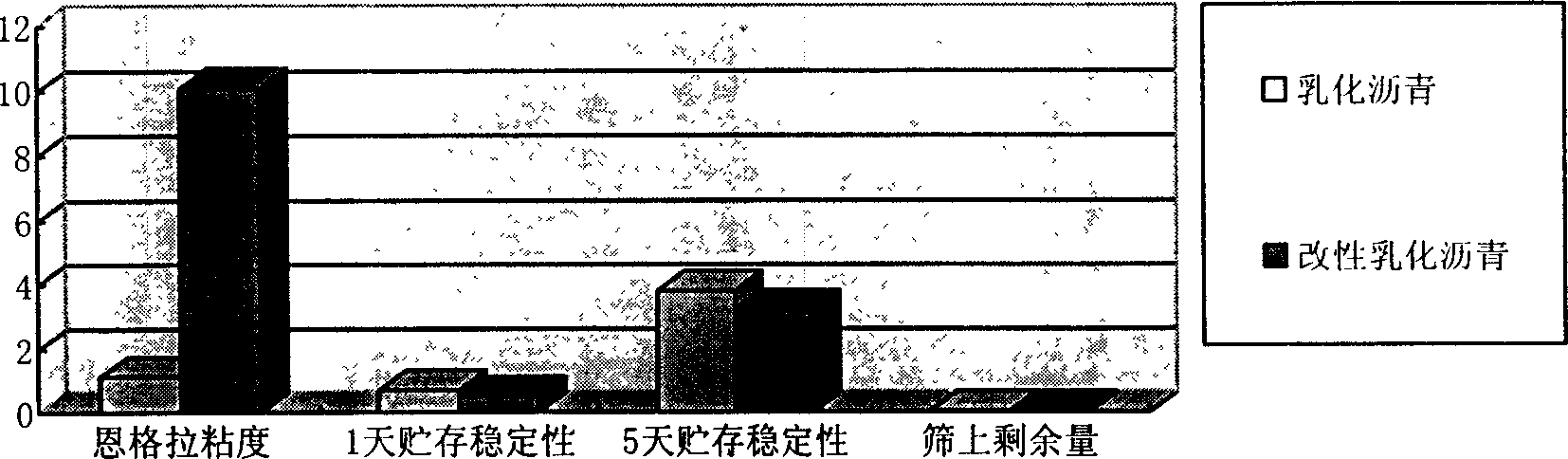

Asphalt modifier, modified emulsified asphalt, modified asphalt mixture and respective preparation methods thereof

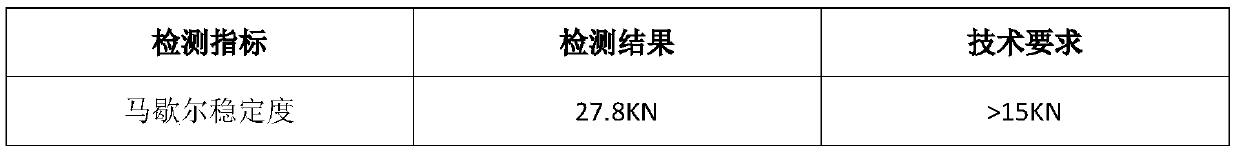

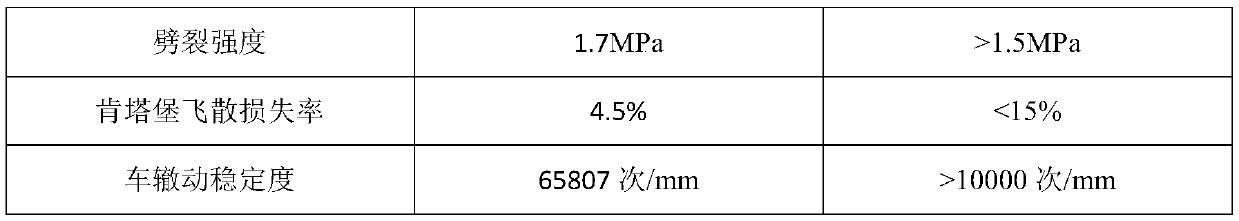

ActiveCN104312175AExtended construction seasonEmission reductionBuilding insulationsEmulsionRoad surface

