Patents

Literature

52results about How to "Strong peeling resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing linear change gradient coating of TiAlCN non-metallic element

ActiveCN101319302AReduce residual stressStrong peeling resistanceVacuum evaporation coatingSputtering coatingLow speedHigh surface

The invention discloses a method for preparing a TiAlCN non metallic element linear variation gradient coating. The coating treatment which adopts the PVD method is divided into four continuous time sections; in the second time section, a furnace chamber is simultaneously filled with argon gas(Ar), nitrogen gas(N2) and acetylene gas(C2H2), wherein the flow rate of the argon gas(Ar) is kept constant, the flow rate of the nitrogen gas(N2) decreases or increases at an uniform speed and the flow rate of the acetylene gas(C2H2) increases or decreases at an uniform speed so that the TiAlCN gradient coating with non metallic element linear variation is formed; the coating prepared by the method has the advantages of high surface finish, strong anti-stripping capability and good anti-knife bonding performance, is more suitable for finishing machining, and particularly shows excellent performances in processing materials with strong viscidity at the medium and low speed under the condition of water solution cooling.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY +1

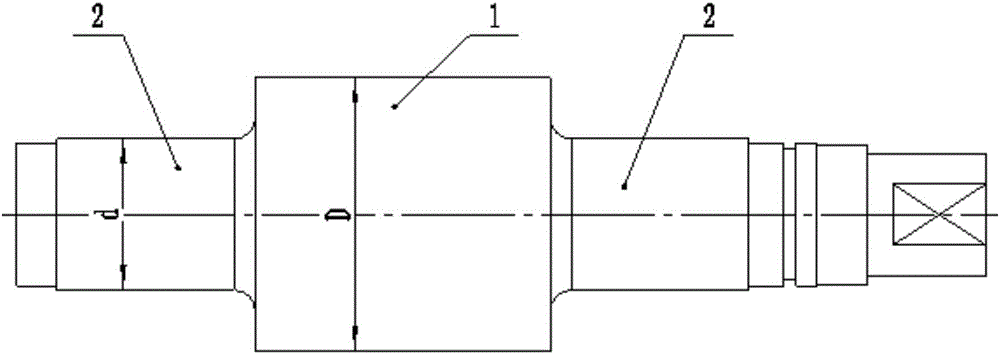

Repair method of cold-rolled support roller

The invention discloses a repair method of a cold-rolled support roller, and belongs to the technical field of cold-rolled support rollers. The method comprises the following operation steps: the cleaning and flaw detecting treatment is firstly performed; then, cracks on the surface of a support roller basal body are removed by machining; a roller sleeve is machined for corresponding heat treatment; and finally, the obtained roller sleeve is heated to embed in the support roller basal body to finish repair of the cold-rolled support roller. Compared with traditional overlaying repair and thermal spraying repair modes, the repair method is simpler, and can repair scraped support rollers with bad wear and deeper cracks; the repaired support rollers satisfy the comprehensive mechanical performances and the service life requirements, and the manufacturing period of the support rollers is shortened; and the method can perform repair by multiple times, reduces the cost, and saves the energy consumption.

Owner:马鞍山市恒强合金科技股份有限公司

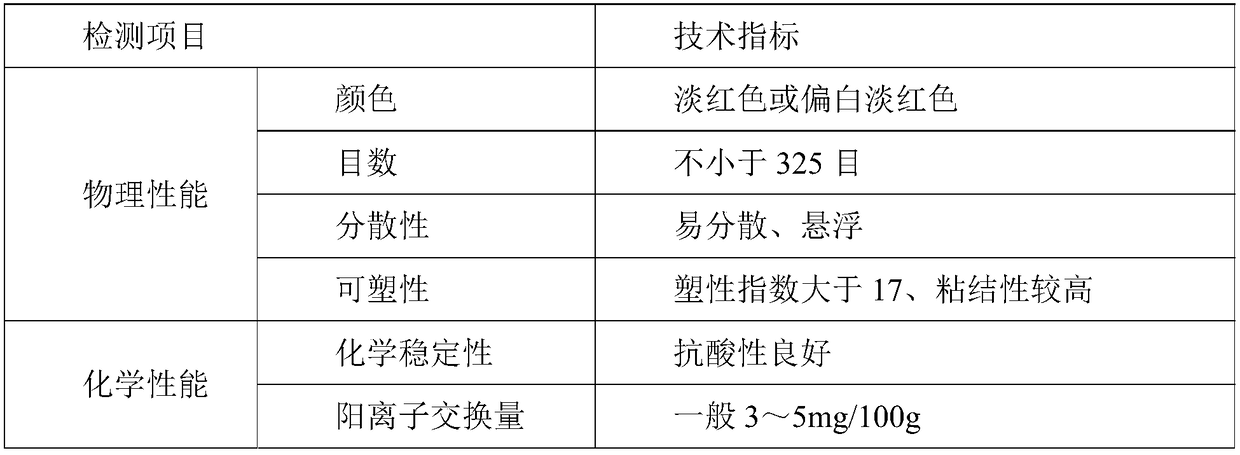

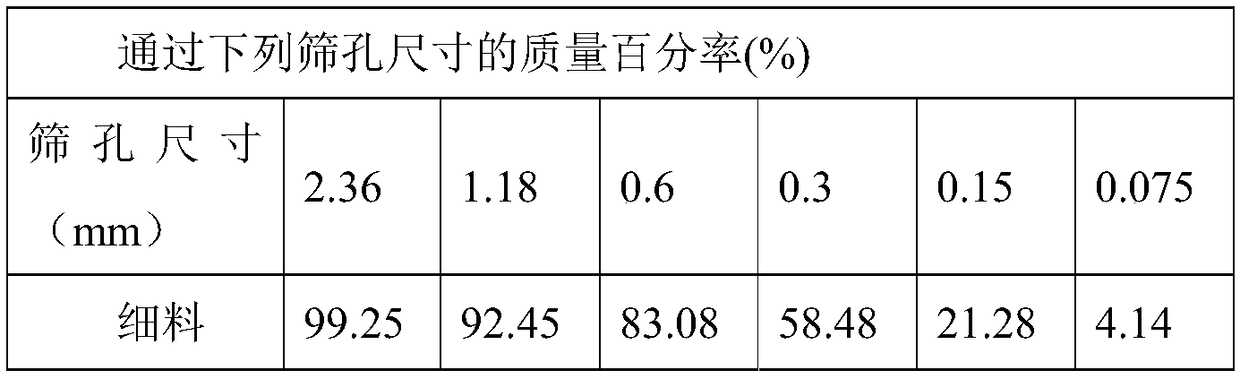

Nano-matrix-combined high-performance fused magnesium calcium brick and manufacturing method thereof

The invention provides a nano-matrix-combined high-performance fused magnesium calcium brick and a manufacturing method thereof. The fused magnesium calcium brick is prepared from 8-5mm high-calcium fused magnesium calcium sand, 5-2mm high-calcium fused magnesium calcium sand, 2-0mm high-calcium fused magnesium calcium sand, <=0.074mm high-calcium fused magnesium calcium sand, 8-5mm fused magnesite, 5-2mm fused magnesite, 2-0mm fused magnesite, <=0.074mm fused magnesite fine powder, nano sea water magnesia fine powder and a binder paraffin. The manufacturing method comprises the following steps: fine powder premixing, integral compounding, molding, drying, firing and the like. The product has the advantages of compact microstructure, fewer low-melting-point minerals, higher erosion resistance, higher scour resistance, higher stripping resistance and higher hydration resistance. The furnace life is prolonged by 30% above on average. Thus, the product satisfies the requirements of high efficiency, long service life and high cleanness for stainless steel and special steel smelting, and lowers the cost for the steel enterprises.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

