Multifunctional liquid soap containing amino propanesulfonic acid inner salt structure, and preparation method for multifunctional liquid soap

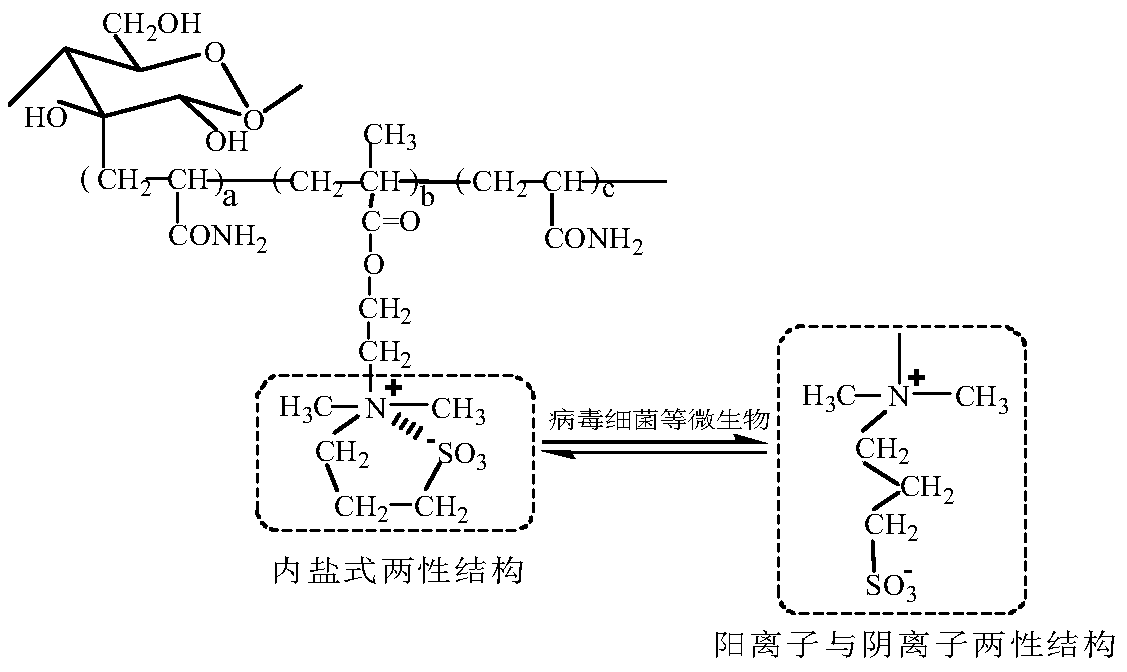

An aminopropanesulfonic acid and multi-functional technology, which is applied in the field of detergents, can solve the problems of small cationic quaternary ammonium salt molecules, can not meet the requirements of use, and short hand contact time, so as to improve the ecological degradable effect and improve sterilization and disinfection. effect, the effect of reducing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the multifunctional hand sanitizer containing aminopropanesulfonic acid internal salt formula amphoteric structure of the present invention specifically comprises the following steps:

[0035] Step 1: Mix 20-25 parts of starch with 100-130 parts of deionized water and 0.2-0.3 parts of high-temperature α-amylase according to parts by weight, heat to 90°C-95°C, keep warm for 2.5-3.5 hours to perform degradation reaction, and obtain Degraded starch solution;

