Graded broken stone filling type semi-flexible composite pavement mixture and pavement construction method

A technology of grading gravel and composite pavement, applied in the direction of on-site coagulation pavement, roads, roads, etc., can solve the problem of reducing the semi-flexible pavement of pouring type, achieve excellent road performance, broad application prospects, Good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

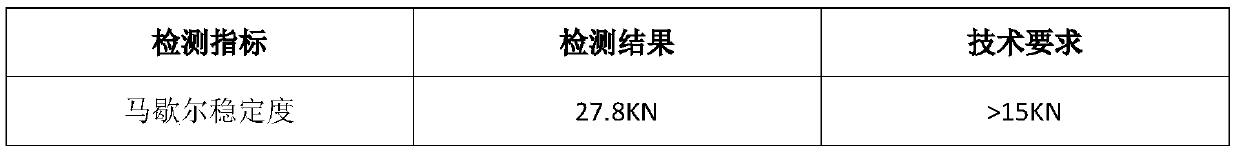

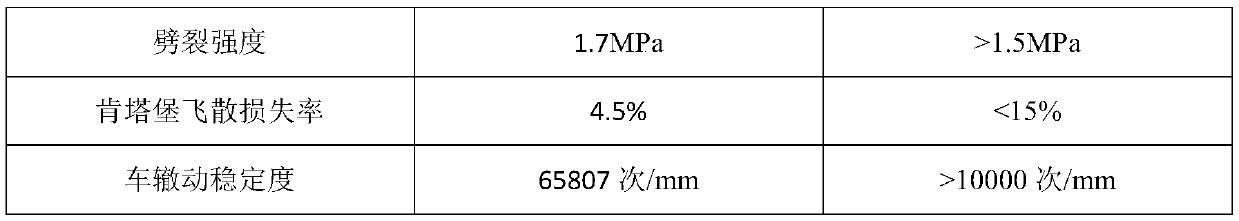

[0036] The invention provides a graded crushed stone pouring type semi-flexible composite pavement mixture which can be constructed at normal temperature.

[0037] The composition of the mixture is calculated in parts by weight: 100 parts of graded crushed stone, 3 parts of drinking water, and 6 parts of high fluidity grouting material; the aggregate used for the graded crushed stone is limestone aggregate, and the The high-fluidity grouting material is composed of cement, water-based acrylic resin, pozzolan material and water, the cement is 2 parts, the water-based acrylic resin is 2 parts, the pozzolan material is 1 part, and the water for 1 serving. Graded gravel has the characteristics of flexible pavement, while high-fluidity grouting material has a certain degree of rigidity. The graded gravel poured semi-flexible composite pavement formed by combining the two has the advantages of both.

[0038] In order to ensure the characteristics of the flexible pavement of graded ...

Embodiment 2

[0052] The invention provides a graded crushed stone pouring type semi-flexible composite pavement mixture which can be constructed at normal temperature.

[0053]The composition of the mixture is calculated in parts by weight: 100 parts of graded crushed stone, 5 parts of drinking water, and 10 parts of high fluidity grouting material; the aggregate used for the graded crushed stone is basalt aggregate, and the The high-fluidity grouting material is composed of cement, water-based acrylic resin, pozzolan material and water, the cement is 4 parts, the water-based acrylic resin is 2 parts, the pozzolan material is 1 part, and the water Makes 2 servings. Graded gravel has the characteristics of flexible pavement, while high-fluidity grouting material has a certain degree of rigidity. The graded gravel poured semi-flexible composite pavement formed by combining the two has the advantages of both.

[0054] In order to ensure the characteristics of the flexible pavement of graded ...

Embodiment 3

[0067] The invention provides a graded crushed stone pouring type semi-flexible composite pavement mixture which can be constructed at normal temperature.

[0068] The composition of the mixed material is calculated in parts by weight: 100 parts of graded crushed stone, 4 parts of drinking water, and 8 parts of high fluidity grouting material; the aggregates used for the graded crushed stone are limestone and basalt aggregates, The high-fluidity grouting material is composed of cement, water-based acrylic resin, pozzolan material and water, the cement is 2 parts, the water-based acrylic resin is 3 parts, the pozzolan material is 2 parts, and the 1 part of water.

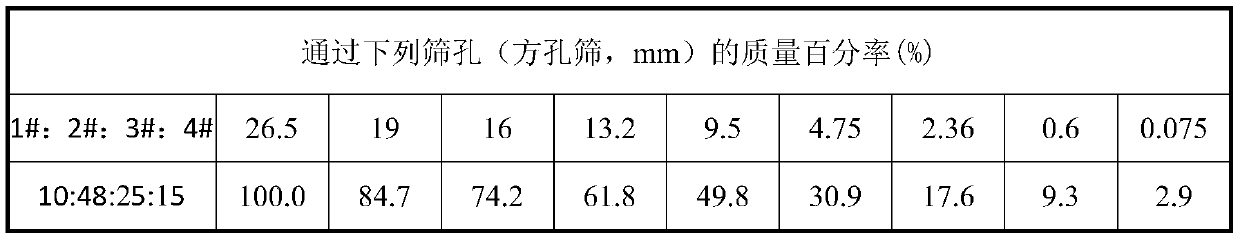

[0069] In order to ensure the characteristics of the flexible pavement of graded crushed stone, by adjusting and controlling the specific gradation, a skeleton void type graded crushed stone mixture is configured, and the grading curve of the mixture is a discontinuous grading curve, that is, more than 4.75mm Coarse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com