A warm-mixed high-viscosity modified asphalt and its preparation and application

A modified asphalt, high-viscosity technology, used in building thermal insulation materials, roads, road repair and other directions, can solve the problems of lack of improvement in dynamic viscosity and Brookfield viscosity of asphalt materials, affecting the health of construction workers, and low dynamic viscosity of asphalt materials. To achieve the effect of being conducive to the development of the ecological environment, cost-effective, and good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

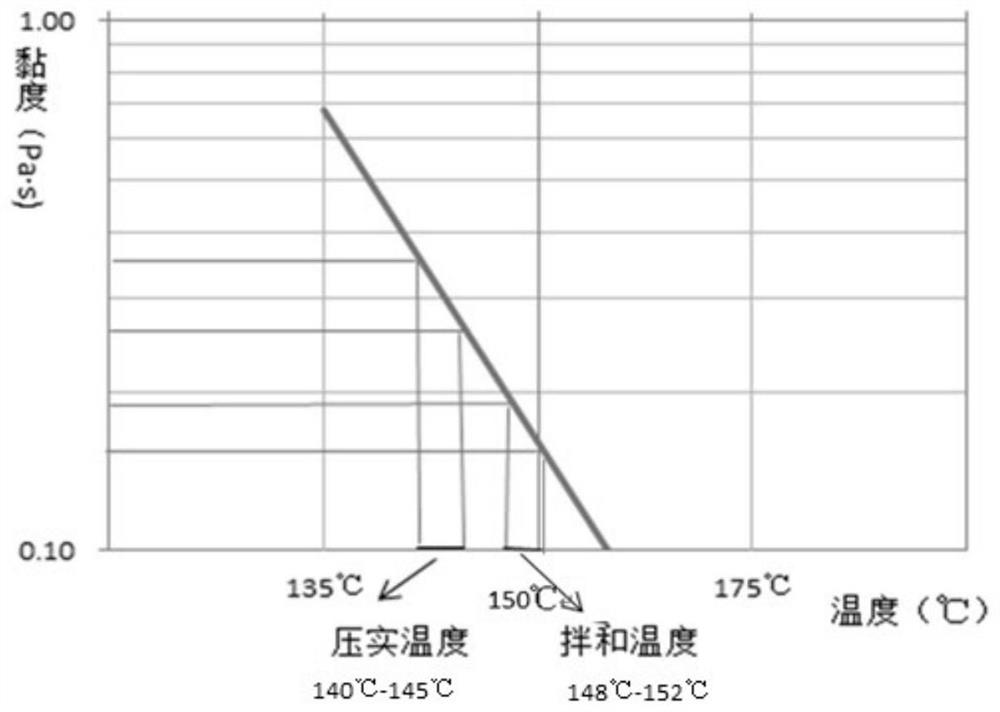

experiment example 1

[0032] Preparation of Warm Mix High Viscosity Modified Asphalt

[0033] Step 1: Add 90 parts of base asphalt (SK90#) at 150°C and add 3 parts of rubber oil and stir for 15 minutes, heat up to 180°C and add 6 parts of SBS (791H, Yueyang Petrochemical) and 1 part of SBR at high speed for 30 minutes while shearing. get the mixture;

[0034] Step 2: Add 2 parts of ethylene bis stearic acid amide, 0.5 part of sodium stearate, and 0.5 part of polyethylene wax (polymer wax) to the mixture obtained in step 1 at a temperature of 175° C., and stir for 10 minutes. Slowly add 0.25 parts of stabilizer at 180°C to shear for 10 minutes, and finally develop at 175°C for 4 hours.

