Resin-rich epoxy glass powder mica tape

A technology of adhesive epoxy glass, powder mica tape, applied in mica, winding insulation materials, insulators and other directions, can solve the problems of poor quality stability of less tape, complex process requirements, large one-time investment, etc., to improve the performance of cured products, The effect of improving processing efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

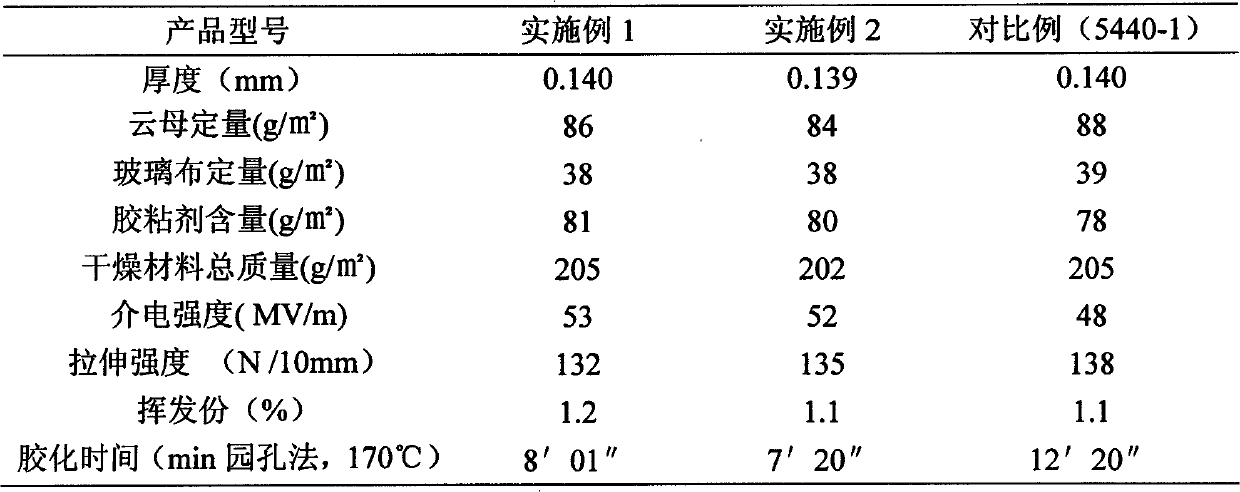

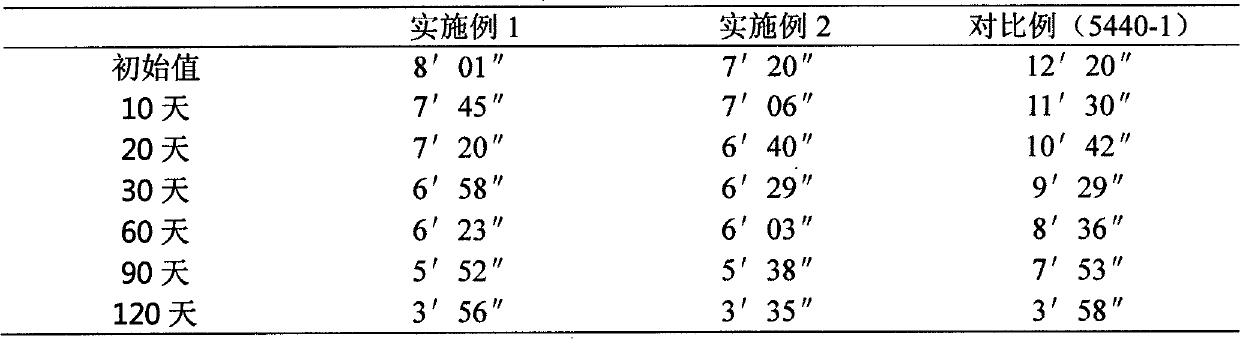

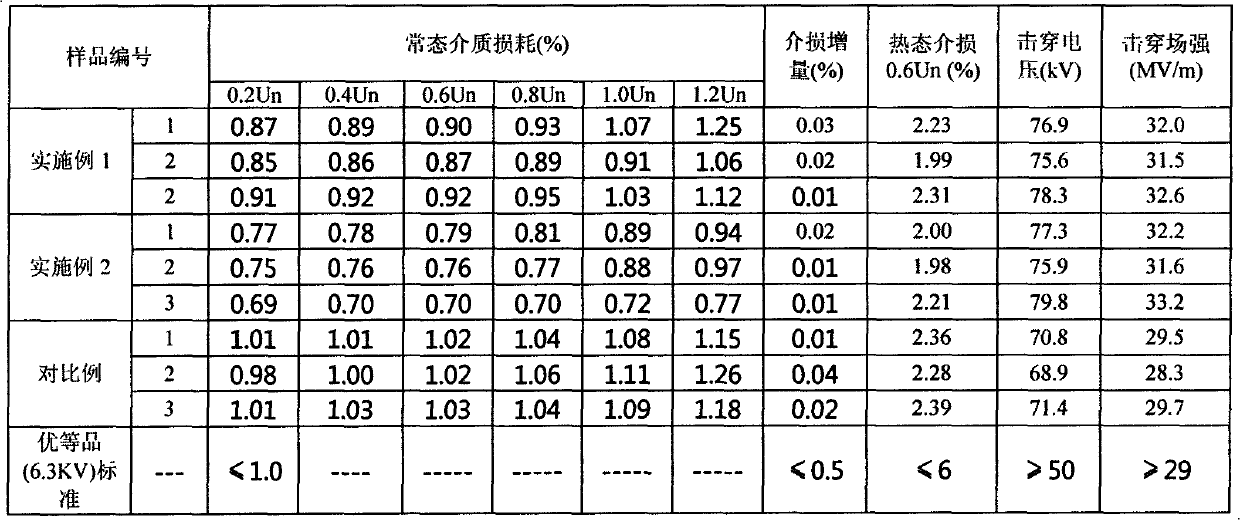

Examples

Embodiment 1

[0019] 1. Preparation of adhesive

[0020] 10 parts of bisphenol A epoxy resin (E44 of Blue Star Company), 5 parts of silicone-modified epoxy resin (R-33 of Jiaxing Rongtai Plastic Co., Ltd.), 15 parts of novolac epoxy resin (F44 of Blue Star Company) 20 parts, 20 parts of bismaleimide tungoleic anhydride, 10 parts of methyl hexahydrophthalic anhydride, 0.6 parts of cerium Ce salt of acetylacetonate, 20 parts of toluene, and 20 parts of acetone. Mix together evenly and serve.

[0021] 2. Fabrication of mica tape

[0022] Two layers of electrician's non-alkali glass cloth (quantitatively 20g / m 2 ), glued by scraping or dipping at room temperature, and compounded with 501 paper (quantitatively 85g / m 2 ), control the glue