Patents

Literature

85results about How to "Achieve ultra-low emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

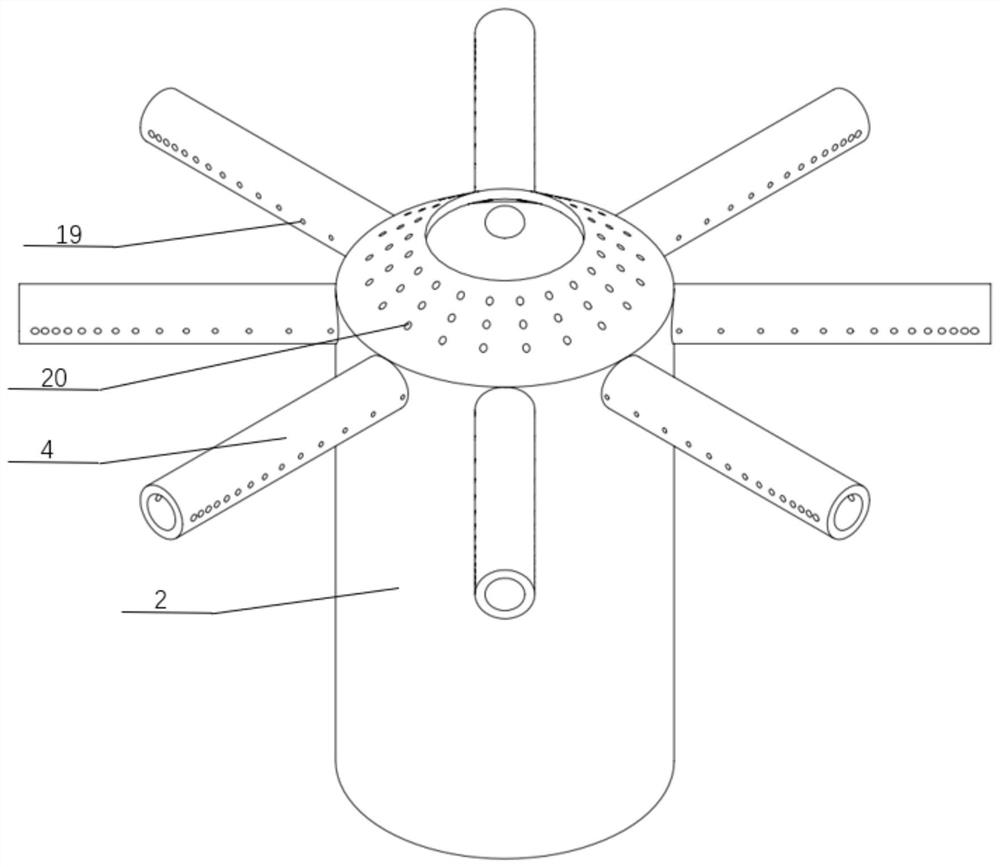

Device and method for removing sulfur trioxide from coal-fired flue gas

PendingCN106345244AWell mixedAchieve ultra-low emissionsGas treatmentDispersed particle separationFlue gasSulfur trioxide

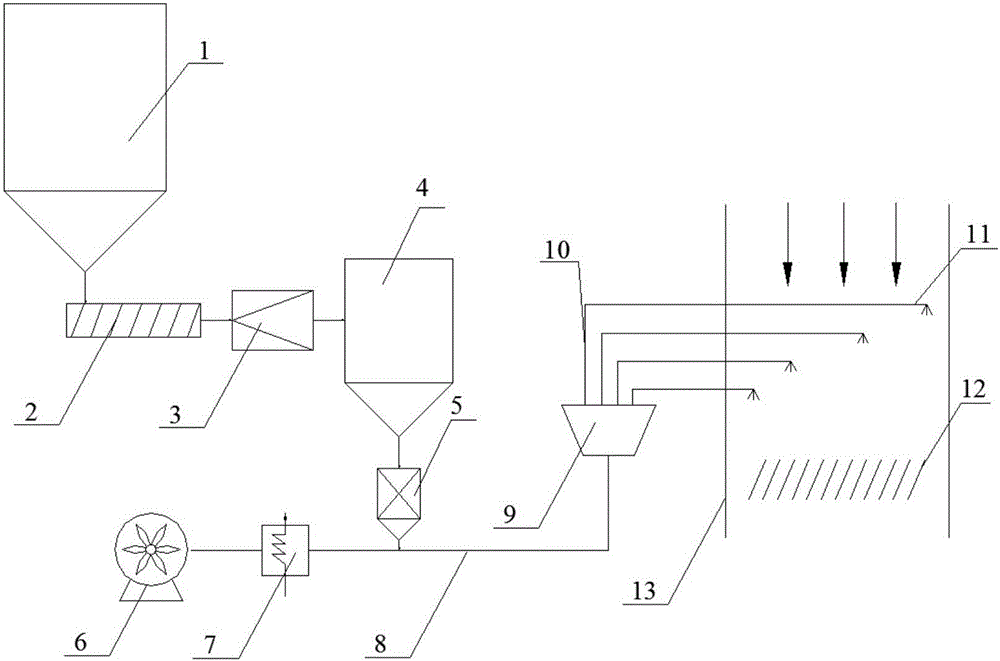

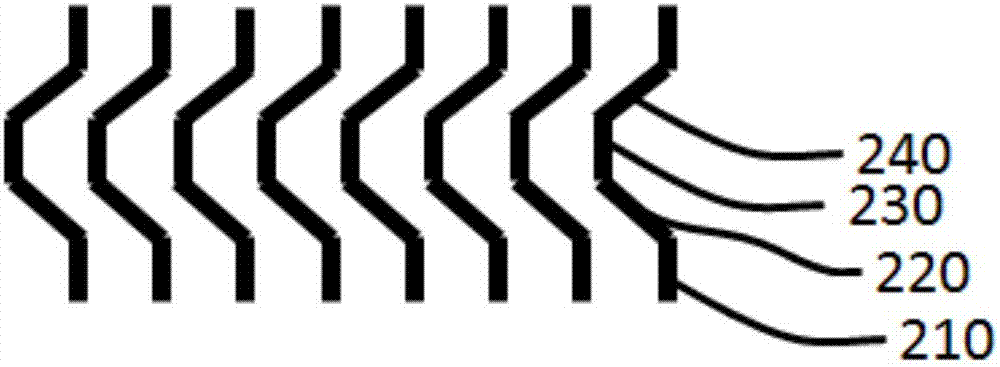

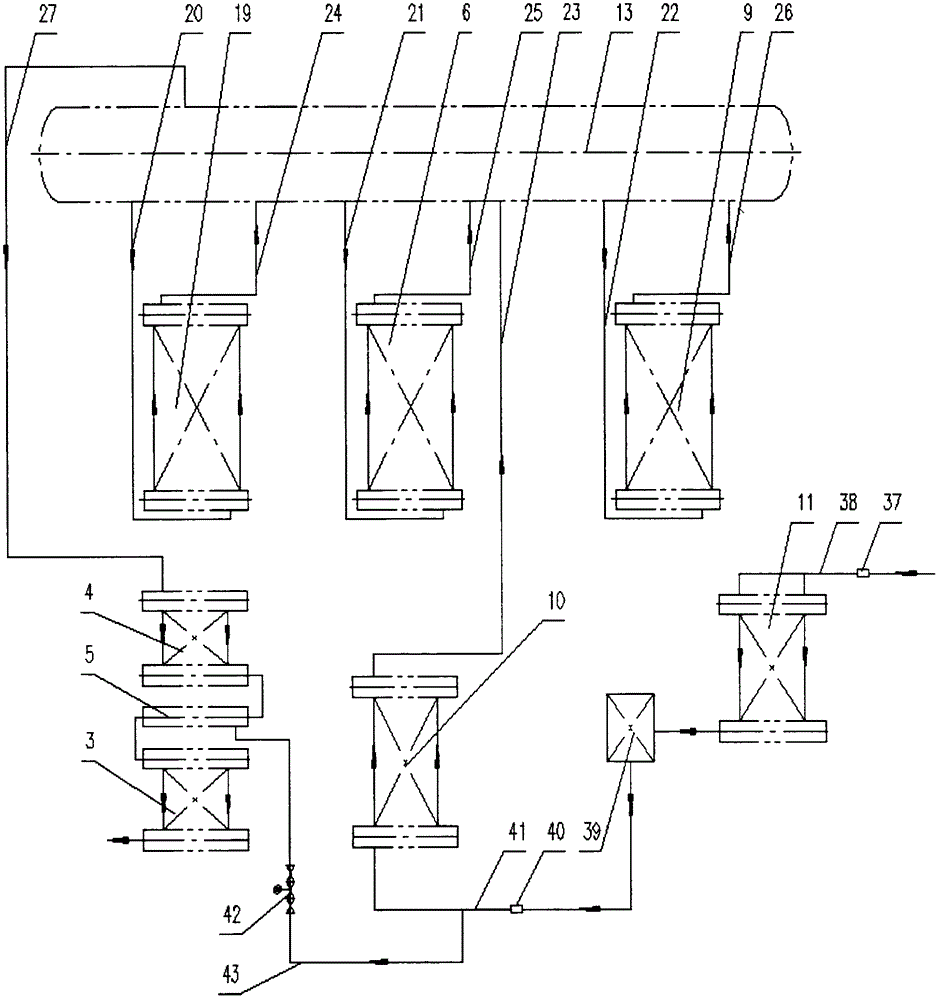

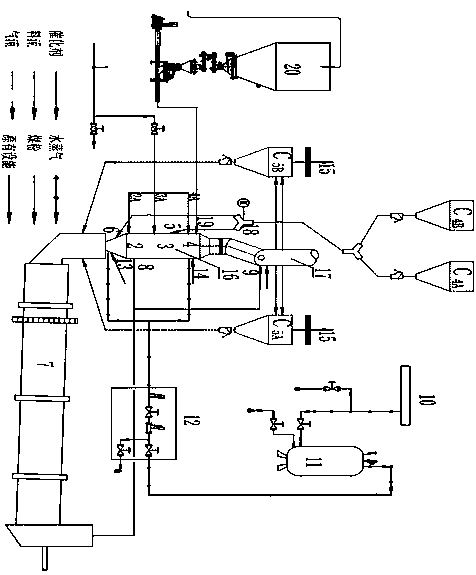

The invention relates to a device and a method for removing sulfur trioxide from coal-fired flue gas. The device comprises a rough stock bin, a screw type feeder, an air gradation mill, a fine stock bin and a weightless type feeder which are connected with each other in turn, wherein the lower part of the weightless type feeder is connected with a main pipeline; air from an air feeder is dried by an air dryer and then is fed into the main pipeline; an alkali absorbent from the weightless type feeder is pneumatically transmitted; a main pipeline terminal is connected with separators; the main pipeline is uniformly divided into a plurality of branches by the separators; a spray gun is respectively connected with each branch; the spray guns are uniformly arranged on a cross section of a flue; a static mixer is arranged on a downstream flue of the spray guns; the alkali absorbents sprayed by the spray guns are uniformly mixed with the flue gas. The device can select different alkali absorbents according to different flue gas conditions and flue positions. The spray guns are used for jetting the alkali absorbents into the flue for absorbing SO3 in the flue gas, so that the harm of SO3 to the operation of the power plant is reduced and the ultralow SO3 emission is realized.

Owner:ZHEJIANG UNIV

Integrated system for efficiently and synergistically removing multiple pollutants

ActiveCN103994456AImprove removal efficiencyImprove compatibilityLighting and heating apparatusAtmospheric pollutionDust collector

The invention relates to an integrated system for efficiently and synergistically removing multiple pollutants. The integrated system reduces discharge values of smoke, SO2, NOx, mercury, SO3 and other main smoke pollutants to achieve the discharge standard of a fuel gas unit. According to the technical scheme, the system comprises an SCR reactor, low-temperature dust removing equipment, a desulfurizing absorption tower and a wet-type electrostatic dust collector, wherein the inlet of the SCR reactor is connected with a smoke outlet through a tail smoke channel of a boiler improved through low-nitrogen combustion, and SCR denitration catalysts are modified catalysts capable of improving oxidation susceptibility of zero-valent mercury; the inlet of the low-temperature dust removing equipment is connected with the outlet of the SCR reactor to be used for removing dust and SO3; the inlet of the desulfurizing absorption tower is connected with the outlet of the low-temperature dust removing equipment to be used for desulfuration and dust removal; the inlet of the wet-type electrostatic dust collector is connected with the outlet of the desulfurizing absorption tower, and the outlet of the wet-type electrostatic dust collector is connected to a chimney through warming equipment to be used for removing the dust, gypsum fogdrops, the mercury and SO3. The integrated system is used for the technical field of atmospheric pollution prevention.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD +1

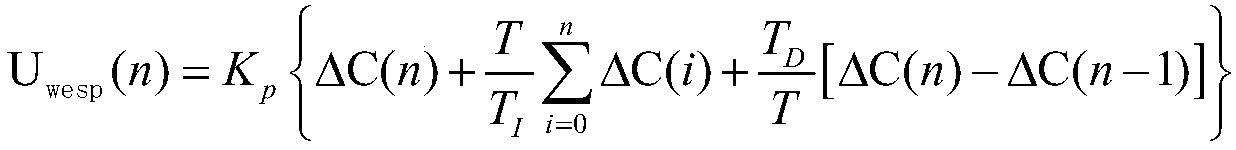

Method for controlling considerable coal-fired boiler NOx discharge by multilevel reduction wind

ActiveCN101245919AEliminate negative issuesAchieve ultra-low emissionsNon-combustible gases/liquids supplyHearthEngineering

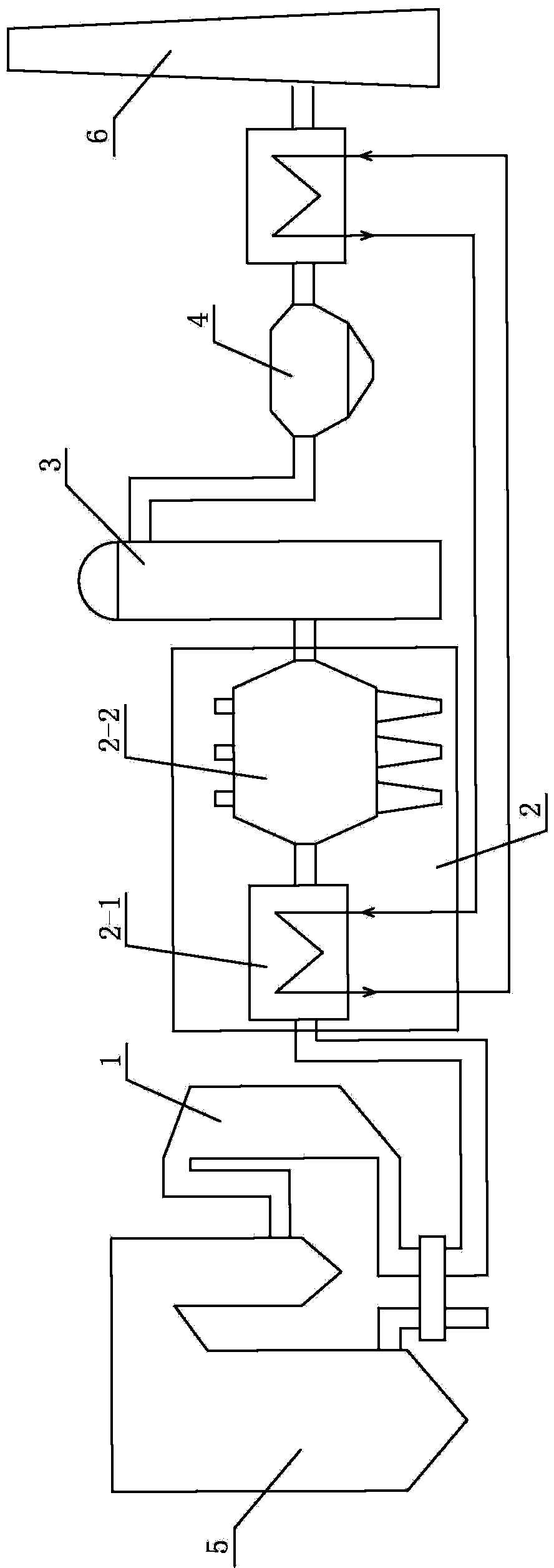

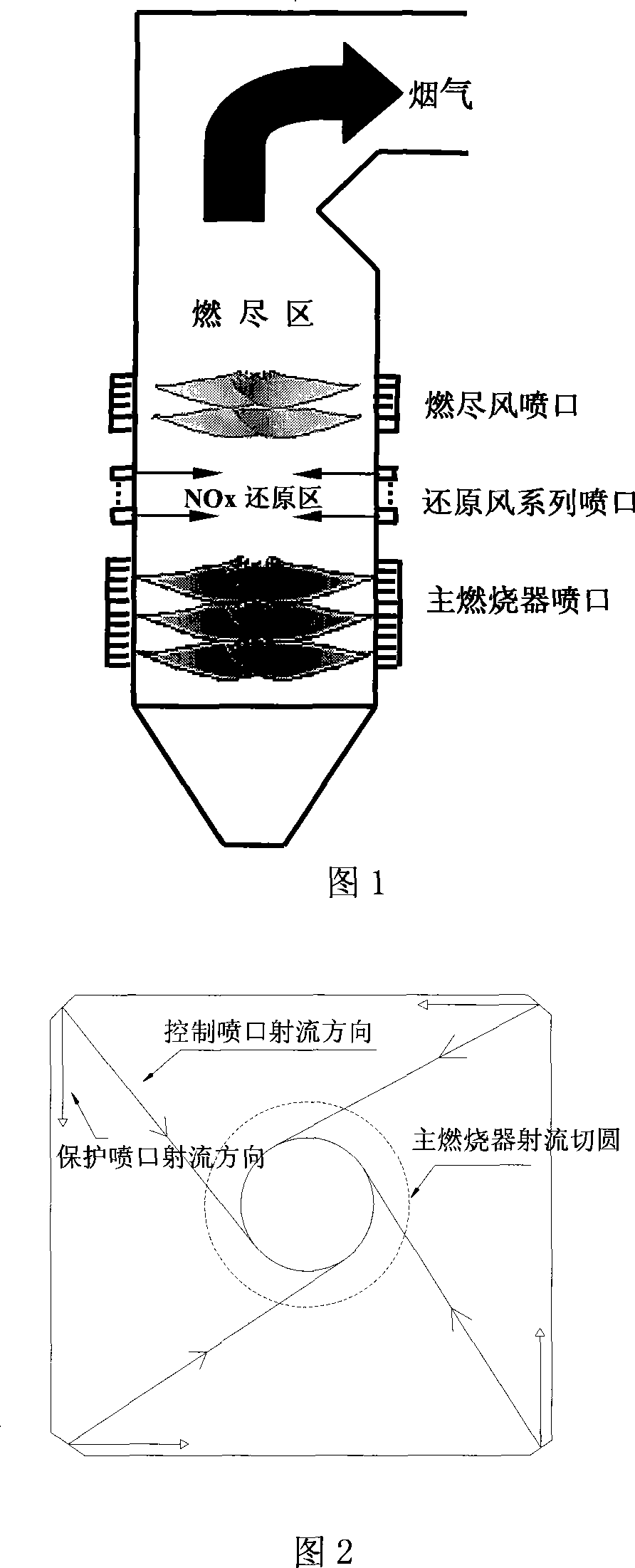

The invention relates to a method used for controlling the exhaust of NOx out of a high-capacity coal burning boiler by a multi-level reduction wind in the environmental protection technical field. A plurality of layers of series reduction wind air spouts are arranged along the stroke in a reduction area between a main burner area at the lower part of a furnace hearth and a burn-out wind spout arranged at the upper part of the furnace hearth. The air which is sprayed out of the series spouts is equal to 13%-20% of the total air quantity which is required by the combustion of the boiler coal-fired quantity and is divided into two parts: one part is used for controlling the oxygen consistency of the flue gas in the reduction area so as to reduce the exhaust of nitrogen oxides and the spouts in this part are called control spouts, while the other part is used for protecting the water cooled wall in the reduction area and the spouts in this part is called protection spouts; the slagging and high temperature corrosion are avoided by the oxidation ambience around the water cooled wall. The method used for controlling the exhaust of NOx out of a large-capacity coal-fired boiler by a multi-step reduction wind has the advantages of further enlarging the air classification degree, reducing the exhaust of the nitrogen oxides to a greater extent, protecting the water cooled wall in the reduction area against slagging or high temperature corrosion, reducing the increase of ash carbon-containing quantity caused by the classification, etc.

