Two-stage warm-mix rubber asphalt method and its products

A rubber asphalt, two-stage technology, applied in the field of rubber asphalt, can solve the problems of no energy saving and emission reduction, and achieve the effects of energy saving, environmental pollution reduction and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

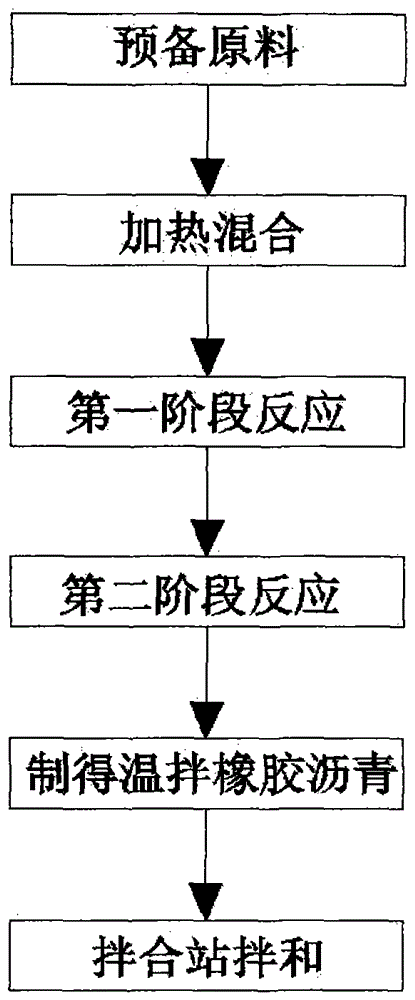

[0036] Embodiment 1: see figure 1 , a two-stage warm-mix rubber asphalt method provided in this embodiment is characterized in that it comprises the following steps:

[0037] (1) Preparing raw materials: each component and weight percentage of raw materials are as follows:

[0038] Base asphalt 75-80%,

[0039] Waste tire rubber powder 16-20%,

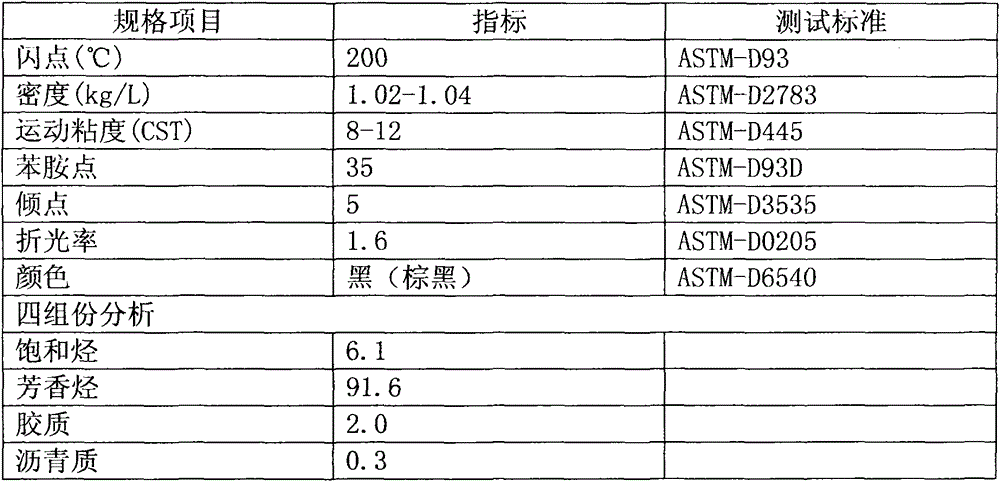

[0040] Reduce line oil by 1 to 3%,

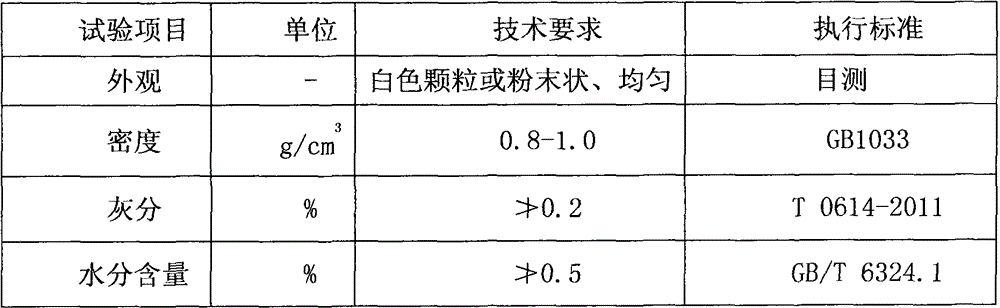

[0041] RH asphalt warm mix modifier 1~3%;

[0042] (2) Heating and mixing: heat the base asphalt to above 190°C, then add waste tire rubber powder to the base asphalt, and stir evenly to obtain a rubber asphalt mixture;

[0043] (3) The first-stage reaction: adding the rubber asphalt mixture to the reactor, then adding the line-reducing oil into the reactor, and heating and stirring at 170-180° C.; the step (3) specifically includes the following steps: ( 3.1) After adding the rubber asphalt mixture to the reactor, immediately add the line oil into the reactor, and keep the reactor at 170-180°C...

Embodiment 2

[0051] Example 2, the two-stage warm-mix rubber asphalt method and its products provided in this example, its components and production steps are basically the same as in Example 1, the difference is that the components of the raw materials and their weight percentages are as follows :

[0052] Base bitumen 78%,

[0053] Waste tire rubber powder 18%,

[0054] Minus line oil 3%,

[0055] RH asphalt warm mix modifier 1%.

Embodiment 3

[0056] Example 3, the two-stage warm-mix rubber asphalt method and its products provided in this example, its components and production steps are basically the same as in Example 1, the difference is that the components of the raw materials and their weight percentages are as follows :

[0057] Base bitumen 80%,

[0058] Waste tire rubber powder 16%,

[0059] Minus line oil 1%,

[0060] RH asphalt warm mix modifier 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com