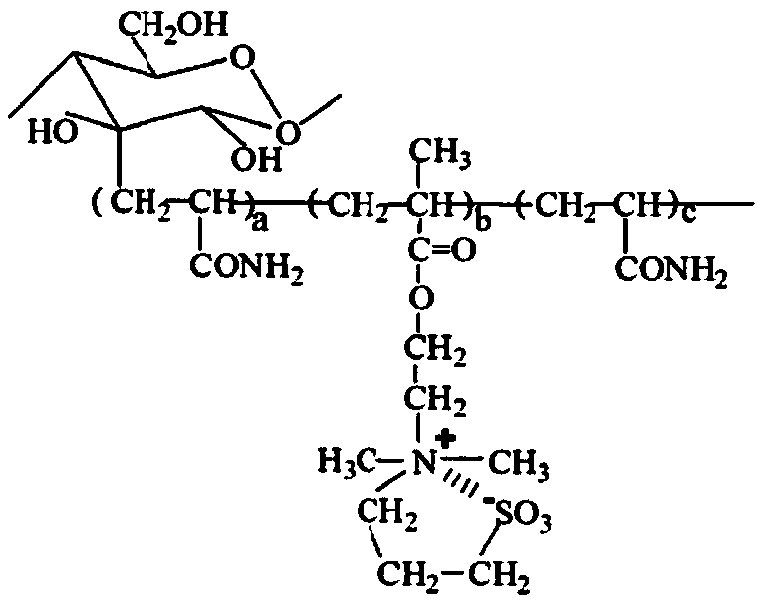

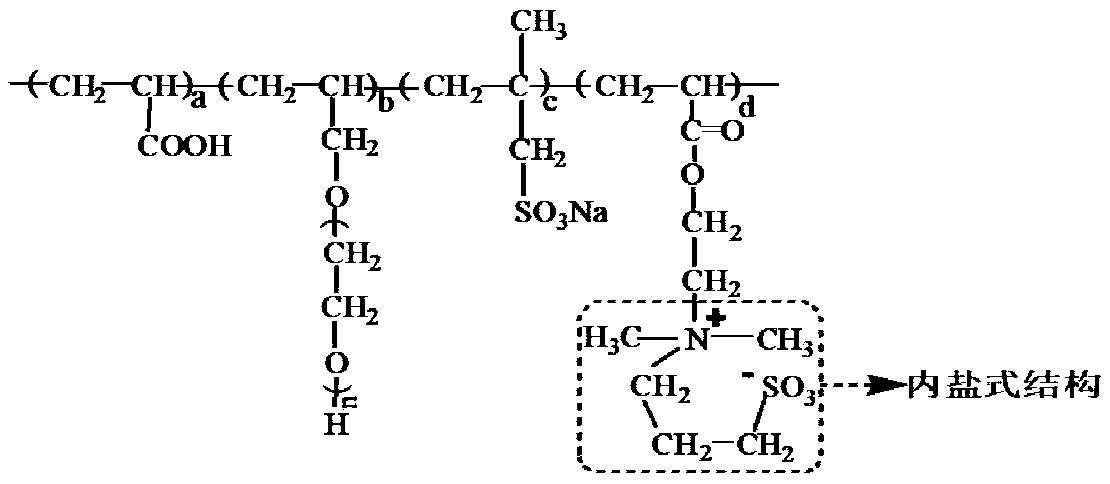

[0036]Step 2: Add 10 to 12 parts of N,N-dimethyl (methacryloyloxyethyl) aminopropanesulfonic acid inner salt and 6 to 8 parts of acrylamide to the above degraded starch solution, stir and heat to 40 At ~45°C, add 4 to 6 parts of buffer solution to adjust the pH value of the system to 6.3 to 6.5, and at the same time add 5 to 8 parts of horseradish peroxidase solution with a mass fraction of 0.09% to 0.15% and a mass fraction of 30% 8 to 10 parts of hydrogen peroxide solution, and the droppi...

Embodiment 1

[0058] Step 1. Mix 20 parts of starch with 100 parts of deionized water and 0.2 parts of high-temperature α-amylase in parts by mass, heat to 90° C., and keep warm for 2.5 hours for degradation reaction to obtain a degraded starch solution;

[0059] Step 2. Add 10 parts of N,N-dimethyl(methacryloyloxyethyl)aminopropanesulfonic acid inner salt and 6 parts of acrylamide to the above degraded starch solution, stir and heat to 40°C, add buffer 4 parts of the solution to adjust the pH value of the system to 6.3, while 5 parts of horseradish peroxidase solution with a mass fraction of 0.09% and 8 parts of a hydrogen peroxide solution with a mass fraction of 30% were added dropwise, and the dropping time was controlled to be 2.0 hours After the dropwise addition is completed, continue the heat preservation reaction for 4.5 hours to obtain the modified starch;

[0060] Step 3: Add 25 parts of polyether macromonomer, 15 parts of N,N-dimethyl (methacryloyloxyethyl) aminopropanesulfonic ...

Embodiment 2

[0067] Step 1. Mix 23 parts of starch with 120 parts of deionized water and 0.25 parts of high-temperature α-amylase in parts by mass, heat to 95° C., and keep warm for 3.5 hours for degradation reaction to obtain a degraded starch solution;

[0068] Step 2. Add 12 parts of N,N-dimethyl(methacryloyloxyethyl) aminopropanesulfonic acid inner salt and 8 parts of acrylamide to the above degraded starch solution, stir and heat to 45°C, add buffer 6 parts of the solution to adjust the pH value of the system to 6.5, while 7 parts of the horseradish peroxidase solution with a mass fraction of 0.12% and 9 parts of a hydrogen peroxide solution with a mass fraction of 30% were added dropwise, and the dropping time was controlled to be 2.5 hours , after the dropwise addition, continue the heat preservation reaction for 5.5 hours to obtain the modified starch;

[0069] Step 3: Add 30 parts of polyether macromonomer, 18 parts of N,N-dimethyl (methacryloyloxyethyl) aminopropanesulfonic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com