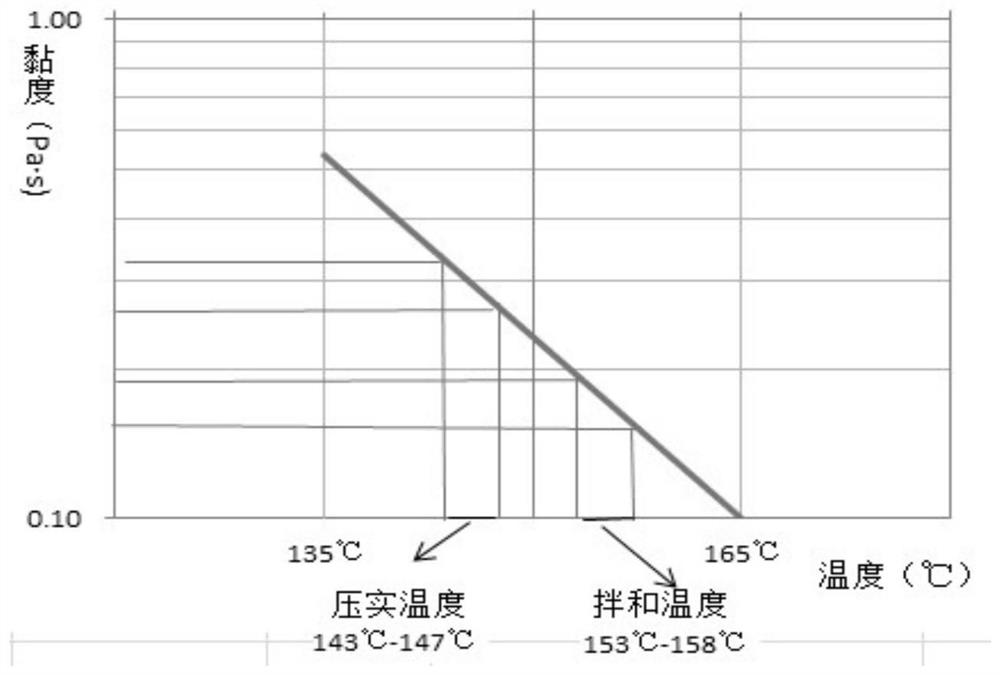

Embodiment 2

[0036] Preparation of Warm Mix High Viscosity Modified Asphalt

[0037] Step 1: Add 86 parts of base asphalt (SK70#) at 145°C and add 4 parts of rubber oil and stir for 20 minutes, then add 5 parts of SBS (791H, Yueyang Petrochemical) and 0.5 parts of SBR for 30 minutes at high speed while heating to 180°C. get the mixture;

[0038] Step 2: Add 6 parts of rubber powder particles to the mixture obtained in Step 1 at a temperature of 180°C and cut for 20 minutes, add 1 part of ethylene bis stearic acid amide and 1 part of sodium stearate at 180°C , 0.5 parts of polyethylene wax, stirring for 15 minutes, slowly adding 0.2 parts of stabilizer at 180°C, shearing for 15 minutes, and finally developing at 175°C for 3 hours.

[0039] In this embodiment, the colloids are made of waste rubber powder. The high molecular polymer SBS is expensive, and the high-volume SBS modified asphalt is easy to stick during the production process, which affects the production of high-viscosity modifie...

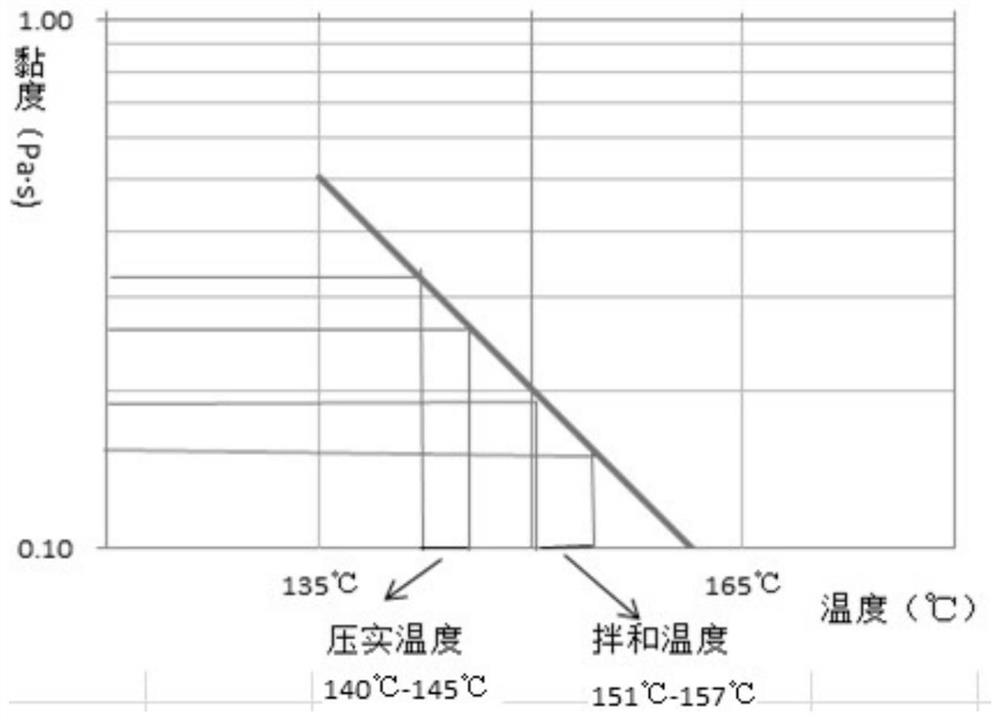

Embodiment 3

[0041] Preparation of Warm Mix High Viscosity Modified Asphalt

[0042] Step 1: Add 3 parts of rubber oil to 82 parts of base asphalt (Shuanglong 70#) at 165°C and stir for 20 minutes, then add 4 parts of SBS (791H, Yueyang Petrochemical) and 1 part of SBR at high speed for 30 minutes while heating up to 180°C , to get a mixture;

[0043] Step 2: Add 6 parts of rubber powder particles (same as in Example 2) to the mixture obtained in Step 1 at a temperature of 180°C for 20 minutes, and add 1 part of ethylene bis-stearamide at 175°C. 1 part of sodium stearate, 0.5 part of polyethylene wax, stir for 20 minutes, slowly add 0.2 parts of stabilizer at 180°C, cut for 10 minutes, and finally develop at 175°C for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com