Graphene heating film

A technology of ene heating film and graphene, which is applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problem of high voltage breakdown resistance and service life discount, the impedance of heating film cannot be monitored separately, and the uniformity of heating is difficult to guarantee, etc. Problems, to achieve the effect of safe and reliable current carrying, increasing the safe carrying capacity and increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further illustrated by the following examples, but these examples are only exemplary, and the present invention is not limited thereto.

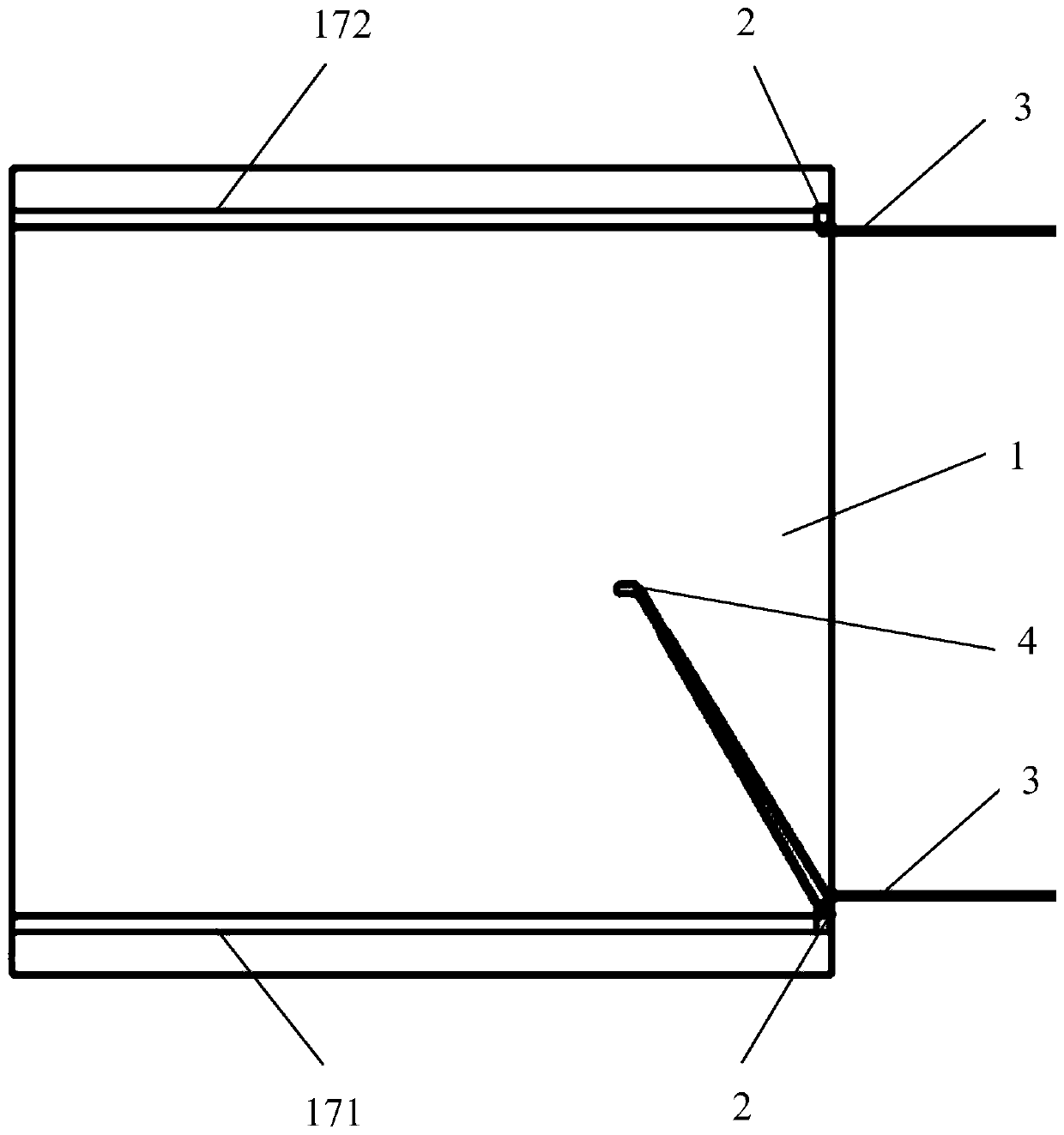

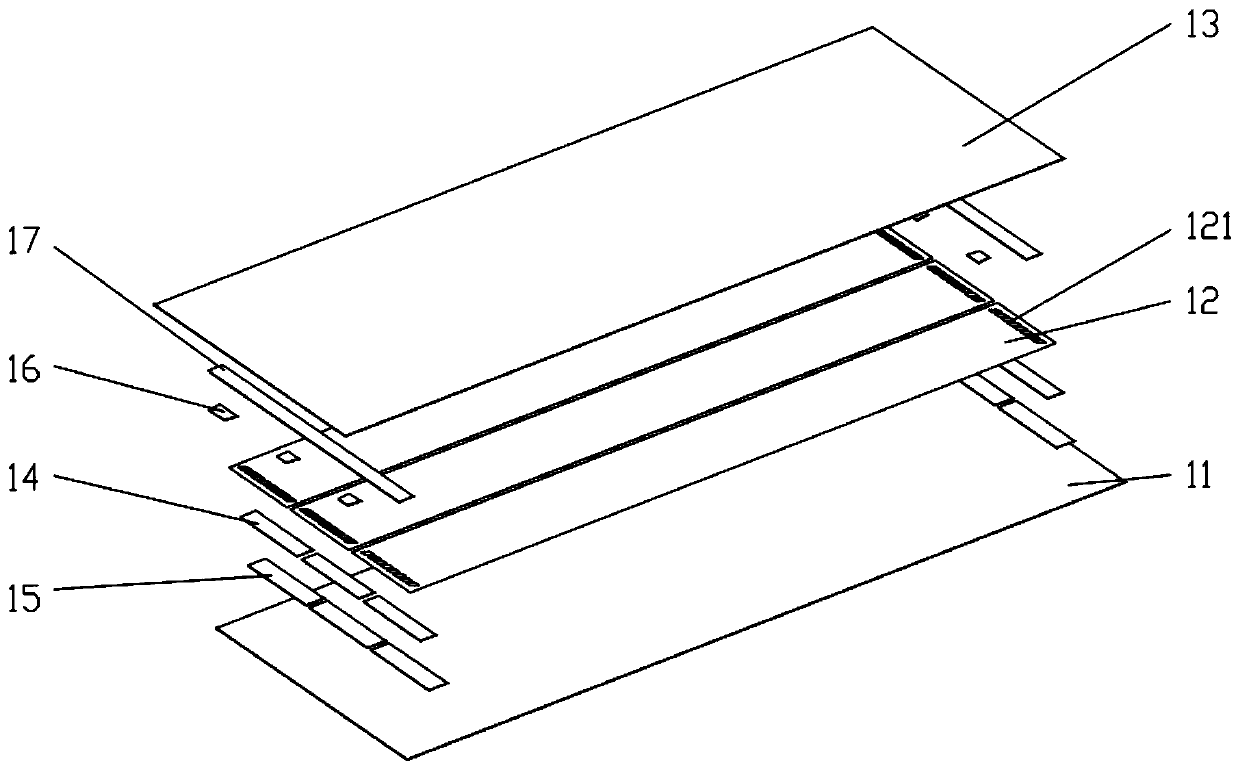

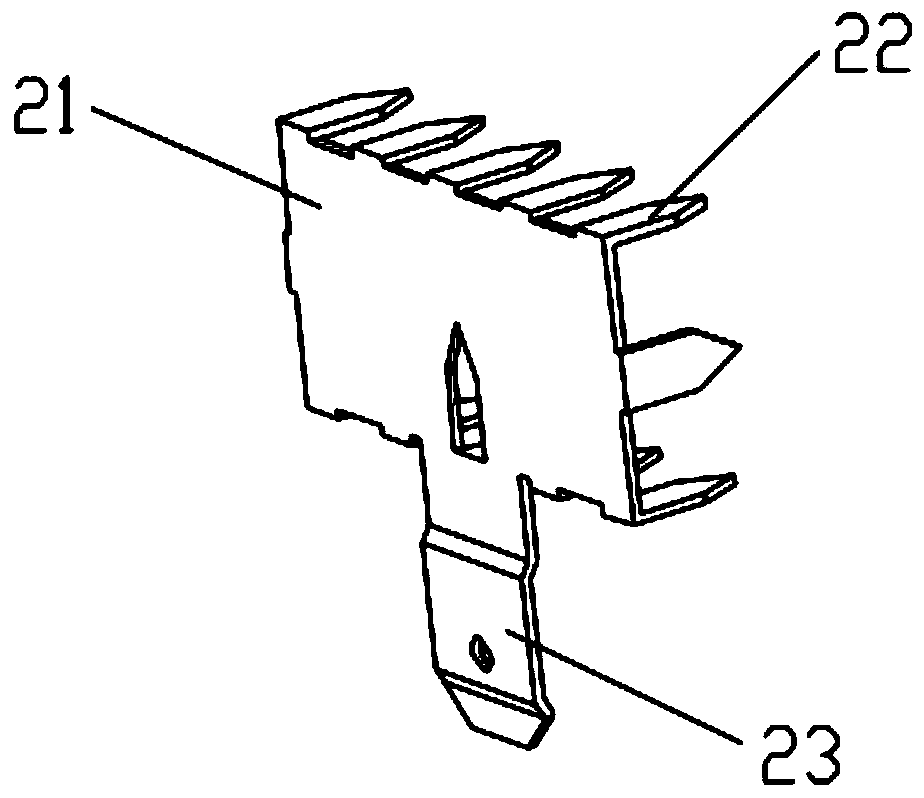

[0034] Such as Figure 1-3 As shown, a graphene heating film of the present invention includes a heating film body 1 , and the heating film body 1 includes a carrier 11 , a graphene heating coating 12 and a polymer insulating film 13 .

[0035] The carrier 11 is a modified PET film. The modified PET film is first corona treated on both sides of the PET film, and then the surface is hard-coated. It is also heat-set and desulfurized before production to ensure that it is stable under high temperature. The dimensional stability is good, the secondary transverse shrinkage rate is close to zero, and the longitudinal shrinkage rate is 2‰-3‰. The modified PET film has strong surface adhesion, which improves the stability and reliability of product quality.

[0036] The graphene heating coating 12 is coated on the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com