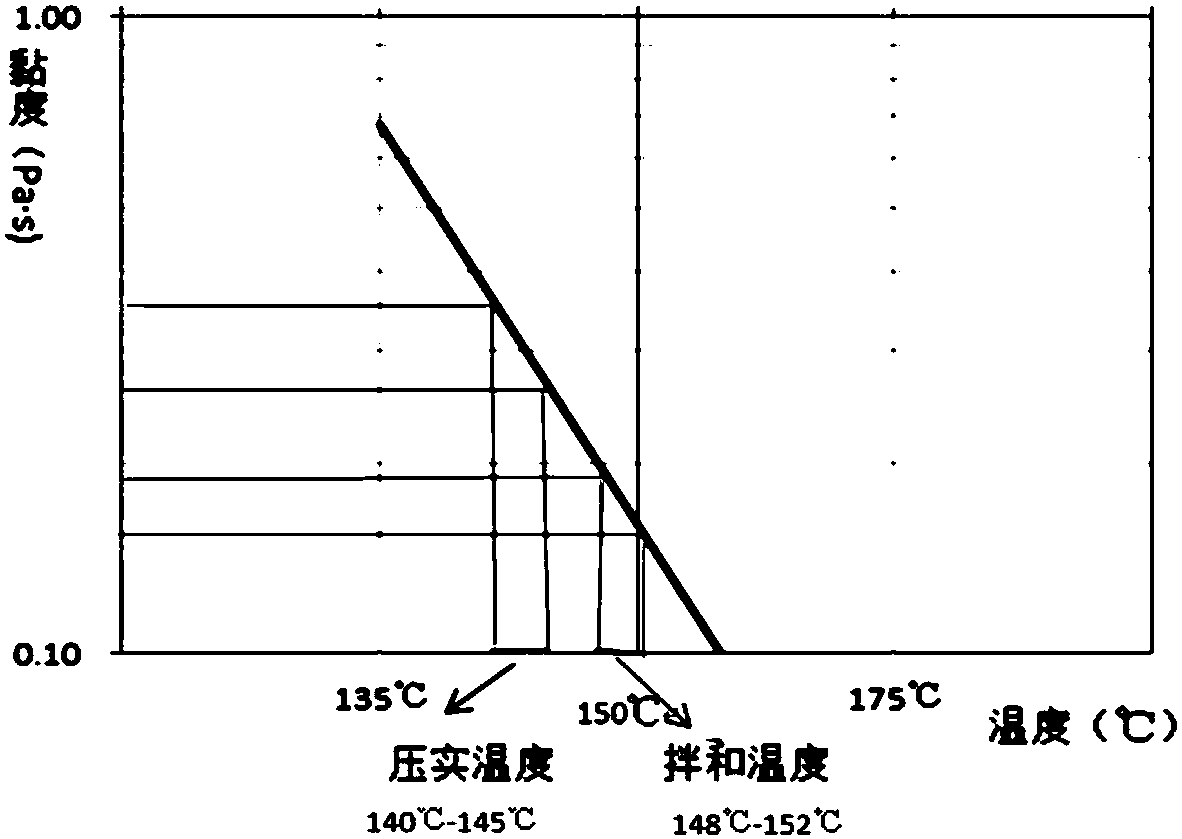

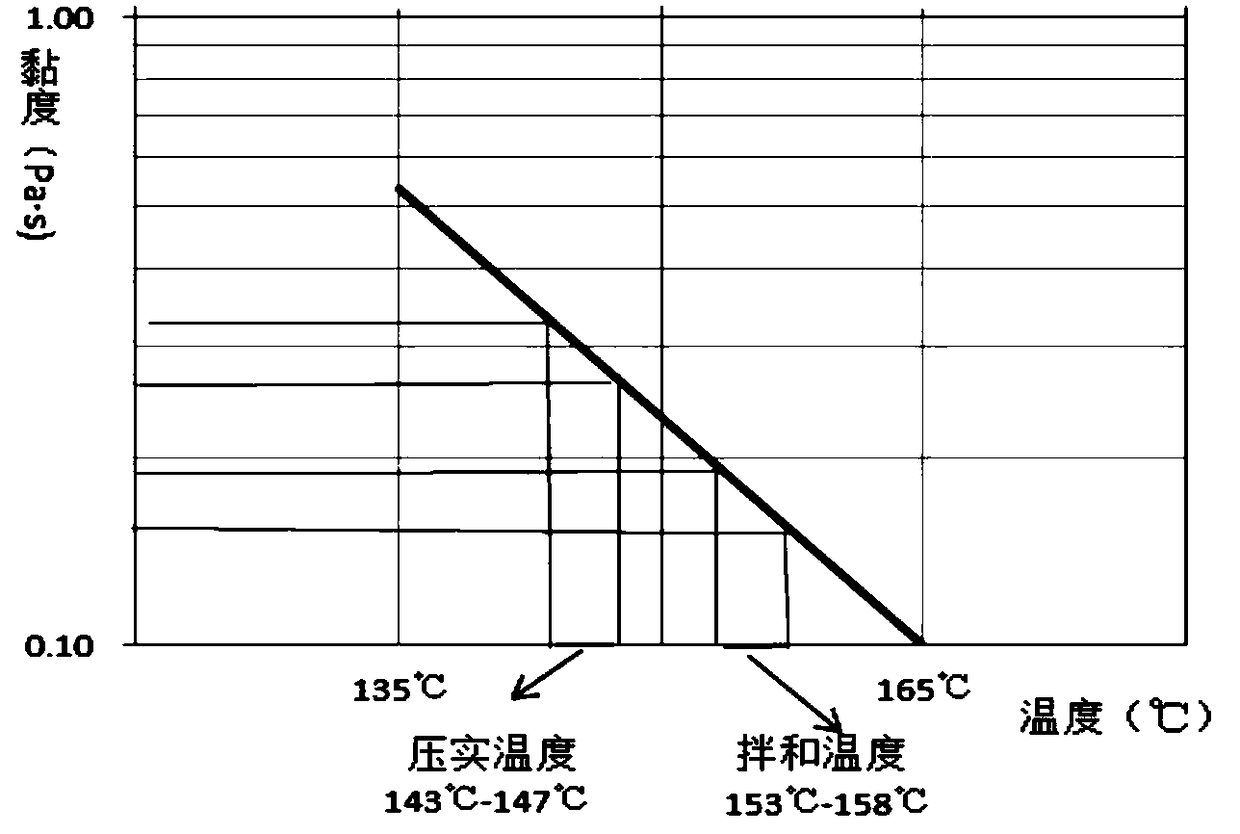

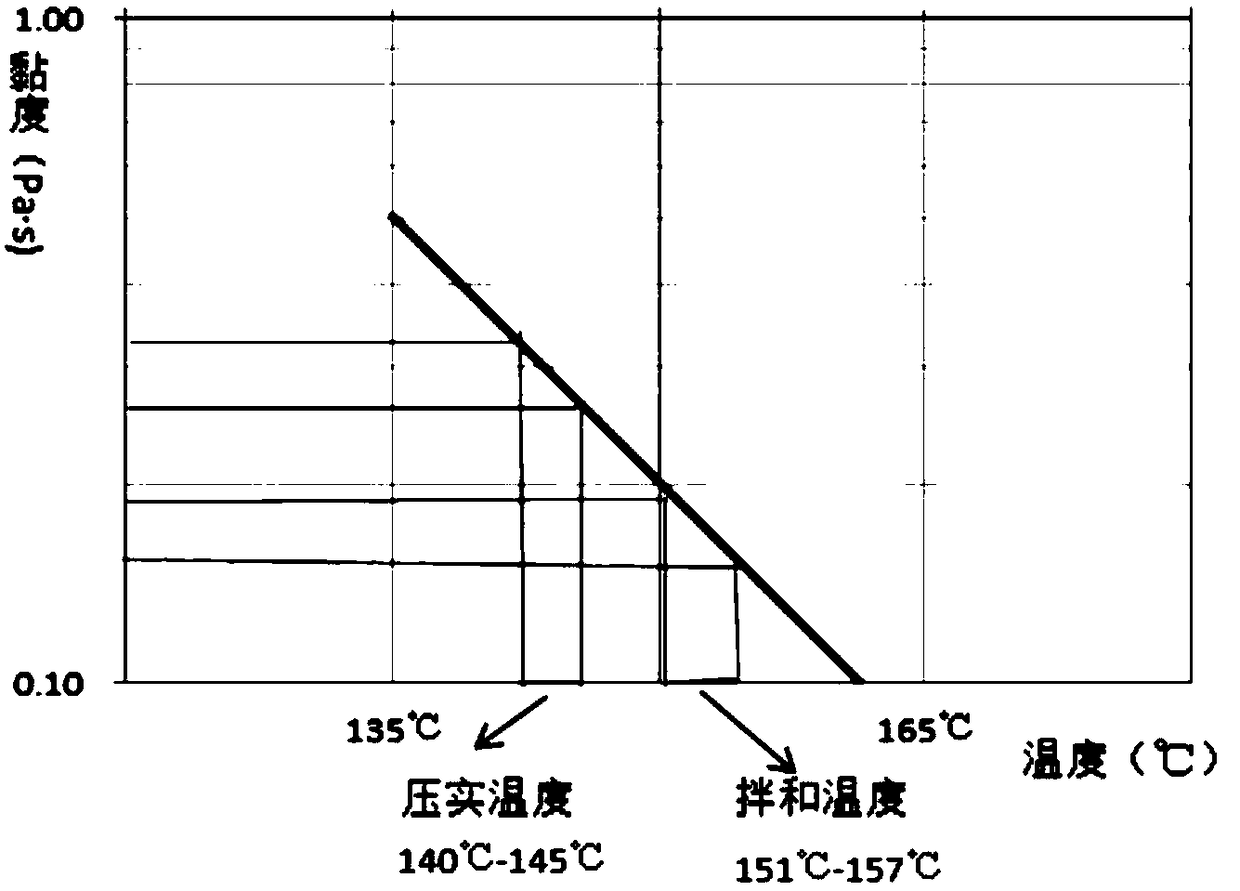

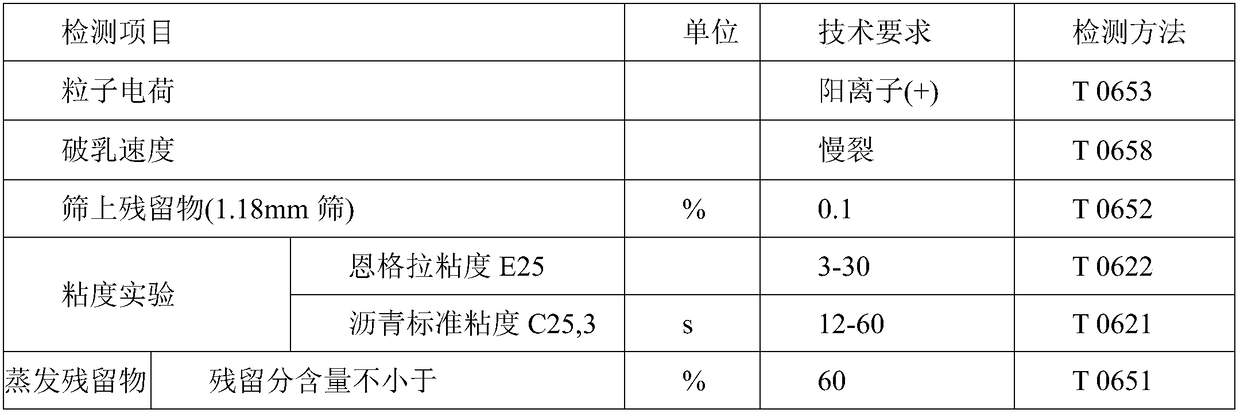

Warm-mix high-viscosity modified asphalt, and preparation and application thereof

ActiveCN108948753AHigh viscosityStrong anti-stripping abilityRoads maintainenceBuilding insulationsWaxButadiene-styrene rubber

