Warm asphalt modifier and preparation method and application thereof

A warm-mix asphalt and modifier technology, which is applied in climate change adaptation, building insulation materials, building components, etc. It can solve the problems that warm-mix asphalt modifiers cannot meet the requirements of road construction and cannot overcome the disadvantages of foaming technology , to achieve the effect of improving water damage resistance, realizing cooling, and solving the effect of being difficult to infiltrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of embodiment 1 warm mix asphalt modifier

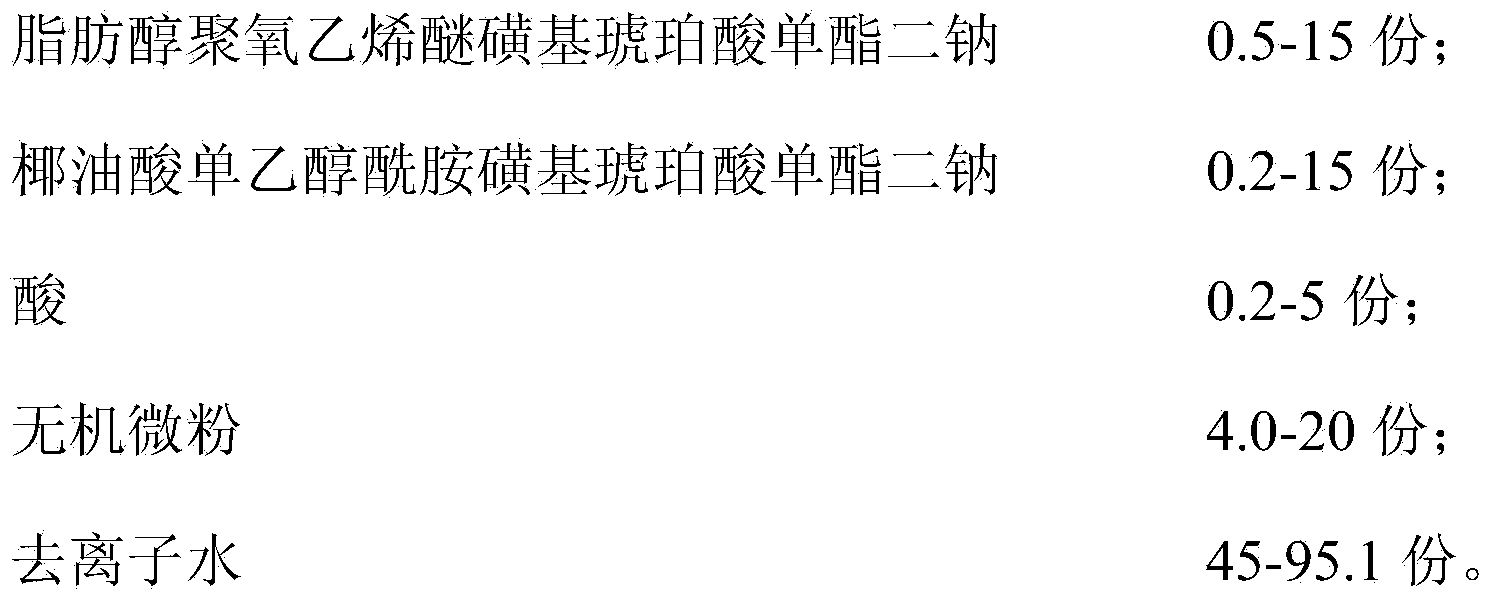

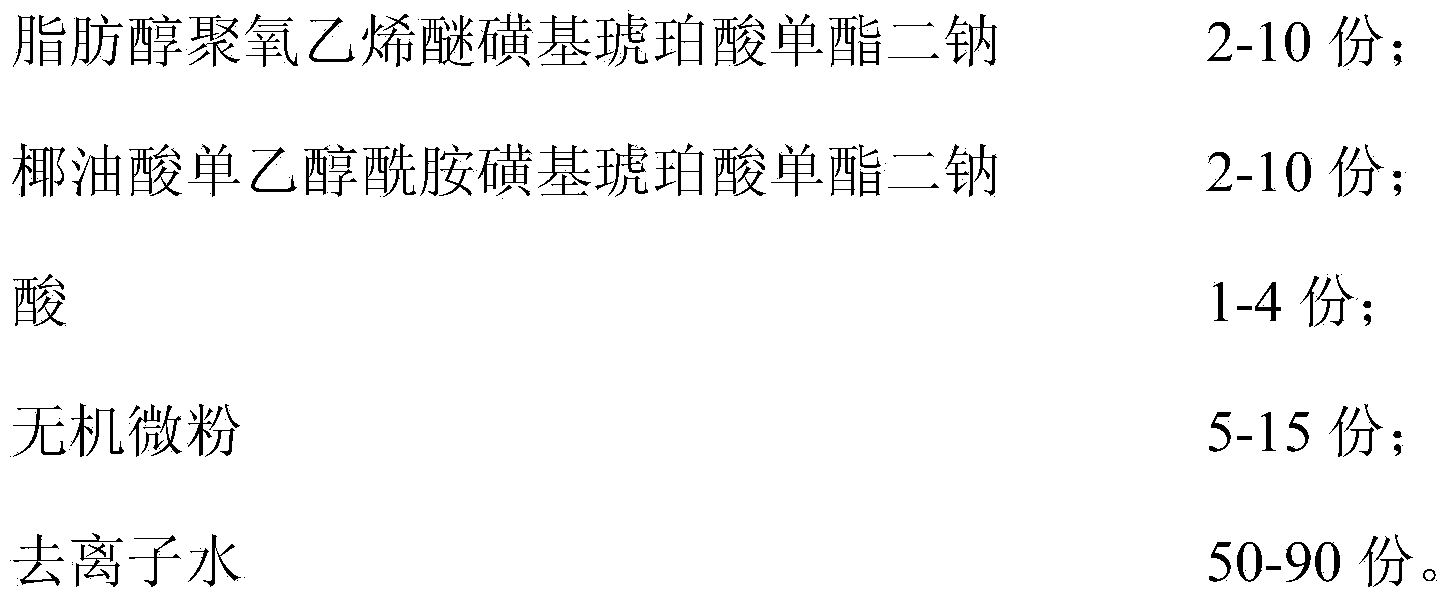

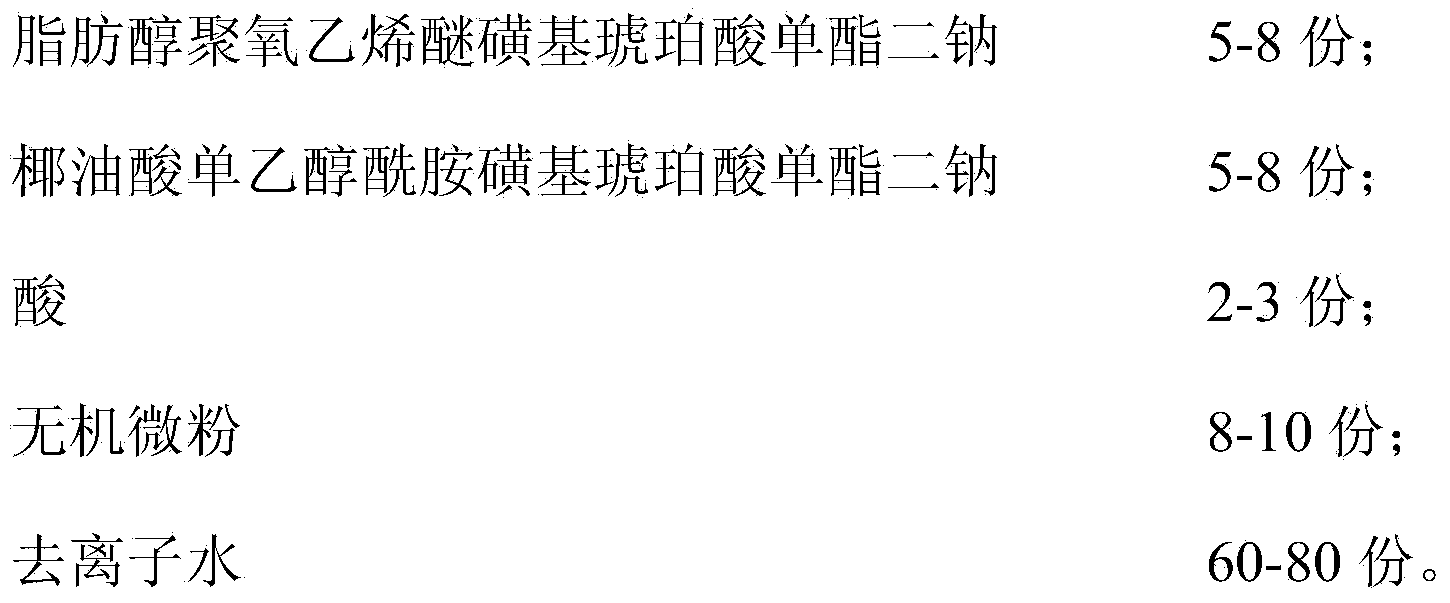

[0044] The raw materials of the warm mix asphalt modifier include: 15 parts of disodium fatty alcohol polyoxyethylene ether sulfosuccinate monoester, 15 parts of disodium cocoic acid monoethanolamide sulfosuccinate monoester, 5 parts of acid, inorganic micropowder 20 parts, 45 parts of water.

[0045] Add fatty alcohol polyoxyethylene ether monosodium sulfosuccinate, monoethanolamide sulfosuccinate disodium cocoate, inorganic micropowder and deionized water into the reactor according to the above ratio, stir and heat up to 50°C , add an acid catalyst, adjust the pH to 5.5, and react at a constant temperature of 70°C for 2 hours to obtain a warm mix asphalt modifier.

Embodiment 2

[0046] Embodiment 2 Preparation of Warm Mix Asphalt Modifier