content between 36-42wt% to obtain a three-in-one compound, bake the three-in-one compound at a temperature of 100-130°C for about 5-10 minutes, and control the volatile matter below 1.5% , through winding and cutting, the low-temperature fast-curing epoxy g...

Embodiment 2

[0024] 1. Preparation of adhesive

[0025] With 15 parts of bisphenol A epoxy resin (DER337 of DOW company), 5 parts of epoxy resin (Jiaxing Rongtai plastic company R-3) of organosilicon modification, 4 parts of novolak epoxy resin (DER431 of DOW company), 30 parts of bismaleimide tungoleic anhydride, 6 parts of methylnadic anhydride, 0.5 parts of neodymium triacetylacetonate, 2 parts of diethoxydimethylsilane, 20 parts of toluene, and 20 parts of acetone. Mix together evenly and serve.

[0026] 2. Fabrication of mica tape

[0027] Two layers of electrician's non-alkali glass cloth (quantitatively 18g / m 2 ), glued by scraping or dipping at room temperature, and compounded with 501 paper (quantitatively 85g / m 2 ), control the glue content between 36-42% to obtain a three-in-one compound, bake the three-in-one compound at a temperature of 100-130°C for about 5-10 minutes, and control the volatile content below 1.5% , through winding and cutting, the low-temperature fast-curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com