A kind of preparation method of 1300mpa grade rare earth reverse transformation q&p steel

A reverse conversion and rare earth technology, applied in the field of iron and steel metallurgy, can solve problems such as increasing costs, and achieve the effect of improving welding performance, increasing content and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present invention relates to a preparation method of 1300MPa grade rare earth reverse transformation Q&P steel, the preparation steps of which are: (1) smelting and casting of the steel plate: the composition is: C: 0.17%, Mn: 2.31%, Si: 1.10 %, Al: 0.80%, V: 0.06%, B: 0.002%, and the balance is Fe and unavoidable impurities. The composition powder of the present invention is smelted in an electric arc furnace, transferred to an IF furnace for refining, and fed Adding 5% cerium, 2.5% lanthanum, the rest is Fe and other unavoidable impurities mixed rare earth ferroalloy by wire method to make cast slab.

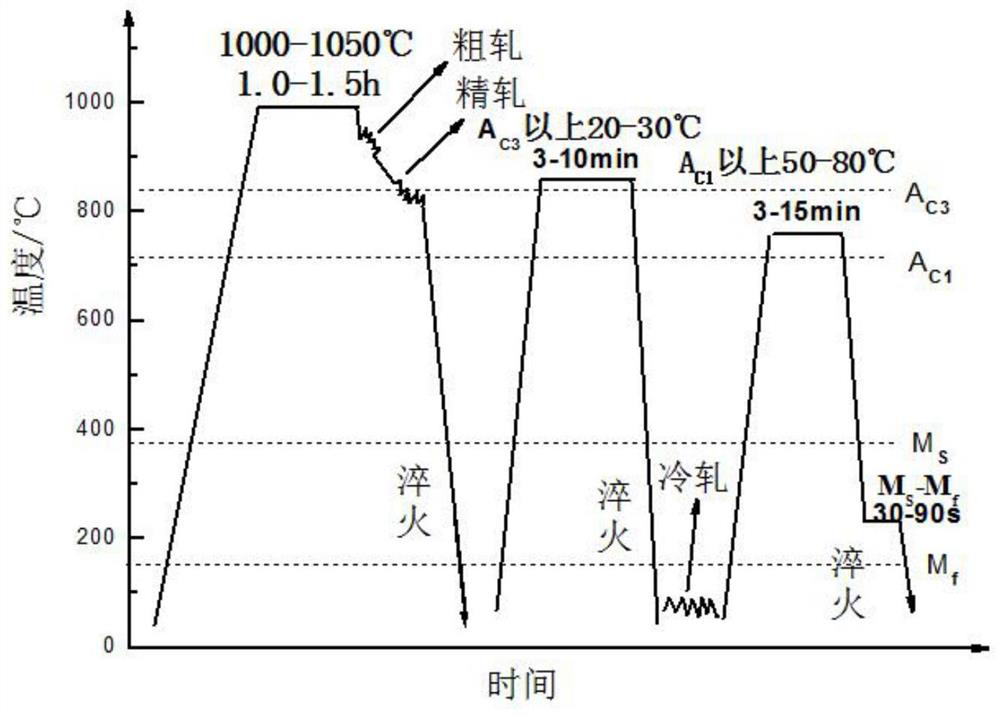

[0036] (2) Heat preservation, hot rolling, and quenching: heat the cast slab to 1050°C, hold heat for 1.2h, carry out hot rolling after heat preservation, start rolling at 950°C, and finish rolling at 850°C to obtain a 1.8mm thick steel plate , quenched to room temperature.

[0037] (3) The first reverse transformation heat preservation quenching: heat the steel pl...

Embodiment 2

[0043] The present invention relates to a preparation method of 1300MPa grade rare earth reverse transformation Q&P steel, the preparation steps of which are: (1) smelting and casting of the steel plate: the composition is: C: 0.17%, Mn: 2.31%, Si: 1.10 %, Al: 0.80%, V: 0.06%, B: 0.002%, and the balance is Fe and unavoidable impurities. The composition powder of the present invention is smelted in an electric arc furnace, transferred to an IF furnace for refining, and fed Adding 5% cerium, 2.5% lanthanum, the rest is Fe and other unavoidable impurities mixed rare earth ferroalloy by wire method to make cast slab.

[0044] (3) Heat preservation, hot rolling, and quenching: heat the cast slab to 1050°C, hold heat for 1.2h, conduct hot rolling after heat preservation, start rolling at 950°C, and finish rolling at 850°C to obtain a 1.8mm thick steel plate , quenched to room temperature.

[0045] (3) The first reverse transformation heat preservation quenching: heat the steel plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com