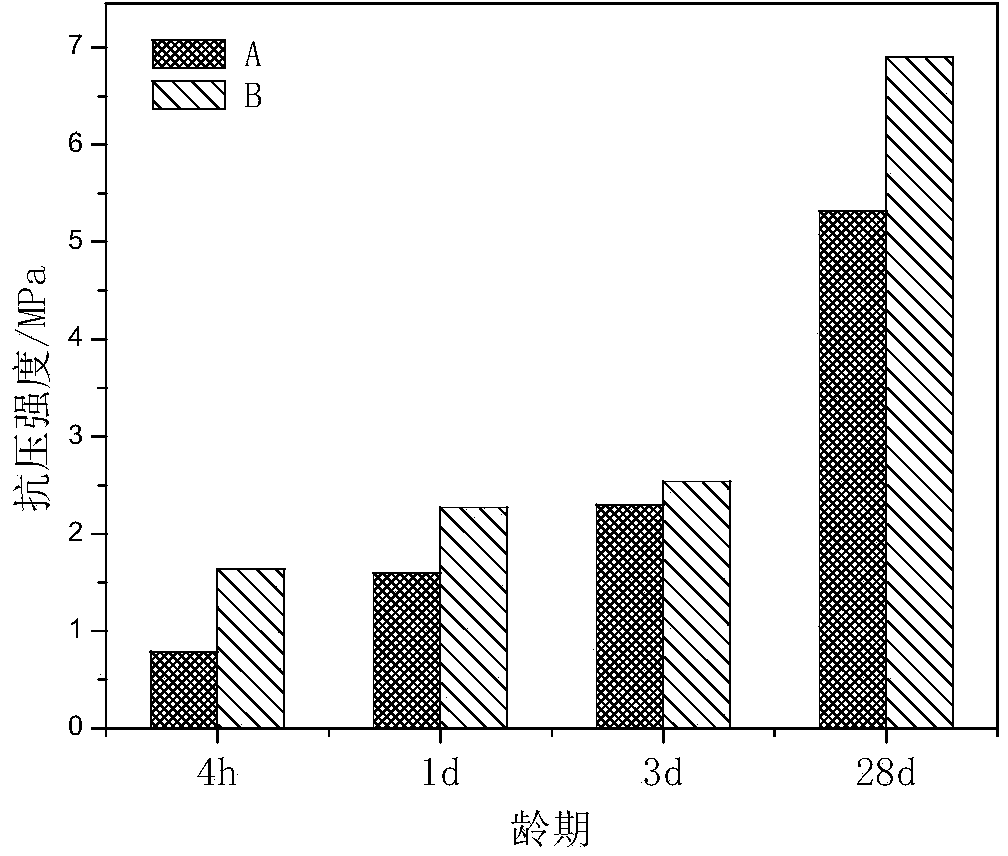

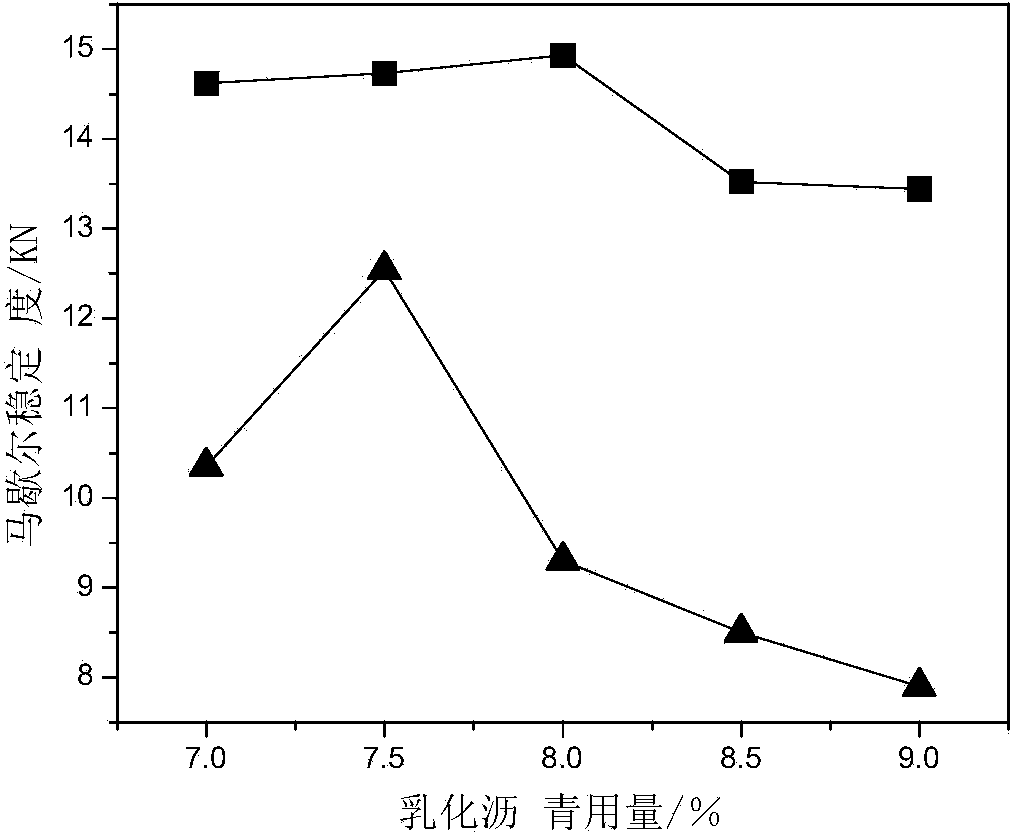

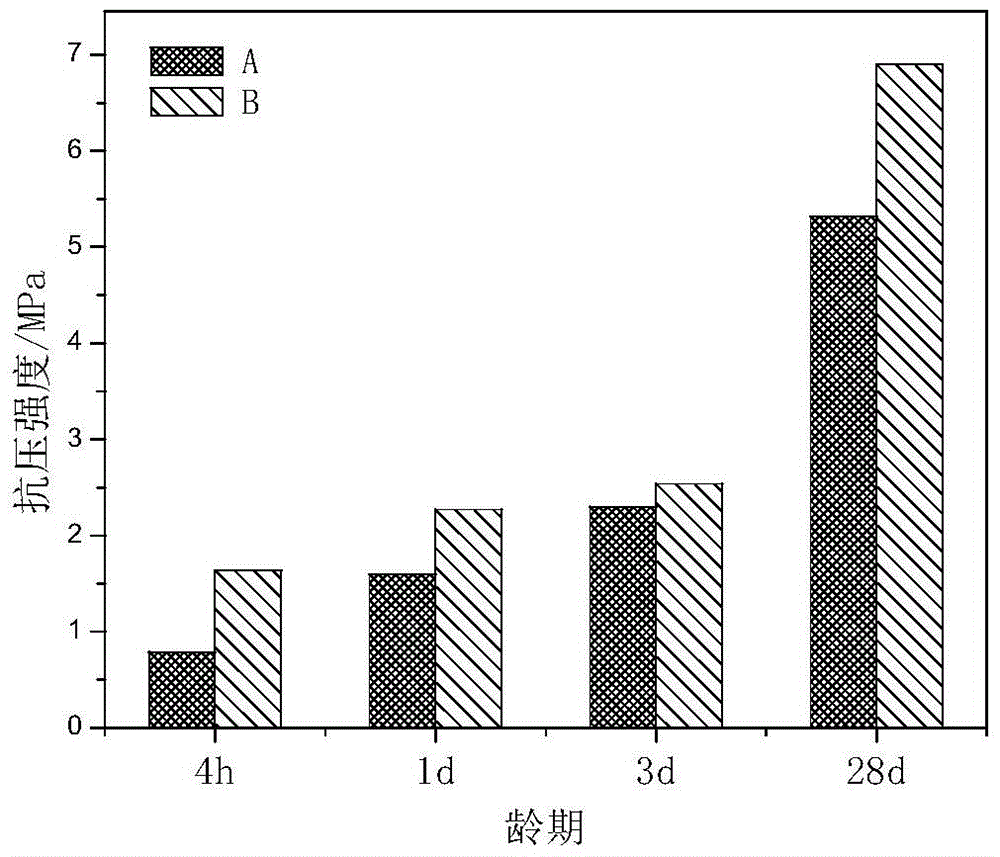

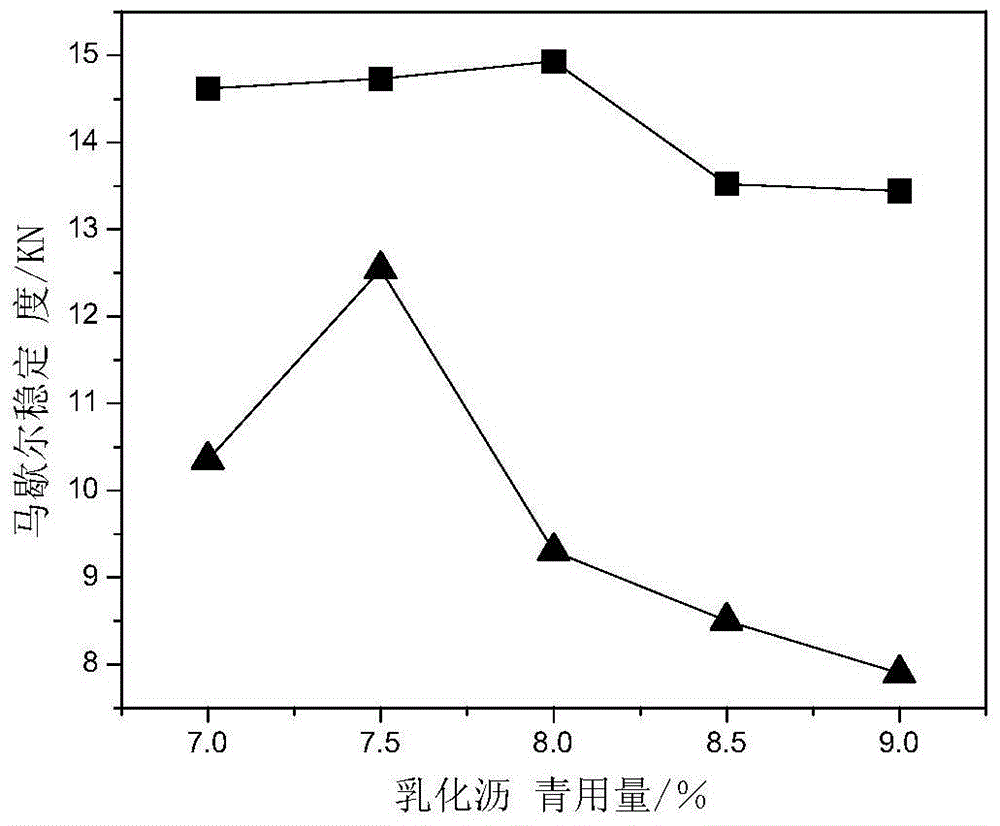

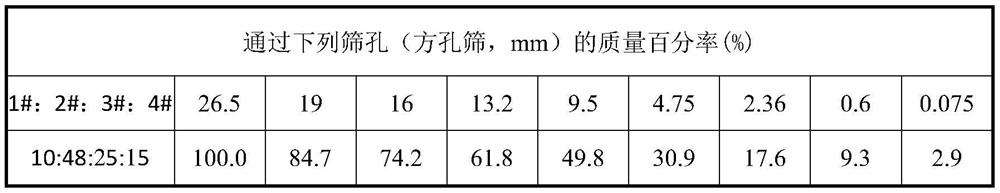

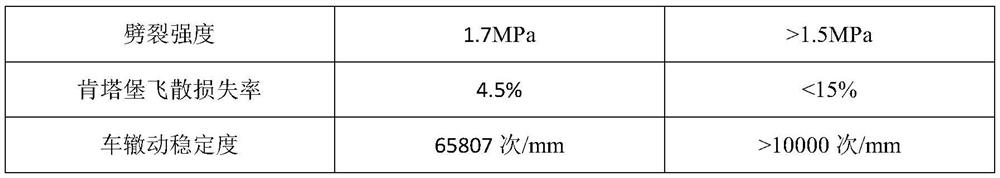

The invention provides an asphalt modifier which consists of a composition I and styrene-butadiene-styrene block copolymer emulsion, wherein the composition I consists of ethylvinylacetate emulsion, styrene-butadiene emulsion, waterborne bisphenol A epoxy resin emulsion and organic silicon modified acrylate emulsion. The invention also provides modified emulsified asphalt and a rapid-curing modified asphalt mixture which comprise the asphalt modifier, and respective preparation methods. The modified asphalt mixture provided by the invention is a brand new rapid-curing high-performance pavement material. The modified asphalt mixture not only has rigidity and intensity of mineral aggregates, but also has flexibility of asphalt and has Marshall stability of over 12KN and a flow value of between 2 to 4mm; and after an asphalt pavement repair layer with a thickness of 1 to 3cm is constructed for about 4 hours, the traffic can be opened.

Owner:XINJIANG MEIHUITE PETROCHEM PROD CO LTD

Reconditioning tracks on asphalt pavement by using thin paste mixture of modified emulsified asphalt and construction method thereof

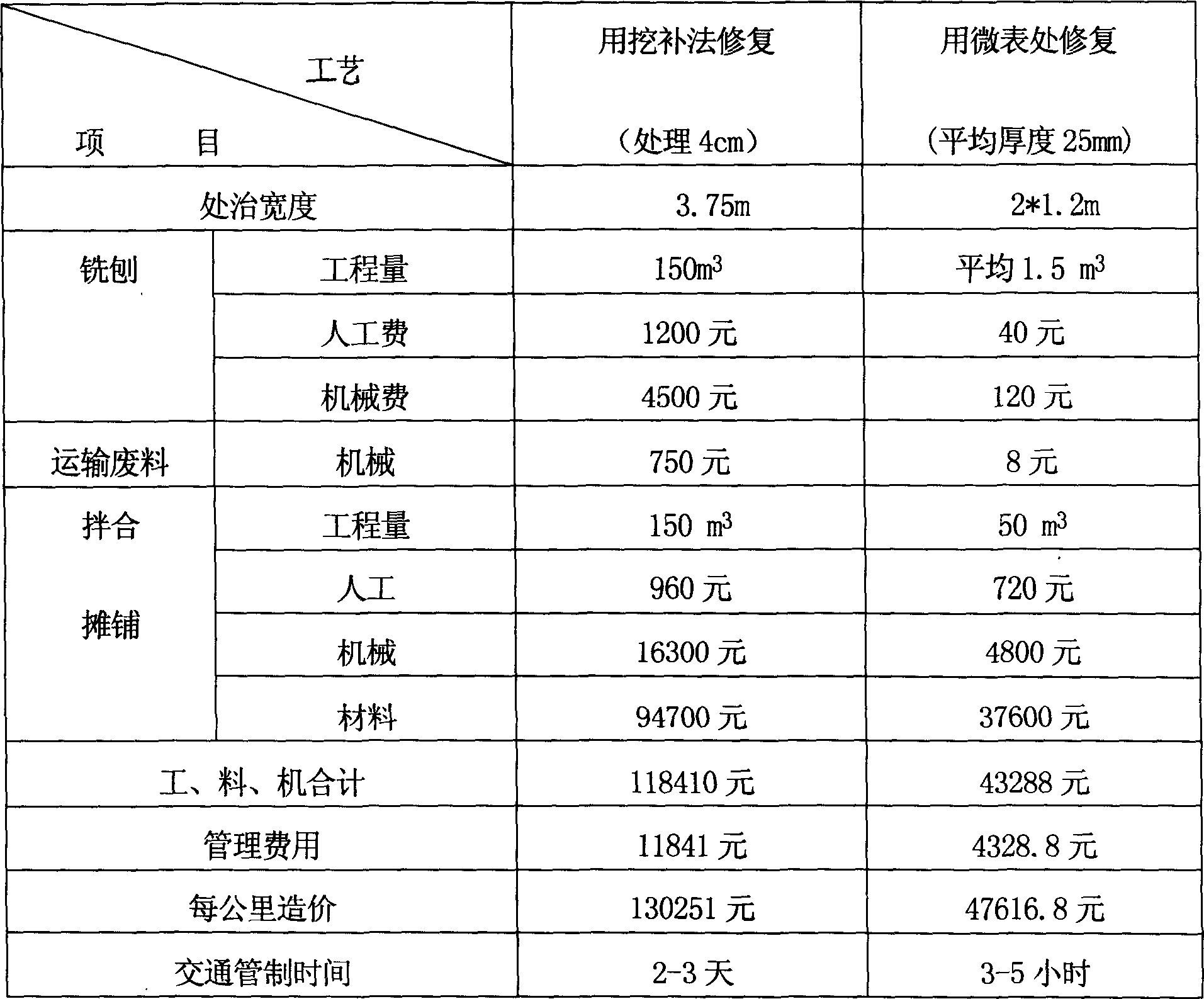

InactiveCN1687526AImprove skid resistanceImprove flatnessIn situ pavingsRoads maintainenceMixed materialsRoad surface

This is a kind of restoring the tracks of the bitumen road surface with the modified emulsified bitumen watery slurry mixed materials and its job practice. Spread single layer modified emulsified bitumen watery slurry mixed materials on the bitumen road surface of 10 - 20 mm depth, and spread double layer modified emulsified bitumen watery slurry mixed materials on the bitumen road surface of 20 - 40 mm depth. The job practice of single layer modified emulsified bitumen watery slurry mixed materials is: close down the traffic, process the original road surface, lay samples, spread, appearance control, joint slots, initial maintenance and quality inspection. Other building steps of the lower layer job practice of the double layer modified emulsified bitumen watery slurry mixed materials are the same as that of single layer, except that the allocated proportion of the single layer modified emulsified bitumen watery slurry mixed materials is different and without quality inspection. The upper layer building steps are: spread, initial maintenance and quality inspection. It has such advantages as high abrading-resistant performance, thin structure layer, long using life, high building speed, fast molding, short building period, fast traffic opening, long building season, low resource waste, no deleterious gas euduction and so on.