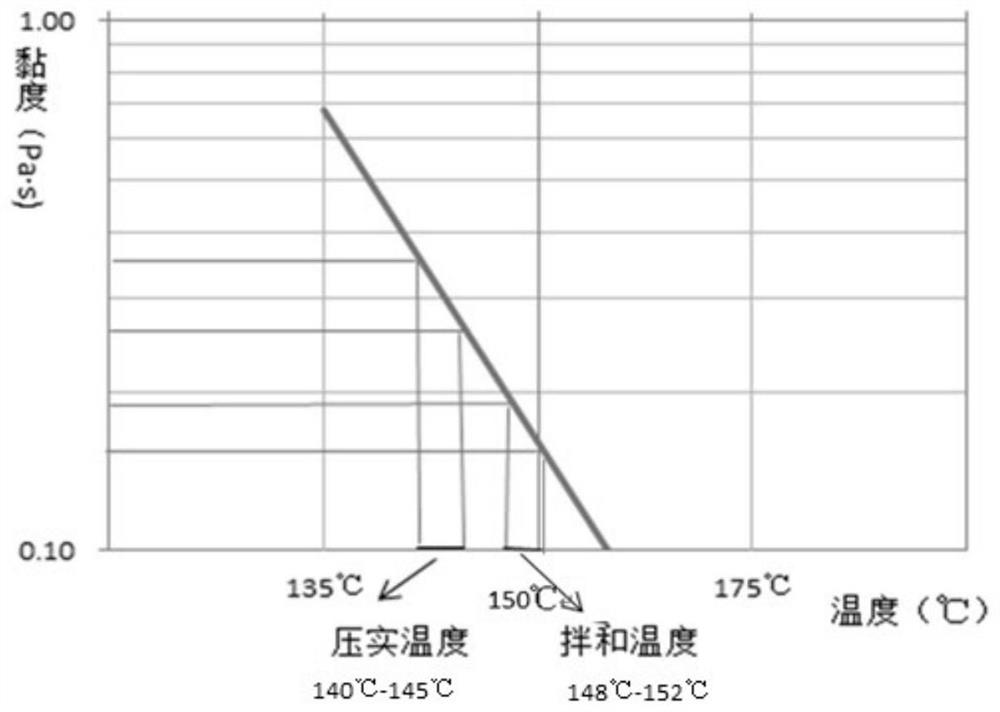

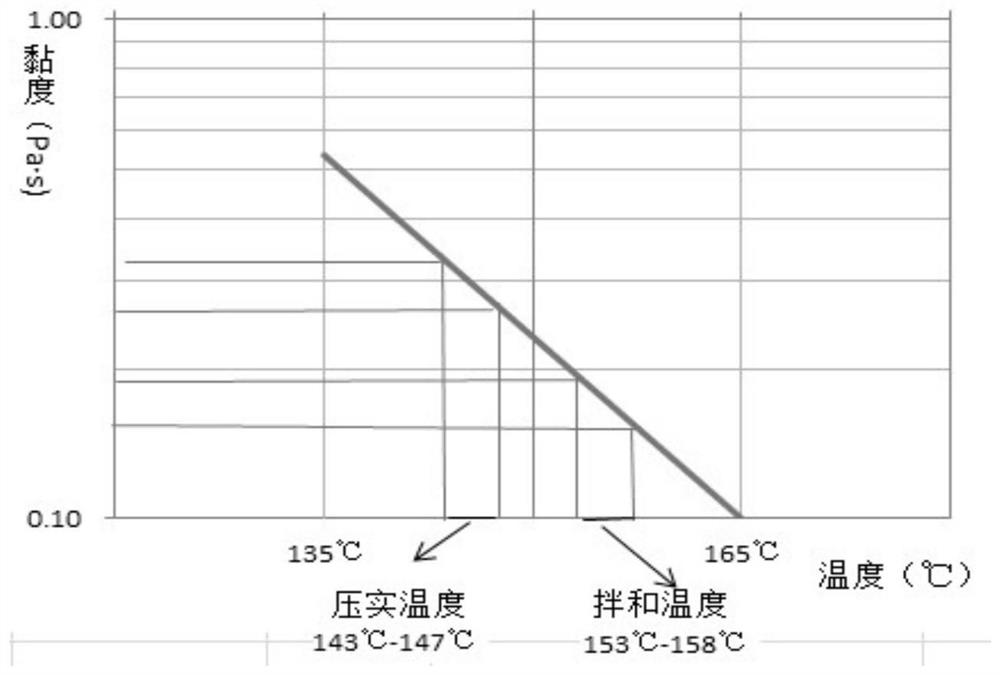

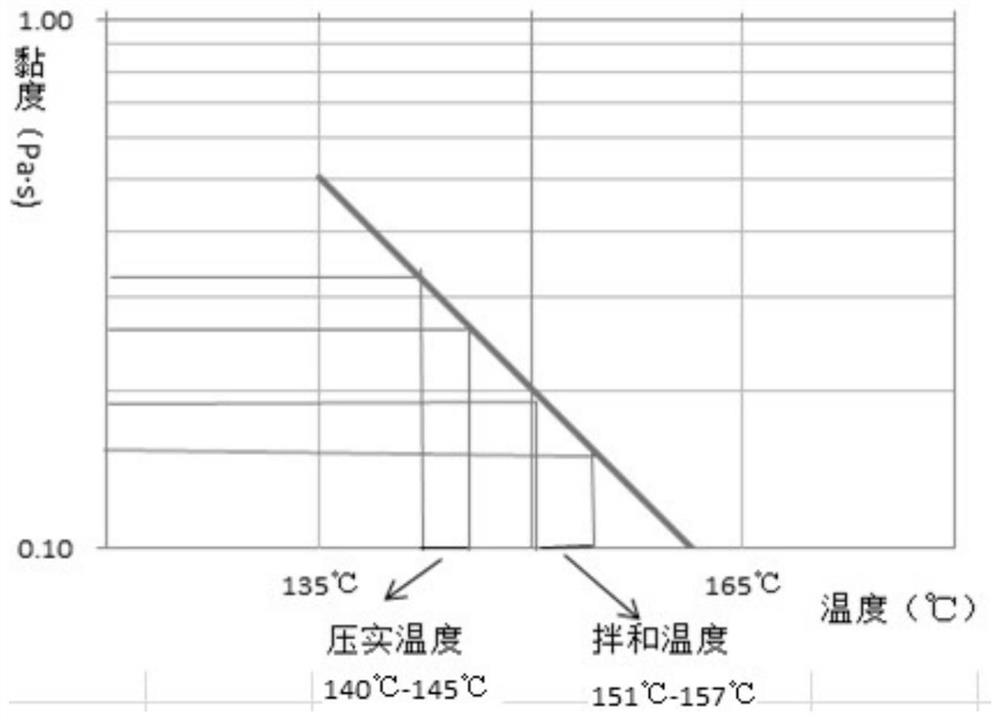

The invention provides a warm-mix high-viscosity modified asphalt, and is prepared from the following raw materials in parts by mass: 80-90 parts of matrix asphalt, 0-3 parts of N,N'-ethylenebis(stearamide), 0-2 parts of stearic acid or stearate, 0-1 part of high-molecular wax, 3-8 parts of styrene-butadiene-styrene block copolymer, 0-2 parts of styrene butadiene rubber, 2-5 parts of rubber oil, 0-8 parts of colloidal particles and 0.1-0.3 part of a stabilizer. According to the warm-mix high-viscosity modified asphalt provided by the invention, the production and mixing temperature of the mixture is reduced while the performance index is not influenced; the power viscosity of the warm-mix high-viscosity modified asphalt at 60 DEG C reaches 100000 Pa.s or above; the Brookfield viscosity at135 DEG C is 2000 mPa.s or below; the mixing temperature and the compaction temperature required by the high-viscosity asphalt mixture are reduced; and compared with the mixing temperature of the heat-mix asphalt mixture, the mixing temperature is reduced by about 20-30 DEG C. The fuel consumption can be reduced, the waste gas emission can be reduced, and the operation environment of a constructorcan be improved.

Owner:ZHONGLU HI TECH (BEIJING) HIGHWAY TECHNOLOGY CO LTD

Corundum-magnesium aluminate spinel refractory material

The invention relates to a refractory material, and in particular relates to a corundum-magnesium aluminate spinel refractory material which is prepared from raw materials, including corundum, magnesium aluminate spinel, fused magnesite and alpha-Al2O3 micro powder. The corundum-magnesium aluminate spinel refractory material is relatively high in refractoriness and strength, good in anti-erosion property, anti-stripping property and anti-slag property, good in thermal vibration stability and long in service life, thereby being a corundum-magnesium aluminate spinel refractory material with excellent quality.

Owner:QINGDAO YONGTONG ELEVATOR ENG

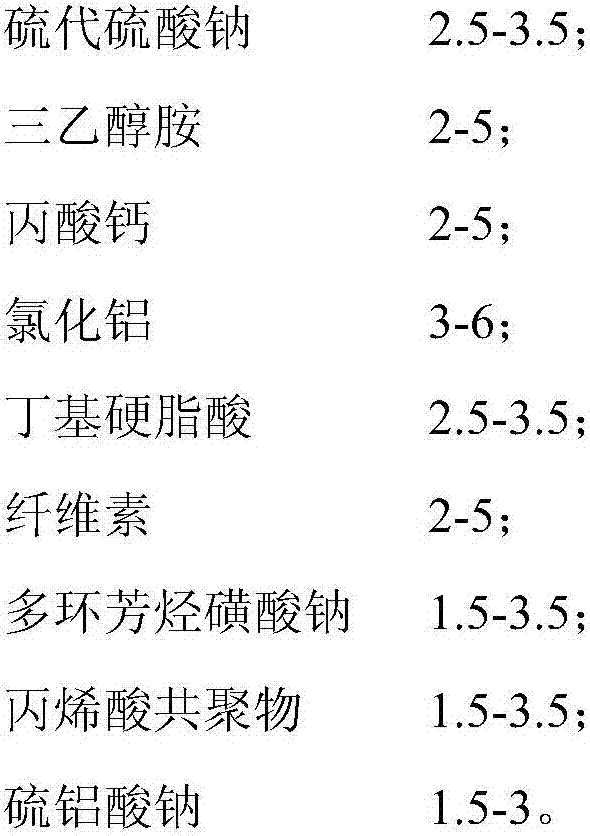

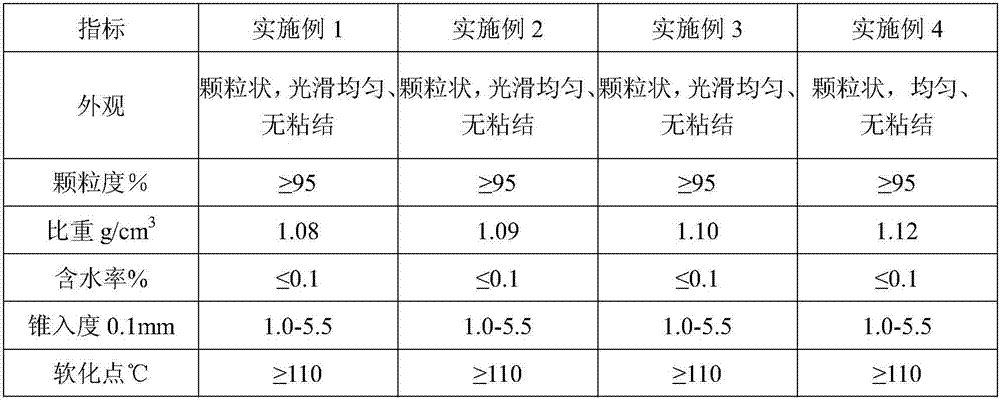

Environment-friendly nonslip ultrathin seal material and preparation method thereof

ActiveCN109486421AHigh softening pointHigh viscosityAntifouling/underwater paintsPaints with biocidesRoad surfaceConstruction aggregate

The invention discloses an environment-friendly nonslip ultrathin seal material and a preparation method thereof and solves the problems that the asphalt pavement has water penetration, poor slip resistance, slightly pitted surface and small cracks. A stable durable seal is provided to protect the asphalt pavement, aggregate of an original asphalt pavement can be locked, oil shortage can be repaired, post-construction traffic opening time is short, little influence is caused to transportation, and the material herein has great technical significance and social significance; the preventive maintenance process used herein helps maintain pavement service level and retard maintenance time of extensive and medium repair, and save lifecycle maintenance cost.

Owner:中山市易路美智能装备有限公司 +1

Quick-drying self-flowing castable used for blast furnace casting runner and made from reclaimed waste castable

InactiveCN108046814AReduce manufacturing costComply with environmental policySilicon dioxideWater reducer

The invention discloses quick-drying self-flowing castable used for a blast furnace casting runner and made from reclaimed waste castable. The quick-drying self-flowing castable is mainly made from, by weight, 48-52% of reclaimed waste castable, 15-20% of compact corundum, 14-18% of black silicon carbide, 3-7% of silicon nitride, 1-2% of a composite water reducer, 1-2% of a composite anti-knock agent, 1-3% of SiO2 sol, 1-3% of silicon dioxide micropowder, 2-4% of activated aluminium oxide micropowder and 2-4% of silica micropowder. Waste self-flowing castable used for an iron runner is taken as a main raw material to prepare quick-drying self-flowing castable which is high in additional value and good in performance, is superior and is used for a blast furnace casting runner. The production cost of an enterprise is reduced, the natural environment is protected, the national environmental protection policy is met, and a great amount of energy is saved. The quick-drying self-flowing castable is significant in economic and social benefit.

Owner:河南欣昌耐材股份有限公司

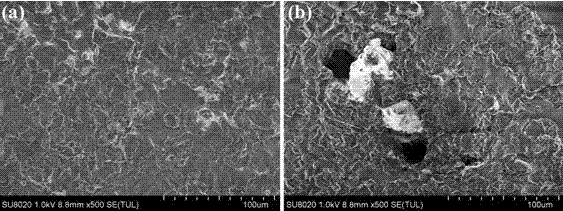

Preparation method of ceramic-based composite coating capable of resisting seawater cavitation erosion

ActiveCN107130202AImprove corrosion resistanceImprove cavitation resistanceMolten spray coatingEpoxyCeramic coating

The invention discloses a preparation method of a ceramic-based composite coating capable of resisting seawater cavitation erosion. The method comprises the specific steps that a metal base material is subjected to sand-blasting roughening and cleaning decontamination treatment, and the metal base material is sequentially sprayed with a metal transition layer, a Al2O3-based or ZrO2-based ceramic coating through atmospheric plasma spraying equipment; epoxy resin and trine are mixed to be uniform, and the surface of the ceramic coating is coated with the mixture; the obtained sample is subjected to vacuum impregnation for 2-5 h under the condition that the vacuum degree is -0.6--0.8 bar; the sample is cured for 3-5 h at the temperature of 50-100 DEG C; the surface of the cured ceramic coating is ground and polished to remove redundant polymer materials on the surface, and the surface of the coating is made flat and smooth. According to the ceramic-based composite coating, the excellent corrosion resistance of the ceramic coating is reserved, and meanwhile the cavitation erosion resistance of the ceramic-based composite coating in seawater is greatly improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Automatic-flowing quick-drying pouring material for blast furnace iron runner

The invention discloses an automatic-flowing quick-drying pouring material for a blast furnace iron runner. The automatic-flowing quick-drying pouring material is composed of the following main raw materials in percentage by weight: 65-70% of dense corundum, 14-18% of black silicon carbide, 3-7% of silicon nitride, 1-2% of a composite water-reducing admixture, 1-2% of a compound anti-blasting material, 1-3% of pure aluminum silicate cement, 1-3% of ultrafine silica powder, 2-4% of reactive alumina micro powder and 2-4% of silica powder. The preparation method comprises the following steps: adding various raw materials into a mixing reactor with a powerful stirring propeller for performing strong stirring, and packaging after stirring, thereby obtaining the product, namely the automatic-flowing quick-drying pouring material for the blast furnace iron runner. The product disclosed by the invention has the advantages of being resistant to corrosion of molten iron and slag, high in erosionresistance, excellent in thermal shock resistance, excellent in flaking resistance, high in oxidation resistance, easy in construction, capable of performing rapid baking without burst and preventingproduction of harmful gases and adhesion of iron slag, and long in service life, and the like.