Owner:SHANGHAI JIAO TONG UNIV +1

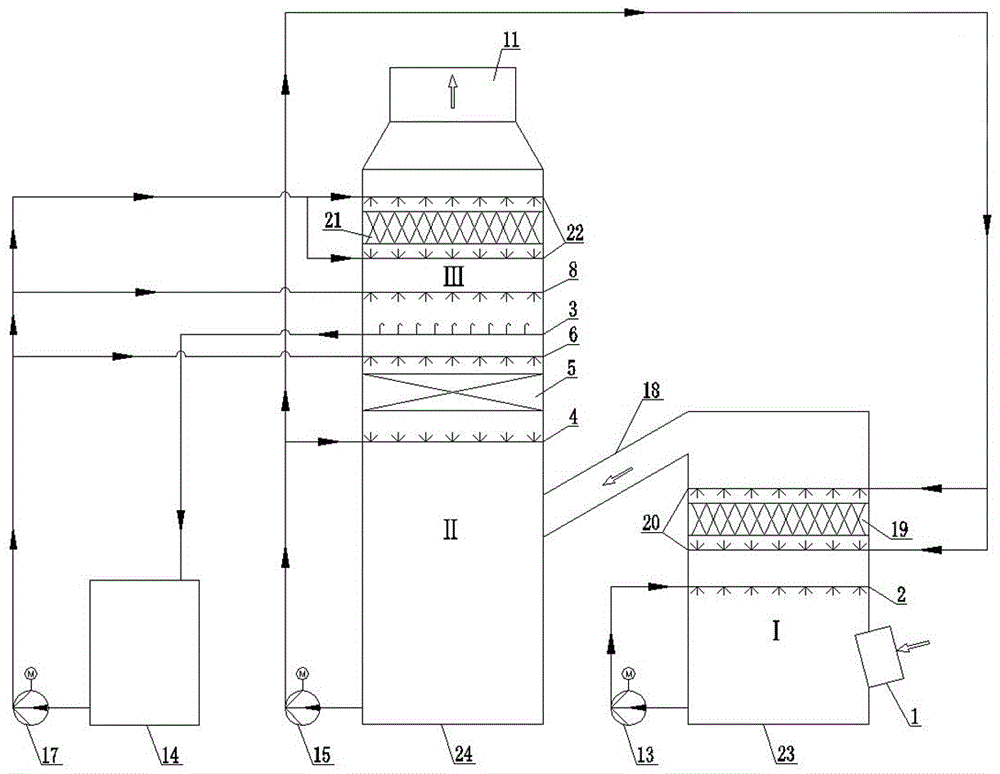

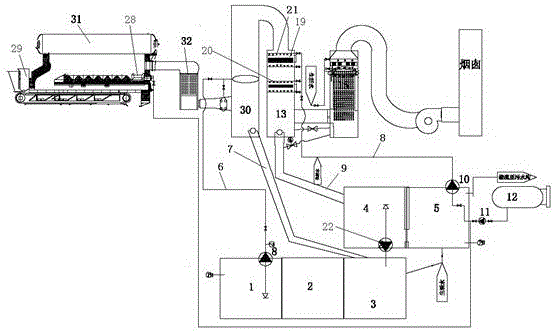

Integrated treating apparatus and treating process for exhaust gas of setting machine used in dyeing and finishing industry

ActiveCN105169863AAchieve ultra-low emissionsHigh removal rateCombination devicesVapor condensationParticulatesAutomatic control

The invention discloses an integrated treating apparatus for exhaust gas of a setting machine. The integrated treating apparatus comprises a spray condensation unit, a wet static oil removing unit, a flue gas discharging unit, an electric control unit and a water treatment unit. The spray condensation unit, the wet static oil removing unit and the flue gas discharging unit are successively connected; the water treatment unit is connected with the wet static oil removing unit and used for treating and recycling waste water produced during treatment of the wet static oil removing unit; and the electric control unit comprises a variety of electric control facilities like an anemometer, a flowmeter and a liquidometer and is used for real-time monitoring and automatic control of each unit of the whole apparatus. According to the invention, water spraying technology and static treatment technology are integrated together instead of simple combination, so integrated wet static technology is realized, the removal rates of particles and oil smoke are increased, ultra-low emission of the oil smoke and the particles is realized, and fire risks brought by dry static treating technology are eradicated; thus, almost zero release is actually realized.

Owner:ZHEJIANG CREATE ENVIRONMENTAL TECH

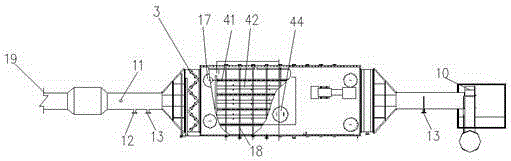

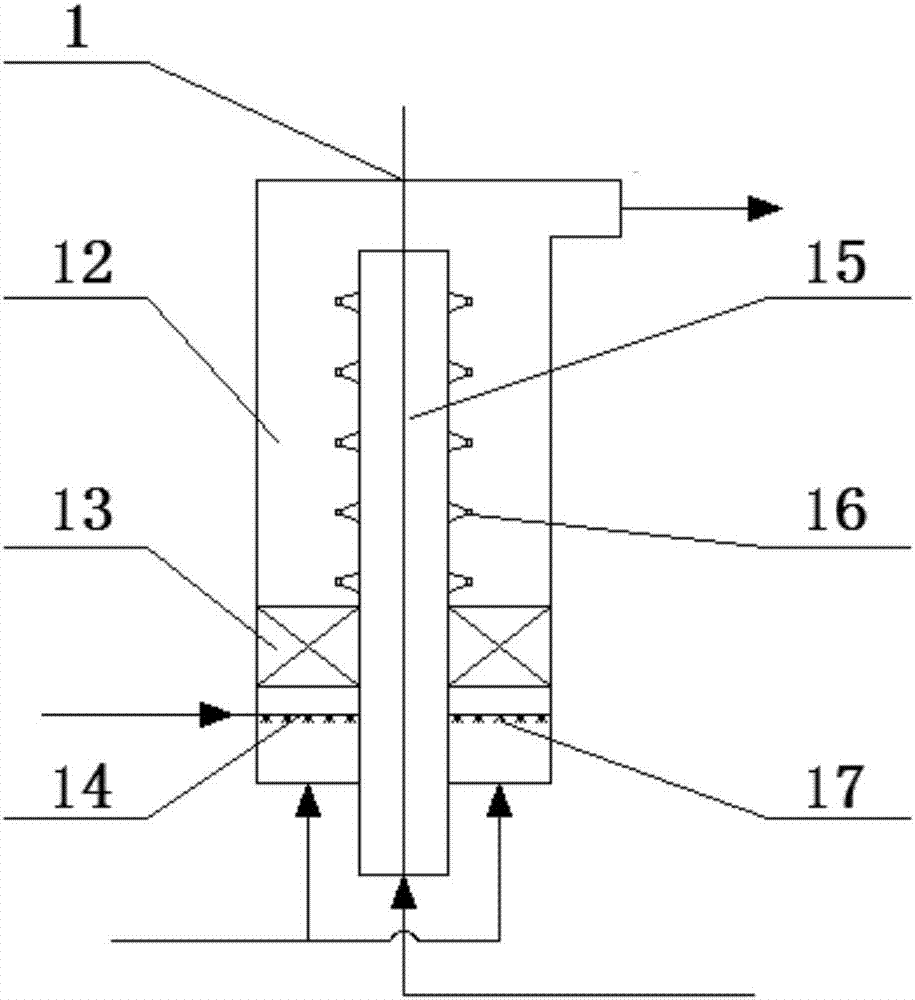

Hydrolysis reaction device for organic sulfur in blast furnace gas

PendingCN111500325ASolve the difficult problem of organic sulfurSolve the problem of excessive emissionsBlast furnace componentsGas purification by catalytic conversionPtru catalystEngineering

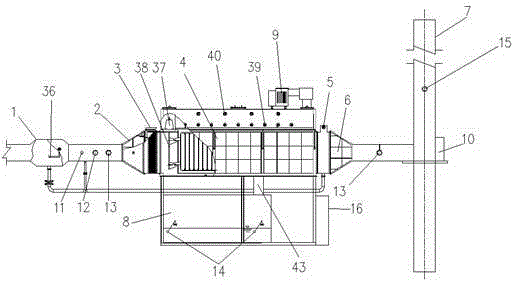

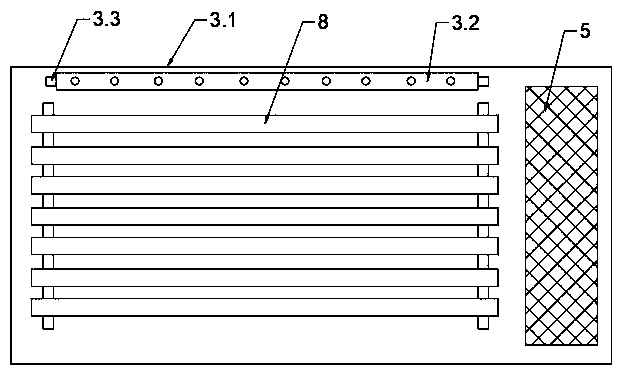

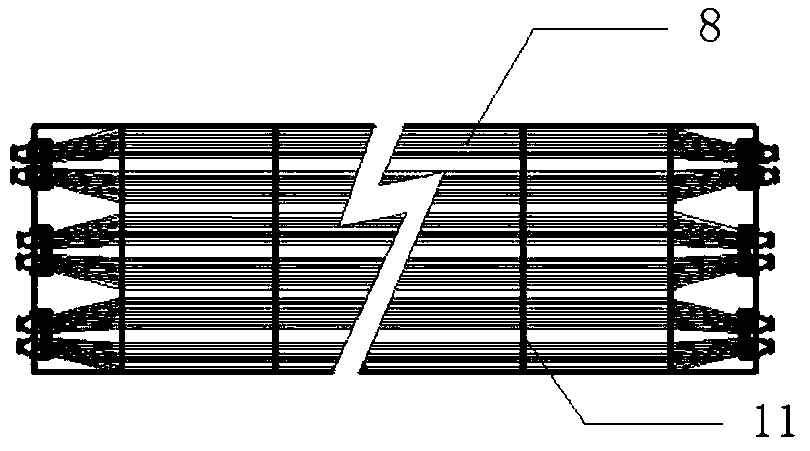

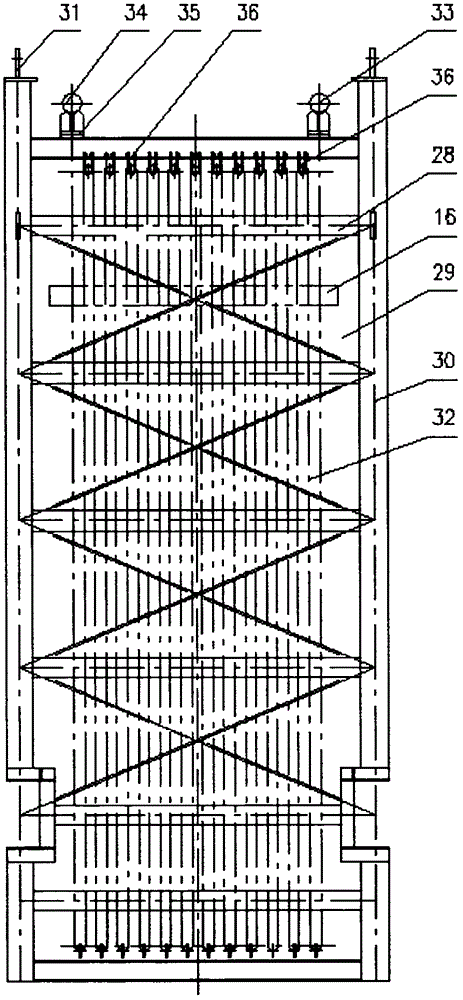

The invention provides a hydrolysis reaction device for organic sulfur in blast furnace gas, belonging to the technical field of fine desulfurization of blast furnace gas. The device comprises a middle flue, a flow baffle, an inlet elbow, an inlet reducing cone, an airflow uniform-distribution plate, a rectification grid, a reactor, a hydrolysis catalyst, an internal support beam, an outlet reducing cone, an outlet elbow and a sound wave soot blower, wherein the middle flue is connected with the inlet elbow of the device; the flow baffle is arranged in the inlet elbow; the inlet elbow is connected with the inlet reducing cone; the airflow uniform-distribution plate is positioned in the inlet reducing cone; the reactor is connected with the inlet reducing cone; the rectification grid is mounted at the uppermost part of the reactor; the internal support beam is arranged in the reactor; a catalyst is placed on the upper portion of the internal support beam and arranged in the reactor; theplacing intervals of all layers of the catalyst are equal; the sound wave soot blower is placed on the upper portion of the catalyst; and the reactor is connected with an external pipeline through the outlet reducing cone and the outlet elbow of the device. The device guarantees that a rear-end coal gas user finally discharges flue gas to achieve ultralow emission of sulfur dioxide.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

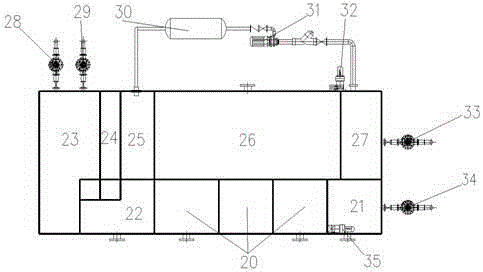

Three-cycle desulphurization method for wet type ammonia-process desulphurization and flue gas desulfurization tower or system

InactiveCN105727723AGuaranteed oxidationGuaranteed crystallizationGas treatmentUsing liquid separation agentFlue gasProcess engineering

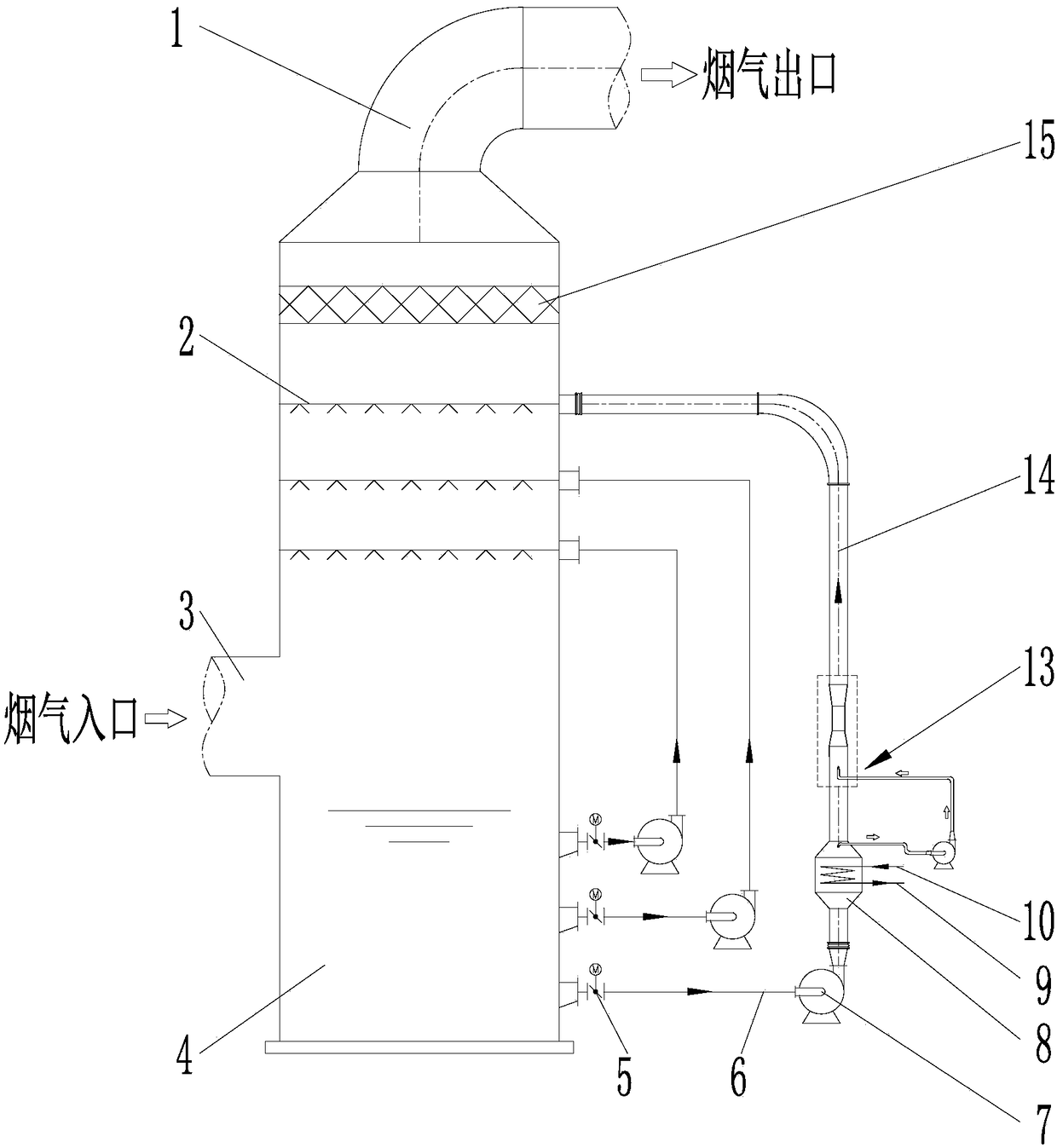

The invention relates to the field of environmental protection and discloses a three-cycle desulphurization method for wet type ammonia-process desulphurization. The desulphurization method is implemented with a first slurry circulating loop, a second slurry circulating loop and a third slurry circulating loop, wherein in the first slurry circulating loop, slurry having mass concentration of 10%-20% and a pH value of 4.0-5.0 is used for carrying out cycle spraying treatment on flue gas, and the temperature of the flue gas treated by the slurry is 50-60 DEG C; in the second slurry circulating loop, slurry having mass concentration of 10%-15% and a pH value of 5.0-6.0 is used for carrying out cycle spraying treatment on the flue gas; and in the third slurry circulating loop, slurry having mass concentration of 3%-10% is used for carrying out cycle spraying treatment on the flue gas. The invention also discloses a flue gas desulfurization tower or system using the three-cycle desulphurization method. According to the three-cycle desulphurization method, the three independent circulating loops are divided according to the concentration of the slurry, the circulating loops separately control the slurry having different concentrations and pH values for treatment of the flue gas, and the contradiction of high desulphurization efficiency and high oxygenation efficiency of by-products is solved.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