Owner:西安高远公路养护技术有限公司

Organic bentonite composition modified emulsified asphalt and its preparing method

The invention relates to an organobentonite composition modified emulsified bitumen and its preparing method. The bitimen is composed of 60-62 protions base bitumen,34-36.4 protions water,0.5-0.8 protions cationic emulsifier,1-3 protions organobentonite,2-4 protions butadiene styrene latex,0.1-0.2 protions thickening agent.Its prparing method comprises: mixing emulsifier solution uniformly, then mixing and emulsifying with base bitumen by emulsifying machine, then adding organobentonite and thickening agent to emulsified bitumen, mechanically stirring, mixing uniformly and deforming to obtain modified emulsifier bitumen. The invention has advantages of fine capability, high production efficiency, easy control, convenient operation and low cost.

Owner:NORTHWEST NORMAL UNIVERSITY

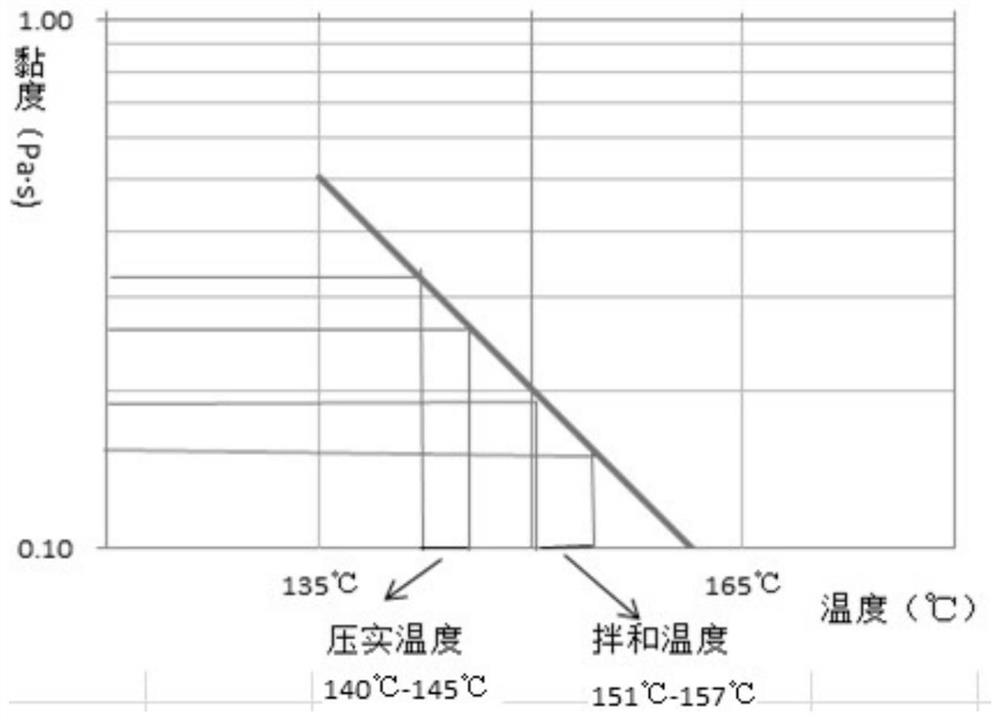

Warmly-mixed TOR (trans-polyoctenamer rubber reactive modifier) rubber asphalt mixture and preparation method thereof

ActiveCN103396043AImprove working environmentLower working environmentClimate change adaptationPolymer scienceAsphalt

The invention provides a warmly-mixed TOR (trans-polyoctenamer rubber reactive modifier) rubber asphalt mixture and a preparation method thereof. The warmly-mixed rubber asphalt mixture comprises TOR rubber asphalt prepared in situ. The TOR rubber asphalt comprises a TOR, rubber powder, asphalt, aggregates, mineral powder and a warm mixing agent, wherein the weight ratio of the rubber powder to the asphalt is 18:100, the weight ratio of the TOR to the rubber powder is 4.5:100, the weight ratio of the TOR rubber asphalt to the sum of the aggregates and the mineral powder is 6:100, the weight ratio of the aggregates to the mineral powder is 88:12, and the weight ratio of the warm mixing agent to the asphalt is 3:100. The invention further provides the preparation method for the warmly-mixed TOR rubber asphalt mixture. The preparation method comprises the following process steps of: preparing the TOR rubber asphalt, preprocessing the aggregates, adding the TOR rubber asphalt, the warm mixing agent and the mineral powder, and molding, so as to prepare the warmly-mixed TOR rubber asphalt mixture. According to the preparation method, the advantages of the TOR rubber asphalt mixture and a warm mixing technique are combined, so that the TOR rubber asphalt mixture has the advantages that the construction conditions can be improved, and the resource conservation, the energy conservation and the environment protection can be realized.

Owner:YANGZHOU UNIV

Warm mix anti-rutting asphalt mixing material and preparation method thereof

InactiveCN103086633ADelay agingEmission reductionIn situ pavingsClimate change adaptationCrack resistancePrice ratio

The invention provides a warm mix anti-rutting asphalt mixing material and a preparation method thereof. The warm mix anti-rutting asphalt mixing material comprises 0.25-0.5% by weight of a warm mix asphalt additive and 0.1-0.6% by weight of an anti-rutting asphalt modifier. The warm mix anti-rutting asphalt mixing material has the following characteristics that: a warm mix effect is significant; a mixing temperature can be reduced by more than 30 DEG C, and a paving temperature can be reduced; and an anti-rutting performance of an asphalt mixing material can be significantly increased, low temperature cracking resistance and other performances can be improved, and a performance price ratio is high.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Graded broken stone filling type semi-flexible composite pavement mixture and pavement construction method

The invention relates to a graded broken stone filling type semi-flexible composite pavement mixture, which comprises the following components in parts by mass: 100 parts of graded broken stone; 4-6 parts of water and 6-10 parts of a grouting material. The grouting material comprises cement, water-based acrylic resin, a volcanic ash material and water. The grouting material is poured into the graded broken stone. The semi-flexible composite pavement mixture can be constructed at normal temperature, thus effectively solving the rutting problem of asphalt pavements and improving the durability of the pavements. The environmental pollution caused by hot mix construction of a filled semi-flexible pavement can be reduced. The construction efficiency of a filled composite pavement is improved, and the production cost is reduced.

Owner:HOHAI UNIV

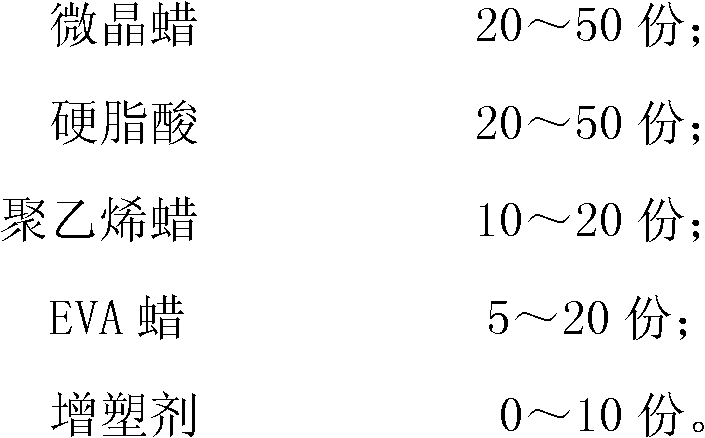

Compound asphalt mixture wet-mixing additive and preparation method thereof

The invention relates to the field of road materials, and discloses a compound asphalt mixture wet-mixing additive and a preparation method thereof. According to the compound asphalt mixture wet-mixing additive, production and construction temperatures of a hot-mix asphalt mixture can be reduced. The compound asphalt mixture wet-mixing additive is characterized by comprising the following components in parts by weight: 20-50 parts of microcrystalline wax, 20-50 parts of stearic acid, 10-20 parts of polyethylene wax, 5-20 parts of EVA (ethyl vinyl acetate) wax and 0-10 parts of plasticizer. The preparation method comprises the following steps of: uniformly mixing the polyethylene wax, the EVA wax, the stearic acid and the plasticizer under the mechanical stirring action, then adding the microcrystalline wax, continuously stirring and uniformly mixing to obtain a mixed dry material; and finally, adding the mixed dry material in a granulating machine melting furnace, heating at a temperature of 120-130 DEG C and melting, then granulating, cooling and drying. According to the compound asphalt mixture wet-mixing additive, the blending temperature of the asphalt mixture can be effectively lowered by about 30 DEG C, and better used road performance can be ensured.

Owner:陕西长大博源公路养护科技有限公司

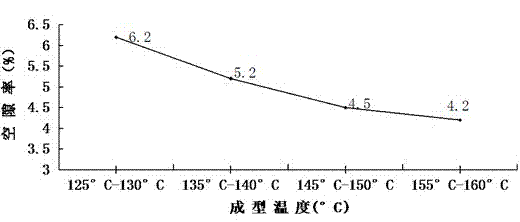

Modified bituminous mixture and preparation method thereof

InactiveCN103755225ALarge rolling temperature rangeThe influence of temperature etc. is smallActive agentPhysical chemistry

The invention relates to a modified bituminous mixture and a method for preparing the modified bituminous mixture. The modified bituminous mixture contains aggregate, common asphalt, an additive and mineral powder, wherein the additive contains water, a cationic surface active agent, a stabilizer and a modifier. The method comprises the following steps: firstly, heating water, adding the cationic surface active agent to dissolve, and then adding the modifier and the stabilizer; grinding by a colloid mill to form the additive; heating the aggregate to 140-160 DEG C, adding to a mixing cylinder to mix for 30 seconds; simultaneously adding the common asphalt heated to 120-140 DEGC and the weighed additive to the mixing cylinder, and then stirring for 40-60 seconds; and adding the cement or the mineral powder to the mixing cylinder to mix for 30-60 seconds, and discharging at 100-120 DEG C, so as to obtain the modified bituminous mixture, wherein the compact molding temperature is 90-110 DEG C. By adopting the modified bituminous mixture, energy source consumption and environmental pollution are reduced, the performance of the asphalt mixture is improved, the modified bituminous mixture can adapt to the requirements of a low-temperature construction technology, and the technology is relatively simple.

