Warm mix anti-rutting asphalt mixing material and preparation method thereof

A technology of asphalt mixture and warm mix asphalt, which can be applied in the field of coagulation pavement, climate change adaptation, construction, etc. requirements, the effect of extending the construction season

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

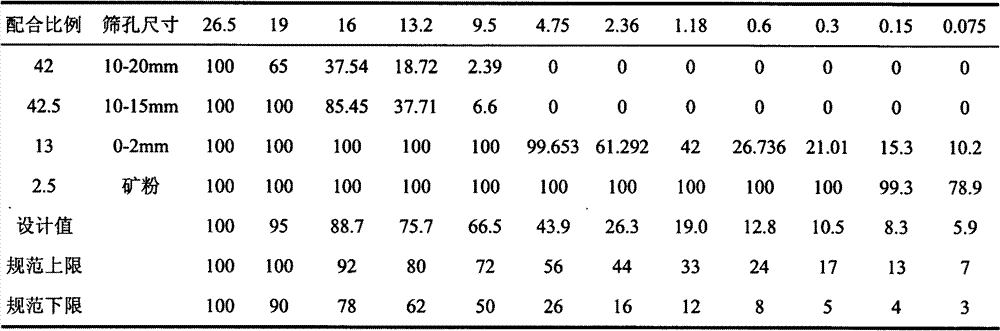

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the warm-mix anti-rutting asphalt mixture of the present invention, the steps are:

[0049] (1) In the mixing plant equipment, add aggregate when the heating temperature reaches 160-230°C;

[0050] (2) Add warm-mix asphalt additive and anti-rutting asphalt modifier, dry mix at 110-170°C for 80-90s;

[0051] (3) Add asphalt when the temperature is adjusted to 140-170°C, and wet mix at 110-170°C for 80-90s;

[0052] (4) The molding temperature of the asphalt mixture is 130-160°C.

[0053] Another preparation method of the warm-mix anti-rutting asphalt mixture of the present invention, the steps are:

[0054] (1) In the mixing plant equipment, add aggregate when the heating temperature reaches 160-230°C;

[0055] (2) Add anti-rutting asphalt modifier, dry mix at 110-170°C for 80-90s;

[0056] (3) When the temperature is adjusted to 140-170°C, add asphalt and warm-mix asphalt additives, and wet mix at 110-170°C for 80-90s;

[0057] (4) The mol...

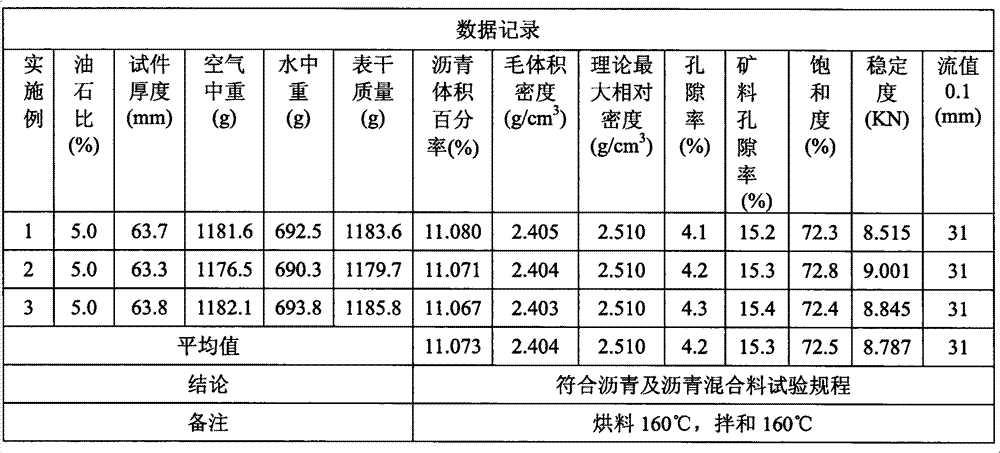

Embodiment 1

[0061] (1) In the mixing plant equipment, add 206400g of aggregate when the heating temperature reaches 160°C;

[0062] (2) Add 764g of warm mix asphalt additive and 655g of anti-rutting asphalt modifier, and dry mix at 110°C for 80s;

[0063] (3) When the temperature is adjusted to 140°C, add 10320g of asphalt, and wet mix at 110°C for 80s;

[0064] (4) The molding temperature of the asphalt mixture is 145°C.

Embodiment 2

[0066] (1) Add 318230g of aggregate when the heating temperature reaches 200°C in the mixing plant equipment;

[0067] (2) Add 1010g of anti-rutting asphalt modifier, and dry mix at 140°C for 90s;

[0068] (3) When the temperature is adjusted to 160°C, add 15,910g of asphalt and 1,180g of warm mix asphalt additive, and wet mix at 140°C for 90s;

[0069] (4) The molding temperature of the asphalt mixture is 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com