Preparation method of Zn-Al-Ni anticorrosion functional impregnation layer

A technology of zn-al-ni and infiltration layer, applied in coating, solid-state diffusion coating, metal material coating process, etc., can solve the problems of difficult screwing of bolts, easy damage of screwing, electro-galvanizing pollution, etc. Achieve the effects of easy industrialized mass production, recyclable powder, and controllable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

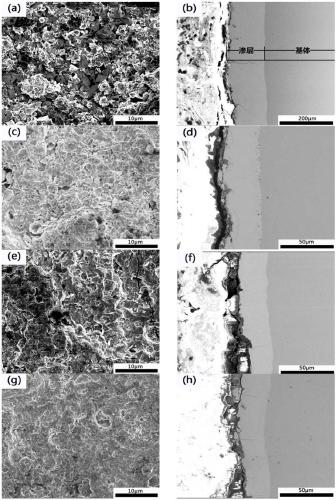

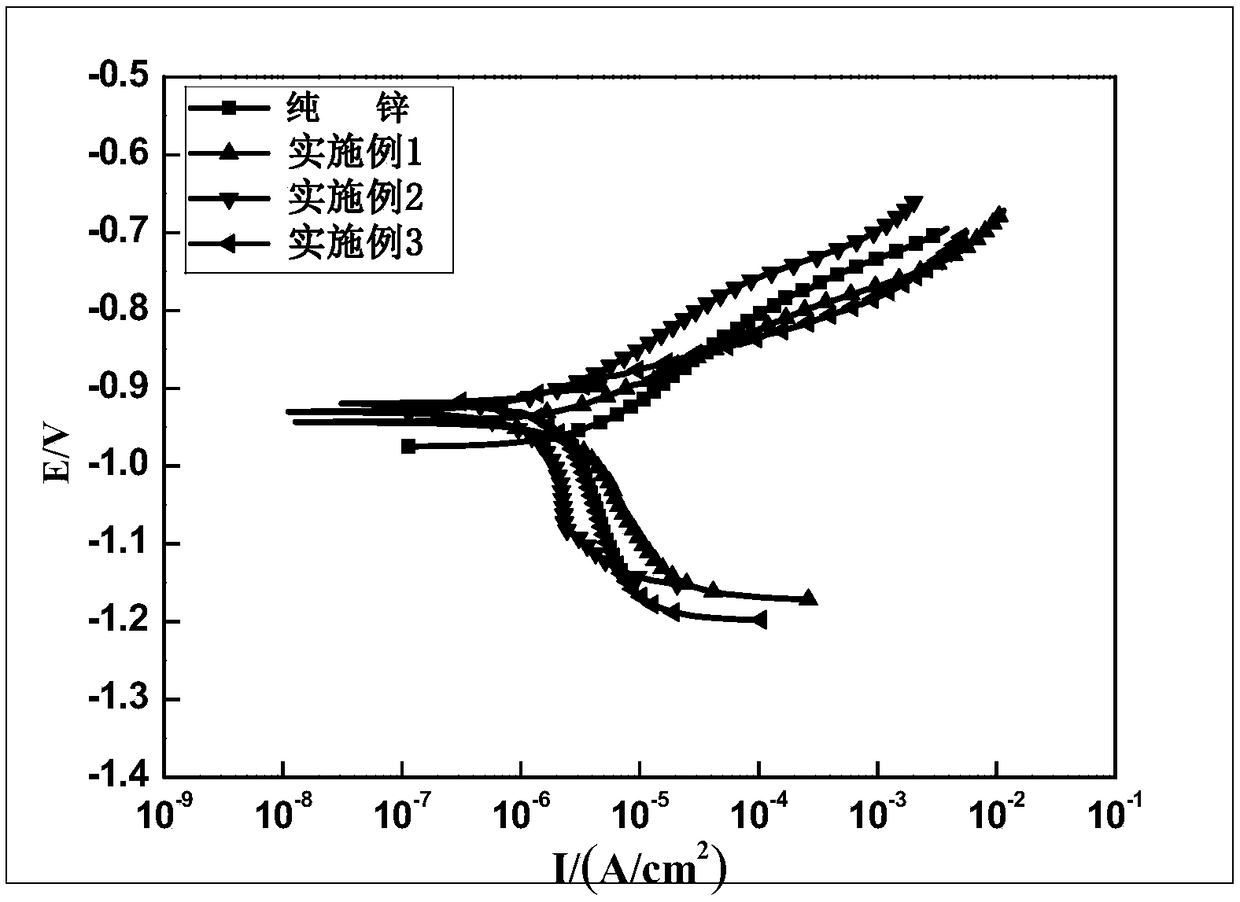

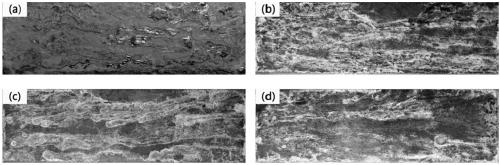

Embodiment 1

[0030] The Zn-Al-Ni anti-corrosion functional impregnation layer of the present embodiment is prepared by the following preparation process parameters and steps:

[0031] 1) Substrate treatment: Put the substrate into the ultrasonic cleaning device for cleaning for 20 minutes to remove the oil stain on the surface of the substrate. After the substrate is taken out and blown dry, the substrate is put into the shot blasting equipment, and the steel shot with a diameter of 0.2mm is used to The substrate is shot blasted for 10 minutes to remove the rust on the surface of the substrate;

[0032] 2) Infiltration agent configuration: According to the infiltration agent formula (100 parts in total): 35 parts of zinc powder (400 mesh), 15 parts of aluminum powder (325 mesh), 1 part of nickel powder (300 mesh), 0.5 part of rare earth (400 mesh) (Mass percentage is 30% La, 55% Ce and 15% Nb), Al 2 O 3 48.48 parts of powder (200 mesh) were respectively weighed and mixed evenly with a po...

Embodiment 2

[0037] The Zn-Al-Ni anti-corrosion functional impregnation layer of the present embodiment is prepared by the following preparation process parameters and steps:

[0038] 1) Substrate treatment: Put the substrate into the ultrasonic cleaning device for cleaning for 20 minutes to remove the oil stain on the surface of the substrate. After the substrate is taken out and blown dry, the substrate is put into the shot blasting equipment, and the steel shot with a diameter of 0.2mm is used to The substrate is shot blasted for 10 minutes to remove the rust on the surface of the substrate;

[0039]2) Infiltration agent configuration: According to the infiltration agent formula (100 parts in total): 35 parts of zinc powder (400 mesh), 15 parts of aluminum powder (325 mesh), 1.5 part of nickel powder (400 mesh), 0.5 part of rare earth (400 mesh) (Mass percentage is 30% La, 52% Ce and 18% Nb), Al 2 O 3 47.98 parts of powder (200 mesh) were respectively weighed and mixed evenly with a p...

Embodiment 3

[0044] The Zn-Al-Ni anti-corrosion functional impregnation layer of the present embodiment is prepared by the following preparation process parameters and steps:

[0045] 1) Substrate treatment: Put the substrate into the ultrasonic cleaning device for cleaning for 20 minutes to remove the oil stain on the surface of the substrate. After the substrate is taken out and blown dry, the substrate is put into the shot blasting equipment, and the steel shot with a diameter of 0.2mm is used to The substrate is shot blasted for 10 minutes to remove the rust on the surface of the substrate;

[0046] 2) Infiltration agent configuration: according to the infiltration agent formula (100 parts in total) 35 parts of zinc powder (400 mesh), 15 parts of aluminum powder (325 mesh), 2 parts of nickel powder (400 mesh), 0.5 part of rare earth (400 mesh) ( The mass percentage is composed of 33% La, 52% Ce and 15% Nb), Al 2 O 3 47.48 parts of powder (200 mesh) were respectively weighed and mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com