Owner:河南欣昌耐材股份有限公司

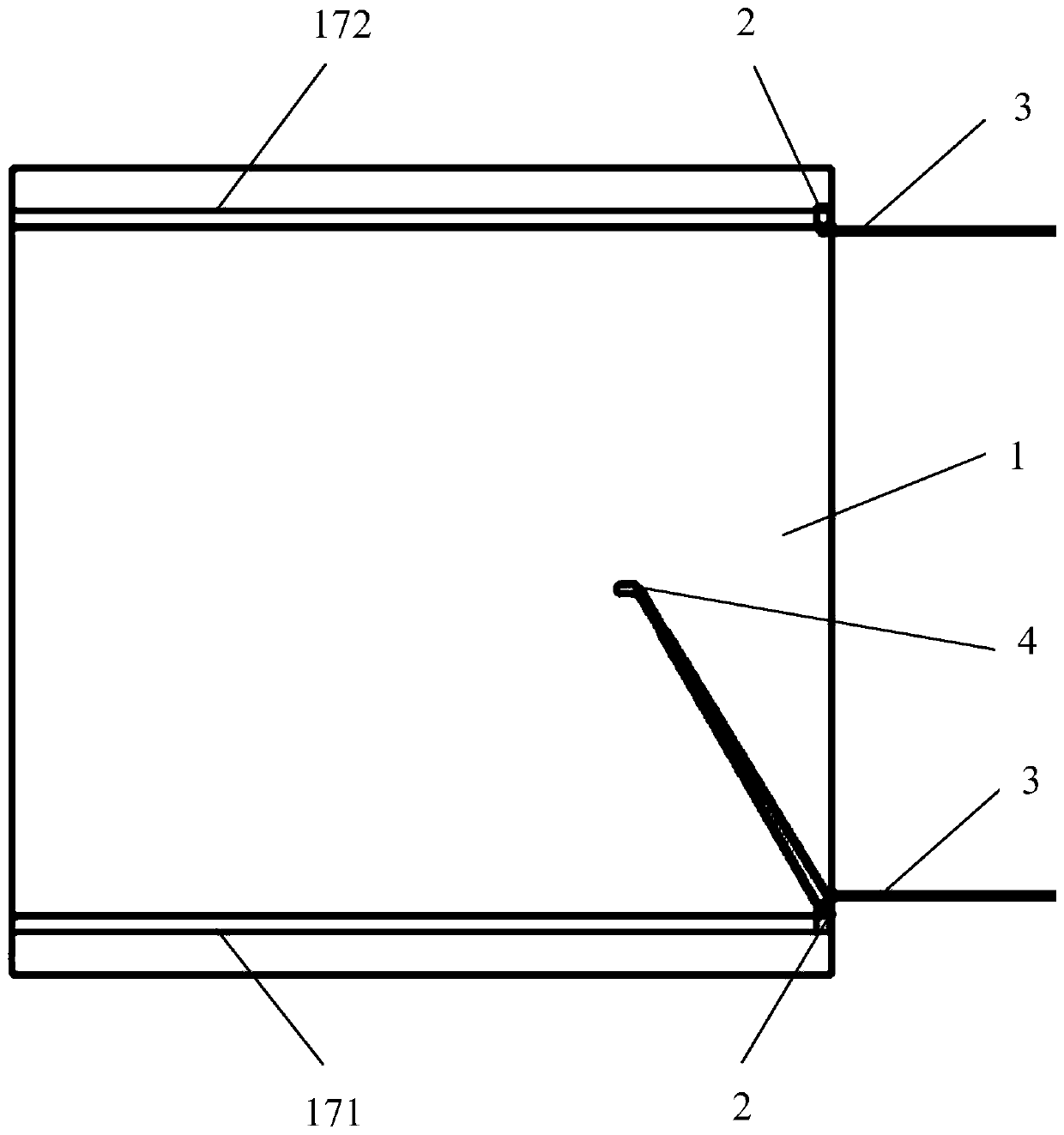

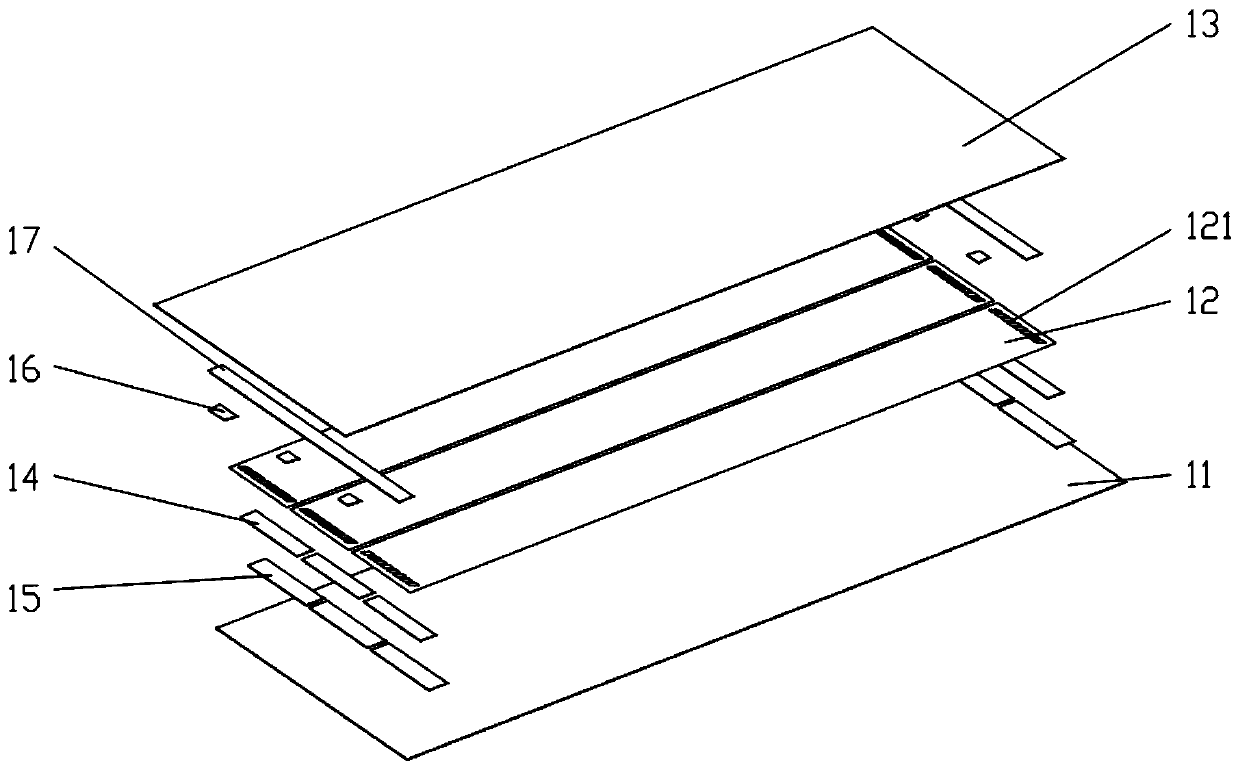

Graphene heating film

PendingCN111163540ABlock direct contactPrevent vulcanization reactionOhmic-resistance heatingSilver electrodeGraphite

The invention relates to the technical field of graphene material application, and particularly discloses a graphene heating film. The graphene heating film comprises a heating film body, and the heating film body comprises a carrier and a plurality of rectangular surface-shaped graphene heating coatings coated on the carrier, and a polymer insulating film is thermally coated on the graphene heating coatings; silver electrode strips are arranged at the bottoms of the two ends of each graphene heating coating, and graphene strips for preventing the silver electrode strips from making contact with the carrier are arranged between the silver electrode strips and the carrier. The adjacent graphene heating coatings are connected in parallel through the electrode connecting sections, electrode current-carrying strips are arranged on the upper surfaces of the graphene heating coatings and the electrode connecting sections, and the electrode current-carrying strips are clamped between the graphene heating coatings and the polymer insulating films; connection terminals are arranged at the two ends of the heating film body, penetrate through the current-carrying strips and are fixed to the heating film body, heating is uniform, heating efficiency is high, safety is high, the service life is long, and production monitoring and rear end machining are easy and convenient.

Owner:FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

Spinel castables for coal water slurry gasification furnace and using method thereof

The invention relates to spinel castables for a coal water slurry gasification furnace and a using method thereof. The spinel castables comprise, by weight, 55-72% of magnesium aluminate spinel particles, 0-15% of tabular corundum particles, 4-10% of magnesium aluminate spinel fine powder, 2-5% of magnesium aluminate spinel micro powder, 4-6% of alpha-Al2O3 micro powder, 0.5-1.5% of Y2O3 micro powder, 0.5-1.5% of CeO2 micro powder, 0.2-1% of TiO2 micro powder, 1-7% of pure calcium aluminate cement, 2-12% of CMA cement, 0.03-0.1% anti-explosion fibers, and 0.1-0.3% of FS series water reducer. The using method comprises the steps of pouring water which accounts for 4.8-6.2%, by weight, of the castables in the castables, stirring evenly, and carrying out forming, conservation, demoulding and baking. Products prepared through the spinel castables for the coal water slurry gasification furnace have the advantages of being environmentally friendly, good in coal slag permeation resistance and anti-corrosion performance, capable of saving energy, high in strength and good in thermal shock stability, and thus demands of the production of the coal water slurry gasification furnace are met.

Owner:湖南立达高新材料有限公司

Fireproof material for steel ladle bottom and preparation method thereof

InactiveCN103482992AEnhanced resistance to molten steel erosionStrong resistance to molten steel erosionGranularityRefractory

The invention discloses a fireproof material for a steel ladle bottom. The fireproof material is made of a framework and castable. The framework is made of large clinkers of which granularity ranges from 50mm to 400m, and the castable is made of aluminum-magnesium auto-flowing castable in which rho-aluminum oxide is used as a binding agent. According to the fireproof material, the large clinkers which are well sintered and are compact in structure are used as the ladle bottom refractory framework, and therefore molten steel washing resistance of the framework is effectively enhanced; the aluminum-magnesium auto-flowing castable in which rho-aluminum oxide is used as the binding agent belongs to non-cement castable, and the castable has the advantages that an integrative system is pure and liquid phase amount generated under high temperature is small; the aluminum-magnesium auto-flowing castable generates spinels in situ under the high temperature condition, the in-situ generated spinels are used as a binder phase, and then the castable has the advantages of being good in thermal shock stability performance and not prone to peeling in the using process, the castable and the framework are encapsulated and poured into a whole, and therefore the fireproof material has the advantages of being high in molten steel washing resistance, good in peeling resistance, long in service life and the like. The fireproof material can have the good using effect in various steel ladle bottoms.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

Low-carbon magnesia carbon refractory and preparation method thereof

The invention discloses a low-carbon magnesia carbon refractory and a preparation method thereof. The technical scheme of the invention comprises the steps of mixing 65-70wt% of fused magnesia particles, 15-20wt% of fused magnesia fine-powder, 5-15wt% of nanocrystalline spinel-carbon composite powder, 0-5wt% of crystalline flake graphite, 1-3wt% of metal aluminum powder, 0-3wt% of Al-Mg alloy and 0-3wt% of crystalline silicon powder as raw materials, adding phenolic resin accounting for 3-5wt% of the raw materials, blending in a high-speed mixing mill, and performing compression moulding by using a brick machine of 6300 KN; naturally drying for 24 hours, and then drying for 24 hours at the temperature of 200-230 DEG C, so that a nanocrystalline spinel-carbon composite powder containing low-carbon magnesia carbon refractory is obtained. The carbon content of the low-carbon magnesia carbon refractory prepared according to the invention is 3-6wt%, and the prepared low-carbon magnesia carbon refractory has the characteristics of uniform matrix structure, good antioxidant effect, high temperature strength, good slag penetration resistance, good stripping resistance and strong slag resistance.

Owner:秦皇岛市首耐新材料有限公司

Corundum durable moisturizing plastic material

The invention discloses a corundum durable moisturizing plastic material which is low in cost, has long storage period and is prepared through a simple production process, and a preparation method thereof. The plastic material is prepared from the following raw materials in percentage by weight: 10-14 percent of 5-3 mm super alum, 20-30 percent of 3-1 mm super alum, 10-12 percent of white corundum particles, 7-9 percent of kyanite, 24-30 percent of white corundum powder, 7-9 percent of Guangxi mud, 2.5-3.5 percent of chrome green, 4.5-5.5 percent of binding agent and 3-4 percent of aluminum sulfate solution. The preparation method of the plastic material comprises the following steps: (1) pre-preparing the aluminum sulfate solution; (2) adding the kyanite, the white corundum powder, the Guangxi mud and the chrome green into a stirrer to mix according to the proportions; (3) adding the two super alums and the white corundum particles into the stirrer and stirring for 3-5 minutes, then adding fine powder to stir for 10 minutes, then adding the binding agent with the weight being 2 / 3 of the weight of the binding agent and discharging; (4) adding the remaining binding agent and stirring for 10-15 minutes after the mixture is aged for 48 hours, discharging and packaging.

