Preparation method of ceramic-based composite coating capable of resisting seawater cavitation erosion

A technology of ceramic matrix composite and ceramic coating, applied in coating, metal material coating process, fusion spraying and other directions, can solve the problems of concentrated mechanical impact force, low cavitation resistance of thermal sprayed ceramic coating, etc. Strong corrosion and spalling resistance, excellent cavitation resistance, porosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

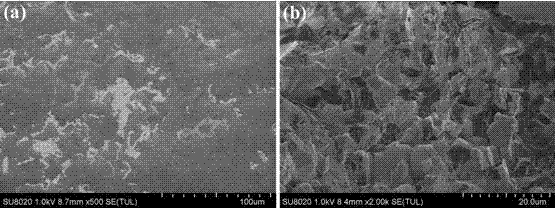

[0019] A: Using the atmospheric plasma spraying process, spray and deposit a NiCr transition layer with a thickness of about 50 μm on the 316L stainless steel substrate, and then spray and deposit Al with a thickness of about 250 μm 2 o 3 -13TiO 2 ceramic coating.

[0020] B. Measure 40 mL of epoxy resin and 5 mL of triethylenetetramine, mix them evenly, and then apply them on Al 2 o 3 -13TiO 2 on the surface of the ceramic coating.

[0021] C. Put the sample into the vacuum chamber, pump it to a vacuum of -0.74 bar, and carry out vacuum impregnation for 4 hours, so that polymers such as epoxy resin can infiltrate and fill the pores in the coating.

[0022] D. Place the sample in an oven, raise the temperature to 80°C at 2°C / min, and keep it warm for 4 hours to solidify the polymer immersed in the micropores of the coating.

[0023] E. For cured Al 2 o 3 -13TiO 2 The surface of the ceramic matrix composite coating is ground and polished to remove excess polymer on th...

Embodiment 2

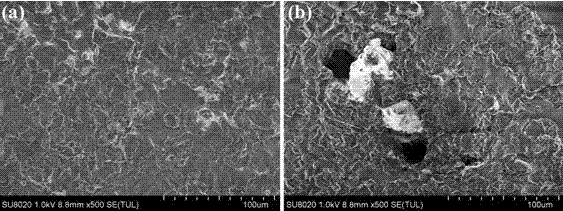

[0026] A: Using the atmospheric plasma spraying process, spray and deposit a CoCrAlY transition layer with a thickness of about 55 μm on the 304 stainless steel substrate, and then spray and deposit a ZrO with a thickness of about 280 μm 2 ceramic coating.

[0027] B. Measure 35 mL of epoxy resin and 5 mL of triethylenetetramine, mix them evenly, and then apply them on ZrO 2 on the surface of the ceramic coating.

[0028] C. Put the sample into the vacuum chamber, pump it to a vacuum of -0.68 bar, and carry out vacuum impregnation for 3 hours, so that polymers such as epoxy resin can infiltrate and fill the pores in the coating.

[0029] D. Place the sample in an oven, raise the temperature to 60°C at 2°C / min, and keep it warm for 3 hours to solidify the polymer immersed in the micropores of the coating.

[0030] E. For cured ZrO 2 The surface of the ceramic matrix composite coating is ground and polished to remove excess polymer on the surface and make the surface roughne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com