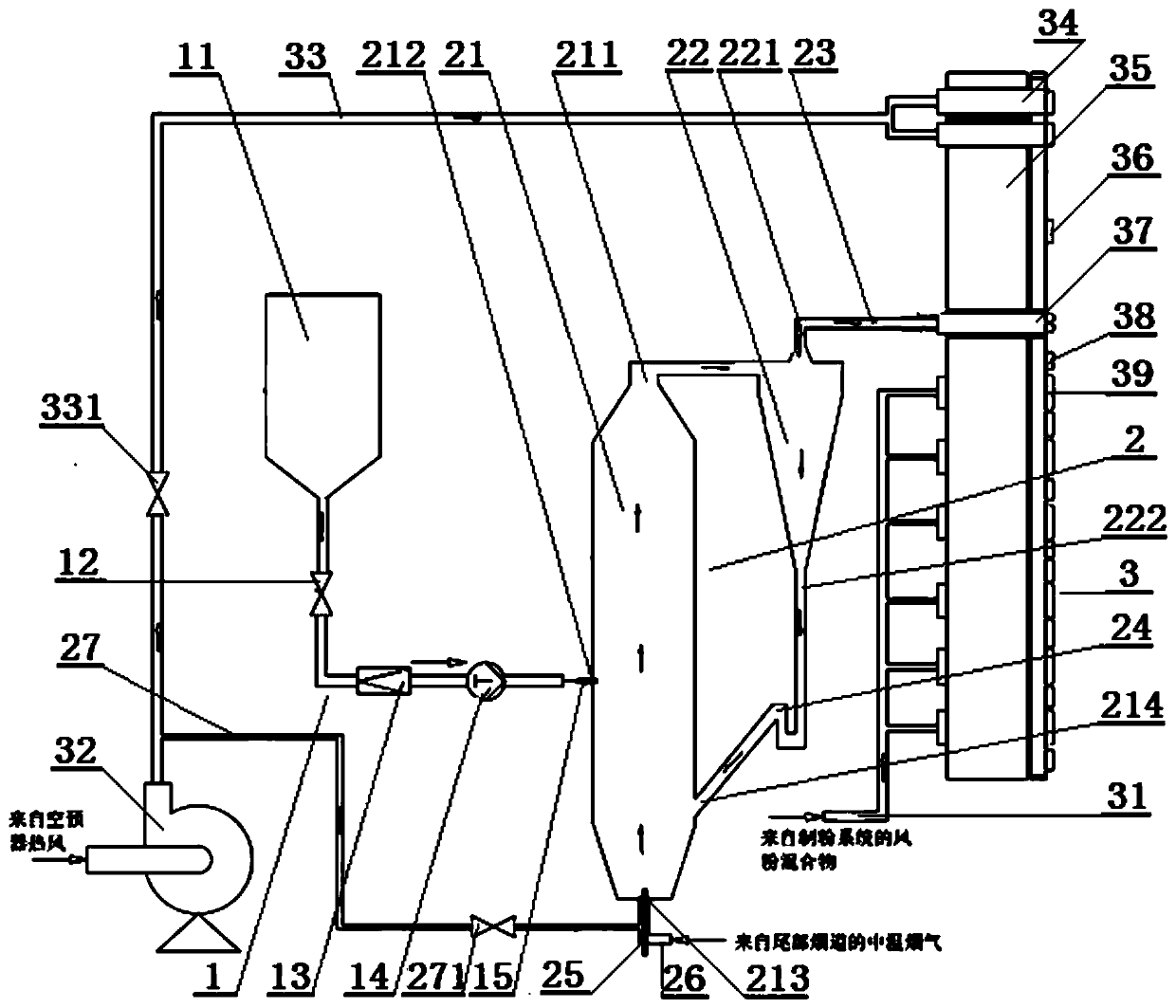

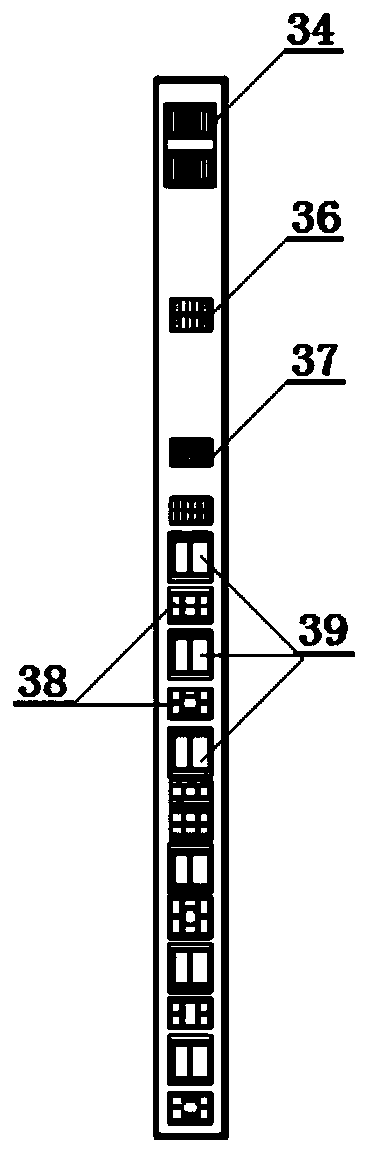

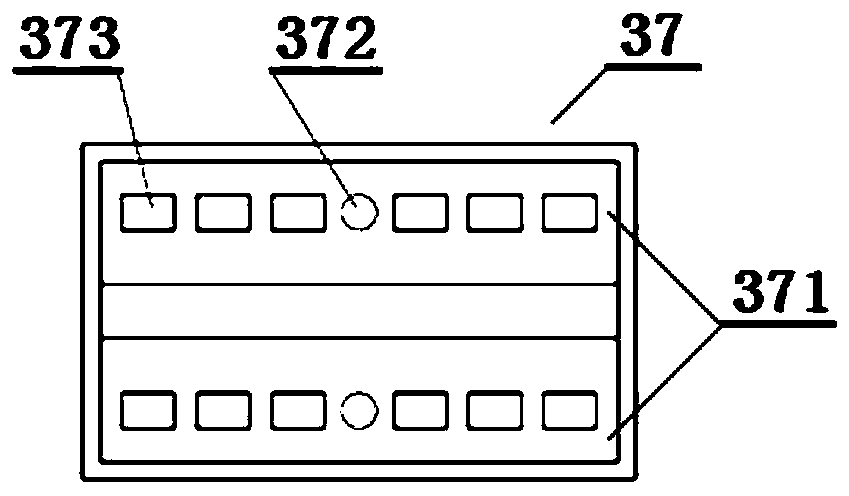

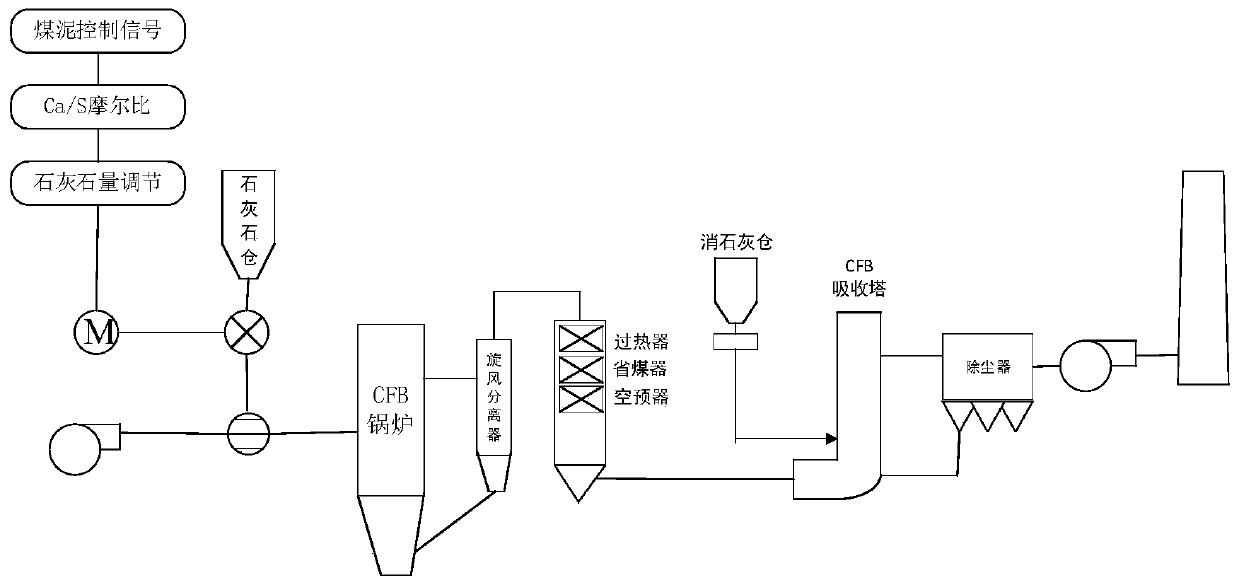

Circulating fluidized bed boiler and desulfurization method

InactiveCN109718660AHigh calcium oxideAchieve ultra-low emissionsFluidized bed combustionDispersed particle separationFluidized bedFlue gas

The invention provides a circulating fluidized bed boiler and a desulfurization method. The circulating fluidized bed boiler comprises an in-furnace desulfurization system and an out-furnace desulfurization system which are communicated in sequence, wherein the in-furnace desulfurization system comprises a hearth; the hearth is provided with a first inlet, the circulating fluidized bed boiler further comprises a limestone conveying pipeline and a quicklime conveying pipeline, and the limestone conveying pipeline and the quicklime conveying pipeline are communicated with the first inlet. In thewhole process of starting the circulating fluidized bed boiler, when the boiler does not reach the optimal temperature range of the limestone reaction, quicklime (calcium oxide) as a desulfurizing agent is first directly adopted for directly reacting with sulfur dioxide in flue gas in the hearth for desulfurization reaction; when the optimal reaction temperature range of the in-furnace limestonedesulfurization system reaches in the boiler, an out-furnace circulating fluidized bed ash circulation system is established, limestone is fed into by the limestone conveying pipeline for desulfurization of sulfur-containing flue gas, high calcium oxide content in the hearth can be kept all the time so as to achieve the efficient desulfurization effect in the furnace.

