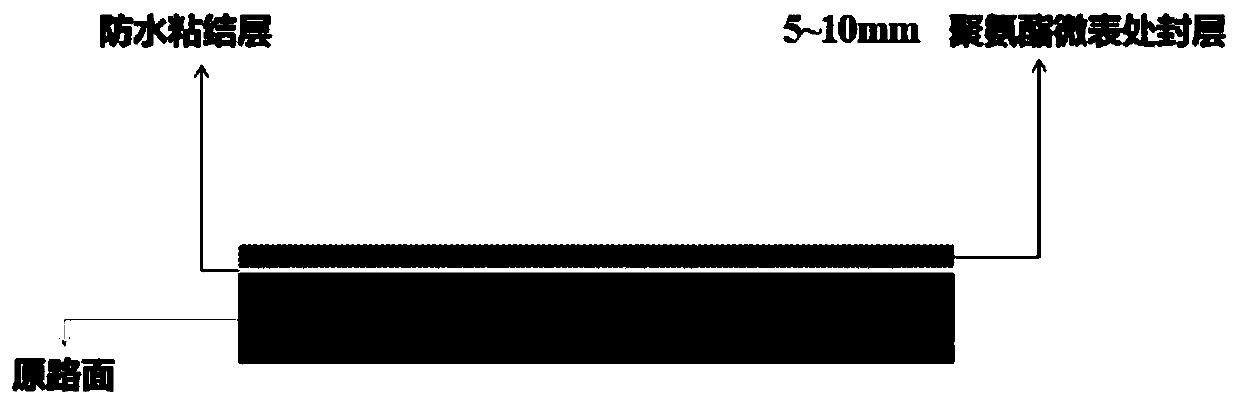

Polyurethane micro-surfacing seal coat mixture and preparation method and application thereof

A micro-surface and compound technology, applied in the field of polyurethane micro-surface sealing compound and its preparation, can solve the problems of inability to meet the road maintenance business, easy to flow at high temperature, easy to crack at low temperature, etc., to achieve the best impermeability and prevent aging. effect with loose, high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

