Asphalt warm-mix agent and asphalt mixture mixed by same as well as preparation methods thereof

A technology of asphalt mixture and warm mixing agent, which is applied in the direction of building insulation materials, building components, and climate change adaptation, and can solve the problem of large-area construction of high-grade roads that are difficult to meet, resource-saving, environment-friendly, and construction personnel. Physical health damage and other problems, to achieve the effect of ensuring service life, saving energy and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

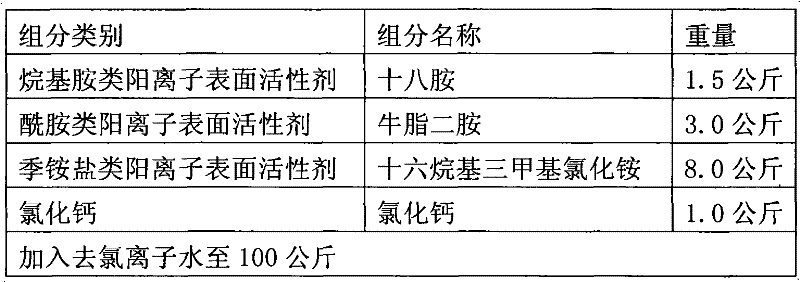

[0034] 1. The composition of asphalt warm mix agent is shown in Table 1:

[0035]

[0036] Table 1: Asphalt Warm Mixing Agent Components and Contents in Example 1

[0037] 2. Preparation of asphalt warm mix agent:

[0038] (1) Slowly add octadecylamine and tallow diamine into water in a variable speed mixer, and stir to make it evenly mixed;

[0039] (2) Add cetyltrimethylammonium chloride in the above-mentioned mixed solution, stir;

[0040] (3) Add calcium chloride then, stir and make it dissolve, make mixed solution stable;

[0041] (4) Stir until evenly mixed.

Embodiment 2

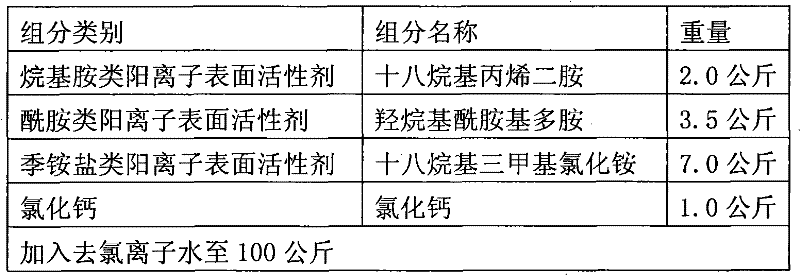

[0043] The composition of the asphalt warm mix agent in this example is shown in Table 2, and its preparation method is the same as that of Example 1.

[0044]

[0045] Table 2: Asphalt Warm Mixing Agent Components and Contents in Example 2

Embodiment 3

[0047] The composition of the asphalt warm mix agent in this example is shown in Table 3, and its preparation method is the same as in Example 1.

[0048] Component category

component name

weight

Alkylamine Cationic Surfactant

Hexadecylpropylenediamine

1.5 kg

Amide Cationic Surfactant

Stearic acid amidopolyamine

4.0 kg

Quaternary Ammonium Cationic Surfactant

Octadecyl Hydroxyethyl Ammonium Bromide

6.5 kg

calcium chloride

calcium chloride

1.0 kg

[0049]

[0050] Table 3: Asphalt Warm Mixing Agent Components and Contents in Example 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com