Owner:CHINA SHENHUA ENERGY CO LTD +2

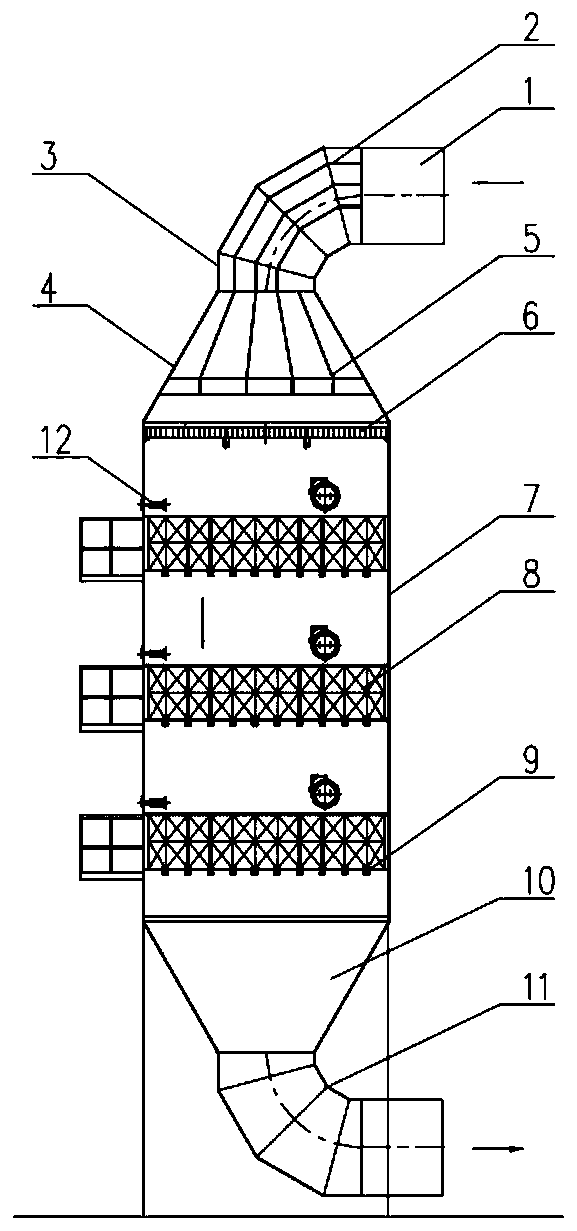

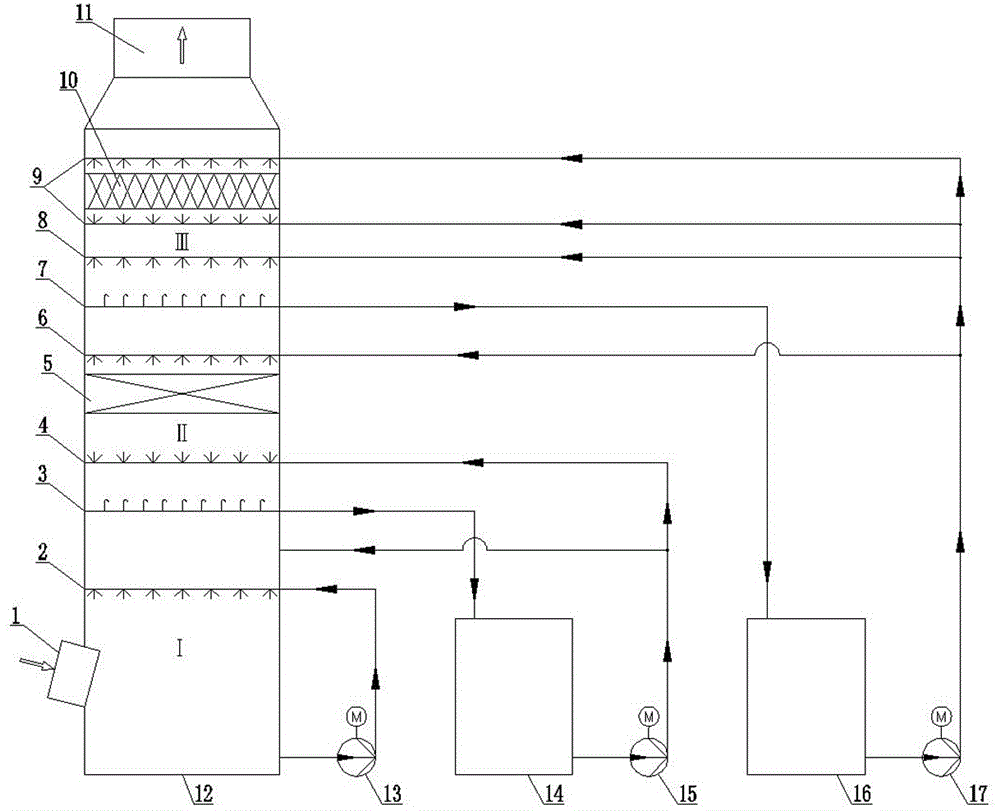

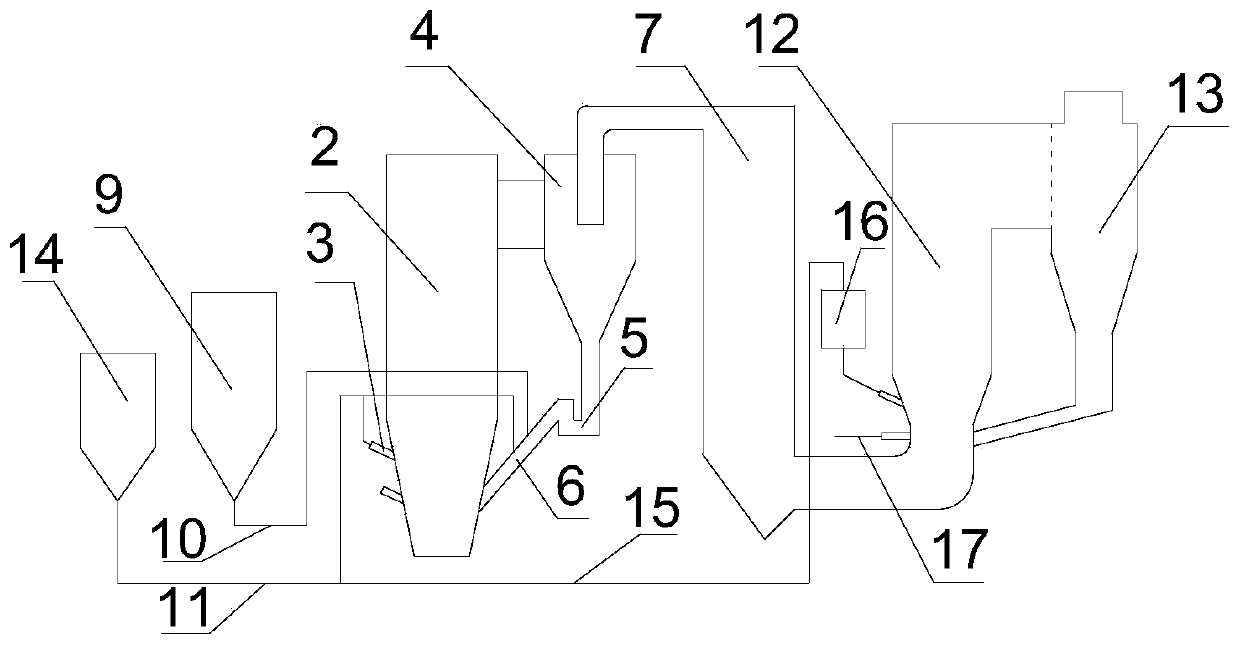

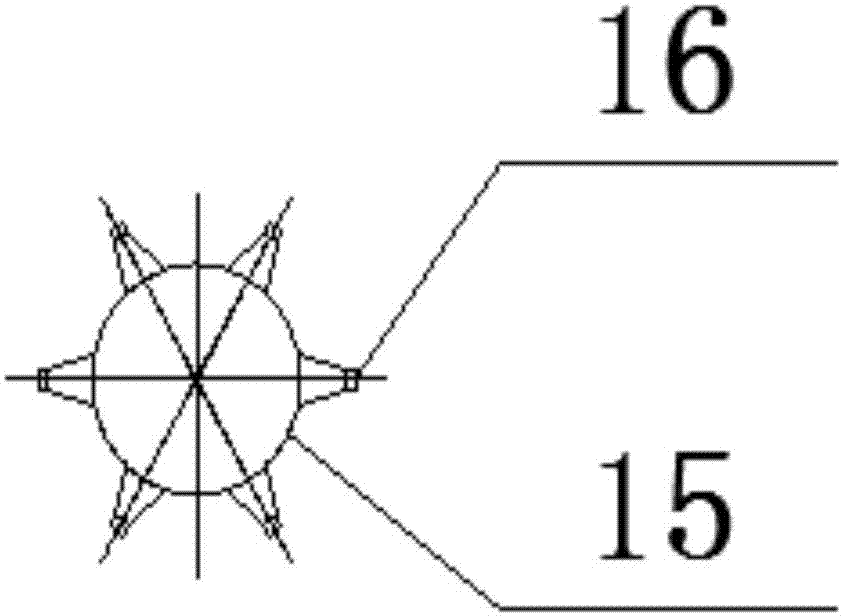

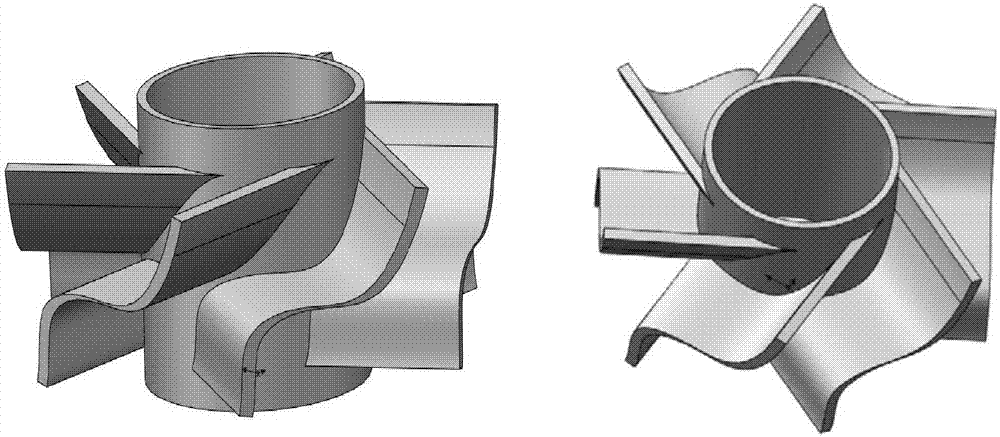

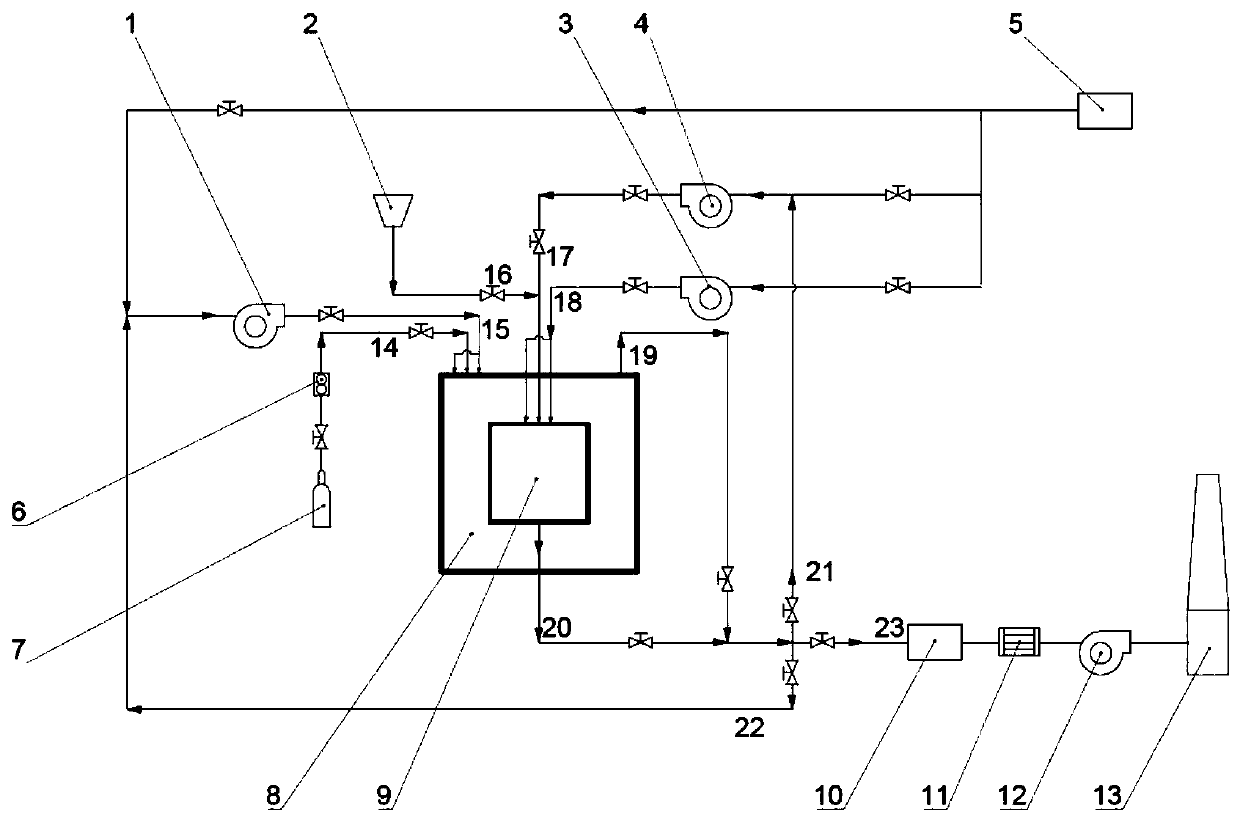

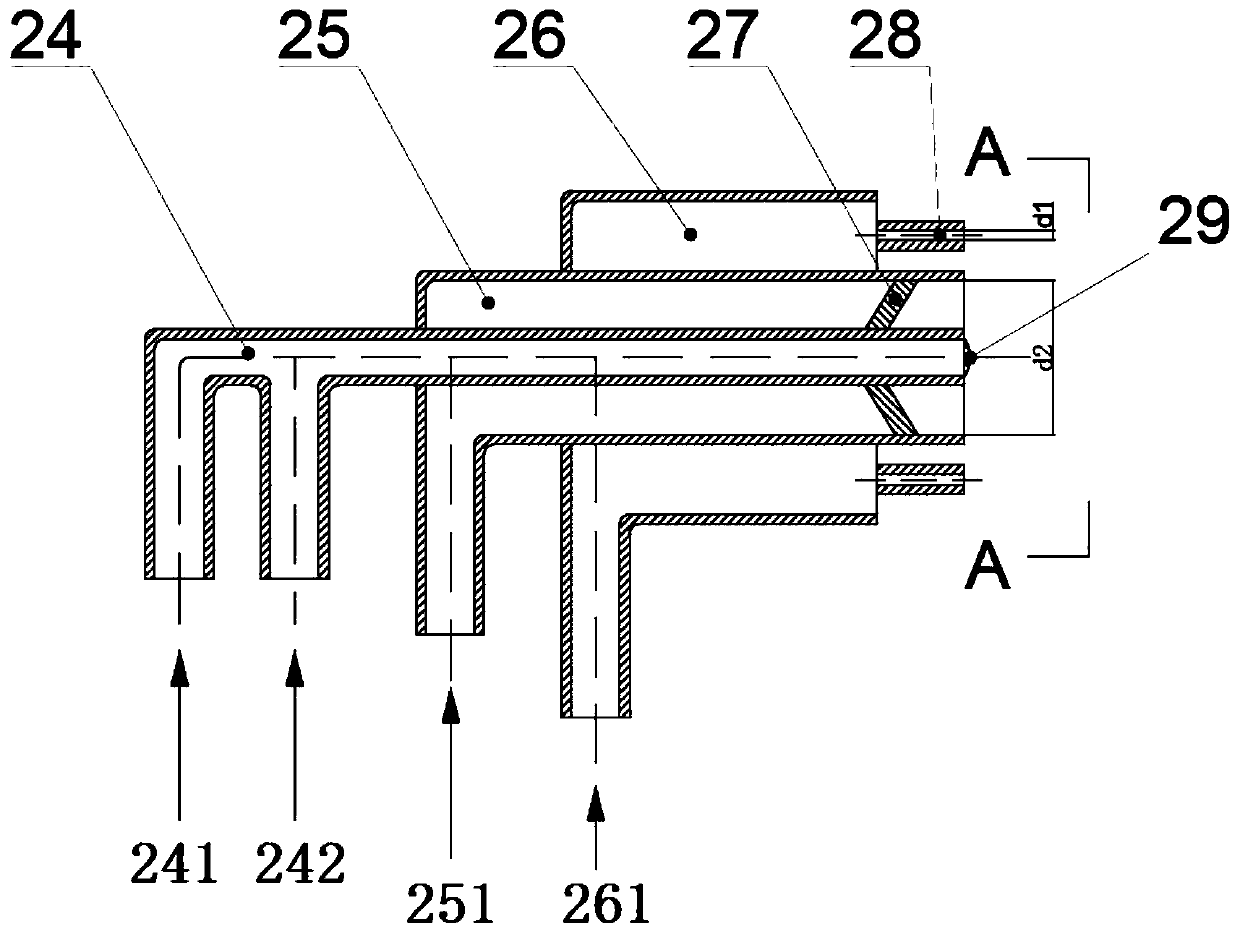

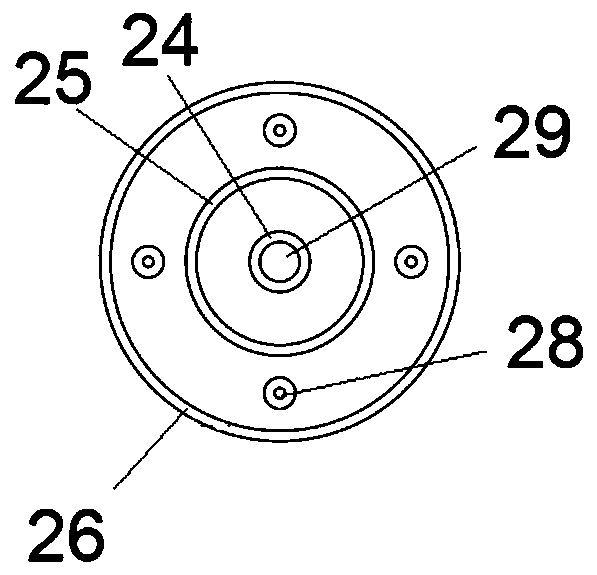

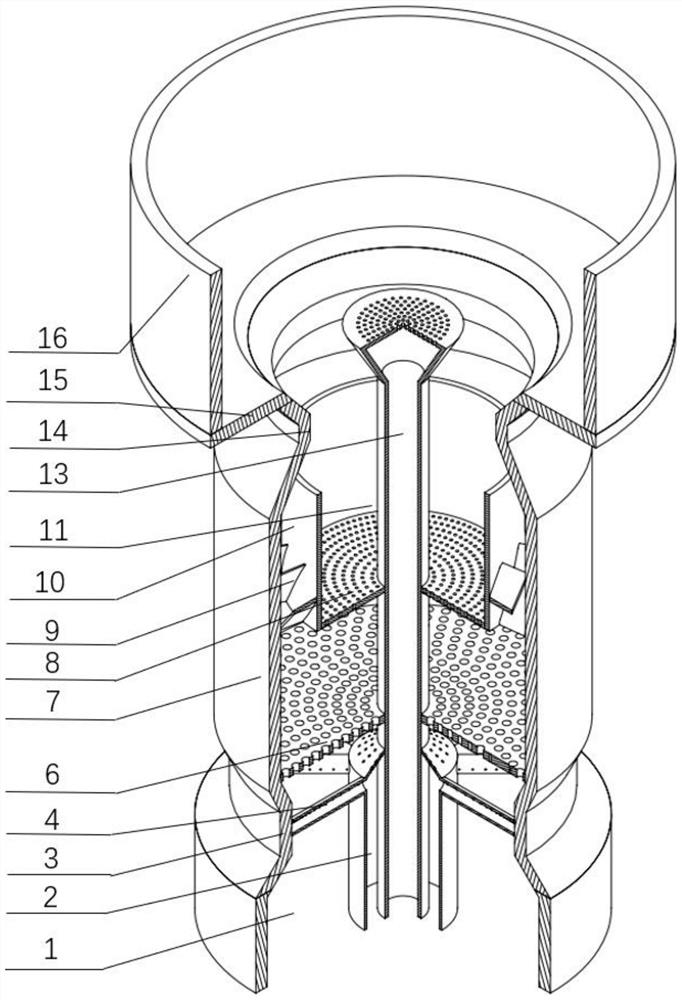

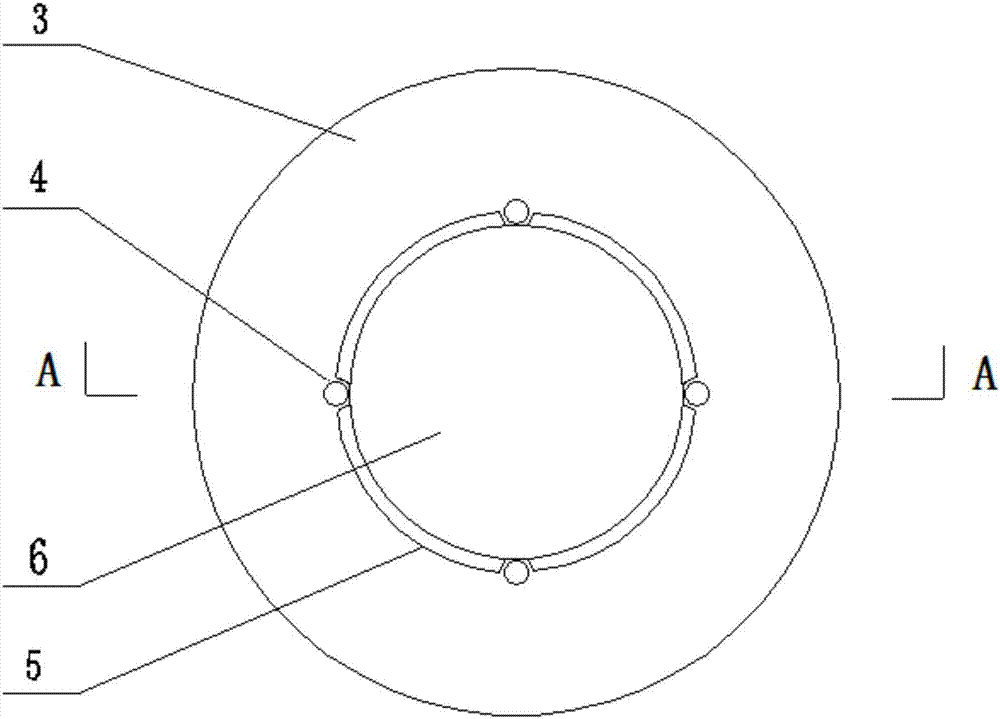

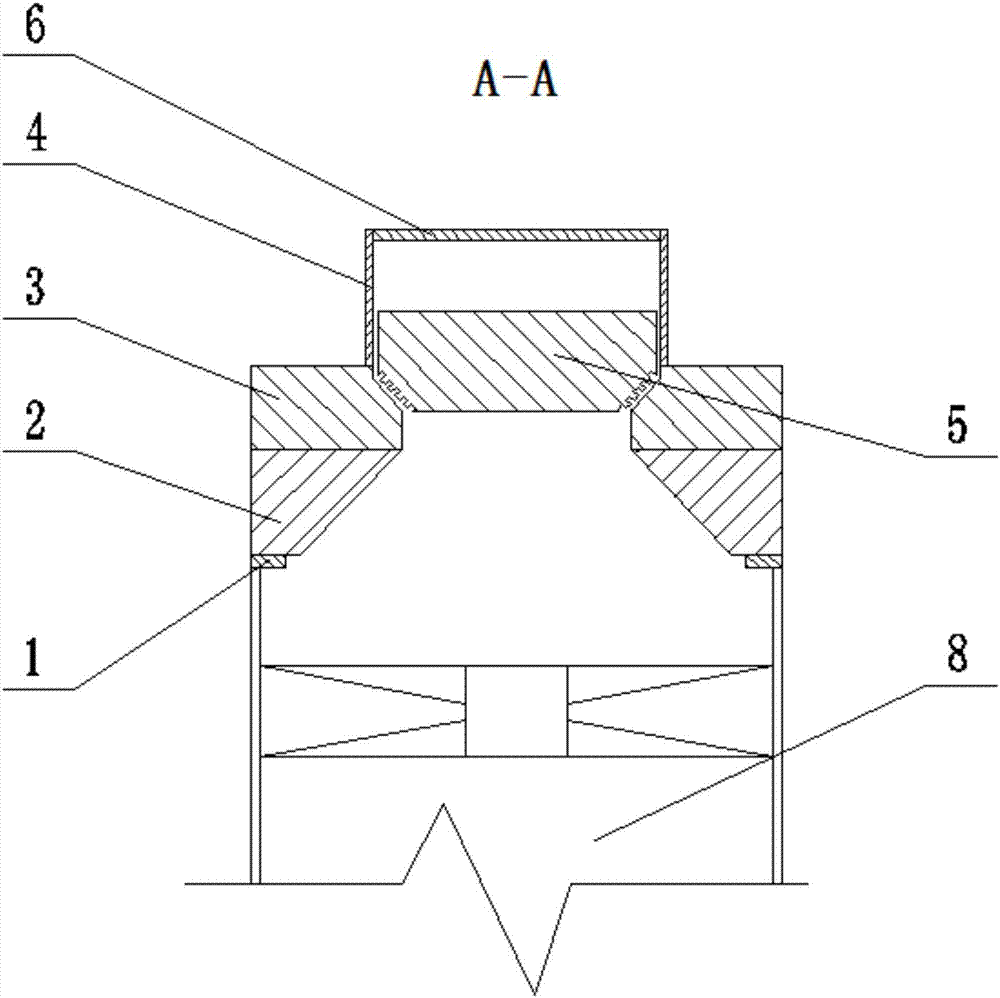

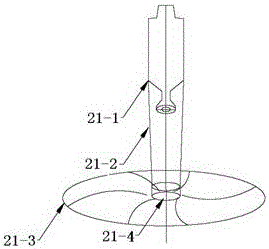

A reaction fluidized bed system and stream guiding type rotating circulating fluidized bed desulphurization equipment including the system

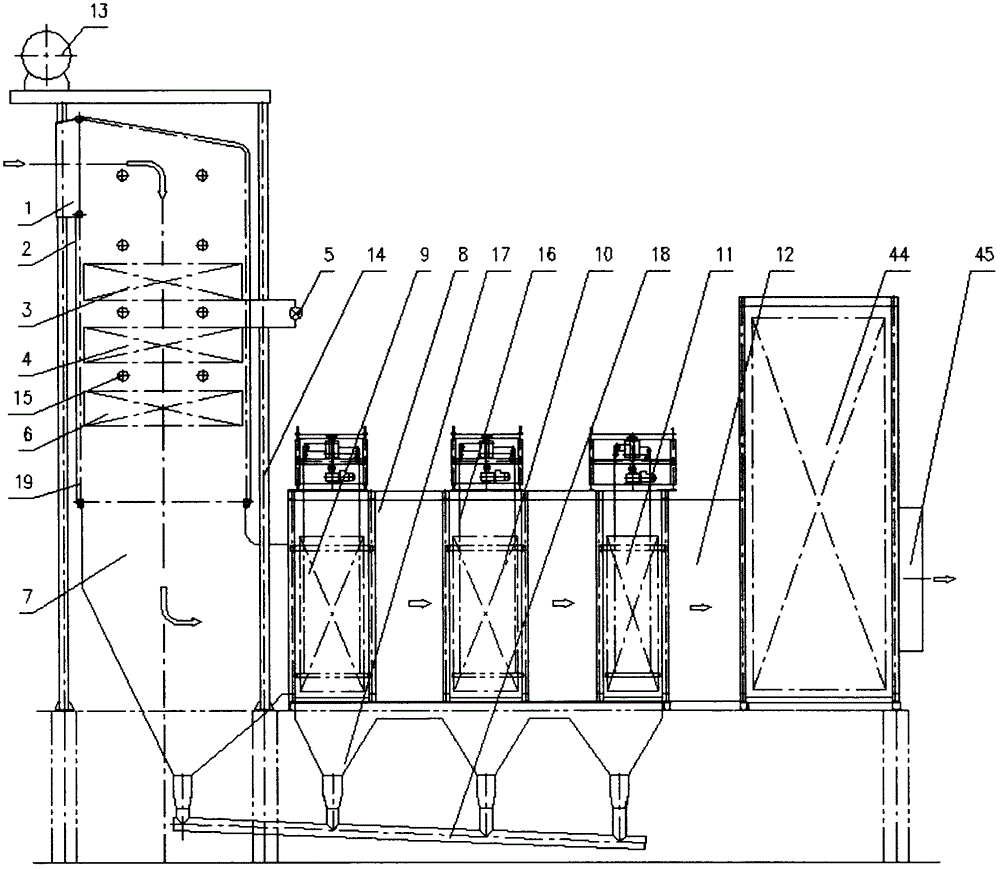

ActiveCN106902622AExtended stayImprove desulfurization efficiencyGas treatmentDispersed particle separationFluidized bedSpray nozzle

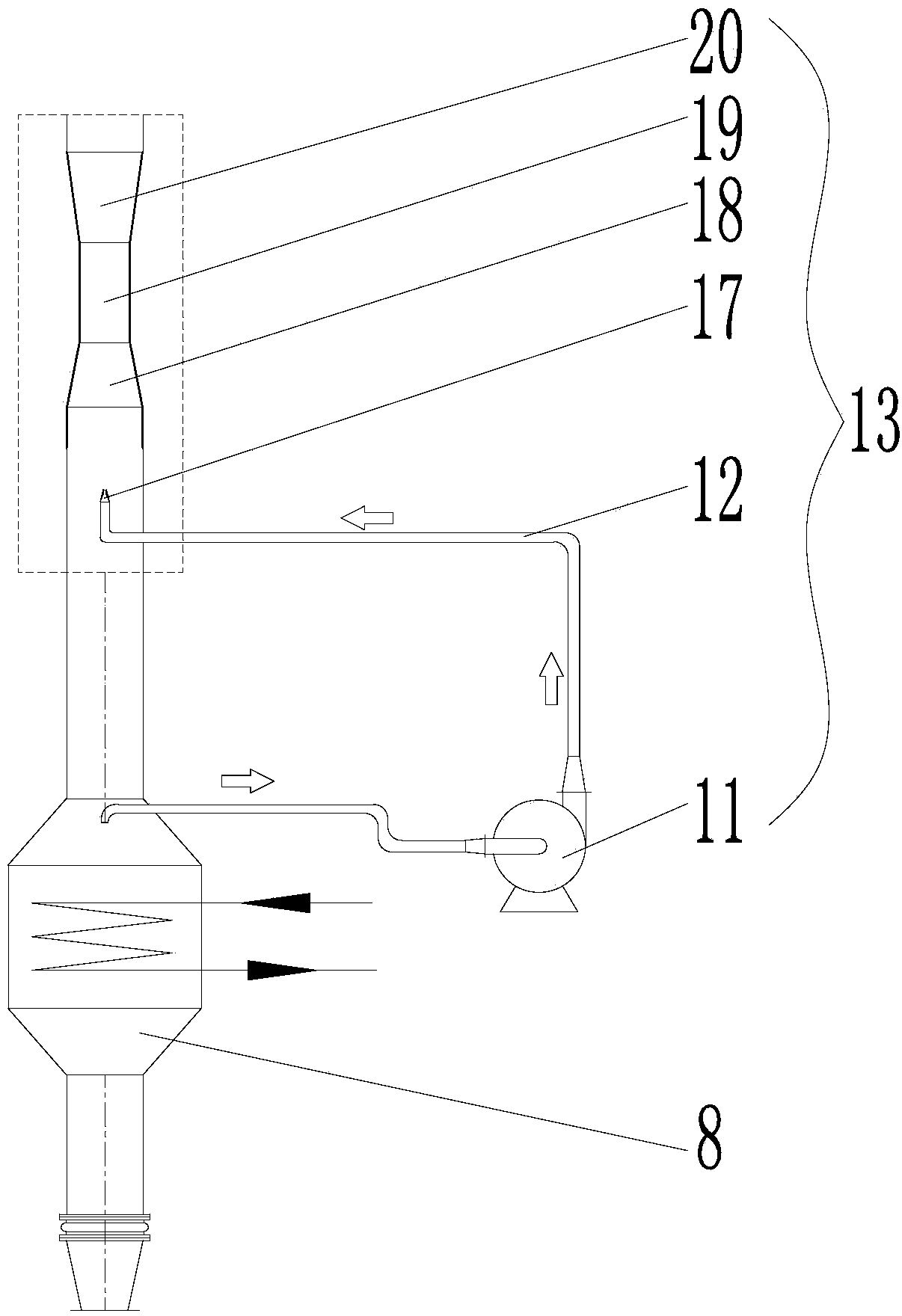

A reaction fluidized bed system and stream guiding type rotating circulating fluidized bed desulphurization equipment including the system are provided. The system includes a reaction fluidized bed, first stream guiding blades capable of allowing gas to rotatably rise, a water annular pipe, mist spraying nozzles, desulphurization agent spray nozzles and a desulphurization agent pipe. The desulphurization agent pipe penetrates through the reaction fluidized bed and penetrates into the reaction fluidized bed, and the tail end of the desulphurization agent pipe is closed. The desulphurization agent spray nozzles are mounted at the periphery of the desulphurization agent pipe and are communicated with the inside of the desulphurization agent pipe. The first stream guiding blades are below the desulphurization agent spray nozzles and connected to the periphery of the desulphurization agent pipe. The water annular pipe has a sealed tail and is disposed under the first stream guiding blades. The mist spraying nozzles are mounted at the water annular pipe and communicated with the inside of the water annular pipe. The reaction fluidized bed is also provided with an axial gas inlet, a gas outlet and a water inlet. The desulphurization equipment includes the system, and has advantages of a high desulphurization efficiency, a simple process and procedures, a low running cost, and / or long-term cyclic efficient using of the desulphurization agent.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Pulverized coal coupled combustion device and combustion method