Owner:姚华彦

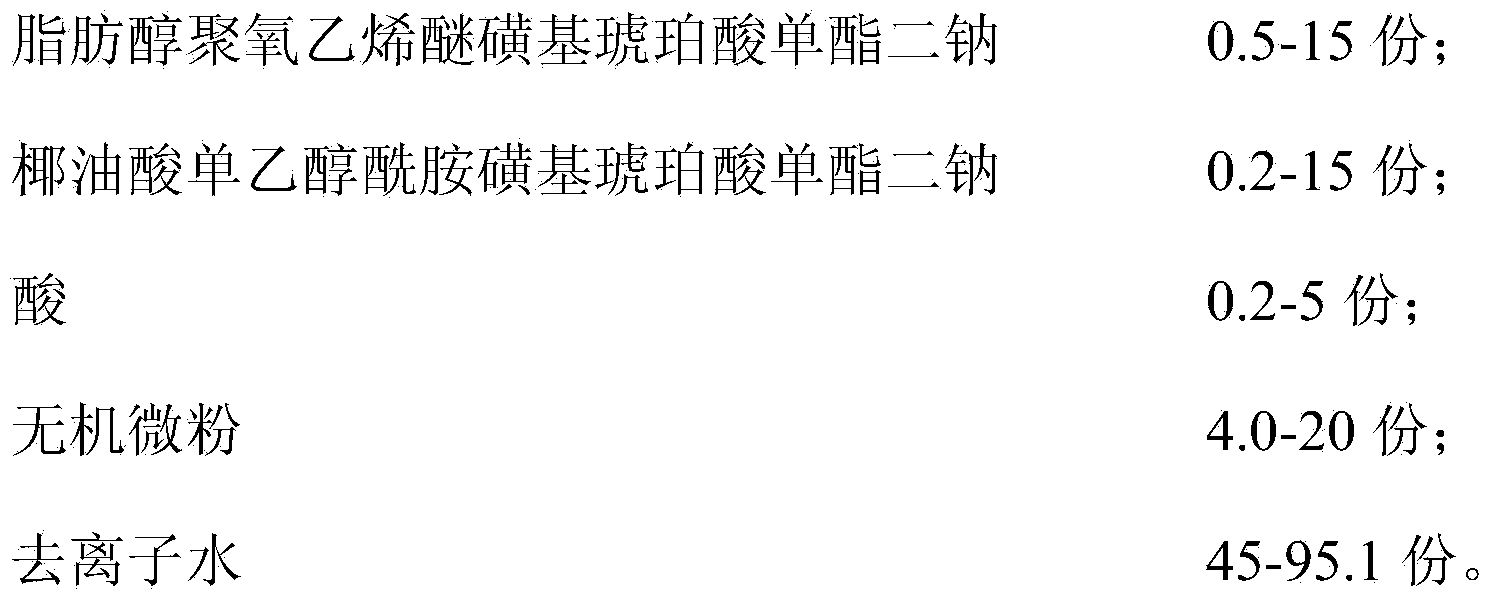

Warm asphalt modifier and preparation method and application thereof

InactiveCN104250446ALow preparation temperatureAchieve coolingClimate change adaptationBuilding insulationsAsphaltRoad construction

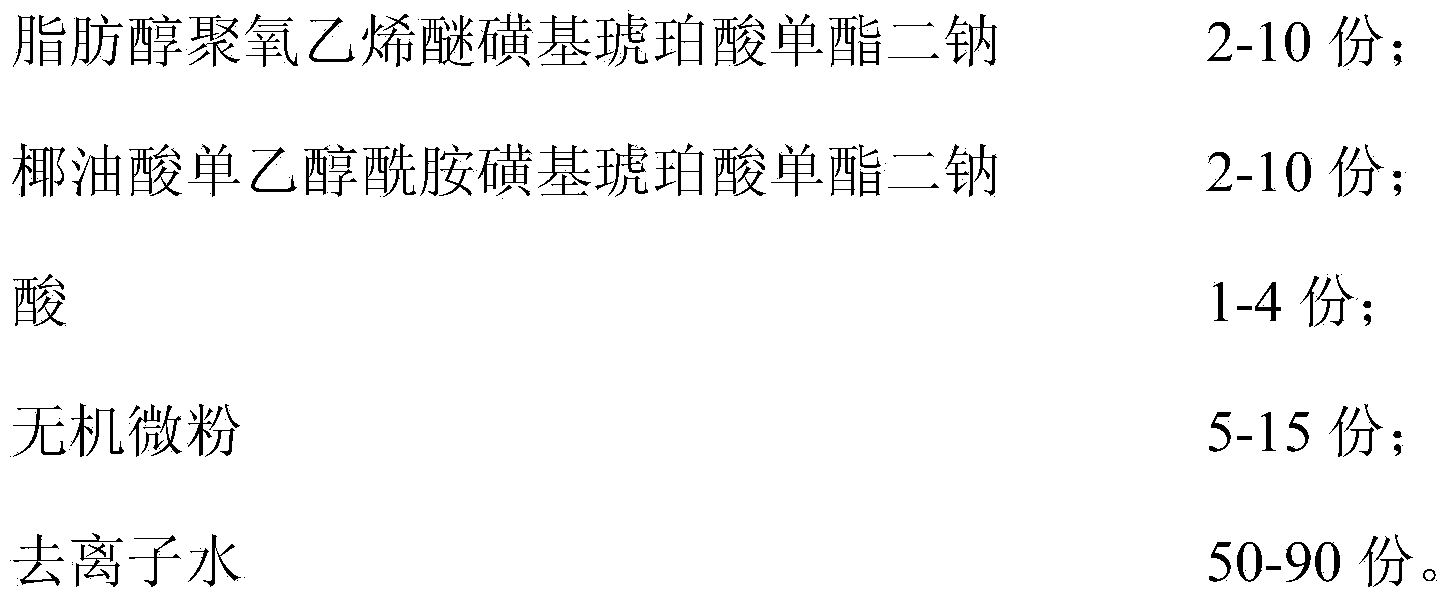

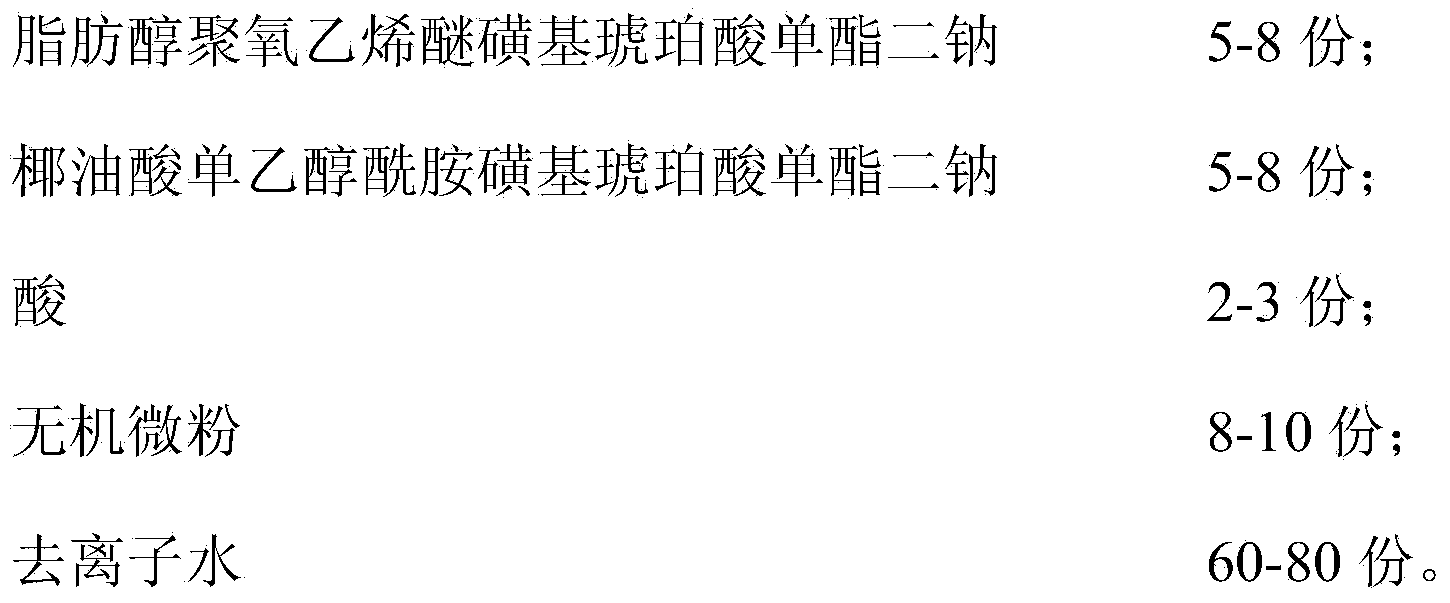

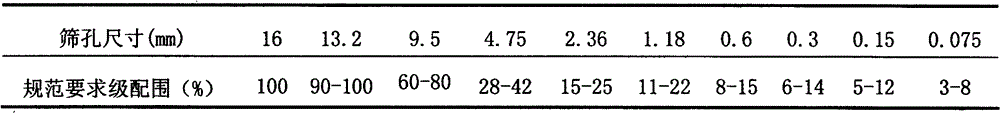

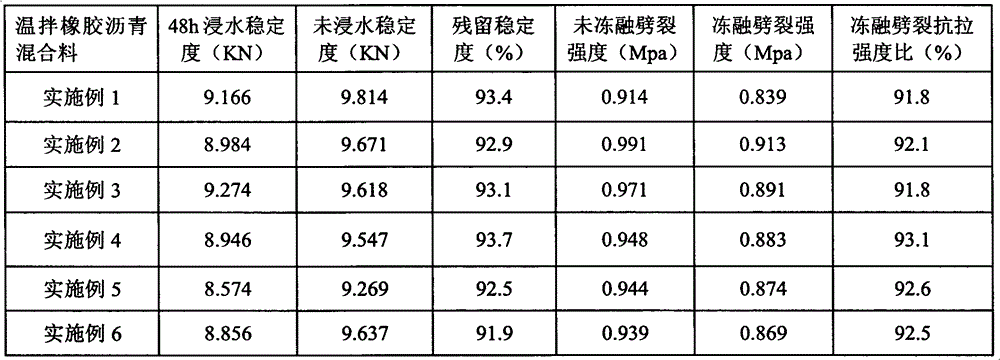

The invention relates to a warm asphalt modifier. The warm asphalt modifier comprises the following raw materials in parts by weight: 0.5-15 parts of disodium laureth sulfosuccinate, 0.2-15 parts of disodium cocoyl monoethanolamide sulfosuccinate, 0.2-5 parts of acid, 4.0-20 parts of inorganic micropowder and 45-95.1 parts of deionized water. The invention further relates to a method and application of the warm asphalt modifier as well as an asphalt mix containing the warm asphalt. The warm asphalt modifier well meets the requirements of road construction.