Owner:无锡市宜宏耐火材料有限公司

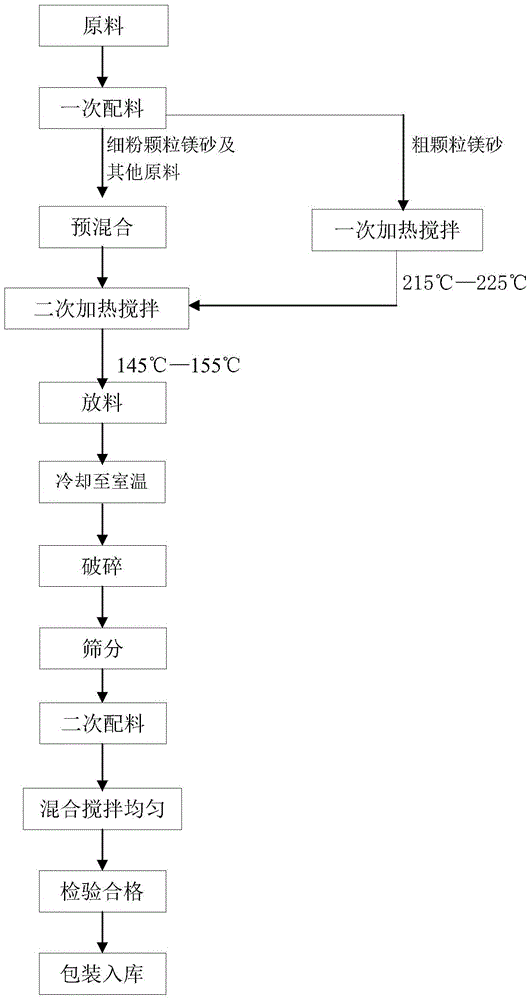

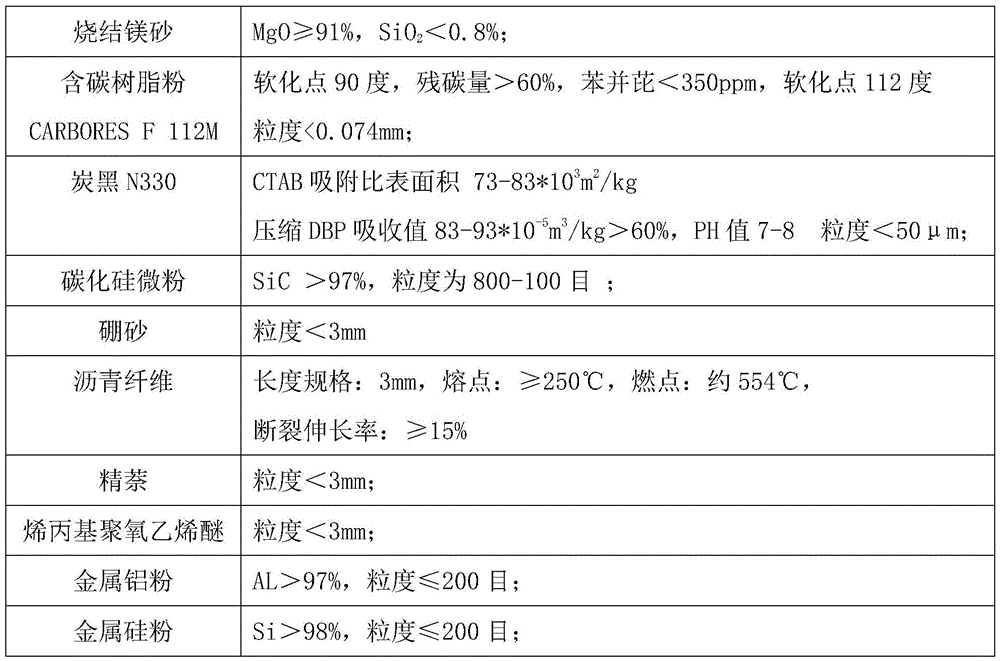

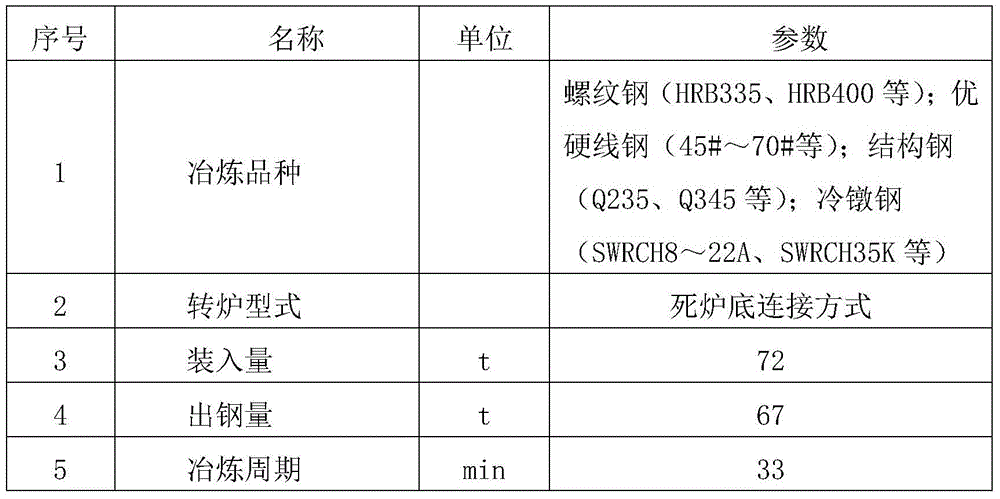

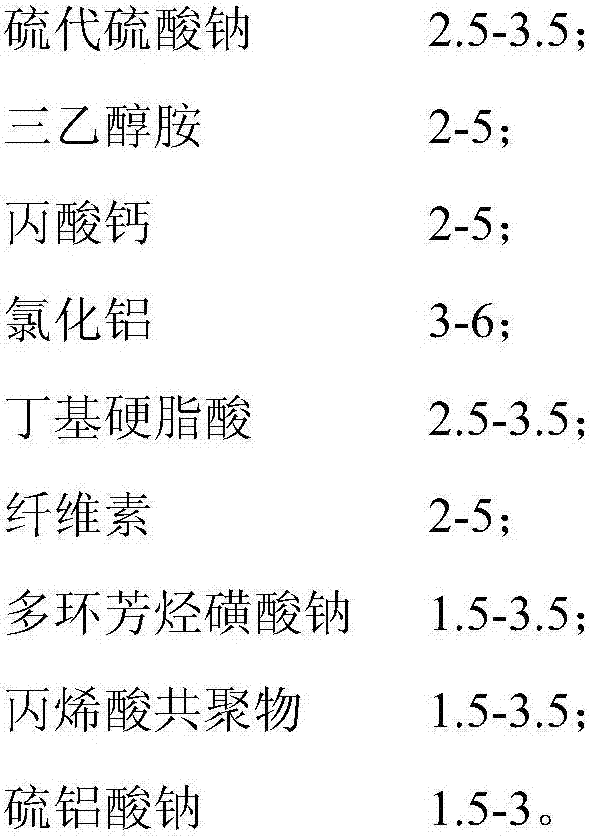

Environment-friendly type long-life fettling sand and production method thereof

The invention relates to environment-friendly type long-life fettling sand, which is prepared from the following raw materials (by weight): 65-90 parts of sintered magnesia, 12-20 parts of a composite carbon source composed of carbon-containing resin powder and carbon black, 0.01-0.20 part of pitch fiber, 2.5-4.5 parts of a composite fluidizing reagent composed of refined naphthalene and allyl polyethenoxy ether, 0.2-1.5 parts of a composite sintering agent composed of silicon carbide micro-powder and borax, and 2.0-5.5 parts of a composite antioxidant composed of metallic aluminum powder and metallic silicon powder. In comparison with the prior art, the invention has the following beneficial effects: sintering time is short; scour resistance and spalling resistance are greatly improved; especially the environmental protection effect is prominent; smoke amount is obviously reduced; there is no peculiar smell; total service life is raised by 25-32%; fettling time is reduced; labor intensity is lowered; and win-win relationship between steel mills and refractory suppliers is realized.

Owner:鞍山市和丰耐火材料有限公司

Modified asphalt mixture

The invention discloses a modified asphalt mixture, relating to the fields of chemistry and chemical engineering. The modified asphalt mixture contains matrix asphalt, an aggregate, mineral powder and a solid SBS modified asphalt mixture modifying agent, wherein the solid SBS modified asphalt mixture modifying agent can form a compact film on the surfaces of the aggregate and the mineral powder after being smelted, and the addition amount of the solid SBS modified asphalt mixture modifying agent is 5wt%-25wt% of the matrix asphalt. The modified asphalt mixture provided by the invention is strong in stripping resistance, easy to prepare and low in cost.

Owner:北京紫瑞天成科技有限公司

Metal glue

InactiveCN106318310AAntisepticHas anti-aging effectNon-macromolecular adhesive additivesRubber derivative adhesivesNitrile rubberAging resistance

The invention discloses a metal glue which is prepared from, by weight, 6-10 parts of phthalic acid, 3-5 parts of bisphenol A epoxy resin, 3-5 parts of polyimide, 6-8 parts of polyamide acid, 4-6 parts of sodium chloride, 6-10 parts of diatomite, 6-8 parts of amino-terminated liquid nitrile rubber buna, 1-3 parts of dispersing agent, and 1-3 parts of nano-silica. The metal glue overcomes the defects in the prior art, formulation design is reasonable, anti-shearing and anti-stripping forces are high when metal wires are mutually pasted, the glue and metal wires are combined firmly, and meanwhile the metal glue has the advantages of having corrosion prevention and ageing resistance effects, and prolonging the service life of equipment.

Owner:莫德合

Magnesium oxide-silicon carbide composite for upper part of copper smelting converter and preparation method of composite

The invention relates to a magnesium oxide-silicon carbide composite for the upper part of a copper smelting converter and a preparation method of the composite. The technical scheme is as follows: firstly, 40wt%-60wt% of fused magnesia particles, 5wt%-25wt% of silicon carbide particles, 6wt%-16wt% of sintered magnesia fine powder, 5wt%-15wt% of zircon fine powder, 4wt%-8wt% of raw alumina micro powder, 3wt%-7wt% of titanium oxide fine powder, 1wt%-3wt% of monatomic silicon fine powder and 2wt%-5wt% of nickel oxide fine powder are taken as raw materials, 6wt%-10wt% of zirconium oxide sol and 1wt%-3wt% of cerium oxide micro powder are added, uniform mixing, forming and drying are performed, the obtained mixture is kept at the constant temperature of 1,250-1,450 DEG C in a carbon embedded atmosphere for 2-8 h, then impregnated in a zirconium oxychloride solution for 0.5-3 h and kept at the constant temperature of 600-900 DEG C for 2-6 h, and the magnesium oxide-silicon carbide compositefor the upper part of the copper smelting converter is obtained. The produced product has the characteristics of environmental friendliness, low apparent porosity, high anti-stripping capacity and excellent residue permeation corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Quick-dry self-flow casting material for ladle permanent layer

The invention discloses a quick-dry self-flow casting material for a ladle permanent layer. The quick-dry self-flow casting material is prepared from the following raw materials in percentage by mass:56-75% of a pyrophyllite and fused mullite composite material of which the particle size is 1-9mm, 14-22% of a pyrophyllite and fused mullite composite material of which the particle size is 0-1mm, 2-8% of silicon nitride of which the particle size is less than or equal to 1mm, 0.5-1.5% of a water reduction agent, 0.8-1.5% of an anti-explosion agent, 1-3% of a combination agent, 1-3% of silicon dioxide micro powder of which the particle size is less than or equal to 60mu m, 1-4% of an active aluminum oxide micro powder of which the particle size is less than or equal to 60mu m, and 2-5% of asilica powder of which the particle size is less than or equal to 50mu m. By adopting the quick-dry self-flow casting material, the ladle permanent layer is good in thermal insulation, good in thermalshock resistance, good in peeling resistance and easy to construct, has the characteristics of excellent self flowing, spreading, filling and the like, can be rapidly baked without cracking, achievesthe purposes of self flowing and quick drying, in addition is free of iron slag adhesion, and is long in service life.