PendingCN109827168AReduce generationOxidation stabilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

The invention discloses a pulverized coal coupled combustion device and a combustion method. The device comprises a gas combustion chamber, and a pulverized coal combustion chamber arranged in the gascombustion chamber; a gas flameless combustor is mounted at the top of the gas combustion chamber; gas is combusted in a flameless mode in a cavity inside the gas combustion chamber and outside the pulverized coal combustion chamber through the gas flameless combustor; a pulverized coal flameless combustor is mounted at the top of the pulverized coal combustion chamber, and penetrates through thetop of the gas combustion chamber; and pulverized coal is combusted in a flameless mode in the pulverized coal combustion chamber through the pulverized coal flameless combustor. The pulverized coalcoupled combustion device can spontaneously maintain the pulverized coal flameless combustion with an uniform temperature field, generated by the gas flameless combustion, as an uniform radiation heatsource, and can stabilize the oxidation under a low-temperature and low-oxygen atmosphere, so that the generation quantity of nitric oxides is greatly reduced, and the ultralow emission of the nitricoxides in the pulverized coal combustion is realized.

Owner:HUAZHONG UNIV OF SCI & TECH +2

Composite reducing type low NOx emission device suitable for power station boiler

PendingCN111140865ACurb emissionsReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoal waterPower station

The invention relates to a composite reducing type low NOx emission device suitable for a power station boiler. The composite reducing type low NOx emission device comprises a coal water slurry generation mechanism, a coal water slurry pyrolytic reaction mechanism and a composite reducing type combustion device, wherein the coal water slurry generation mechanism has the function of treating coal powder into coal water slurry and is internally provided with a coal water slurry tank, the coal water slurry pyrolytic reaction mechanism has the function of pyrolysis generation of pyrolysis gas withreducing active components and is internally provided with a pyrolysis reactor and a cyclone separator, and the composite reducing type combustion device has the function of deeply reducing of NOx incombustion smoke. By adoption of high-speed separation air and the proper over fire air rate, the created oxygen content in the combustion area is smaller than 1%, the NOx generated low-oxygen area in combustion can be restrained, a composite spraying port is utilized for conveying pyrolysis gas generated through the coal water slurry pyrolytic reaction and internally containing reducing active components and ammonia into the area, the reducing reaction with NOx in smoke happens in the reducing atmosphere, the limitation of usage of a temperature window during NOx reducing through a conventional reducing agent is broken through, furnace interior efficient combustion and economical reducing are ensured, the NOx concentration in smoke is totally reduced, and NOx ultra-low emission of a coalpowder combustion furnace is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Dehumidification and emission reduction system and process of smoke of coal-fired power plant

PendingCN109157941AInitial partial pressure dropImproved white plumeCombination devicesGas treatmentSocial benefitsMulti pollutant

The invention discloses a dehumidification and emission reduction system of smoke of a coal-fired power plant. The system comprises a high-efficiency electric dust remover, a wet desulfurization device and a dehumidification and emission reduction device that are connected with one another in sequence by a pipeline, wherein the dehumidification and emission reduction device comprises a cylindricalcasing, a tubular heat exchanger, a washing mechanism and a first demister are arranged in the casing; the washing mechanism comprises a water spray pipe and a water distribution pipe; an annular sliding rail is arranged on each of the two sides of the inner wall of the casing; the two ends of the water spray pipe are glidingly connected in the annular sliding rails respectively by sliding blocksof the annular sliding rails, so as to drive the water spray pipe to move; the water distribution pipe is fixedly arranged on the top wall in the casing and communicates with a water inlet formed inthe top of the casing; the water distribution pipe communicates with the water spray pipe by a hose. The system has the advantages that various pollutants such as smoke, SO2 and the like can be effectively removed, the reliability and stability of discharge of the pollutants such as the smoke and the like under certain standard are improved, and good environmental protection benefit and social benefit are achieved.

Owner:JIANGSU CTIEC ENVIRONMENTAL PROTECTION RES INST

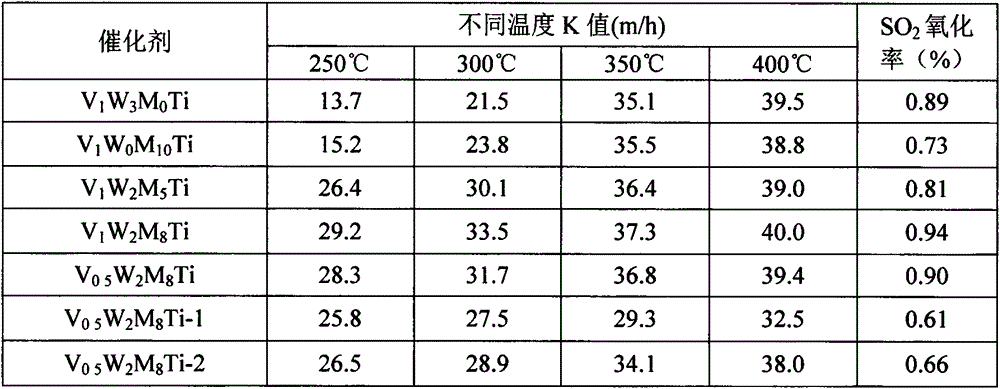

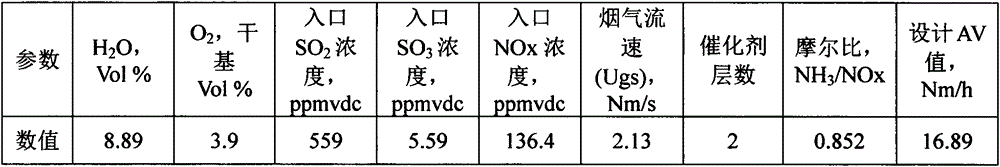

Low-vanadium-content wide-active-temperature-window denitration catalyst and preparation method thereof

InactiveCN106215931APromotes uniform dispersion levelsIncrease profitGas treatmentHeterogenous catalyst chemical elementsIonChemistry

The invention discloses a low-vanadium-content wide-active-temperature-window denitration catalyst, which is made from raw materials of 0.05-0.2 by weight of ammonium metavanadate, 0.1-3 parts by weight of ammonium metatungstate or a mixture of 0.1-3 parts by weight of ammonium metatungstate and 0.1-10 parts by weight of ammonium molybdate, 60-80 parts by weight of TiO2, 10-20 parts by weight of an additive, and 15-30 parts by weight of deionized water. Vanadium in the denitration catalyst is controlled at a low content, so that the cost of the catalyst is reduced at a certain degree, and the low vanadium content in the range doesn't cause secondary pollution. Through introduction of the new additive, vanadium in the denitration catalyst is uniformly dispersed, so that vanadium active sites are formed on the surface of the catalyst as much as possible, and the use ratio of vanadium is increased. Furthermore, through introduction of the new additive, the surface acidity and redox performance of the catalyst are improved, thereby improving the performance of the catalyst. The testing result of a pilot-plant test system for simulating industrial smoke and the industrial actual operation of demonstration projects show that the catalyst can well satisfy the operating requirements of variable load conditions in a coal-fired power plant.

Owner:ZHEJIANG ZHENENG CATALYST TECH CO LTD

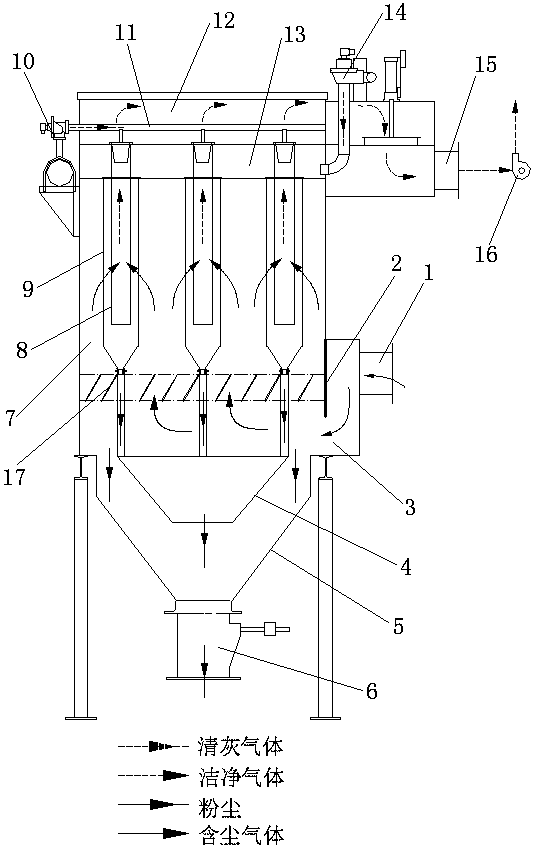

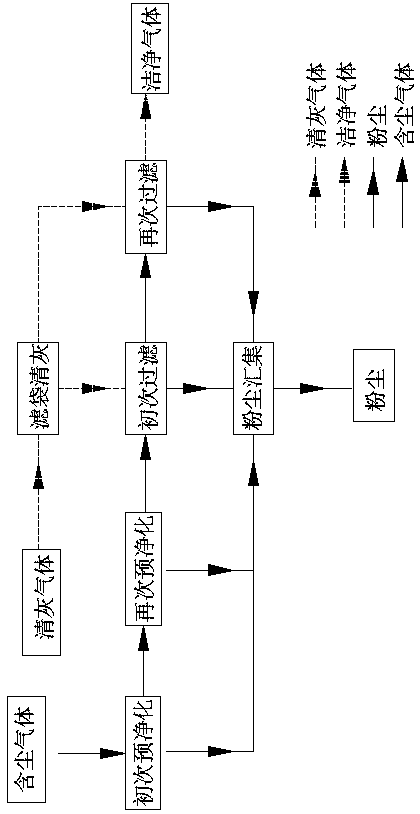

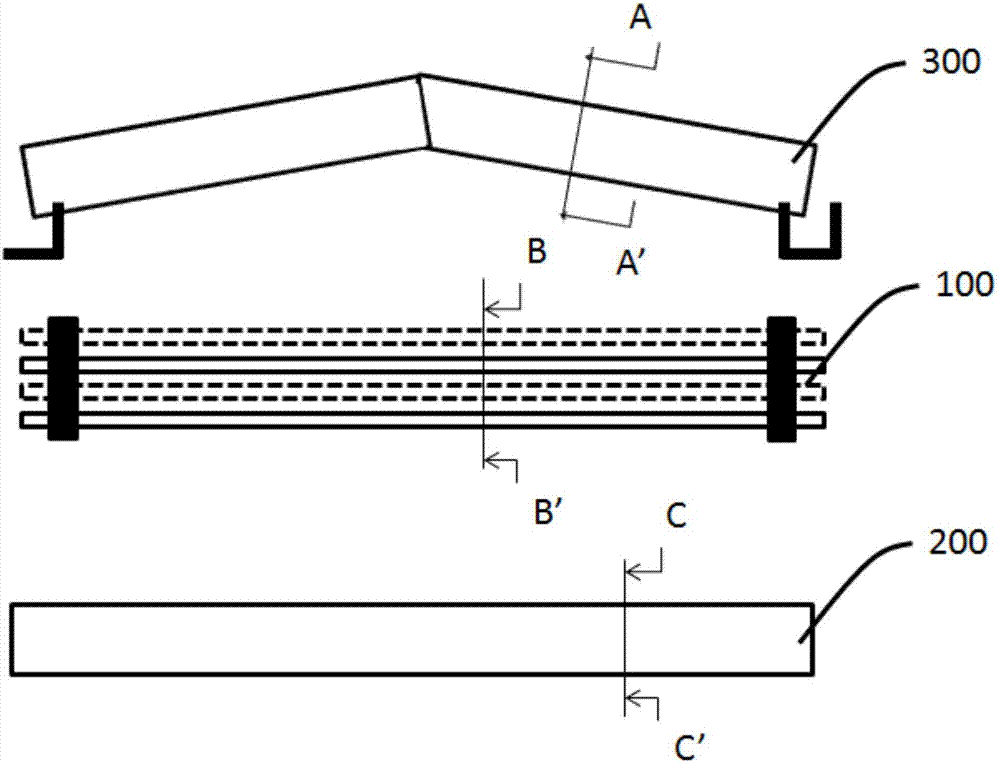

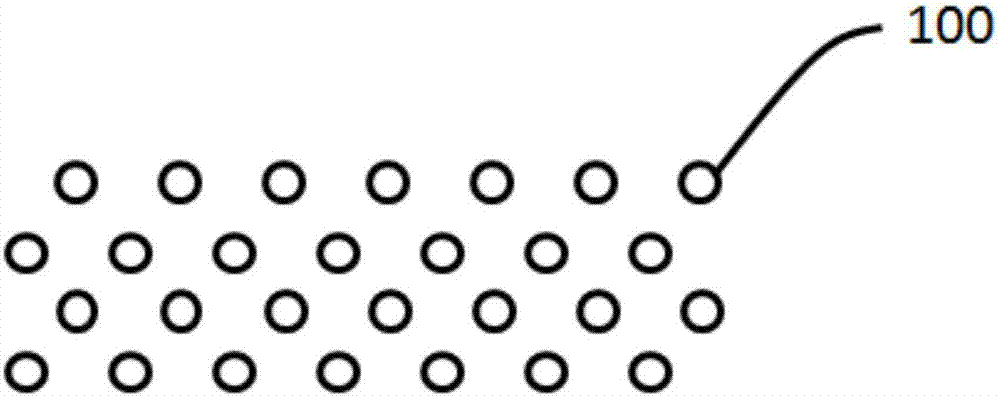

Dedusting method and device for achieving ultralow emissions of dusty gas

ActiveCN107648975AReduce dust concentrationReduce loadHuman health protectionCombination devicesEngineeringWaste management

The invention discloses a dedusting method and device for achieving ultralow emissions of dusty gas. The dedusting device comprises an air inlet, an air guide plate, a settling room, dust deposition buckets, a filtering room, gas purifying rooms, an inner blowing device, an outer blowing device, an air outlet and an exhaust blower. The air guide plate is arranged between the air inlet and the settling room, the inner dust deposition bucket and the outer dust deposition bucket are arranged below the settling room, and the dust deposition buckets are communicated with the settling room. The filtering room is located above the settling room, a kinetic energy losing device is arranged between the filtering room and the settling room, the gas purifying rooms are arranged above the filtering room, and a blowing pipe is arranged in the upper gas purifying room. The inner blowing device and the outer blowing device are arranged outside the gas purifying rooms, the inner blowing device is communicated with the blowing pipe, and the outer blowing device is communicated with the lower gas purifying room. Sleeve type filtering bags are arranged in the filtering room, the inner sleeve type filtering bag and the outer sleeve type filtering bag are communicated with the inner dust deposition bucket and the outer dust deposition bucket respectively, the upper end of the inner sleeve type filtering bag and the upper end of the outer sleeve type filtering bag are arranged in the upper gas purifying room and the lower gas purifying room respectively, the upper gas purifying room is communicated with the air outlet, and the exhauster blower is arranged on the air outlet. The dedusting device has the advantages of being compact in structure, low in operation cost and high in adaptability, and ultralow emissions of dust can be achieved.

Owner:泰安中意重型工业设备有限公司

High-humidity flue gas purifying device

InactiveCN107485881AEfficient captureSynergistic removalCombination devicesGas treatmentHigh humidityWater vapor

The invention relates to a high-humidity flue gas purifying device, which is used for purifying flue gas with water steam and fine particulate matters. The high-humidity flue gas purifying device comprises a heat exchange tube and a turbulence structure, wherein the flue gas can flow through a surface of the heat exchange tube and the turbulence structure, a refrigerant flows in the heat exchange tube, the water steam in the flue gas can be condensed on the surface of the heat exchange tube and surfaces of the fine particulate matters so as to form a water film and liquid drops, the turbulence structure has a bending part, and the flue gas can flow through the bending part and forms a turbulent flow, so that the liquid drops and the fine particulate matters are collided and agglomerated so as to be acquired and removed.

