High-shearing and high-bonding coating material and preparation method thereof

A technology of high adhesion and coating materials, applied in the field of coatings, can solve problems such as insufficient adhesion, poor temperature adaptability, weak adhesion, etc., to achieve increased interlayer adhesion, strong waterproof performance, The effect of not easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

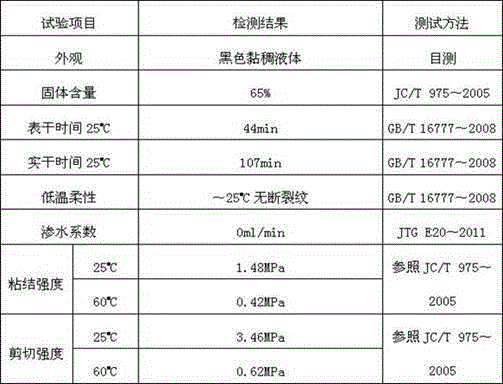

Embodiment 1

[0028] A high-shear and high-cohesive coating material, which is composed of 0.4 parts of powdered nitrile rubber, 0.3 parts of flame retardant, 0.2 parts of reactive tackifier, 5 parts of asphalt modifier, and asphalt 25 parts of base powder, 35 parts of base pitch, and 35 parts of solvent. The specific configuration steps are as follows:

[0029] Step 1: Mix ethyl acetate, butyl acetate, xylene, etc. by weight at room temperature uniformly to form a solvent;

[0030] Step 2. Add 0.4 parts of powdered nitrile butadiene rubber, 0.3 parts of flame retardant, 5 parts of asphalt modifier, and 25 parts of asphaltene powder to the prepared solvent at room temperature, stir evenly, and place it in a sealed container until completely dissolved;

[0031] Step 3: 35 parts of A70 base asphalt are heated to 135 o After C, add 0.2 parts of stabilizer to the base asphalt and stir until it melts;

[0032] Step 4. Slowly inject the mixed asphalt in step 3 into the mixture obtained in step 2 and sti...

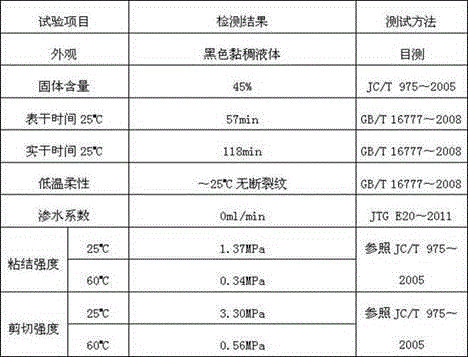

Embodiment 2

[0036] A high-shear and high-cohesive coating material, which is composed of 0.5 parts by weight of powdered nitrile rubber, 0.25 parts of flame retardant, 0.25 parts of reactive tackifier, 4 parts of asphalt modifier, and asphalt 20 parts of base powder, 30 parts of base pitch, 45 parts of solvent. The specific configuration steps are as follows:

[0037] Step 1: Mix ethyl acetate, butyl acetate, xylene, etc. by weight at room temperature uniformly to form a solvent;

[0038] Step 2: Add 0.5 parts of powdered nitrile rubber, 0.25 parts of flame retardant, 4 parts of asphalt modifier, and 20 parts of asphaltene powder to the prepared solvent at room temperature, stir evenly, and place it in a sealed container until completely dissolved;

[0039] Step 3: 30 parts of A70 base asphalt are heated to 135 o After C, add 0.25 parts of stabilizer to the base asphalt, stir and let it melt;

[0040] Step 4. Slowly inject the mixed asphalt obtained in Step 3 into the mixture obtained in Step 2 ...

Embodiment 3

[0044] A high-shear and high-cohesive coating material, which is composed of 0.6 parts by weight of powdered nitrile rubber, 0.2 parts of flame retardant, 0.3 parts of reactive tackifier, 3 parts of asphalt modifier, and asphalt 15 parts of base powder, 25 parts of base pitch, 55 parts of solvent. The specific configuration steps are as follows:

[0045] Step 1: Mix ethyl acetate, butyl acetate, xylene, etc. uniformly to form a solvent at room temperature;

[0046] Step 2. Add 0.5 parts of powdered nitrile butadiene rubber, 0.25 parts of flame retardant, 3 parts of asphalt modifier, and 15 parts of asphaltene powder to the prepared solvent at room temperature, stir evenly, and place it in a sealed container until completely dissolved;

[0047] Step 3: Heat 15 parts of A~70 base pitch to 135 o After C, add 0.25 parts of stabilizer to the base asphalt, stir and let it melt;

[0048] Step 4. Slowly inject the mixed asphalt in step 3 into the mixture obtained in step 2 and stir evenly to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com