Owner:YANSHI ZHONGYUE REFRACTORY MATERIALS

Quick-drying self-flowing castable for reclaimed ladle permanent layer

The invention discloses a self-flowing castable for a reclaimed ladle permanent layer. The castable is prepared from raw materials in percentage by mass as follows: 46%-56% of a waste ladle permanentlayer reclaimed material with granularity being 1-9 mm, 13%-20% of a pyrophyllite and fused mullite compound with granularity being 1-9 mm, 14%-22% of a pyrophyllite and fused mullite compound with granularity being 0-1 mm, 2%-6% of silicon nitride with granularity being smaller than or equal to 1 mm, 0.5%-1.5% of a water reducer, 0.5%-1.5% of an antiknock agent, 2%-5% of a binder, 1%-3% of silicafine powder with granularity being smaller than or equal to 60 mu m, 2%-5% of activated alumina powder with granularity being 60 mu m and 1%-4% of silica powder with granularity being smaller than orequal to 50 mu m. The self-flowing castable has good heat insulation, good thermal shock resistance and high stripping resistance, has excellent characteristics of self-flowing, leveling and filling,is easy to construct and can be quickly baked without bursting, and purposes of self-flowing and quick drying are achieved.

Owner:YANSHI ZHONGYUE REFRACTORY MATERIALS

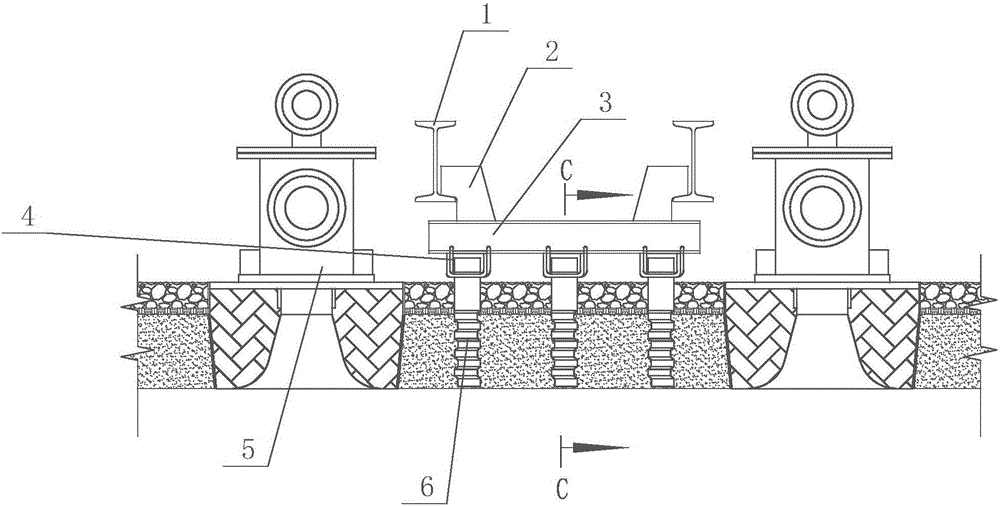

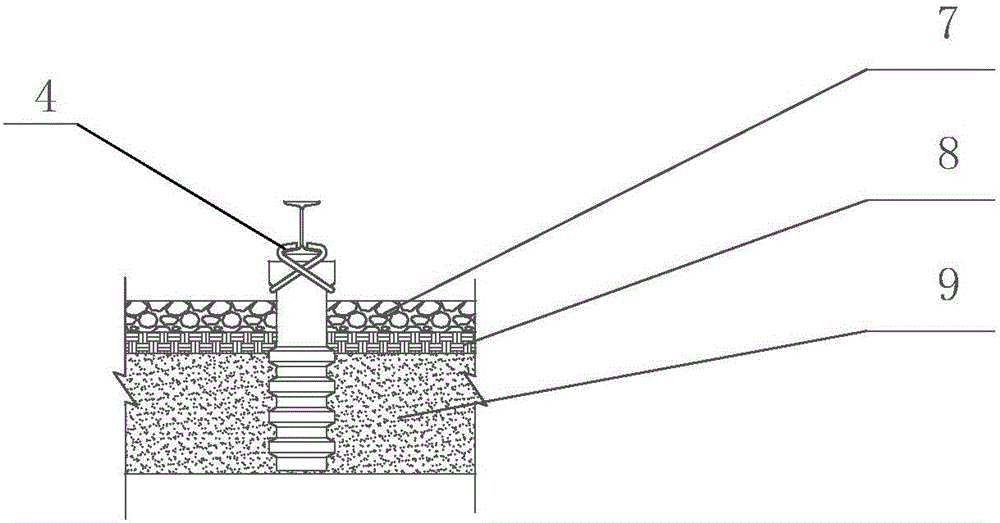

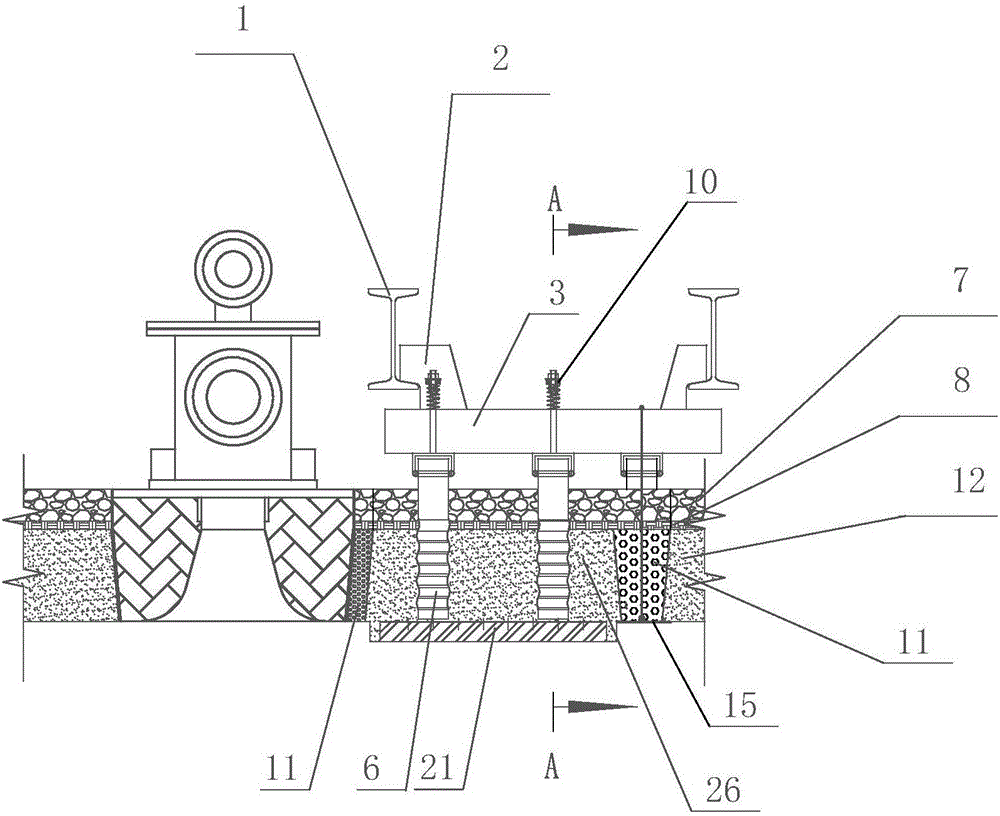

Repairing furnace top and repairing method for collapsed portion of furnace top of steel-rolling heating furnace

InactiveCN106766927AStrong high temperature strengthStrong peeling resistanceLinings repairFurnace crowns/roofsHeating timeBrick

The invention discloses a repairing furnace top and repairing method for a collapsed portion of the furnace top of a steel-rolling heating furnace. By adoption of a plastic prefabricated part, the advantages that the temperature and strength in the plastic furnace top are not decreased, the temperature and strength are high, the thermal shock resistance is good, and the stripping resistance is high are maintained; deformation caused by uneven stress of flexibly-hung anchoring bricks is automatically compensated by adoption of the structure that the furnace top is flexibly hung through springs, and the phenomenon that the anchoring bricks are pulled broken is completely eradiated; and a gap between the plastic prefabricated part and the normal furnace top is poured in site. The problems that repairing construction of the collapsed portion of the original furnace top is difficult, and the construction quality cannot be guaranteed easily are solved; the construction difficulty is greatly lowered, and the construction efficiency is improved; and the repairing furnace top and repairing method for the collapsed portion of the furnace top of the steel-rolling heating furnace have the advantages that the construction period is short, and the furnace heating time is short.

Owner:SHANDONG IRON & STEEL CO LTD

Anti-stripping sulfur asphalt as well as preparation method and application thereof

PendingCN114479489ASense of smellTo achieve a sustained release effectBuilding insulationsParticulatesPhenol

The invention discloses anti-stripping sulfur asphalt as well as a preparation method and application thereof. The anti-stripping sulfur asphalt is prepared from the following raw materials: 5 to 20 parts of sulfur, 1 to 5 parts of naphthalene series, 2 to 8 parts of ethylene-vinyl acetate copolymer, 1 to 3 parts of styrenated phenol, 1 to 3 parts of nitrogen-containing aromatic compound and 60 to 90 parts of petroleum asphalt. The preparation method of the anti-stripping sulfur asphalt comprises the following steps: (1) carrying out a reaction on sulfur and a naphthalene-based substance in an inert atmosphere, and (2) mixing and granulating an ethylene-vinyl acetate copolymer, styrenated phenol, a nitrogen-containing aromatic compound and a reaction product obtained in the step (1) to obtain particles, and (3) heating and melting the petroleum asphalt, and then adding the particulate matters to obtain the anti-stripping sulfur asphalt. The anti-stripping sulfur asphalt is particularly suitable for paving airport runways. The anti-stripping sulfur asphalt disclosed by the invention not only has relatively strong anti-stripping capability and very strong adaptability to a high-temperature wake flow environment of an airplane, but also has an ecological bird repelling function.