Owner:TSINGHUA UNIV

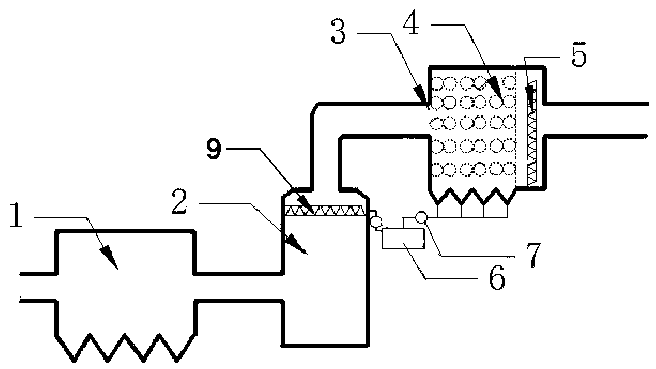

Self-supply hydrogen fuel cell system and operating method thereof

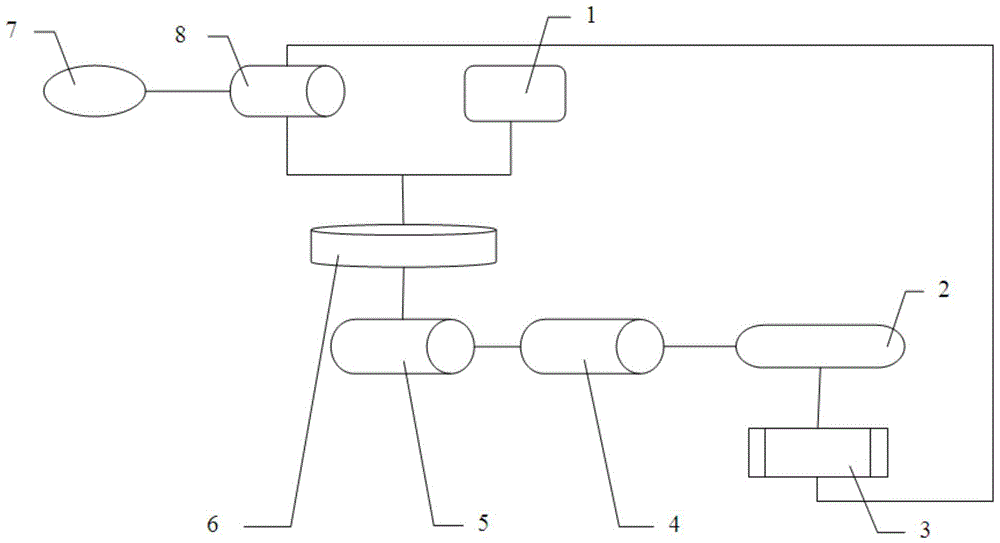

ActiveCN104953147AAchieve ultra-low emissionsEliminate generationReactant parameters controlParticulatesNuclear engineering

The invention discloses a self-supply hydrogen fuel cell system. The self-supply hydrogen fuel cell system comprises a diesel fuel tank (1), a gas separator (2), a fuel cell (3), a low-temperature separation reactor (4), a high-temperature separation reactor (5), a self-heating reforming device (6), a water tank (7) and a catalytic combustor (8). The high-temperature separation reactor (5), low-temperature separation reactor (6) and self-heating reforming device (7) are adopted to cracking diesel to H2 and CO, H2 is used as fuel of the fuel cell to react with O2 in the air to generate electric energy, the unreacted H2 and CO enter the catalytic combustor (8) to be combusted, so that the heating of water can be guaranteed; therefore, not only is hydrogen provided for the fuel cell, but also high-temperature water is provided for a self-heating converter for generating the hydrogen, the electric energy is generated without combusting the diesel in the entire process, the generation of NOx and particulate matters can be avoided, only CO2 is generated, and the ultra-low emission is realized. The invention also discloses an operating method of the self-supply hydrogen fuel cell system.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Mine heat furnace kiln waste heat recycling system

InactiveCN105716436AReasonable designQuick installationLiquid degasificationEnergy industryShock waveSuperheater

The invention discloses a mine heat furnace kiln waste heat recycling system which comprises an inlet flue, a water cooling channel, a high-temperature superheater, a low-temperature superheater, a temperature reduction adjusting device, a high-temperature evaporator, a reversing flue, a horizontal flue, a low-temperature evaporator module, a coal economizer module, a water heater module, an outlet flue, a boiler barrel, a steel frame, a shock wave dust blowing device, a steel brush dust removing device, a dust falling hopper, a dust discharging device, a pollutant cooperative releasing device and a tail flue. The mine heat furnace kiln waste heat recycling system has the beneficial effects that the mine heat furnace kiln waste heat recycling system is in an L shape overall, design is reasonable, installation is rapid, the structure is compact, the performance is reliable, a dust removing effect is good, the waste heat recycling heat efficiency is high, and ultra-low pollutant emission is achieved.

Owner:南通万达能源动力科技有限公司

Cooling and white smoke eliminating device and method for circulating slurry for desulfurizing tower of thermal power plant

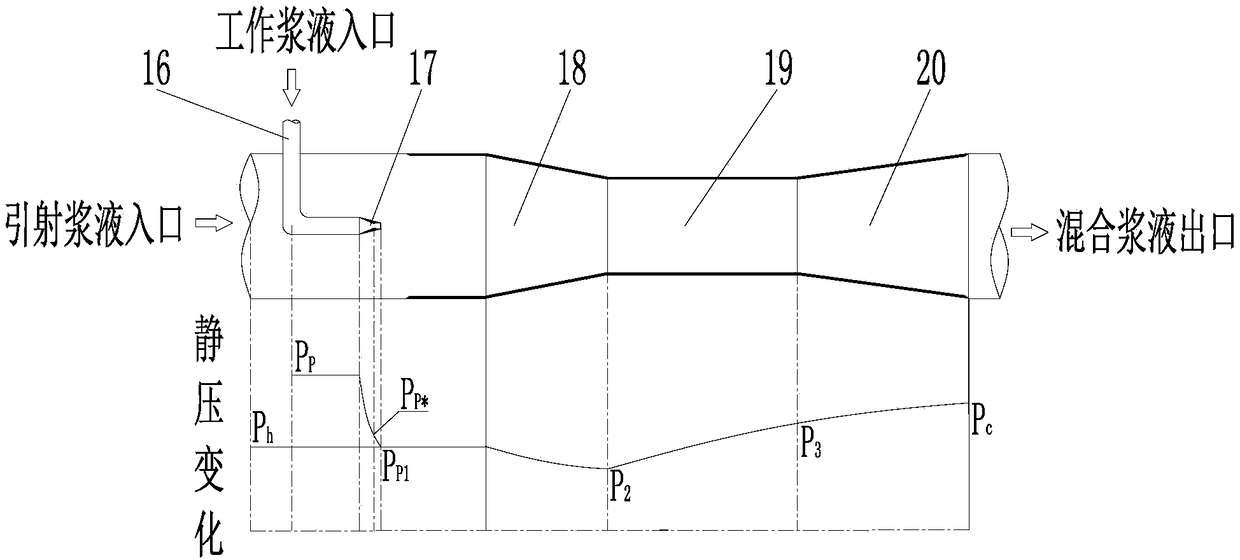

ActiveCN108295633ASimple crafting systemShort transformation periodUsing liquid separation agentCombustion technology mitigationSlurryButterfly valve

The invention discloses cooling and white smoke eliminating device and method for circulating slurry for a desulfurizing tower of a thermal power plant, and belongs the fields of the flue gas purification and the white smoke elimination of utility boilers and metallurgical coking and relevant industrial boilers, and the like. The side surface of the bottom of the desulfurizing tower in the deviceis provided with electric butterfly valves; the electric butterfly valves, slurry circulating pump inlet pipes, slurry circulating pumps, a slurry cooler, a slurry jetting and boosting device, a slurry circulating pump outlet pipe and top-layer spray layers are connected in sequence. The device can be used for reducing the water replenishing amount of the desulfurizing tower, is used for decreasing the moisture content of flue gas, and is used for further eliminating white smoke. Meanwhile, the invention also provides the cooling and white smoke eliminating method for the circulating slurry for the desulfurizing tower of the thermal power plant. The latent heat of vaporization in the flue gas is recovered; the heat loss of the smoke exhausted from a boiler is further decreased; the moisture carried in the flue gas is reduced; the water resource is saved, and the white smoke from a chimney outlet is eliminated.

Owner:CHINA HUADIAN ENG +1

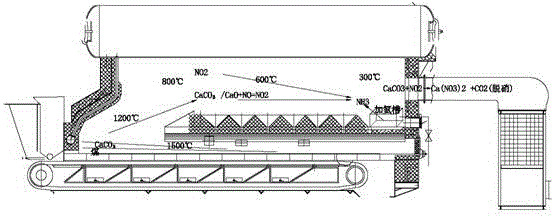

Device and process method for ERDIII cement plant ultra-low emission denitration

PendingCN110218584AReduce escapeReduce the burden of denitrificationGas treatmentDispersed particle separationDecompositionAmmonia

The invention discloses a device and a process method for ERDIII cement plant ultra-low emission denitration. The device for ERDIII cement plant ultra-low emission denitration comprises a decomposition furnace and a powder denitration agent conveying unit, wherein the bottom part of the decomposition furnace is provided with a secondary wind inlet which is connected with a cement rotary kiln; thedecomposition furnace comprises a reducing zone, a main burning zone, a reburning zone and a burnout zone from bottom to top; the reducing zone is equipped with a reducing zone saturated steam catalytic burner; the reburning zone is equipped with a reburning zone saturated steam catalytic burner; the main burning zone is connected with tertiary wind; the burnout zone is connected with burnout wind; and the discharge pipe of the powder denitration agent conveying unit is connected with a denitration agent spray gun which is connected with the reburning zone. According to the invention, throughintroduction of a denitration catalyst, the usage amount of ammonia water for denitration is reduced; the cost is saved; ammonia escape is reduced; more economy and environmental friendliness are achieved; and due to reduction of ammonia escape, corrosion to subsequent equipment is avoided.

Owner:上海三融环保工程有限公司

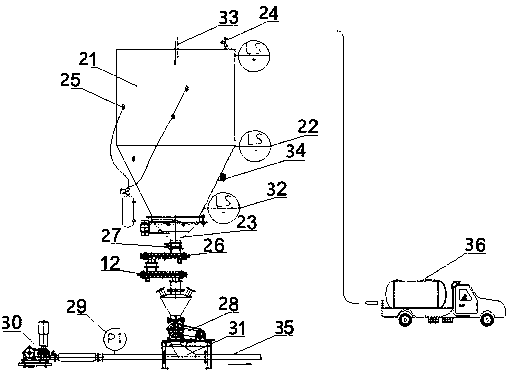

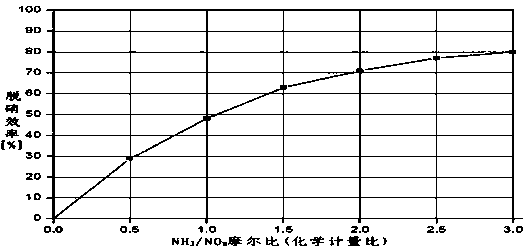

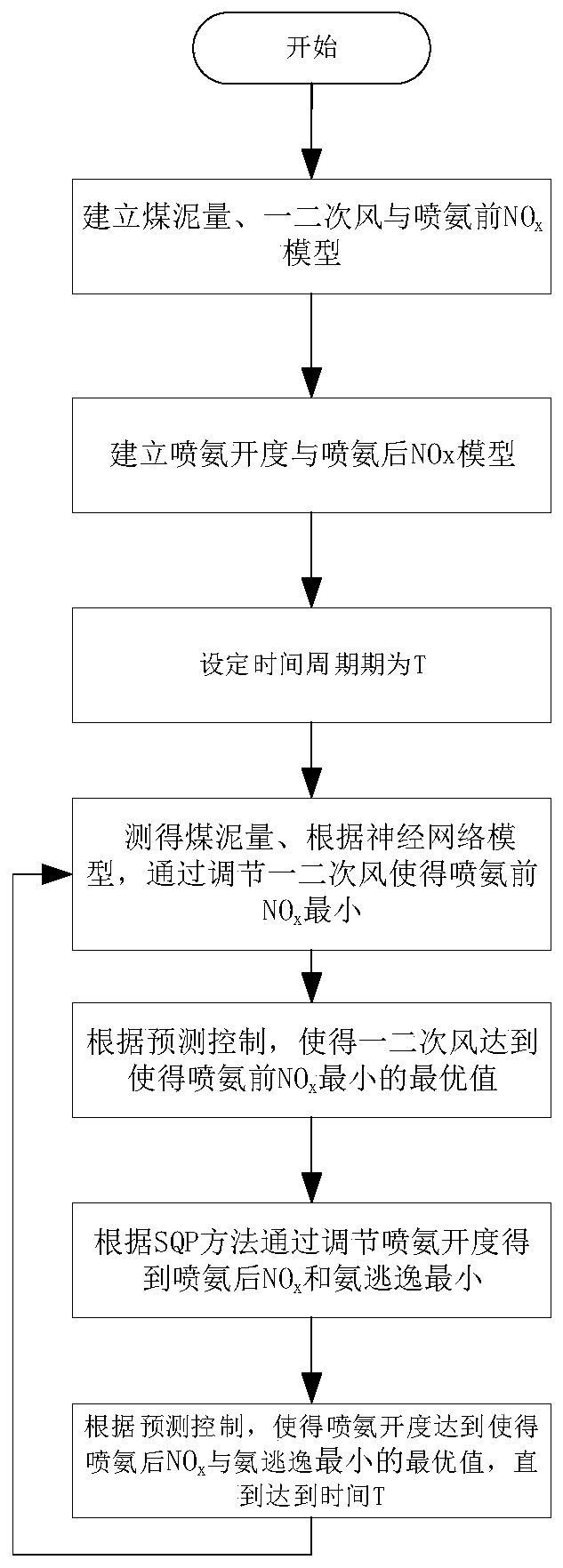

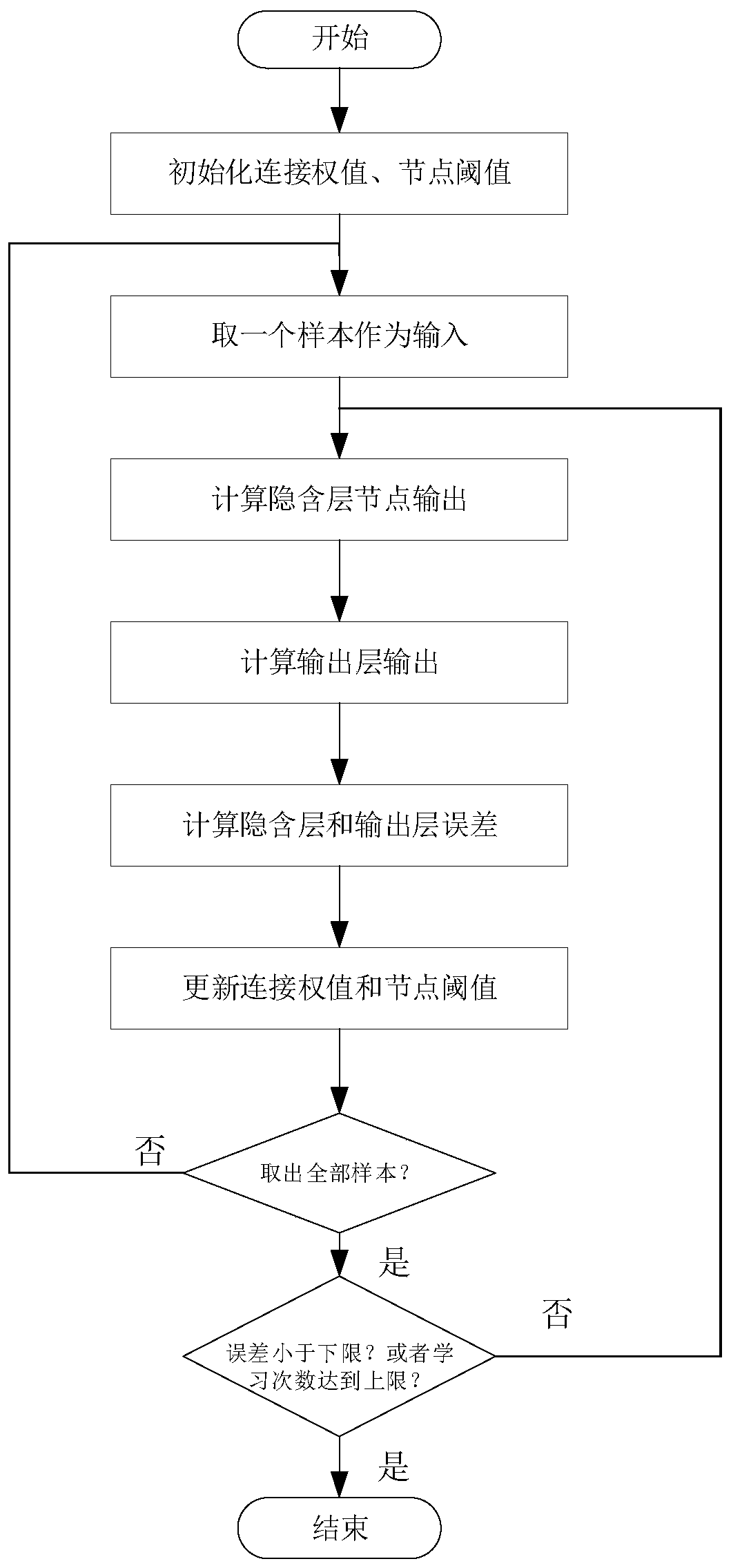

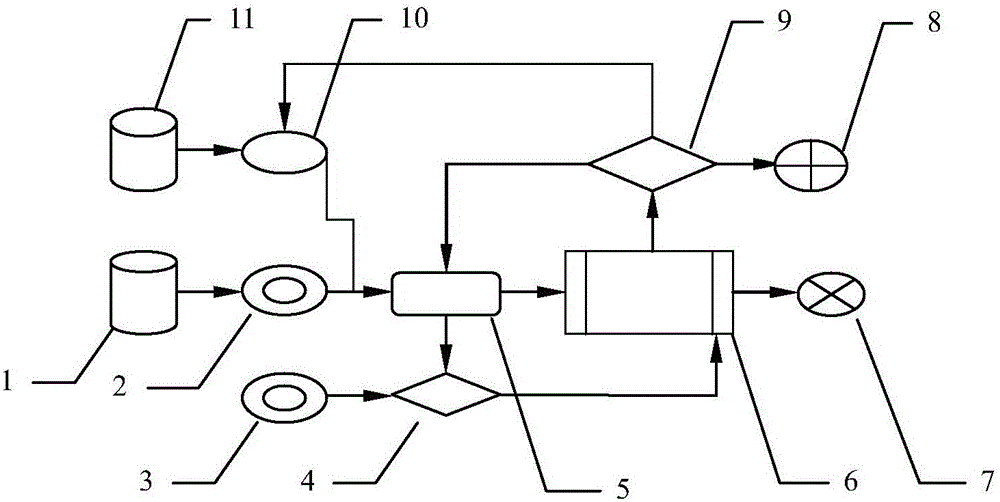

Optimization method for ammonia escape of coal slime fluidized bed boiler denitration system

PendingCN111460726AAchieve ultra-low emissionsSave resourcesGas treatmentDispersed particle separationNeural network learningFluidized bed

The invention relates to the field of NO<x> pollutant treatment of coal-fired power plants, and discloses an optimization method for ammonia escape of a coal slime fluidized bed boiler denitration system, which mainly comprises four steps in order to solve the problem of overlarge ammonia escape amount of the coal slime fluidized bed boiler denitration system in the prior art. According to the method, the NO<x> generation amount before ammonia spraying and the NO<x> generation amount after ammonia spraying are modeled respectively by adopting neural network learning and a Lagrange interpolation method; within a prescribed period, NO<x> before ammonia spraying, NO<x> after ammonia spraying and ammonia escape are optimized through a neural network model and an SQP method respectively; predictive control is adopted to enable the primary air and secondary air and the ammonia spraying opening degree to reach the optimal values respectively, and circulation is continued; and according to themethod, the defects that the ammonia escape amount in an existing denitration system is too large and the like are overcome, the ammonia water cost is saved conveniently, the denitration efficiency is improved, a guarantee is provided for optimal control over ammonia escape in the denitration system, and the method has important significance in achieving ultralow emission of a power plant and saving resources.