[0047] Warm mix asphalt additives include in parts by weight: 0.5 part of disodium fatty alcohol polyoxyethylene ether sulfosuccinate monoester, 0.2 part of disodium cocoyl monoethanolamide sulfosuccinate monoester, 0.2 part of acid, and inorganic micropowder 4.0 parts, water 95.1 parts.

[0048] Add fatty alcohol polyoxyethylene ether monosodium sulfosuccinate, cocoic acid monoethanolamide sulfosuccinate disodium, inorganic micropowder and deionized water into the reactor according to the above ratio, stir and heat up to 70°C , add an acid catalyst, adjust the pH to 6.5, and react at a constant temperature of 90°C for 0.5 hours to obtain a warm mix asphalt modifier.

Embodiment 3

[0049] Example 3 Warm mix asphalt production process conditions

[0050] Warm mix asphalt additives include, in parts by weight: 6 parts of disodium fatty alcohol polyoxyethylene ether sulfosuccinate monoester, 7 parts of disodium cocoic acid monoethanolamide sulfosuccinate monoester, 3 parts of acid, and inorganic micropowder 10 parts, 75 parts of deionized water.

[0051] Add fatty alcohol polyoxyethylene ether monosodium sulfosuccinate, cocoic acid monoethanolamide sulfosuccinate disodium, inorganic micropowder and deionized water into the reactor according to the above ratio, stir and heat up to 70°C , add an acid catalyst, adjust the pH to 6.5, and react at a constant temperature of 90°C for 0.5 hours to obtain a warm mix asphalt modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com