Owner:CHINA PETROLEUM & CHEM CORP +1

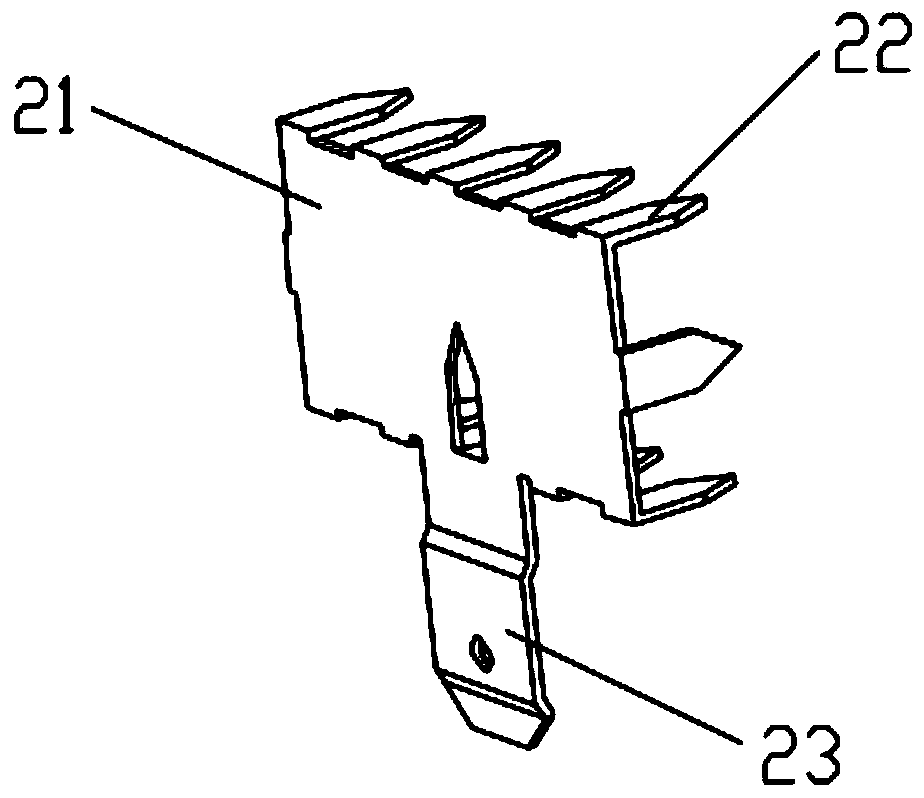

Conveying tank and manufacturing method thereof, and pumping equipment with conveying tank

ActiveCN102330127BImprove wear resistanceExtend your lifePositive displacement pump componentsLiquid fuel engine componentsDehydrogenationEngineering

The invention discloses a conveying tank and a manufacturing method thereof, and pumping equipment with the conveying tank. The manufacturing method for the conveying tank comprises the following steps of: machining to form a preparation tank body; performing primary electroplating on the surface of the preparation tank body, and performing dehydrogenation treatment on a plating layer after the primary electroplating to form a first chromium layer with the rigidity of HRC58 to 60 and the thickness of 0.15 to 0.2mm; and performing secondary electroplating on the surface of the first chromium layer to form a second chromium layer with the rigidity of HRC66 to 68 and the thickness of 0.15 to 0.2mm so as to form the conveying tank. In the method, the first hard chromium layer and the second hard chromium layer which have matched thickness and rigidity are electroplated on the inner surface of the tank body, so that the abrasion resistance of the whole conveying tank is improved, the anti-stripping capacity of all the hard chromium layers is improved, and the service life of the conveying tank is prolonged.

Owner:ZOOMLION HEAVY IND CO LTD

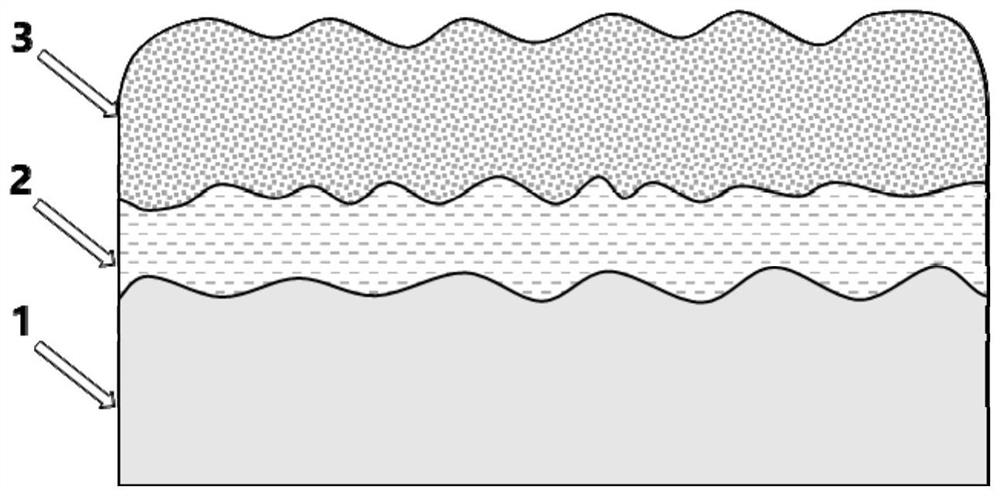

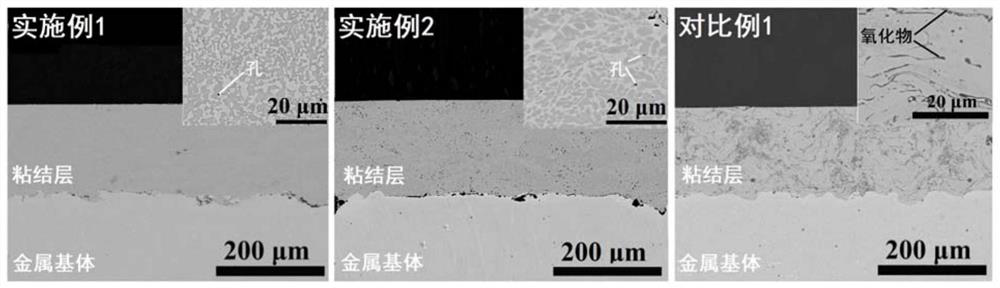

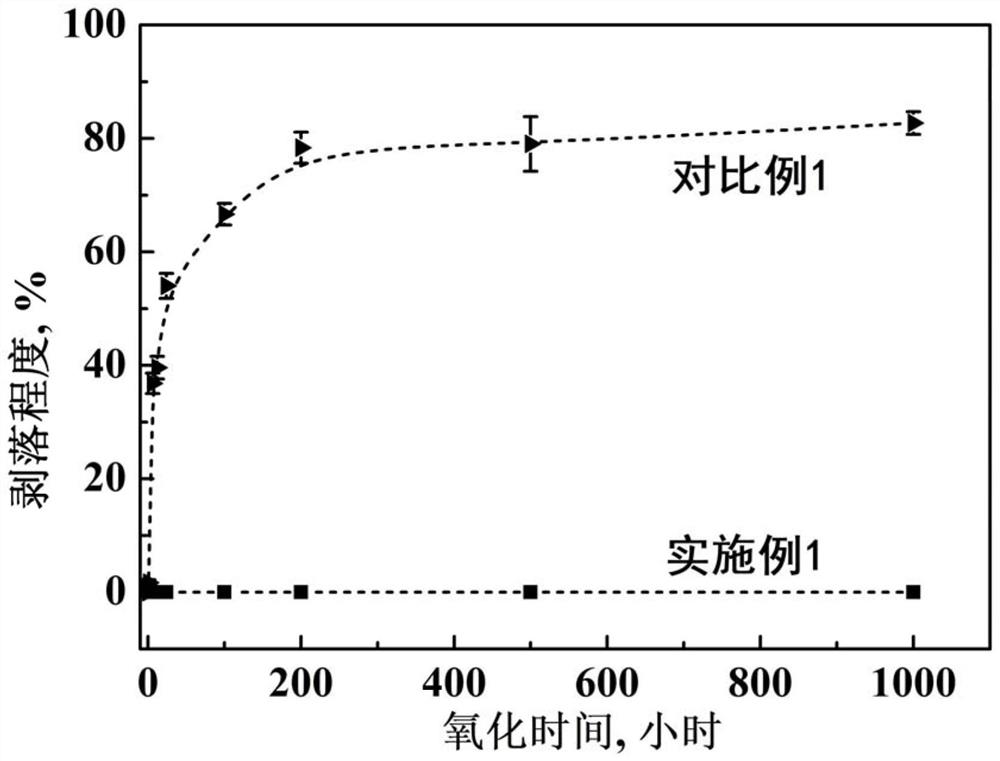

Anti-oxidation bonding layer and preparation method of thermal barrier coating of anti-oxidation bonding layer

PendingCN114438432AIncrease working temperatureUniform structureMolten spray coatingAbrasive blastingAlloy substrate

The invention relates to a preparation method of an anti-oxidation bonding layer and a thermal barrier coating of the anti-oxidation bonding layer, which comprises the following steps of: (1) sequentially carrying out ultrasonic cleaning on a metal matrix by using acetone and alcohol, and then carrying out cold sand blasting treatment by using Al2O3 particles to obtain higher surface roughness; (2) depositing a metal bonding layer on the sand-blasted substrate through a high-speed gas flame spraying technology; (3) the surface of the metal bonding layer is treated through thermal sand blasting, and certain surface roughness and thickness are obtained; (4) depositing a ceramic layer on the bonding layer by adopting an atmospheric plasma spraying technology; and (5) carrying out vacuum heat treatment on the prepared thermal barrier coating. Compared with the prior art, the NiCoCrAlYHf bonding layer is deposited on the high-temperature alloy substrate through the high-speed gas flame spraying technology, the prepared bonding layer is more uniform in organization structure and has more excellent oxidation resistance, and meanwhile the ceramic layer is prepared on the bonding layer through the atmosphere plasma spraying technology by regulating and controlling the thickness and surface roughness of the bonding layer.

Owner:上海交通大学包头材料研究院 +1

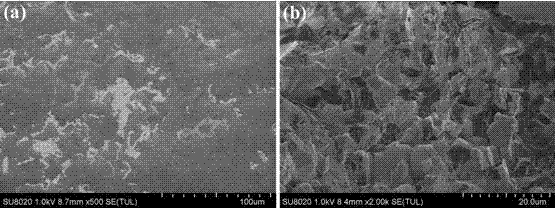

Special runner pipe for casting and preparation method thereof

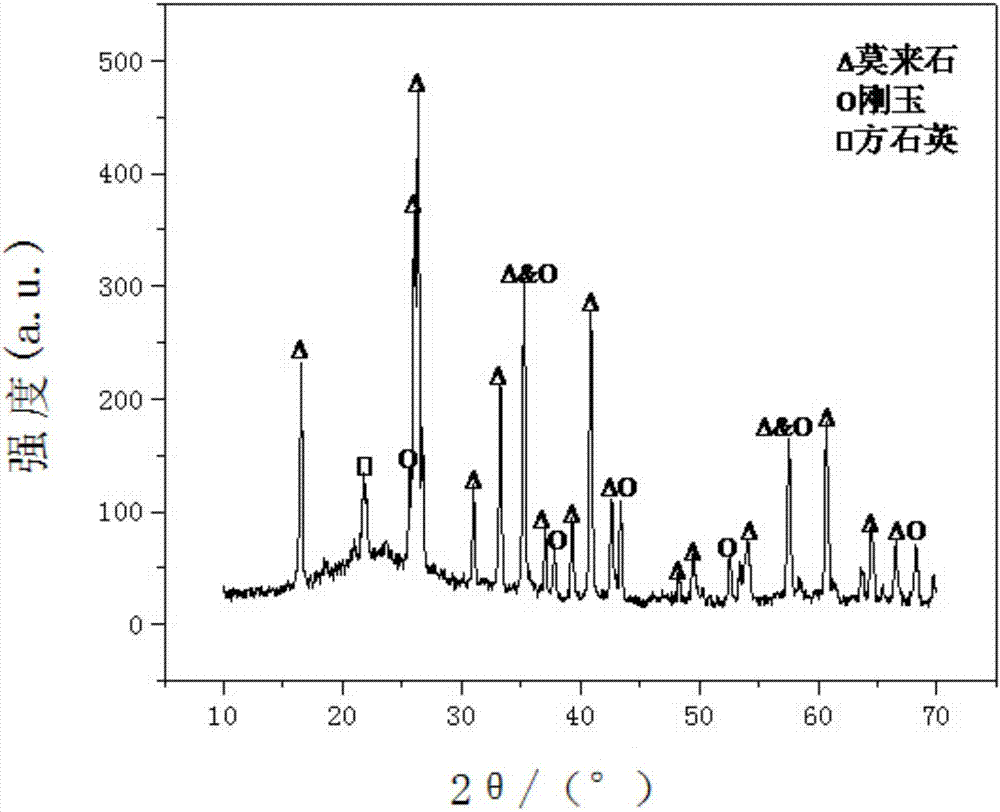

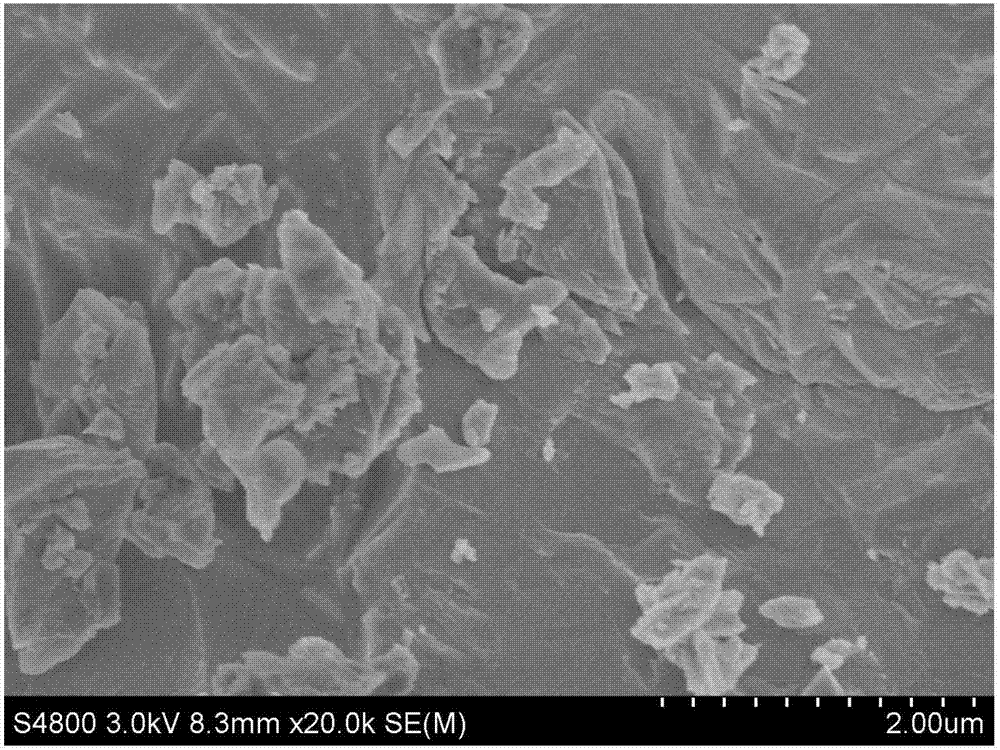

ActiveCN107311674APhase content increaseHigh alumina contentFoundry mouldsFoundry coresCrucibleMullite