Owner:HANGZHOU DIANZI UNIV

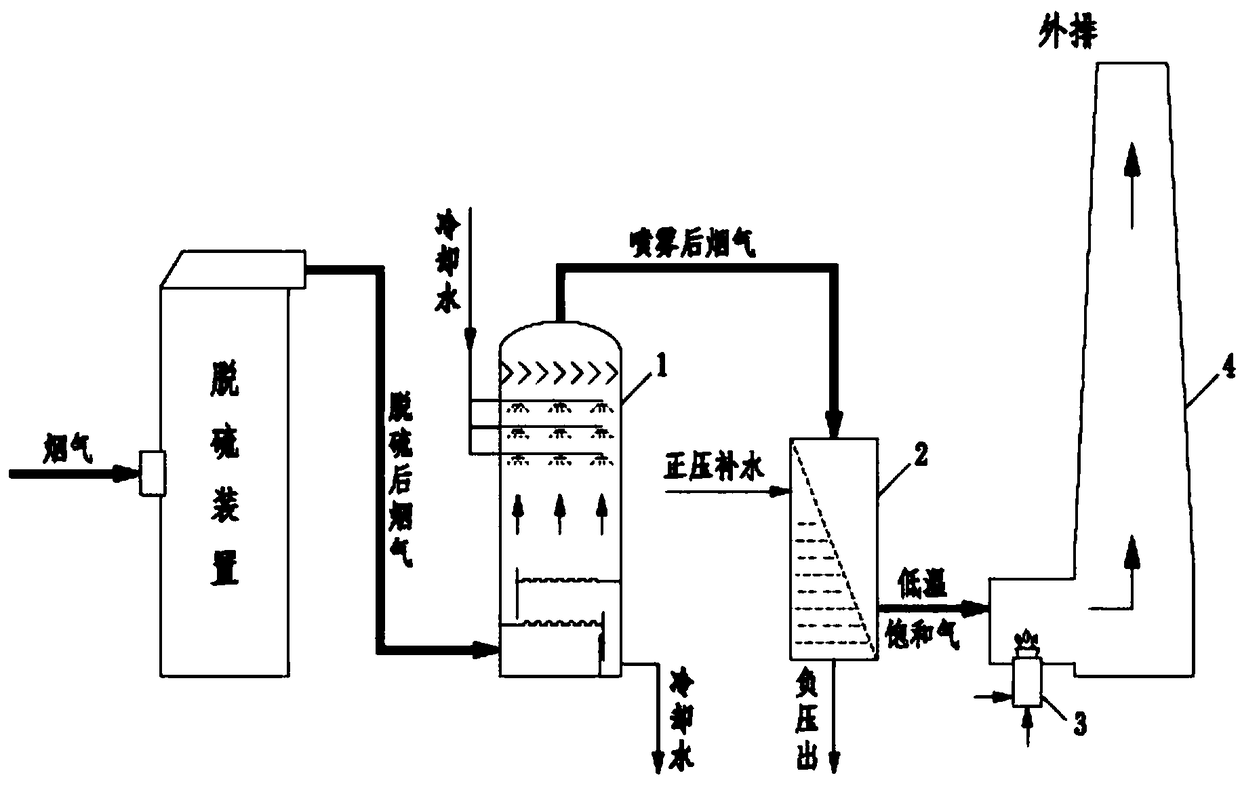

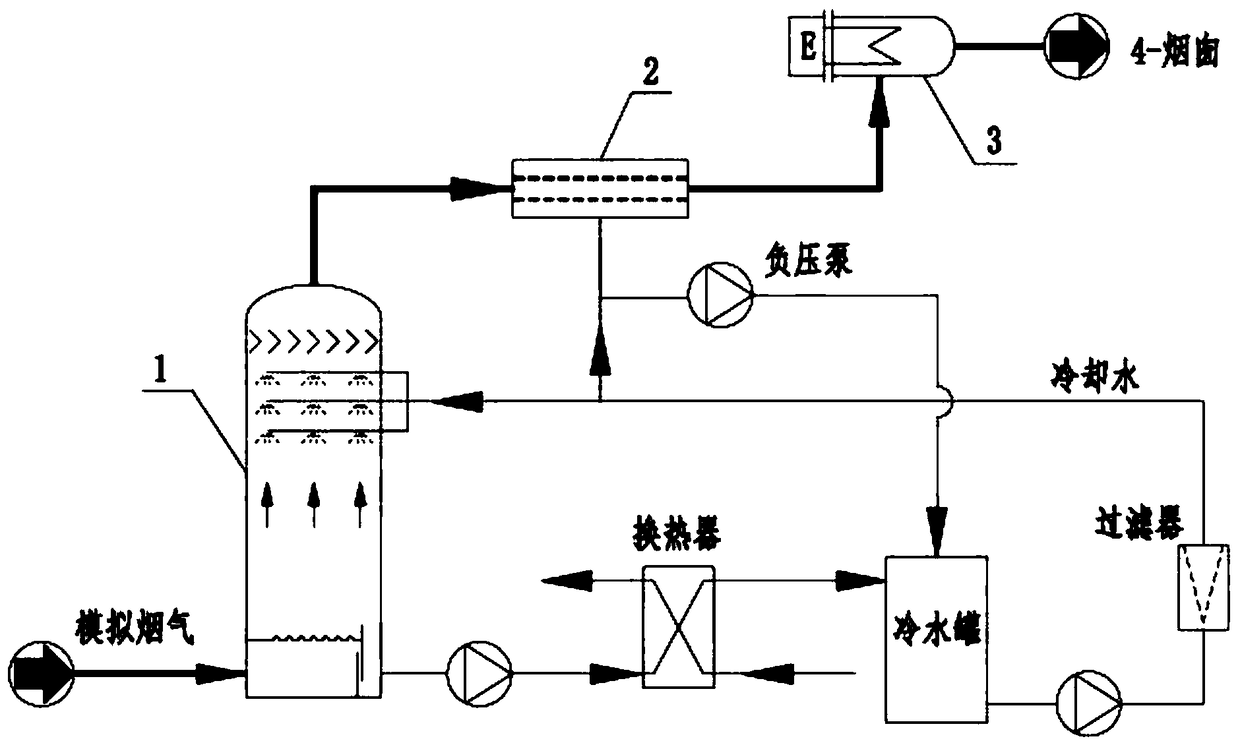

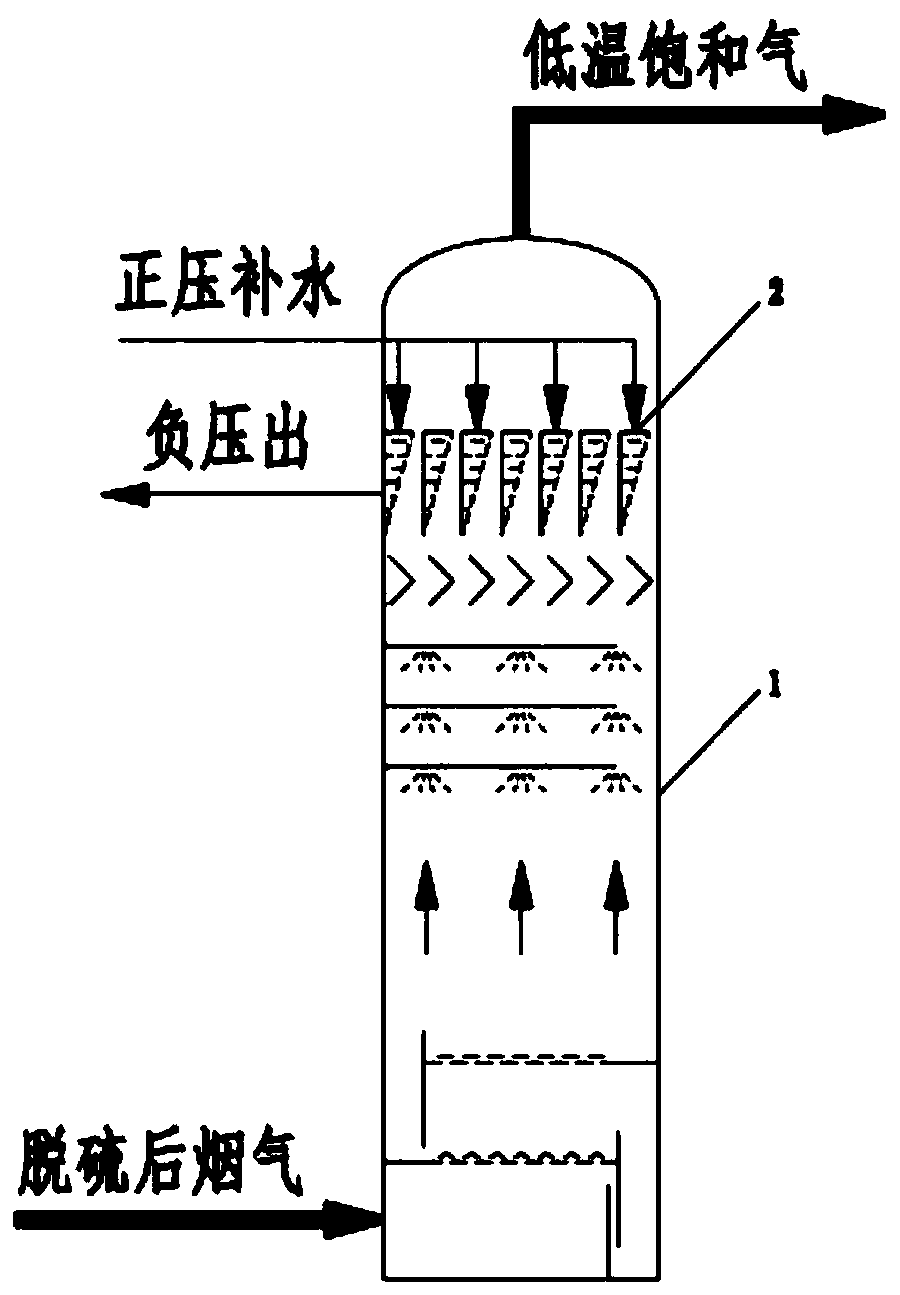

Method and device for eliminating white smoke of wet-containing flue gas

PendingCN109126363AReduce the amount of cooling waterReduce unit consumptionGas treatmentUsing liquid separation agentGas heaterFlue gas

The invention discloses a method and a device for eliminating white smoke of a wet-containing flue gas and belongs to the technical field of gas or steam separation. The method comprises the followingsteps: carrying out cooling spraying on a flue gas after desulfuration, mixing a wet-containing flue gas with cooling mist in a countercurrent manner till the wet-containing flue gas is cooled to a cooling water temperature approximately; carrying out imbibitions demisting on the wet-containing flue gas after cooling spraying, and enabling the flue gas to sufficiently contact the surface of a hydrophilic porous membrane in a membrane demister so as to obtain a low-temperature saturated gas; further heating the low-temperature saturated gas in the step II by using a flue gas heater, and discharging an unsaturated flue gas through a chimney, thereby eliminating white smoke. By adopting the method, the flue gas after desulfuration is fed into a spraying tower, a cooling spraying device is arranged at the upper part inside the spraying tower, and a tower disc is arranged at the lower part of the spraying tower; the cooling spraying device is connected with the membrane demister, the membrane demister is connected with the chimney, and a secondary glue gas heater is arranged between the outlet of the membrane demister and the inlet of the chimney. By adopting the method, a 'white smoke' phenomenon caused when flue gases are discharged can be effectively eliminated, and pollutants such as dust and aerogel can be deeply removed.

Owner:南京圣卡孚科技有限公司

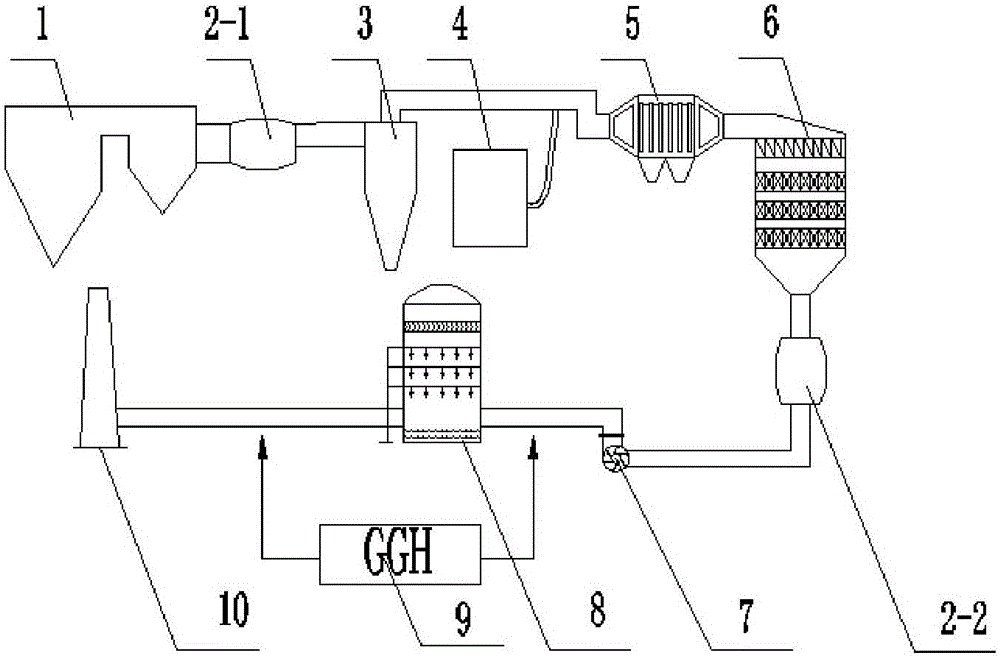

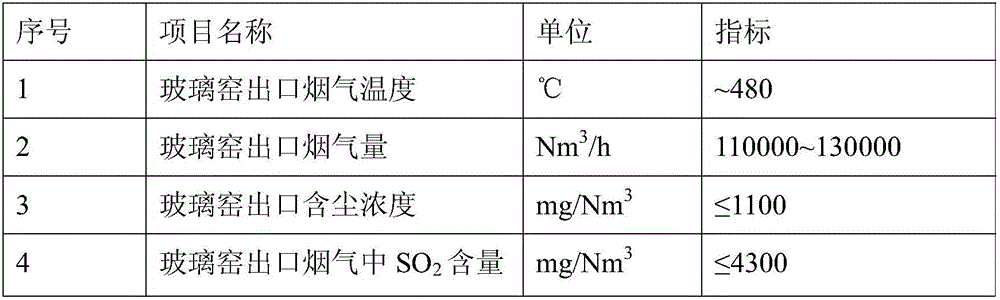

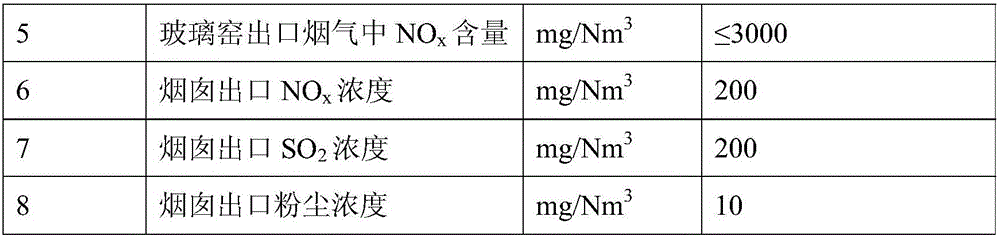

Glass kiln smoke deep purification process

ActiveCN106123613AMature technologyUse more performanceCombination devicesGas treatmentCyclonic spray scrubberLarge particle

The invention discloses a glass kiln smoke deep purification process. According to the process, a kiln smoke purification system is adopted for purifying glass kiln smoke. The kiln smoke generated by a glass kiln enters a high-temperature waste heat boiler, and heat energy is recycled for power generation. Kiln smoke coming out from the high-temperature waste heat boiler enters a cyclone dust collector first so as to remove large-particle-size flying ash and then enters a metal sintering filter material dust collector for deep dedusting. The dedusted kiln smoke enters an SCR reactor for denitrification. The denitrified kiln smoke enters a low-temperature waste heat boiler, and heat energy is recycled for power generation. Kiln smoke coming out from the low-temperature waste heat boiler enters a wet desulphurization tower for desulphurization after heat-exchange-cooled by a GGH. The desulphurized kiln smoke is discharged by a chimney after heated by the GGH. Through the glass kiln smoke deep purification process, glass kiln smoke deep purification can be achieved efficiently and stably with low cost.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

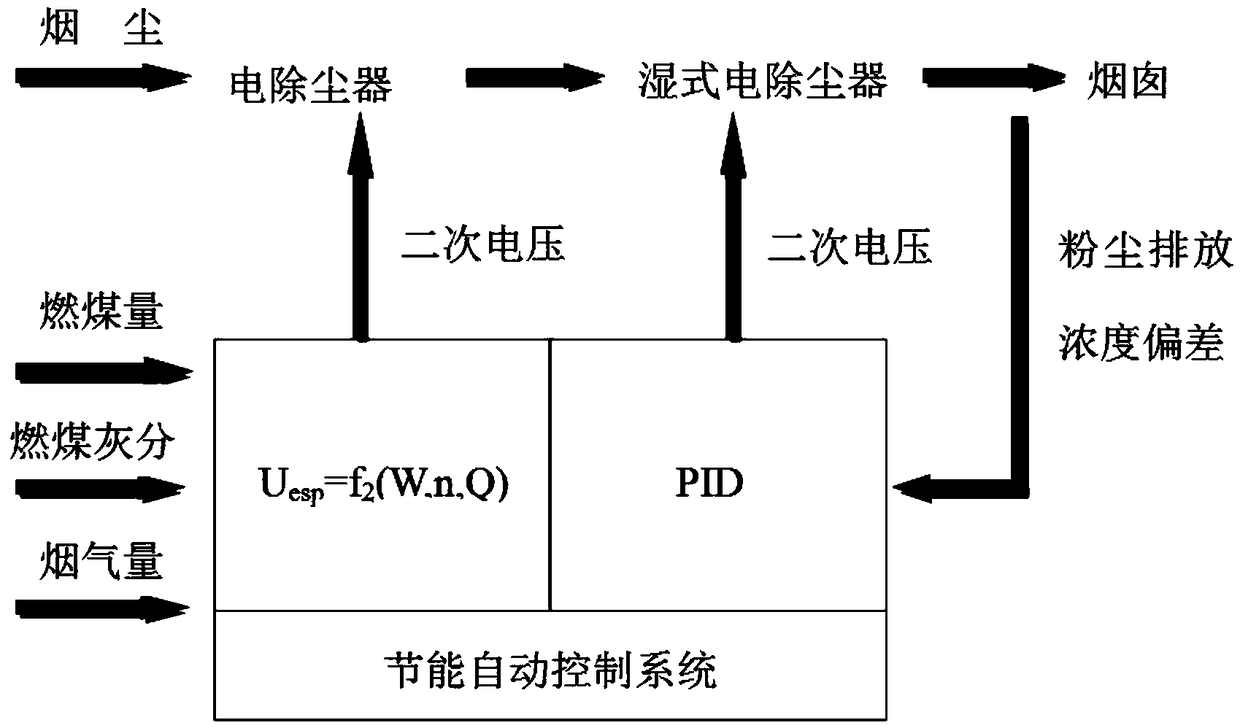

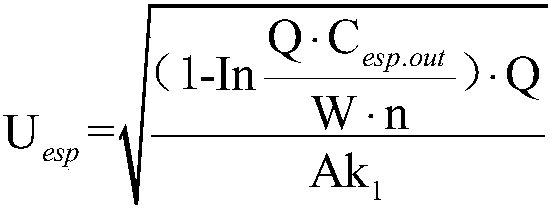

Intelligent energy-saving automatic control method of dust removal system in thermal power plant

ActiveCN109365135AStable emissionsEmission concentration is stableElectric supply techniquesElectricityAutomatic control

The invention discloses an intelligent energy-saving automatic control method of a dust removal system in a thermal power plant. The method comprises the following steps that a coal combustion amount,a coal ash content and a flue gas quantity of a unit are acquired in real time, then according to the fire coal amount, fire coal ash content and smoke amount of the unit, a set value Uesp of a secondary voltage U-electricity of a high-voltage power supply of an electric dust remover is calculated, and then the secondary voltage U-electricity of the high-voltage power supply of the electric dustremover is adjusted according to the set value Uesp of a secondary voltage U-electricity of the high-voltage power supply of the electric dust remover; and the actual smoke dust emission concentrationof an outlet of a wet-type electric dust collector is measured in real time, then a set value Uwesp (n) of U-wet electricity of the secondary voltage of the high-voltage power supply of the wet-typeelectric dust remover is calculated according to the actual smoke dust emission concentration of the outlet of the wet-type electric dust remover through a PID mode, and then according to a set valueUwesp (n) of the secondary voltage U-wet-type electric dust collector of the high-voltage power supply of the wet electric dust remover, the secondary voltage U-wet-type electric dust collector of thehigh-voltage power supply of the wet-type electric dust remover is adjusted. According to the method, the high-voltage power supply of the electric dust remover and the high-voltage power supply of the wet electric dust remover can be efficiently and efficiently operated under different working conditions.

Owner:HUANENG XINDIAN POWER GENERATION CO LTD +2

Low-emission low-swirl direct-injection combustor for gas turbine

PendingCN112128800AEnhanced blendingInhibit growthContinuous combustion chamberSpontaneous combustionThermodynamics

The invention discloses a low-emission low-swirl direct-injection combustor for a gas turbine. The low-emission low-swirl direct-injection combustor comprises a buffer cavity, a premixing air inlet pipe and a flame tube which are connected and communicated from bottom to top; air enters the buffer cavity through the bottom of the combustor, a main fuel spray pipe and a low-swirl combustor are arranged in the premixing air inlet pipe; the main fuel spray pipe is connected with main fuel through a central air delivery pipe; the low-swirl combustor is located above the main fuel spray pipe; a lean-burn direct spray pipe is arranged in the premixing air inlet pipe and the buffer cavity in the axial direction, the bottom end of the lean-burn direct spray pipe is connected with on-duty fuel, andthe top end of the lean-burn direct spray pipe is higher than the low-swirl combustor and faces the flame tube; and premixed gas is mixed with the on-duty fuel sprayed out from the downstream of thelean-burn direct spray pipe through a swirl channel and a straight-flow channel of the low-swirl combustor to be combusted. According to the low-emission low-swirl direct-injection combustor for the gas turbine provided by the invention, a weak swirl fluid field is guaranteed while an geometric angle of a blade and the blockage ratio of a pore plate are increased, the premixing uniformity of fuel / air is improved, formation of NOx is reduced, risks of spontaneous combustion, tempering, lean-burn flameout and combustion oscillation are reduced, the combustion efficiency is improved, and the combustor is suitable for various combustion modes.