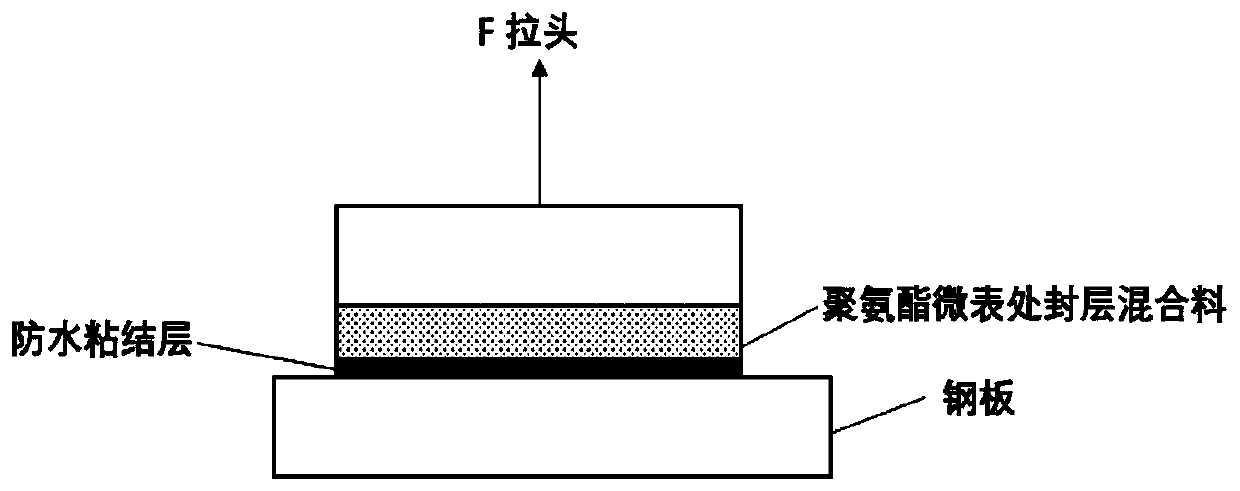

Method used

Image

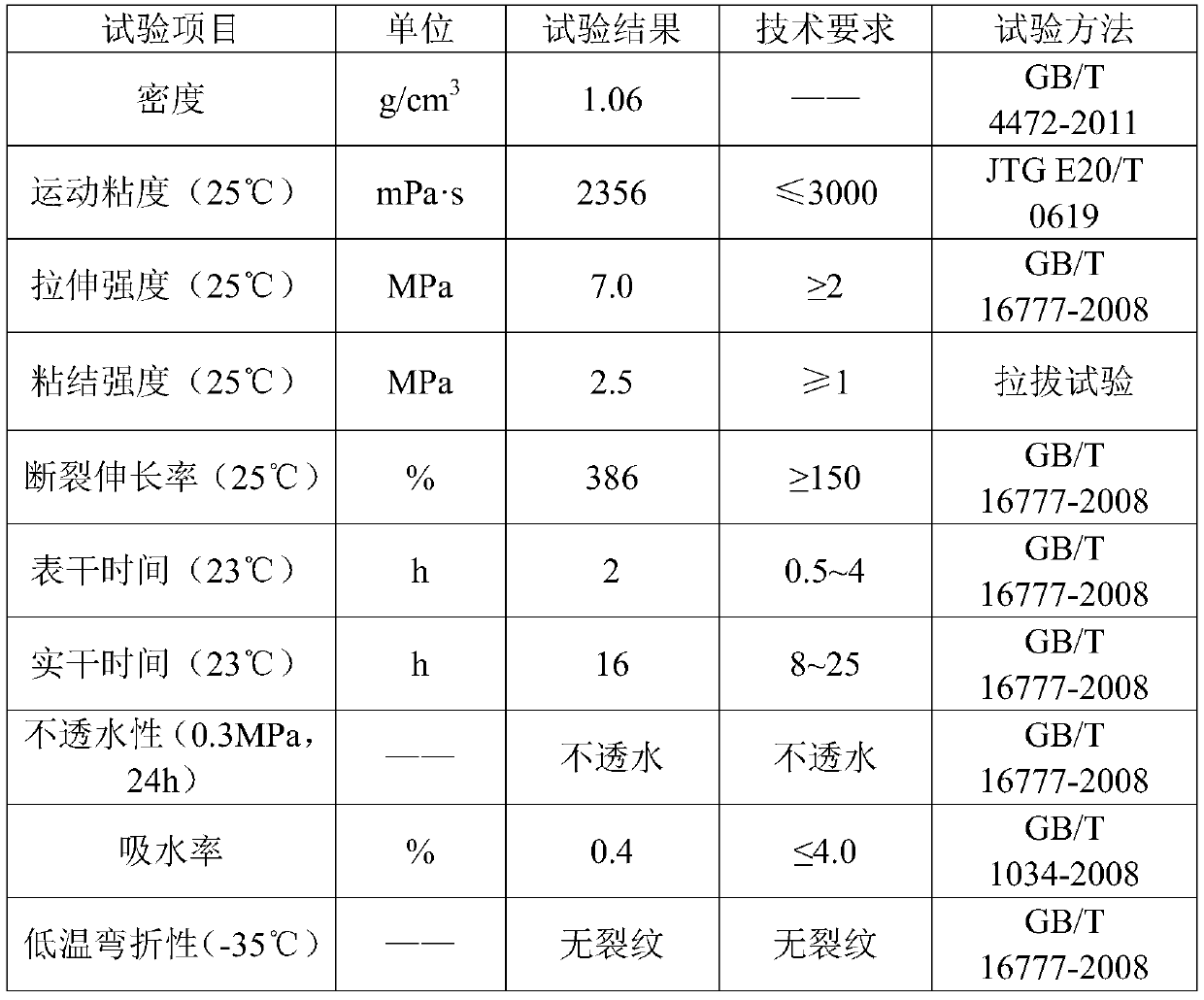

Examples

Embodiment 1

[0069] The preparation method of the polyurethane micro-surface sealing layer mixture of the present invention, taking the MS-3 type slurry mixture as an example, includes the following materials by weight: aggregate: 90 parts by weight; filler: 10 parts by weight; polyurethane: 10 parts by weight parts by weight; catalyst: 0.2 parts by weight.

[0070] Above-mentioned aggregate is made up of the raw material of following mass parts ratio:

[0071] Coarse aggregate: 54 parts by weight;

[0072] Fine aggregate: 36 parts by weight.

[0073] The performance test results of the above aggregates are shown in Table 2:

[0074] Table 2 Aggregate Performance Test Results

[0075]

[0076] The above-mentioned coarse aggregate is basalt, the fine aggregate is limestone, the particle size of the coarse aggregate is 5-10mm, and the particle size of the fine aggregate is 0-5mm; Relevant requirements in JTG F40); Polyurethane is a polyether polymer, its soft segment is polyether poly...

Embodiment 2

[0081] The preparation method of the high-performance polyurethane micro-surface sealing layer mixture of the present invention is the same as in Example 1, and the difference is that, taking the MS-3 type slurry mixture as an example, the material comprising the following parts by weight:

[0082] Aggregate: 92 parts by weight;

[0083] Filler: 8 parts by weight;

[0084] Polyurethane: 9 parts by weight;

[0085] Catalyst: 0.18 parts by weight.

[0086] Above-mentioned aggregate is made up of the raw material of following mass parts proportioning:

[0087] Coarse aggregate: 46 parts by weight;

[0088] Fine aggregate: 46 parts by weight.

Embodiment 3

[0090] The preparation method of the high-performance polyurethane micro-surface sealing layer mixture of the present invention is the same as in Example 1, and the difference is that, taking the MS-3 type slurry mixture as an example, the material comprising the following parts by weight:

[0091] Aggregate: 94 parts by weight;

[0092] Filler: 6 parts by weight;

[0093] Polyurethane: 8 parts by weight;

[0094] Catalyst: 0.16 parts by weight.

[0095] Above-mentioned aggregate is made up of the raw material of following mass parts proportioning:

[0096] Coarse aggregate: 37 parts by weight;

[0097] Fine aggregate: 57 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com