Owner:BEIJING ZHONGJIE WEIYE TECH DEV

Construction method of asphalt surface course under overcast, rainy, wet and cold conditions

InactiveCN102839582ASolve the problem that the construction of asphalt pavement cannot be carried outExtended construction seasonIn situ pavingsClimate change adaptationRoad surfaceAsphalt pavement

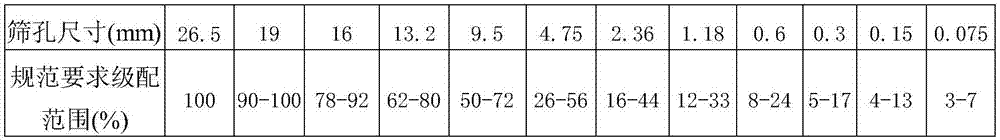

The invention discloses a construction method of an asphalt surface course in a low temperature and wet environment, and the construction method comprises the steps of designing a warm mixed asphalt mixture and preparing a raw material; adopting a coarse dense-graded asphalt mixture and forming a level S-shaped grading curve, mixing and producing the warm mixed asphalt mixture in a mixing cylinder, transporting the warm mixed asphalt mixture to a construction site, drying and heating a pavement, keeping a working plane dry, paving the warm mixed asphalt mixture continuously and uniformly, and conducting initial rolling, rerolling and final rolling on the pavement. The invention provides a general and feasible drying method of the wet, icy and snowy working plane. A heater used for reclamation construction of the asphalt pavement is adopted to heat and dry the pavement, so that the problem that the asphalt surface course cannot be constructed in the low temperature and wet environment in winter is solved.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Warm-mixed rubberized asphalt mixture and preparation method thereof

InactiveCN102795811AEasy to produceReduce consumptionIn situ pavingsClimate change adaptationMoistureHealth hazard

The invention discloses a warm-mixed rubberized asphalt mixture and a preparation method thereof. The warm-mixed rubberized asphalt mixture comprises rubberized asphalt, aggregates, mineral powder and a warm-mixed agent; the warm-mixed agent is inorganic aluminosilicate with moisture content of 18-23%; and through taking the weight part of the rubberized asphalt as one part, the warm-mixed rubberized asphalt mixture comprises 10-20 parts of aggregates, 0.15-1 part of mineral powder and 0.02-0.08 part of warm-mixed agent. Meanwhile, the invention also discloses a preparation method of the warm-mixed rubberized asphalt mixture; and in the method, the adding sequence, control temperature and mixing time of each material are described in detail. The warm-mixed rubberized asphalt mixture disclosed by the invention effectively reduces the mixing temperature of the rubberized asphalt, solves the problem that a rubberized asphalt mixture is uneasy to compact, reduces the consumption of fuel and the emission of harmful gas, reduces the damages on the environment and the health hazards on the construction personnel, and facilitates the stored production.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

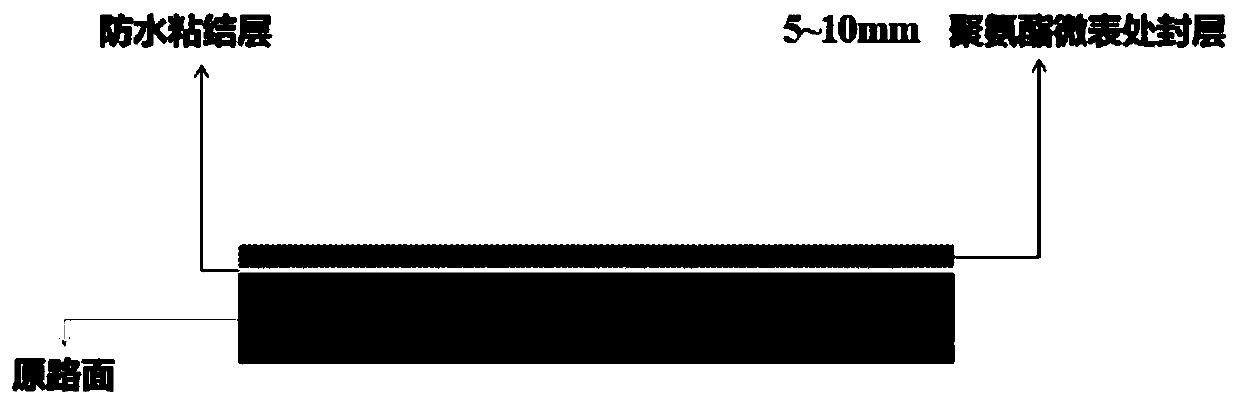

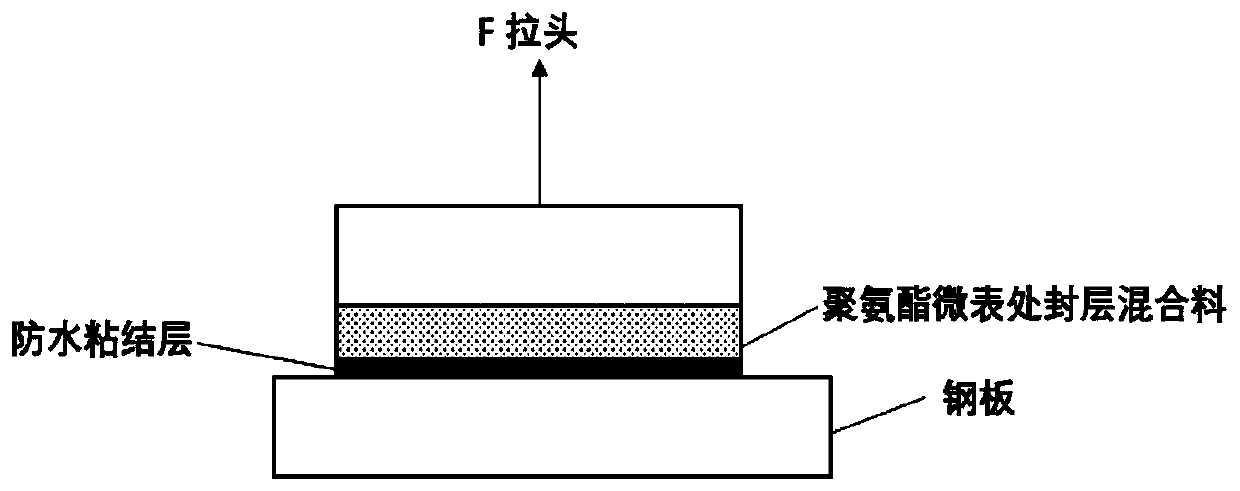

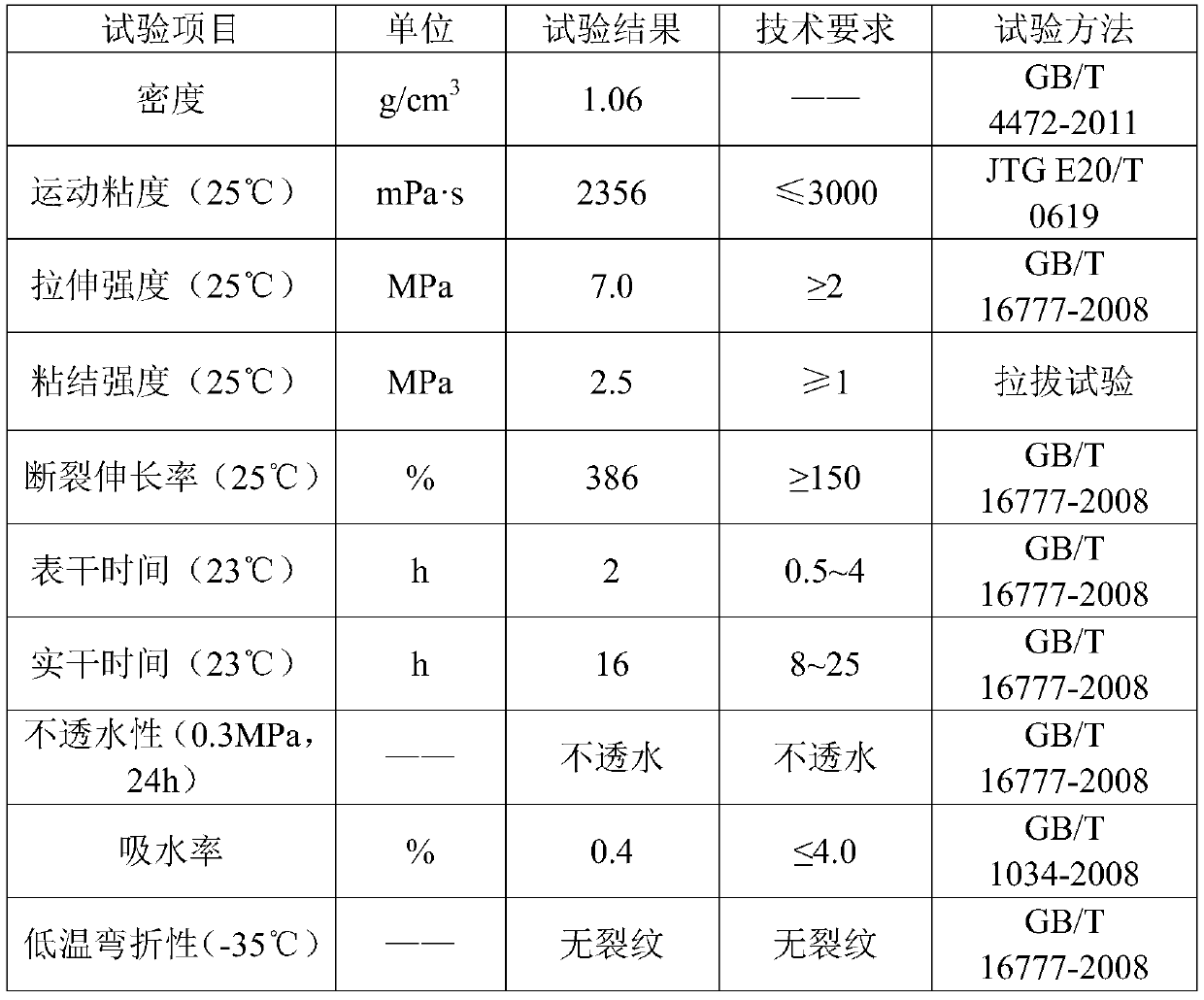

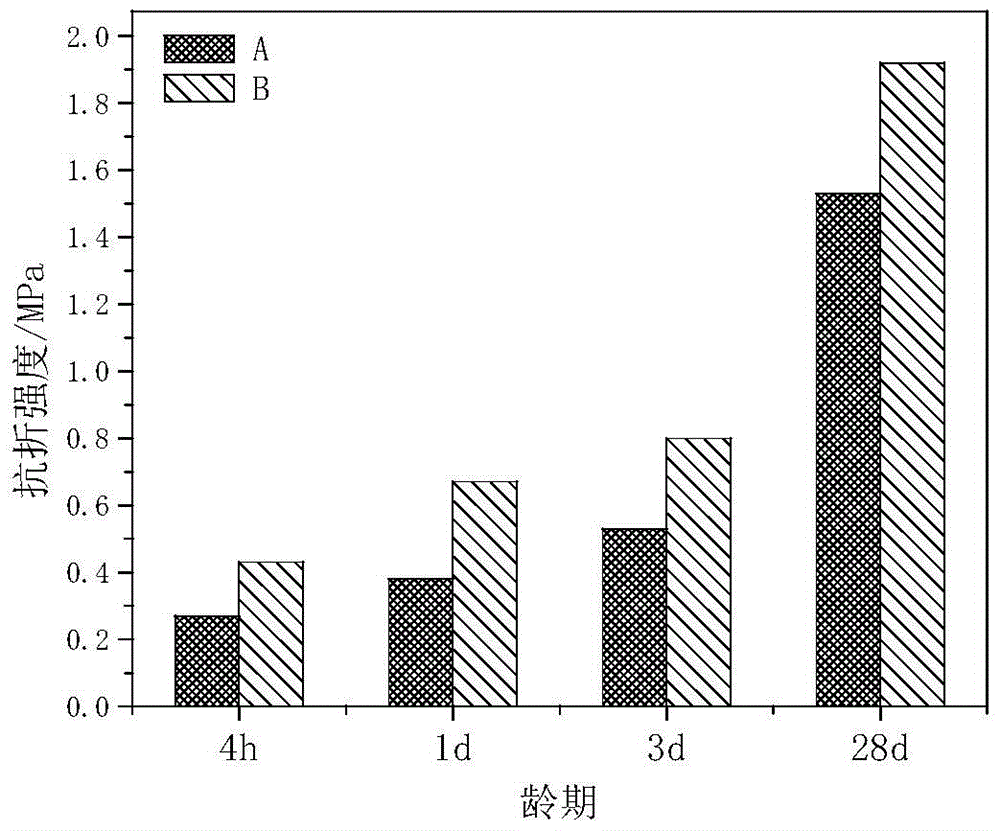

Polyurethane micro-surfacing seal coat mixture and preparation method and application thereof