The invention discloses a special runner pipe for casting and a preparation method thereof. The preparation method comprises the following steps: using bauxite as a high-aluminum raw material and green crucible as bonding clay; firstly lightly sintering the raw bauxite material, then designing a formula according to a ratio that the mass percent of Al2O3 is 56-60% and the mass percent of SiO2 is 30-34%, weighing the lightly sintered bauxite material and the green crucible clay respectively, mixing and co-grinding; coarsely pugging, aging, finely pugging in vacuum, performing injectable tube extrusion moulding, and drying a co-ground material, and finally sintering at the temperature of 1250-1300 DEG C. A ceramic product prepared by the preparation method of the invention has an orange yellow appearance, high compactness and high mechanical strength; detection shows that a main crystal phase is a mullite phase with good crystal development and a minor crystal phase is a corundum phase, so that various requirements on a high-end casting runner pipe are met.

Owner:BAOJI HUAGUANG CASTING MATERIAL TECH

A microporous chromium-free unfired brick having high thermal shock resistance and used for an RH refining furnace and a preparing method thereof

ActiveCN107473753AImproved thermal shock stabilityUniform pore sizeCeramicwareChromium freeSocial benefits

A microporous chromium-free unfired brick having high thermal shock resistance and used for an RH refining furnace and a preparing method thereof are disclosed. Main raw materials of the chromium-free unfired brick include microporous fused magnesite-alumina synthetic composite materials having various particle sizes, fused magnesium aluminate spinel having a particle size of 325 meshes, and metal aluminum powder having a size of 200 meshes. In addition, thermosetting phenolic resin is added and adopted as a binding agent. Firstly, weighed raw materials are added into an intensive sand mixer and premixed to obtain a material mixture; the material mixture is added into an assembled mould and subjected to compression moulding; and a moulded green brick is put into a drier and subjected to heat treatment to obtain the microporous chromium-free unfired brick. The product is suitable as a refractory material used for the RH refining furnace. Compared with common chromium-free unfired brick, the microporous chromium-free unfired brick has excellent thermal shock resistance, erosion resistance and penetration resistance, the service lifetime of the RH refining furnace is obviously prolonged, the production efficiency of a steel plant is increased and the microporous chromium-free unfired brick has significant economic benefit and social benefit.

Owner:TONGDA REFRACTORY TECH CO LTD +2

A warm-mixed high-viscosity modified asphalt and its preparation and application

ActiveCN108948753BHigh viscosityStrong peeling resistanceRoads maintainenceBuilding insulationsButadiene DioxideExhaust fumes

The invention provides a warm-mix high-viscosity modified asphalt, and is prepared from the following raw materials in parts by mass: 80-90 parts of matrix asphalt, 0-3 parts of N,N'-ethylenebis(stearamide), 0-2 parts of stearic acid or stearate, 0-1 part of high-molecular wax, 3-8 parts of styrene-butadiene-styrene block copolymer, 0-2 parts of styrene butadiene rubber, 2-5 parts of rubber oil, 0-8 parts of colloidal particles and 0.1-0.3 part of a stabilizer. According to the warm-mix high-viscosity modified asphalt provided by the invention, the production and mixing temperature of the mixture is reduced while the performance index is not influenced; the power viscosity of the warm-mix high-viscosity modified asphalt at 60 DEG C reaches 100000 Pa.s or above; the Brookfield viscosity at135 DEG C is 2000 mPa.s or below; the mixing temperature and the compaction temperature required by the high-viscosity asphalt mixture are reduced; and compared with the mixing temperature of the heat-mix asphalt mixture, the mixing temperature is reduced by about 20-30 DEG C. The fuel consumption can be reduced, the waste gas emission can be reduced, and the operation environment of a constructorcan be improved.

Owner:ZHONGLU HI TECH (BEIJING) HIGHWAY TECHNOLOGY CO LTD +1

Electric smelting magenisum aluminum spinel brick for coal water slurry gasifying furnace and preparation method thereof

The invention particularly relates to an electric smelting magenisum aluminum spinel brick for a coal water slurry gasifying furnace and a preparation method of the electric smelting magenisum aluminum spinel brick. The technical scheme is as follows: the preparation method comprises the following steps of: taking 58-74 wt% of industrial aluminum oxide powder and 26-42 wt% of light roasting magenisum oxide powder as raw materials; additionally adding carbon powder which is 0.5-3.0 wt% of the raw materials; uniformly agitating; putting the mixture into an electric arc furnace and electrically smelting by utilizing a 100-220 V voltage until all the raw materials are fused; continually smelting for 30-60 minutes and casting a smelted high-temperature synthetic material into a casting mould; then, placing the material into a tunnel kiln to be annealed by a belt mould under the condition of 1350-1550 DEG C, wherein the annealing period is 72-120 hours; discharging the material out of the kiln under the condition of 30-80 DEG C and de-molding; and finally, carrying out mechanical machining on a de-molded product to obtain the electric smelting magenisum aluminum spinel brick. The electric smelting magenisum aluminum spinel brick prepared by the invention has the characteristics of low apparent porosity, strong anti-stripping capability and good anti-coal-slag penetrating performance, and can better adapt to a working environment of a hot surface of a liner of the coal water slurry gasifying furnace.

Owner:WUHAN UNIV OF SCI & TECH

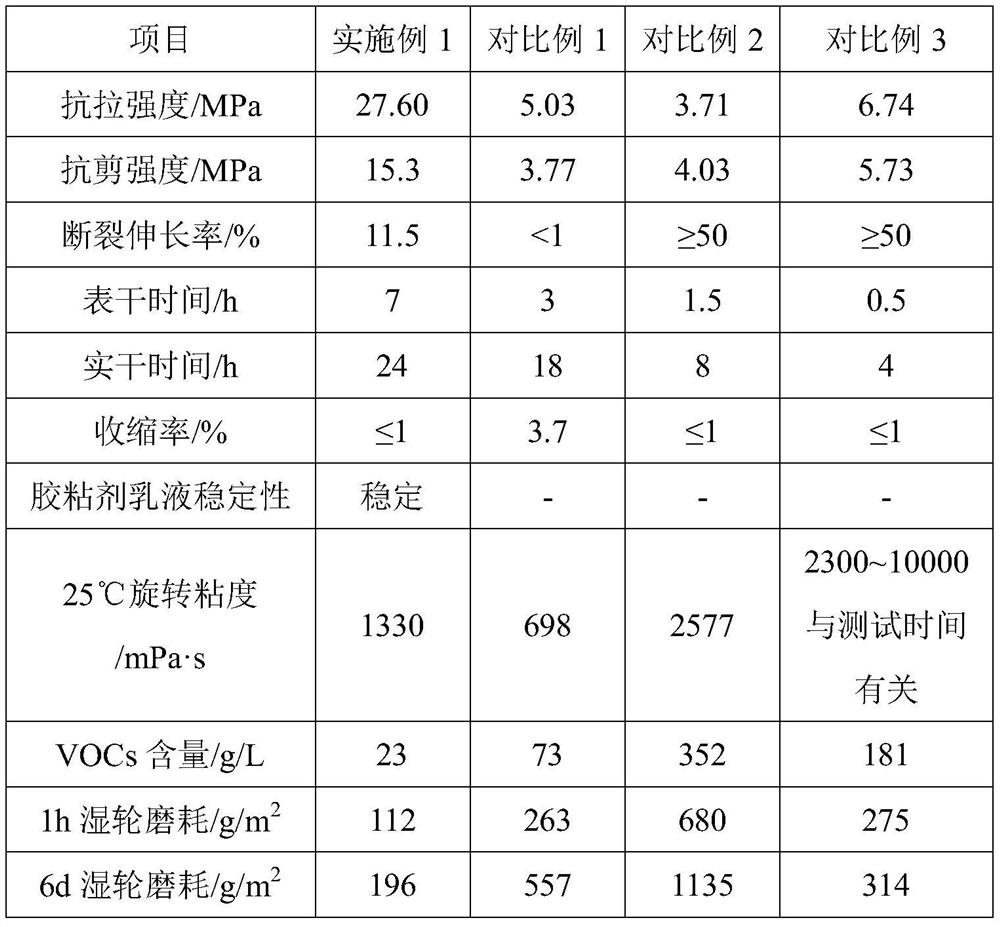

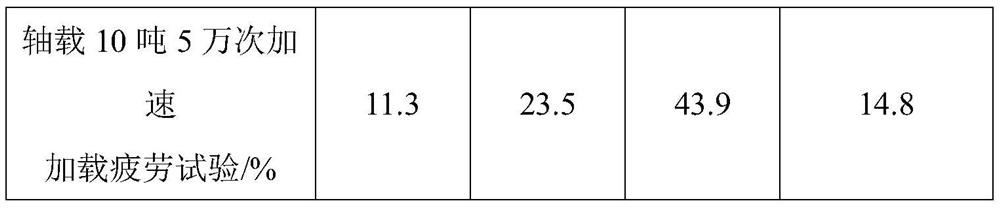

Environment-friendly adhesive capable of being mixed for construction and preparation method of environment-friendly adhesive

ActiveCN112778949AImprove toughnessHigh elongation at breakNon-macromolecular adhesive additivesSolid waste managementEpoxyAdhesive cement

The invention discloses an environment-friendly adhesive capable of being mixed for construction and a preparation method of the environment-friendly adhesive. The adhesive is composed of a component A and a component B. When the adhesive is used, 100 parts by mass of the component A, 150 parts by mass of the component B, 100 parts by mass of tap water and 10 parts by mass of pigment are mixed, then colored ceramic particles with the particle size being 1-3 mm are added, the mixture is stirred evenly, then the mixture is poured on a construction road surface, and the mixture is scraped to be flat through a flat rubber scraper. The environment-friendly adhesive capable of being mixed for construction is waterborne epoxy resin toughened and modified by polyurethane, the elongation at break and the shear strength are remarkably improved compared with those of commercially available waterborne epoxy resin, the crack resistance and the fatigue resistance of a colored anti-skid pavement prepared from the environment-friendly adhesive are remarkably improved, and the introduction of hydrophilic molecular chains is controlled, so that the water damage resistance can be effectively improved. Compared with a conventional colored anti-skid pavement , the colored anti-skid pavement constructed by mixing has the advantages that the anti-stripping capability is higher, and the use amount of the ceramic particles is greatly reduced.

Owner:山西省交通科技研发有限公司 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com