Cleaning agent with cronobacter spp. biofilm inhibiting effect and preparation method and application of cleaning agent

A Cronobacter and biofilm technology, applied in the field of biomedicine, can solve the problems of complicated preparation methods and frequent occurrence of bacterial drug resistance, and achieve the effects of simple preparation, reduced pollution and harm, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: preparation of chitosan oligosaccharide mixture

[0041] Chitosan with a deacetylation degree of 95% was hydrolyzed with chitosanase to obtain a mixture, which contained 16.7% chitobiose, 11.7% chitotriose, 13.6% chitotetraose, 9.5% chitopentaose, and 8.3% chitosan %, chitosan 7.6%, chitosan 6.2%, chitosan 5.1%, chitosan 4.9%, chitosan 3.1%, chitosan 2.2%, chitosan 1.3%, chitosan 14 Sugar 1.2%, Pentadecanoose 1.6%, Hexadecanose 1.2%, Heptadecanose 1.3%, Octadecanose 1.8%, Nonadecanose 1.5%, Eicosan 1.2%, the above percentage content Both refer to quality scores.

Embodiment 2

[0042] Embodiment 2: preparation of chito-oligosaccharide mixture

[0043] Chitin is hydrolyzed with chitinase to obtain a mixture, which contains 12.8% chitobiose, 16.7% chitotriose, 8.6% chitinotetraose, 7.6% chitopentaose, and 10.3% chitohexaose , chitin heptaose 6.2%, chitooctaose 7.9%, chitin nine sugar 8.1%, chitin decaose 3.3%, chitin undecanose 1.8%, chitin decaose 2.3%, chitin thirteen sugar 2.8%, chitin tetradecanoose 2.5%, chitin pentadecose 2.1%, chitin hexadecanose 1.9%, chitin heptadecanose 1.2%, chitin octadecanoose 1.3%, chitin nonadecanose 1.5% , Chitoeicosan 1.1%, the above percentages refer to mass fractions.

Embodiment 3

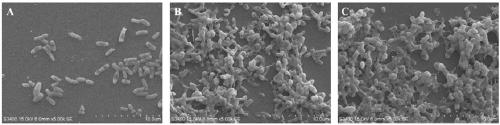

[0044] Example 3: Biofilm formation after cleaning with different cleaning agents

[0045](1) In this example, the effects of the cleaning agent of the present invention and common cleaning agents on the apparent morphology of the biofilm were compared. The specific implementation is as follows: 15 parts of chitosan oligosaccharide mixture, 7 parts of sodium lauroyl sarcosinate, 8 parts of cocamidopropyl betaine, 6 parts of decyl glucoside, 4 parts of glycerin, 60 parts of water, and the heating temperature is 35°C , and stir to combine until clear. Set up control group 1 simultaneously: common commercially available feeding bottle dishwashing agent (domestic product, composition is: glycerin 4%, cocamidopropyl betaine 8%, decyl glucoside 6%, aloe extract 3%, all the other are water Control group 2: common commercially available baby bottle dishwashing agent (imported product, composition: glycerin 4%, cocamidopropyl betaine 8%, sodium lauroyl sarcosinate 7%, methylisothiazol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com