The invention provides a polyurethane micro-surfacing seal coat mixture and a preparation method thereof. The polyurethane micro-surfacing seal coat mixture is prepared from the following raw materials in parts by weight: 80-100 parts of an aggregate, 0-20 parts of a filler, 8-15 parts of a polyurethane adhesive and 0.08-0.3 part of a catalyst. The polyurethane micro-surfacing seal coat mixture provided by the invention has good pavement performances and durability. According to the invention, a thin slurry mixture formed by mixing the polyurethane, aggregate, filler and the like according toa designed ratio is paved on a thin layer formed by an original pavement by using mechanical equipment, the concrete has the advantages of favorable durability, high compression resistance, high breaking strength, high strength formation speed, favorable stability, excellent low-temperature crack resistance, excellent fatigue resistance, environment friendliness, energy saving, longer constructiontime and the like, and can be cured at normal temperature.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

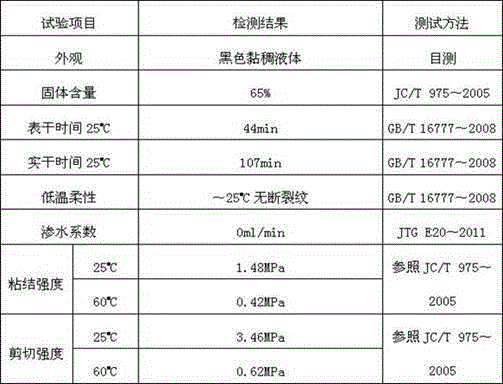

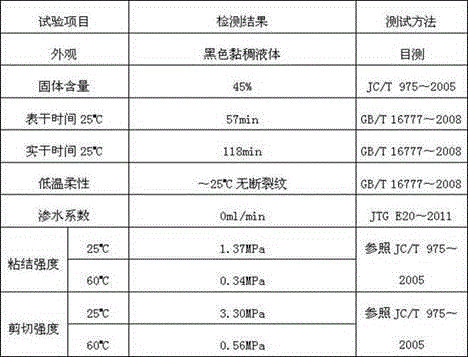

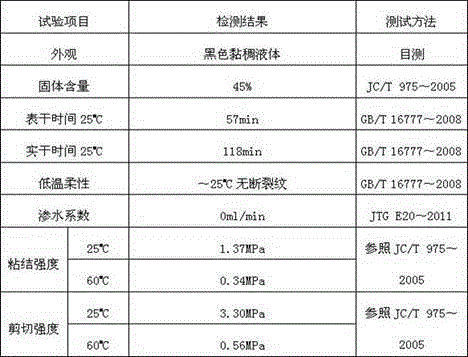

High-shearing and high-bonding coating material and preparation method thereof

ActiveCN104479552AIncrease shear forceImprove temperature adaptabilityConjugated diene hydrocarbon coatingsBituminous coatingsAcrylonitrileRoom temperature

The invention discloses a high-shearing and high-bonding coating material and a preparation method thereof. The coating material is prepared from the following components in parts by weight: 0.4-0.6 part of powdery butadiene-acrylonitrile rubber, 0.2-0.3 part of a flame retardant, 0.2-0.3 part of a stabilizer, 3-5 parts of an asphalt modifier, 15-25 parts of asphaltene powder, 25-35 parts of matrix asphalt and 35-55 parts of a solvent. The coating material disclosed by the invention is reasonable in formula and simple in preparation method, has relatively high shearing strength between layer and bonding force, is good in low-temperature flexibility, free of cracks at -25 DEG C, strong in waterproof performance and great in construction temperature range, and the construction season is prolonged, and moreover, the coating material can be smeared, sprayed or sprinkled under a room temperature condition and is wide in application range.

Owner:北京通途技术有限公司

Foamed asphalt warm-mixing mixture and preparation method thereof

ActiveCN111960730ASave resourcesImprove dispersion uniformitySolid waste managementFoaming agentAsphalt pavement

The invention discloses a foamed asphalt warm-mixing mixture and a preparation method thereof, and belongs to the field of asphalt mixtures. The preparation method comprises the following steps: heating 1-6 parts of matrix asphalt to 140-160 DEG C, and adding water which is 0.8-1.5% of the mass of the asphalt and contains a foaming agent and a stabilizer to obtain foamed asphalt; b, mixing 10-40 parts of waste cement concrete recycled aggregate and 20-80 parts of an old asphalt pavement material and stirring for 40-90 s at the temperature of 95-130 DEG C; then adding the foamed asphalt, and stirring for 40 to 90s at 130 to 140 DEG C; and finally, adding 2-20 parts of mineral powder, and mixing for 40-90 s at the temperature of 95-130 DEG C. According to the invention, the discharge amountof harmful gas and dust can be greatly reduced, the energy consumption in the production process can be reduced, the aging of the asphalt cement in the production process can be reduced, and the pavement performance of the mixture can be improved.

Owner:THE 5TH CONSTR COMPANY LTD OF CHINA RAILWAY 15TH BUREAU GRP

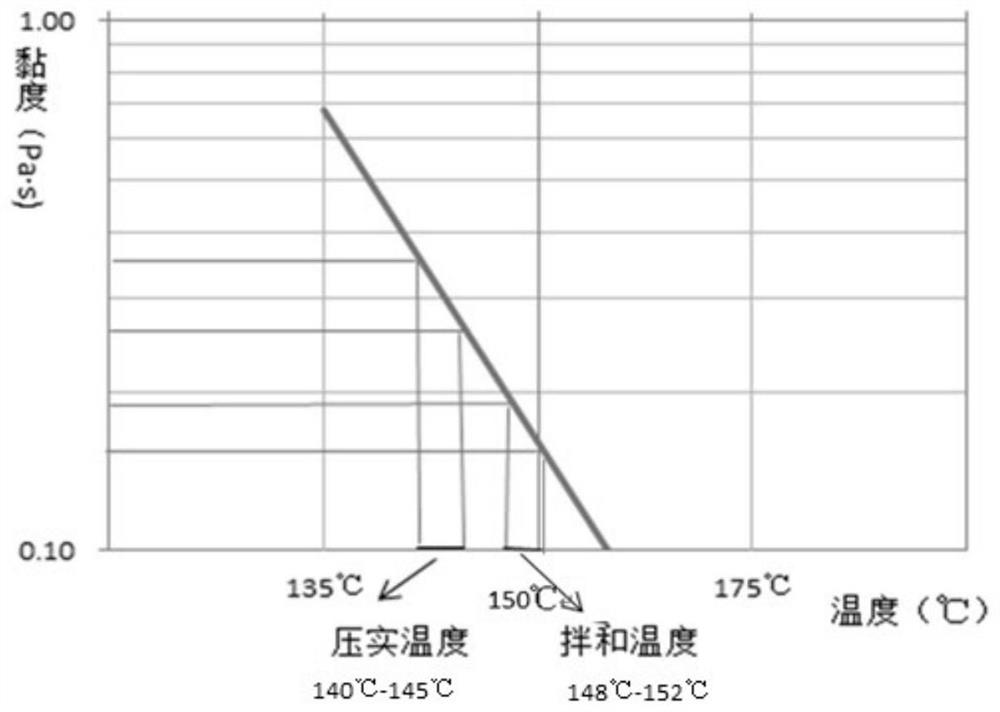

Warm-mixing SBS (styrene-butadiene-styrene) modified asphalt mixture and preparation method thereof

InactiveCN107140898AEasy to addDelay agingSolid waste managementClimate change adaptationAsphaltButadiene-styrene rubber

The invention discloses a warm-mixing SBS (styrene-butadiene-styrene) modified asphalt mixture which comprises the following ingredients in parts by weight: 1 part of SBS modified asphalt, 11-36 parts of aggregate, 0.5-1.5 parts of mineral powder and 0.02-0.04 parts of an organic warm-mixing agent, wherein the organic warm-mixing agent is EC-120. Moreover, the invention discloses a preparation method of the warm-mixing SBS modified asphalt mixture. In the invention, on a basis of maintaining the basic performance of the asphalt mixture, the construction temperature is remarkably reduced, the construction peaceability is improved, the energy consumption in construction is reduced, the emission of harmful gas is reduced, and the destruction to the environment and the damage to the health of constructors are reduced.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH +1

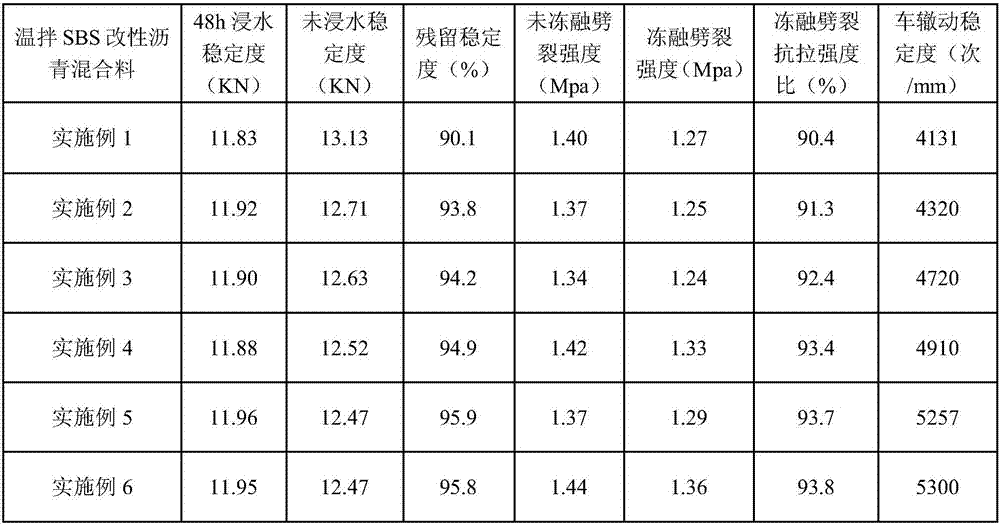

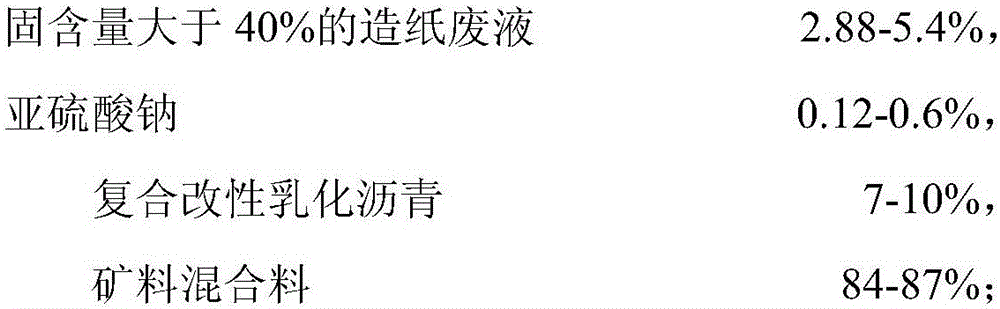

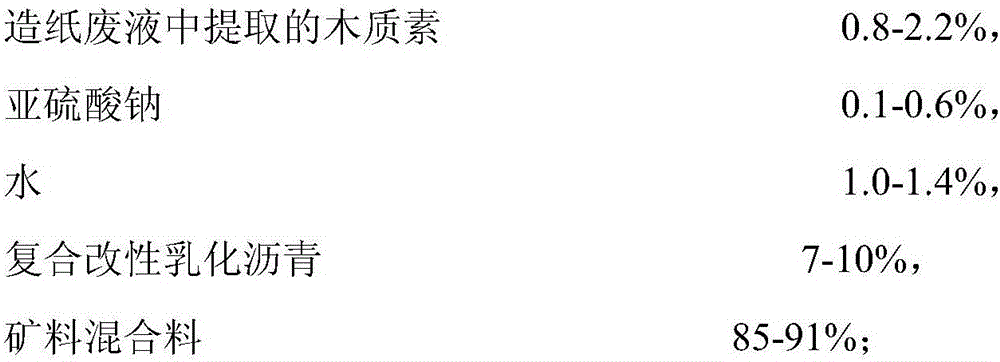

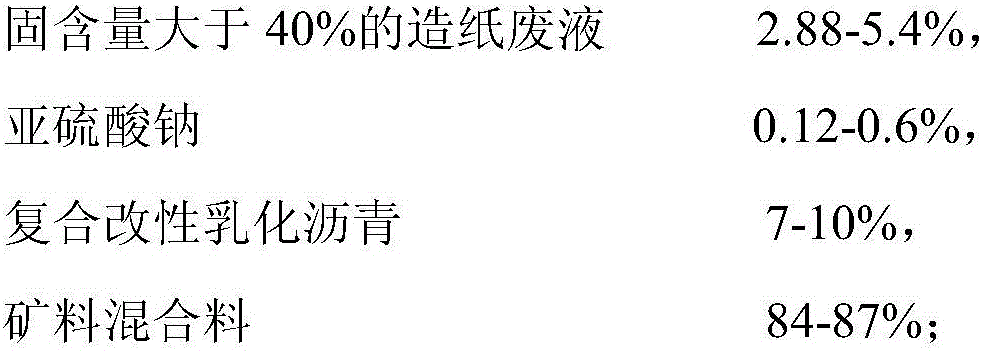

Preparation of cold-mixed cold-paved asphalt mixture and its construction method by using papermaking waste liquid

InactiveCN104446155BShort maintenance timeSimple production equipmentIn situ pavingsLiquid wasteSulfite salt

The invention discloses a method for preparing a cold-mixed cold-laid asphalt mixture by utilizing papermaking waste liquor and a construction method. The method for preparing the cold-mixed cold-laid asphalt mixture comprises the following steps: mixing the papermaking waste liquor or lignin with sodium sulfite to prepare a papermaking waste liquor mixed solution; preparing an ore mixed material according to a mix proportion at normal temperature, adding into a stirring tank of a stirrer, and dry-mixing for 10-20 seconds; adding the papermaking waste liquor or lignin mixed solution, mixing for 25-35 seconds to ensure that the surface of the ore material is uniformly wetted; adding modified emulsified asphalt and mixing for 58-63 seconds to prepare a cold-mixed cold-laid modified emulsified asphalt mixture. The transportation time is determined in a way that the amount of the added papermaking waste liquor mixed solution or the mixed solution of lignin extracted from the papermaking waste liquor can be regulated according to transportation distance; the spreading speed in the construction is controlled to be 4m / min to 5m / min; rolling is started immediately after the emulsion is demulsified; the cold-laid road surface is controlled to be in use within 2-6 hours according to different laying thickness.

Owner:王利泉 +2

Emulsified asphalt for slurry envelop and micro-surfacing and preparation method thereof

InactiveCN101294000AImprove the construction environmentExtended construction seasonWorking-up pitch/asphalt/bitumenBuilding insulationsInorganic saltsThermal water

The invention discloses an emulsified asphalt used for slurry seal and micro-surfacing. The emulsified asphalt contains the following components in weight proportion: 30-80 parts of asphalt, cationic emulsifier C-450 with asphalt accounting for 0.1-5%, 30-52 parts of water at 30-80 DEG C, a trace amount of inorganic salt stabilizer, and concentrated hydrochloric acid with pH value in the range of 1.5-7.0. The product is mainly applied on slurry seal technology, for example, reconstruction of old asphalt pavement, seal coat of new asphalt pavement, overlay of wearing layer on sand-gravel road, maintenance of cement concrete and bridge surface, etc. The emulsified asphalt can improve construction environment and prolong construction period without changing the performance thereof; and also can reduce noise and environmental pollution.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +2

Modified emulsified asphalt and preparation method thereof

ActiveCN104046047AImprove integrityAvoid crackingBuilding insulationsCrack resistancePolyethylene glycol

The invention belongs to the technical field of petroleum asphalt and processing preparation thereof and particularly relates to modified emulsified asphalt applicable to a cold-mixed and cool-spread asphalt mixture and a preparation method of the modified emulsified asphalt. The modified emulsified asphalt comprises the following raw materials in parts by weight: 50-65 parts of SBS modified asphalt, 0.5-2 parts of pentamethyl-alkyl-trimethylene di-quaternary ammonium salt emulsifier, 0.2-0.8 part of polyethylene glycol emulsifier, 0.5-1.5 parts of alkylphenol polyoxyethylene alkyl emulsifier, 0.02-0.1 part of rheology modifier, 0.005-0.05 part of plasticizer and 30-45 parts of water. According to the modified emulsified asphalt disclosed by the invention, the application time of the modified asphalt can be effectively prolonged; the modified emulsified asphalt has good compatibility with aggregated rock and has good storage stability and is very applicable to construction of the cold-mixed and cool-spread asphalt mixture; the high-temperature deformation resistance, the low-temperature cracking resistance and the fatigue resistance of the asphalt mixture can be greatly improved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +1

Asphalt warm-mix agent and asphalt mixture mixed by same as well as preparation methods thereof

ActiveCN101899218BWith viscosity reductionWith foamClimate change adaptationBuilding insulationsChlorideRoad surface

Owner:天津市市政工程研究院 +1

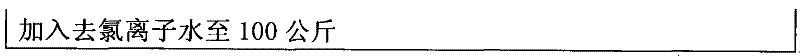

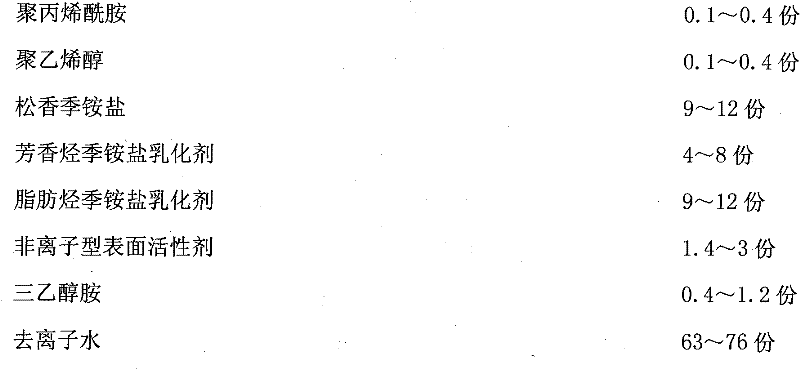

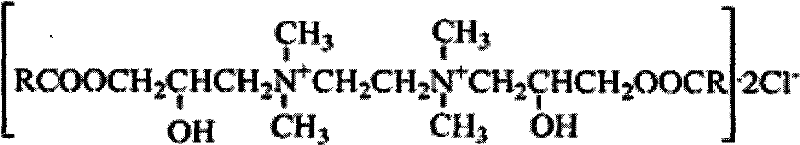

Warm-mixed asphalt additive and preparation method thereof

InactiveCN101602862BReduce the temperatureTo achieve the purpose of warm mixingClimate change adaptationPaint thinnerPolyvinyl alcohol

The invention discloses a warm-mixed asphalt additive and a preparation method thereof. The additive is prepared by the following steps: adding deionized water into prepared polyvinyl alcohol water solution, then adding rosin quaternary ammonium salt, aromatic quaternary ammonium salt emulsifier, aliphatic quaternary ammonium salt emulsifier and nonionic surfactant into the water solution in turn, stirring and dissolving the mixture, adding prepared polyacrylamide water solution and triethanolamine into the mixture, and mixing and stirring the mixture till the mixture is evenly dissolved so as to obtain a finished product. During application, when the temperature of the asphalt mixture reaches 110 to 130 DEG C, 5 percent of the diluent of the additive is added by the mass of asphalt in a spraying mode so as to realize the warm mixing technology of mixing and spreading the asphalt mixture; and test data show that various road indexes of the warm-mixed asphalt mixture are not lower thanthat of hot-mixed asphalt mixture under the condition that the mixing and molding temperature of the warm-mixed asphalt mixture is obviously reduced relative to the hot-mixed asphalt mixture.

Owner:TIANJIN UNIV

Ultrasonic welding construction method for small-caliber PE natural gas pipeline

ActiveCN113048312AFast welding speedExtended construction seasonPipe connection arrangementsTubular articlesPhysicsSurface oxidation

The invention discloses an ultrasonic welding construction method for a small-caliber PE natural gas pipeline, and relates to a pipeline connection method. The ultrasonic welding construction method for the small-caliber PE natural gas pipeline is high in construction efficiency and easy and convenient to operate. The ultrasonic welding construction method for the small-caliber PE natural gas pipeline comprises the following steps that the pipeline is subjected to section cleaning, chamfering and surface oxide skin removing treatment; the pipeline is installed in a clamping and welding device; the position of the clamping and welding device is fixed; an upper fixing block and a lower fixing block are arranged to fix the upper pipeline section and the lower pipeline section correspondingly; a plurality of ultrasonic wave generating devices are arranged on the periphery of the upper fixing block, and the ultrasonic wave generating devices are pressed by pressing blocks; an electromagnetic valve and a push rod are arranged on each pressing block, and the bottom of each push rod is connected with the pressing block; and the ultrasonic wave generating devices are started, ultrasonic waves are generated on the pressing faces of the two pipeline sections, the pressing faces of an upper PE natural gas pipeline body and a lower PE natural gas pipeline body are melted, and the welding process is completed.

Owner:BEIJING GAS DESIGN

A kind of high-shear and high-adhesion coating material and preparation method thereof

ActiveCN104479552BIncrease shear forceImprove temperature adaptabilityConjugated diene hydrocarbon coatingsBituminous coatingsAcrylonitrileRoom temperature

The invention discloses a high-shearing and high-bonding coating material and a preparation method thereof. The coating material is prepared from the following components in parts by weight: 0.4-0.6 part of powdery butadiene-acrylonitrile rubber, 0.2-0.3 part of a flame retardant, 0.2-0.3 part of a stabilizer, 3-5 parts of an asphalt modifier, 15-25 parts of asphaltene powder, 25-35 parts of matrix asphalt and 35-55 parts of a solvent. The coating material disclosed by the invention is reasonable in formula and simple in preparation method, has relatively high shearing strength between layer and bonding force, is good in low-temperature flexibility, free of cracks at -25 DEG C, strong in waterproof performance and great in construction temperature range, and the construction season is prolonged, and moreover, the coating material can be smeared, sprayed or sprinkled under a room temperature condition and is wide in application range.

Owner:北京通途技术有限公司

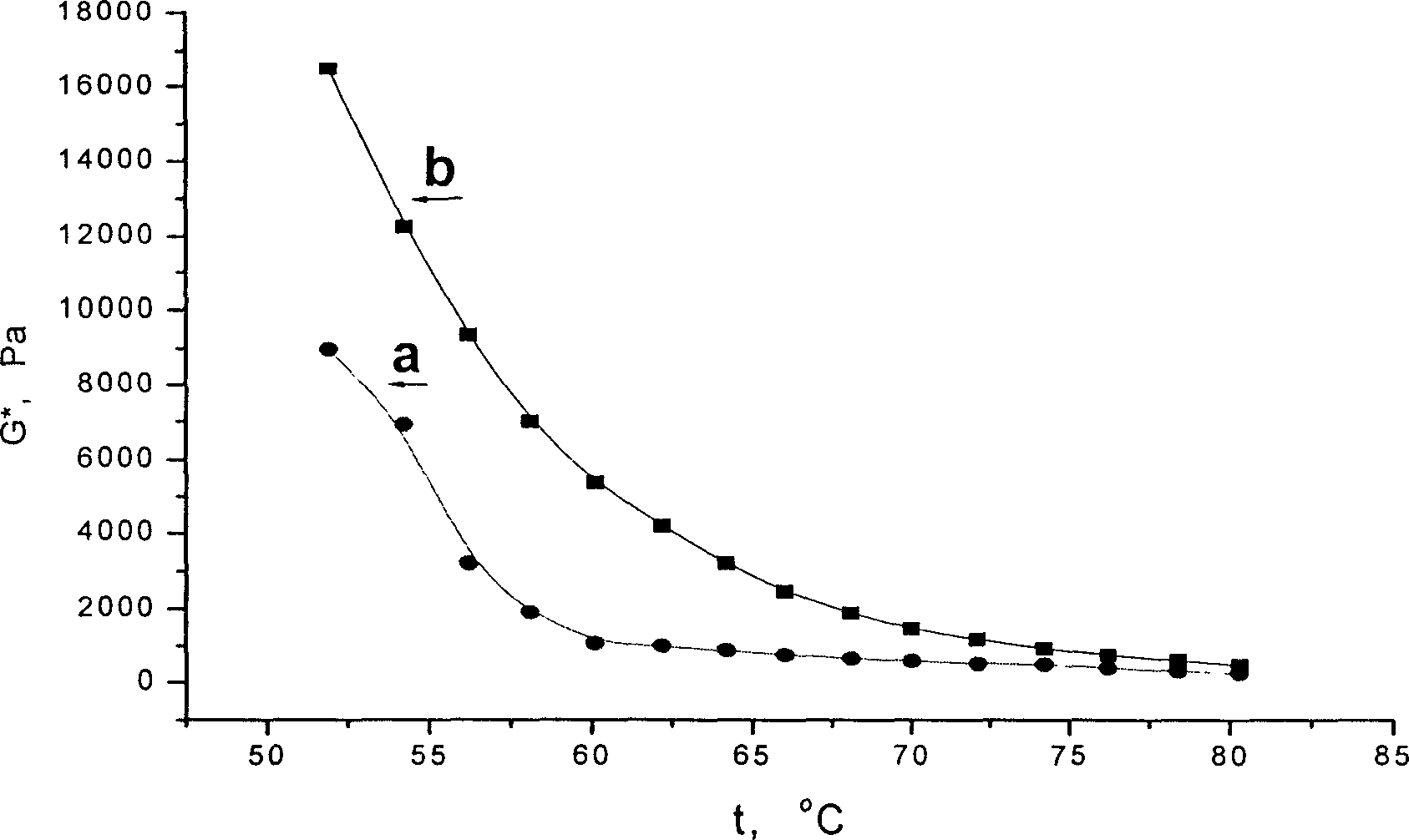

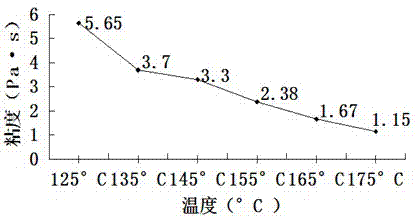

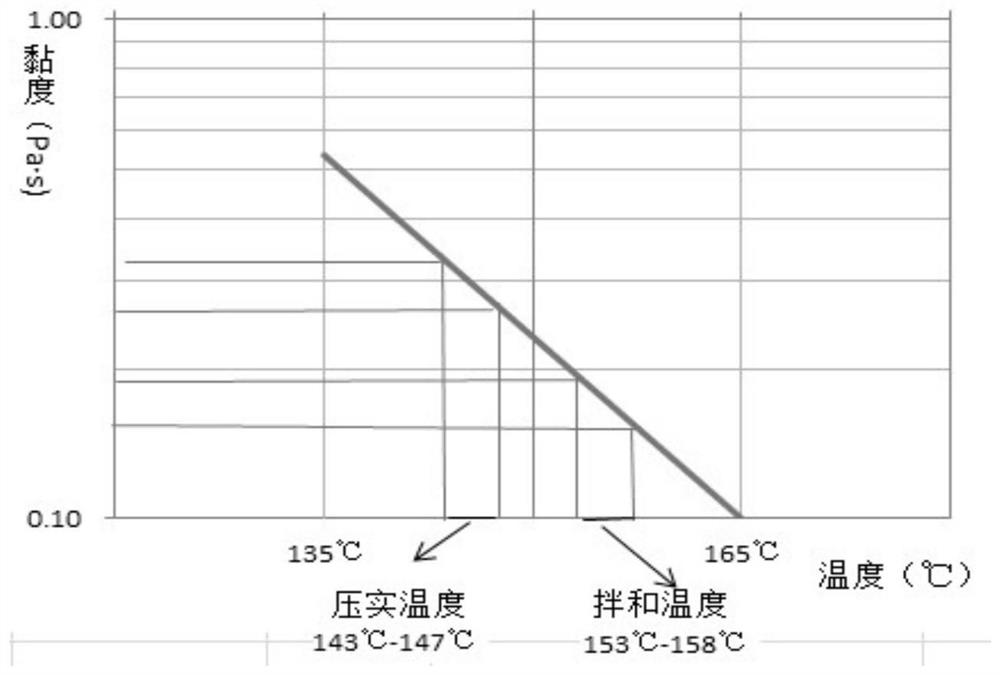

A warm-mixed high-viscosity modified asphalt and its preparation and application

ActiveCN108948753BHigh viscosityStrong peeling resistanceRoads maintainenceBuilding insulationsButadiene DioxideExhaust fumes

The invention provides a warm-mix high-viscosity modified asphalt, and is prepared from the following raw materials in parts by mass: 80-90 parts of matrix asphalt, 0-3 parts of N,N'-ethylenebis(stearamide), 0-2 parts of stearic acid or stearate, 0-1 part of high-molecular wax, 3-8 parts of styrene-butadiene-styrene block copolymer, 0-2 parts of styrene butadiene rubber, 2-5 parts of rubber oil, 0-8 parts of colloidal particles and 0.1-0.3 part of a stabilizer. According to the warm-mix high-viscosity modified asphalt provided by the invention, the production and mixing temperature of the mixture is reduced while the performance index is not influenced; the power viscosity of the warm-mix high-viscosity modified asphalt at 60 DEG C reaches 100000 Pa.s or above; the Brookfield viscosity at135 DEG C is 2000 mPa.s or below; the mixing temperature and the compaction temperature required by the high-viscosity asphalt mixture are reduced; and compared with the mixing temperature of the heat-mix asphalt mixture, the mixing temperature is reduced by about 20-30 DEG C. The fuel consumption can be reduced, the waste gas emission can be reduced, and the operation environment of a constructorcan be improved.

Owner:ZHONGLU HI TECH (BEIJING) HIGHWAY TECHNOLOGY CO LTD +1

A kind of asphalt modifier, modified emulsified asphalt and modified asphalt mixture and their respective preparation methods

ActiveCN104312175BExtended construction seasonEmission reductionBuilding insulationsEmulsionRoad surface

Owner:XINJIANG MEIHUITE PETROCHEM PROD CO LTD

A kind of modified asphalt mixture and its preparation method

InactiveCN103755225BLarge rolling temperature rangeThe influence of temperature etc. is smallActive agentOrganic chemistry

The invention involves a modified asphalt mixture and preparation method.Modified asphalt mixture contains collective materials, ordinary asphalt, outer doping and mineral powder.Among them, the outer doping contains water, cationic surfactants, stabilizers, and modifiers; first heated water, adds the cationic surfactant to dissolve, and then adds a modified agent and stabilizer.Heat the collection material to 140 ° C-160 ° C, add it to the mixing cylinder, and stir for 30 seconds; add ordinary asphalt and outer doping that have been heated to 120 ° C-140 ° C to the mixing tank, and then stir at stirred40-60 seconds; add the cement or mineral powder to the mixing tank and then stir for 30-60 seconds. The ingredients must be modified asphalt mixture, the material of the dismissal is 100 ℃ -120 ° C, and the actual molding temperature is 90 ° C-110 ° C ° C ° C ° C ° CEssenceThe present invention reduces energy consumption and environmental pollution, improves the performance of asphalt mixture, can adapt to the technical requirements of low temperature construction, and the process is relatively simple.

Owner:姚华彦

Graded crushed stone poured semi-flexible composite pavement mixture and pavement construction method

The invention relates to a graded crushed stone pouring type semi-flexible composite pavement mixture, comprising 100 parts of graded crushed stone in the following mass fractions; 4-6 parts of water; 6-10 parts of grouting material; the grouting material includes cement , water-based acrylic resin, pozzolan material and water, the tank slurry is poured into the graded crushed stone. The semi-flexible composite pavement mixture of the present invention can be constructed at normal temperature, which can effectively solve the problem of asphalt pavement rutting and improve the durability of the pavement; reduce the pollution of the poured semi-flexible pavement hot-mix construction to the environment; improve The construction efficiency of the poured composite pavement reduces the production cost.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com