Owner:XI AN JIAOTONG UNIV

Automotive fuel cell combined heat and power generation system and working method thereof

InactiveCN105826583AAchieve ultra-low emissionsEmission reductionFuel cell heat exchangeMotive system fuel cellsCogenerationElectrochemical response

The invention discloses an automotive fuel cell combined heat and power generation system. The system mainly comprises a natural gas tank (1), a natural gas compressor (2), an air compressor (3), an air preheater (4), a natural gas reformer (5), a solid oxide fuel cell stack (6), a combustor (9), a water evaporator (10) and a water tank (11). The invention further provides a working method on the basis of the automotive fuel cell combined heat and power generation system. According to the working method, the hydrogen ions in the natural gas are separated by the natural gas reformer (5) to form hydrogen, the hydrogen and high-temperature air passing through the air preheater (4) generate electrochemical reaction in the solid oxide fuel cell stack (6), and the hydrogen and oxygen, which do not generate electrochemical reaction, generate hot gas through the combustor (9). According to the automotive fuel cell combined heat and power generation system and the working method thereof, the natural gas not only can be used for providing power for the vehicles through natural gas engines, but also can generate electric energy and heat energy when the natural gas engines do not work, so as to satisfy certain special purposes.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

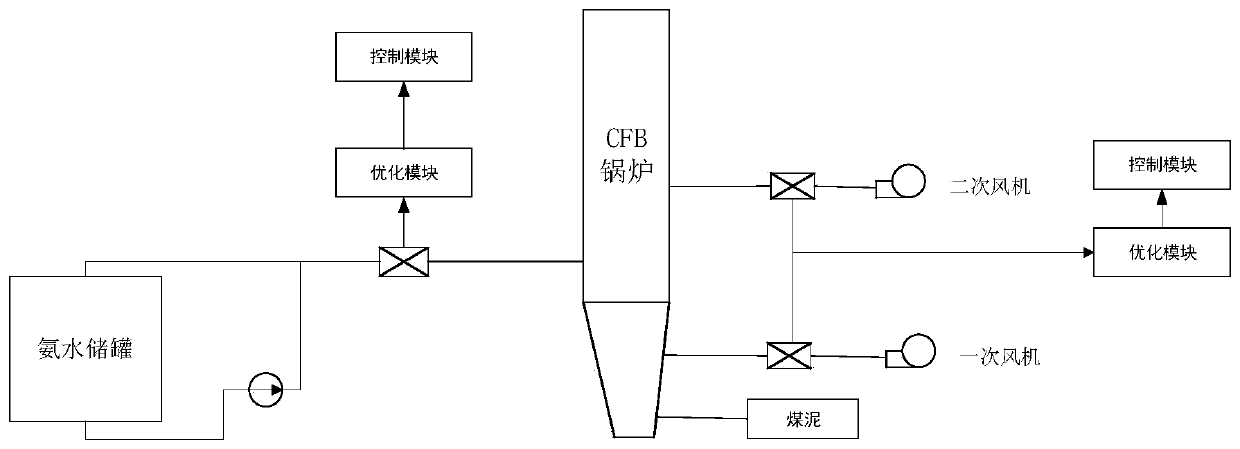

Coal slime fluidized bed boiler desulfurization collaborative optimization operation method

ActiveCN111461391ALow running costImprove operating conditionsDispersed particle separationForecastingFluidized bedData acquisition

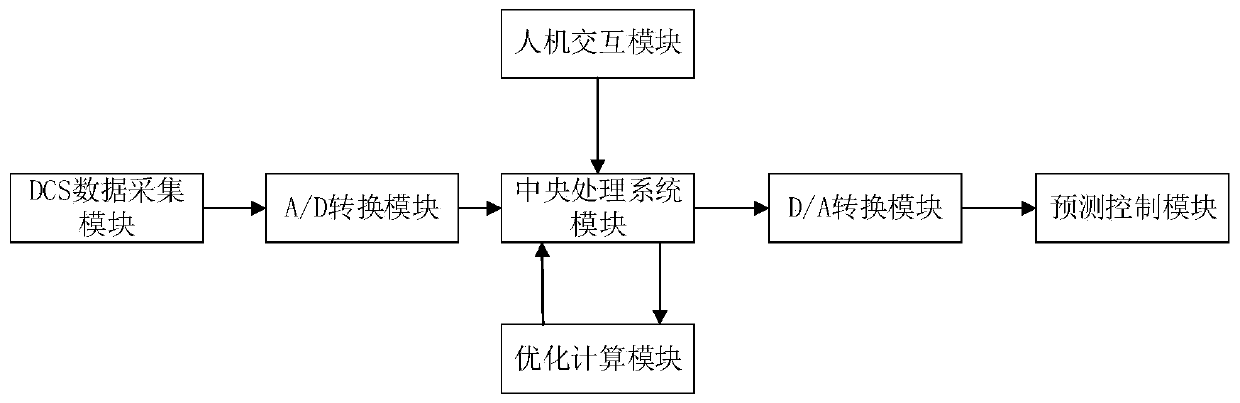

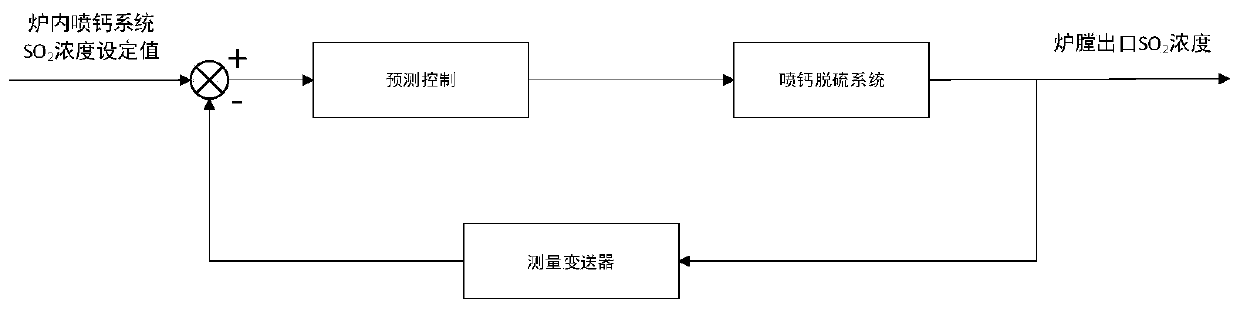

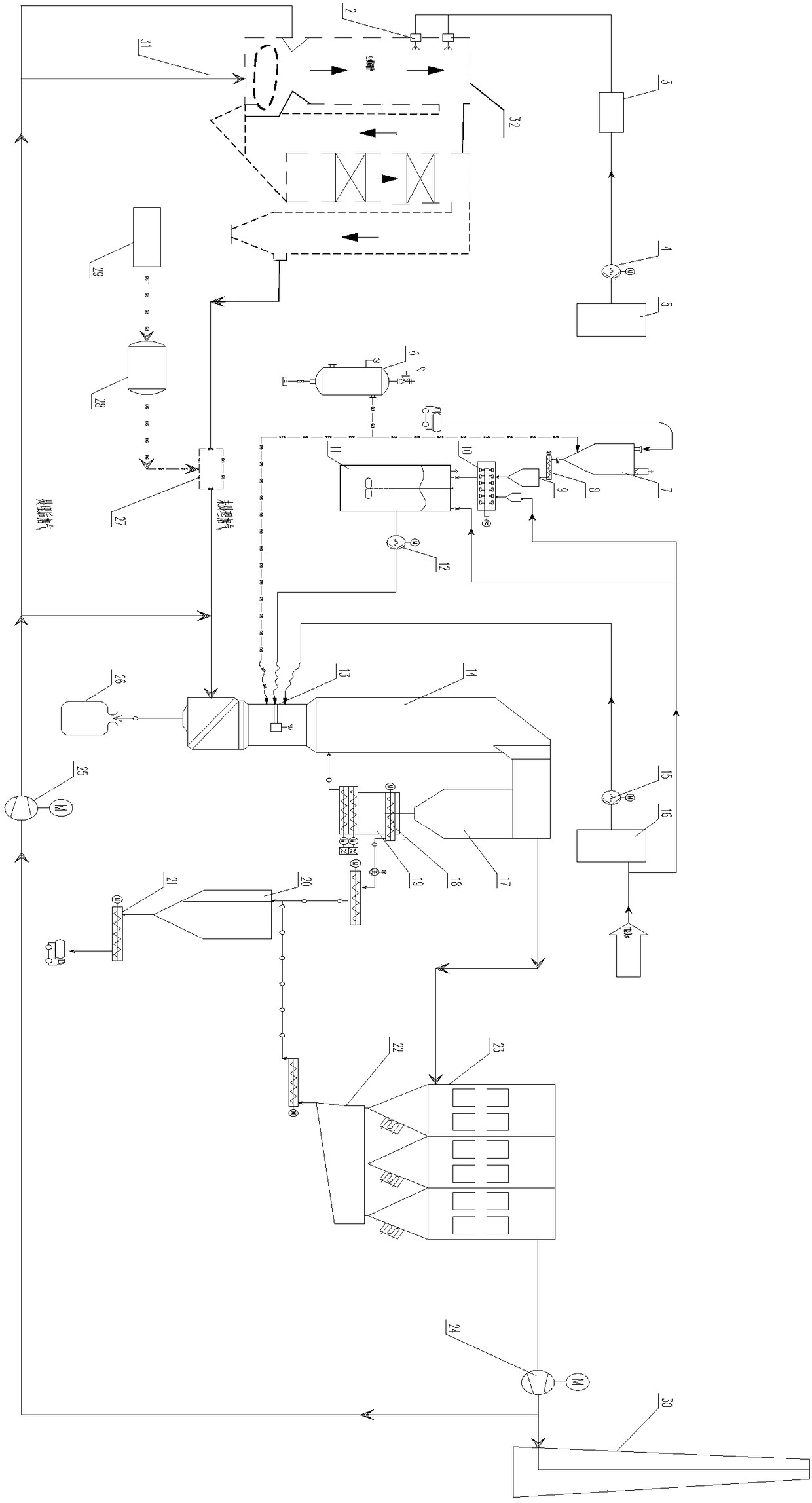

The invention relates to the field of SO<2> pollutant treatment of coal-fired power plants. The invention aims to solve the problem of high SO<2> emission after desulfurization in the prior art. The invention discloses a coal slime fluidized bed boiler desulfurization collaborative optimization operation method. A desulfurization collaborative optimization operation system comprises the followingmodules: a DCS data acquisition module, an A / D and D / A conversion module, a central processing system module, a prediction control module, a man-machine interaction module and an optimization calculation module. The invention provides the coal slime fluidized bed boiler desulfurization collaborative optimization operation method. According to the method, modeling and optimization calculation are carried out on the process of the whole desulfurization system, and the SO<2> concentration value after optimization calculation is subjected to predictive control, so that the operation cost of the whole desulfurization system is minimized, and the result after optimization solution is subjected to predictive control to obtain the lowest operation cost, thereby realizing the economic and stable operation of SO<2> removal and improving the economic benefits of enterprises.

Owner:HANGZHOU DIANZI UNIV

Flue gas purifying and discharge device and method for fire grate type biomass power station boiler

PendingCN108201784AGuaranteed uptimeAchieve ultra-low emissionsCombination devicesGas treatmentPower stationBaghouse

The invention discloses a flue gas purifying and discharge device and method for a fire grate type biomass power station boiler. The device comprises a biomass boiler, an oxidizing and mixing device,a desulfurization tower, a bag dust remover and a chimney, wherein a primary air hole and a secondary air hole are formed in the biomass boiler; an outlet of the biomass boiler is connected with the desulfurization tower through the oxidizing and mixing device; an outlet of the desulfurization tower is connected with the bag dust remover; a first branch of the outlet of the bag dust remover is connected with the chimney; a second branch is connected with the primary air hole and the secondary air hole of the biomass boiler through a re-circulating fan to form a circulating loop; desulfurization, denitration and dust-removal processes are optimized, so that ultralow emission of pollutants such as biomass boiler flue gas sulfur dioxide, nitric oxide and dust is realized. The device is relatively small in influences on the boiler, flexibly operates according to the load and a practical pollutant condition, is convenient for controlling operation of the whole biomass power plant system, isflexible to operate, and saves water and operation cost.

Owner:陕西大秦环境科技有限公司

Automatic load regulating device and method used for tube bundle type dust-removing mist eliminator

PendingCN106964205AStable flow rateGood removal effectDispersed particle separationLow loadControl engineering

The invention provides an automatic load regulating device and method used for a tube bundle type dust-removing mist eliminator, and belongs to the technical field of flue gas wet desulfurization, dust removing and demisting. The device and the method aim to solve the problem that when the dust-removing mist eliminator works under the low-load condition, the gas flow rate is low, the dust removal and demisting performance is declined, and fine dust and gypsum fog drops are difficult to remove. A liquid retaining ring is mounted on an outlet in the upper portion of a tube bundle type dust-removing mist eliminator cylinder body, the upper portion of the liquid retaining ring is sequentially provided with a flow guide ring and a floater support ring, the inner wall of the floater support ring is provided with a wedge-shaped gap, several fins are annularly distributed at the wedge-shaped gap of the floater support ring, a floater is in sliding connection with the fins, the outer wall of the floater is provided with sliding grooves matched with the fins, the lower end of the floater is matched with the wedge-shaped gap in the floater support ring, and a top plate is fixedly installed on the fins. The automatic load regulating device and method used for the tube bundle type dust-removing mist eliminator can automatically conduct load regulating of the dust-removing mist eliminator according to the change of gas flow rate of the tube bundle type dust-removing mist eliminator.

Owner:哈尔滨电气环保有限公司

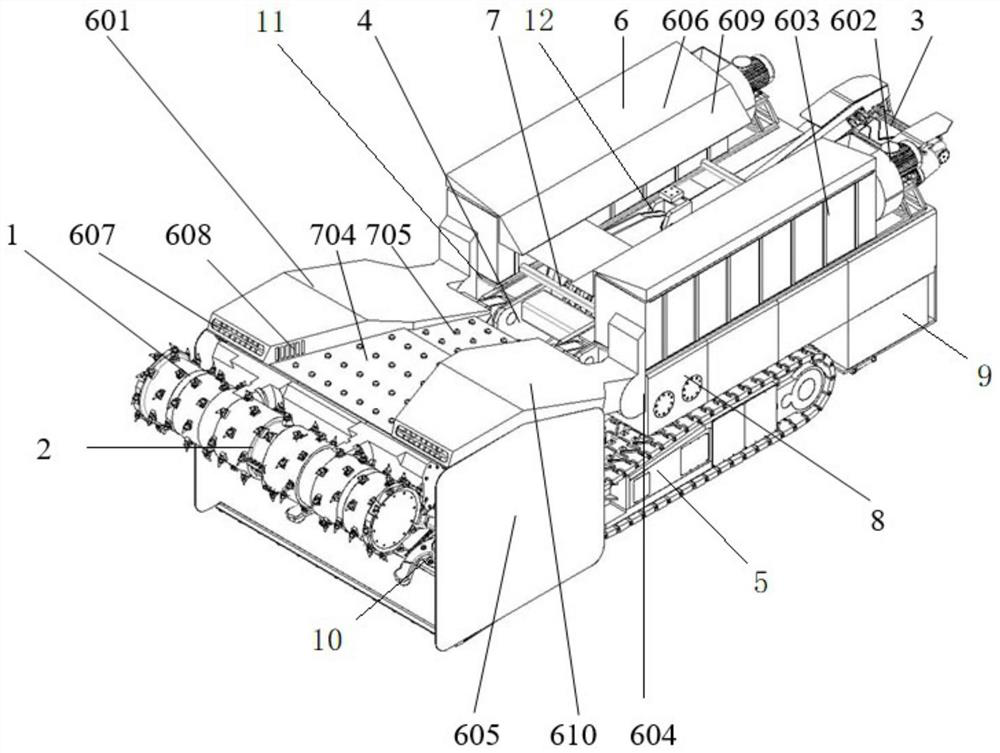

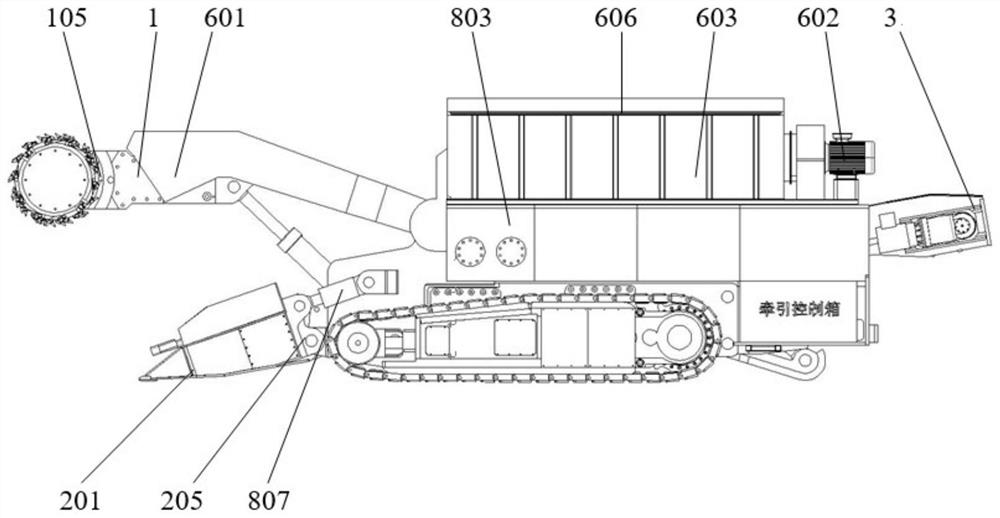

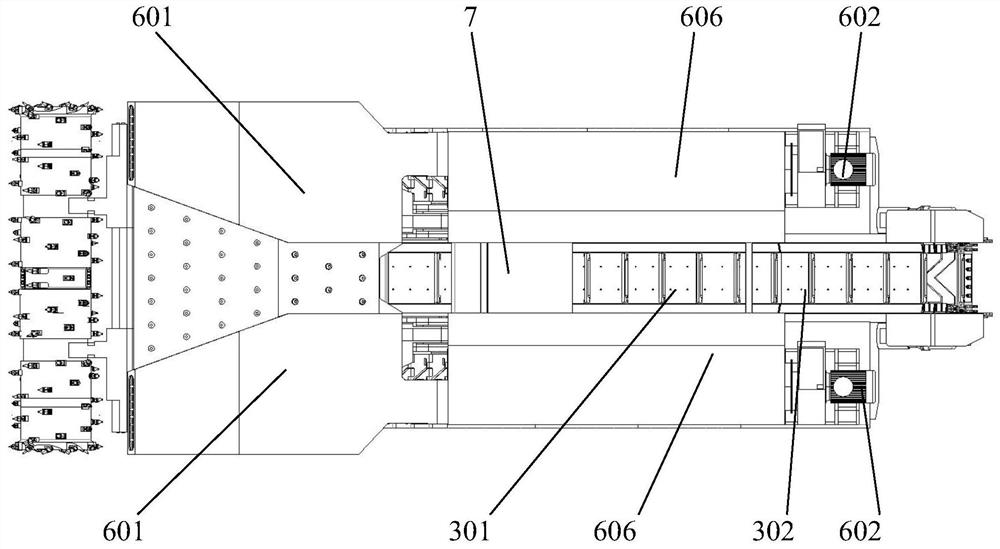

Intelligent continuous mining equipment for strip mine

PendingCN111810159AEfficient and fully continuous mining processVersatileOpen-pit miningFluid-pressure actuator componentsMining engineeringDust control

The invention discloses intelligent continuous mining equipment for strip mine. The intelligent continuous mining equipment for strip mine comprises a rack part and further comprises a cutting part, aloading part, a crushing part, a conveying part and a dust removal system, wherein the cutting part is located on the upper portion of the front end of the rack part, the loading part is located on the lower portion of the front end of the rack part, the conveying part is located on the upper portion of the rack part, the crushing part is located on the right side of the rack part, and the dust removal system is located at the upper part of the rack part. The intelligent continuous mining equipment for strip mine integrates material cutting, loading, crushing, transportation and dust removal,and can replace matched operation of equipment such as a bucket shovel, a bucket wheel excavator, a reversed loader and a belt conveyor in the prior art to form an efficient full-continuous mining process.

Owner:SHANGHAI CHUANGLI GRP

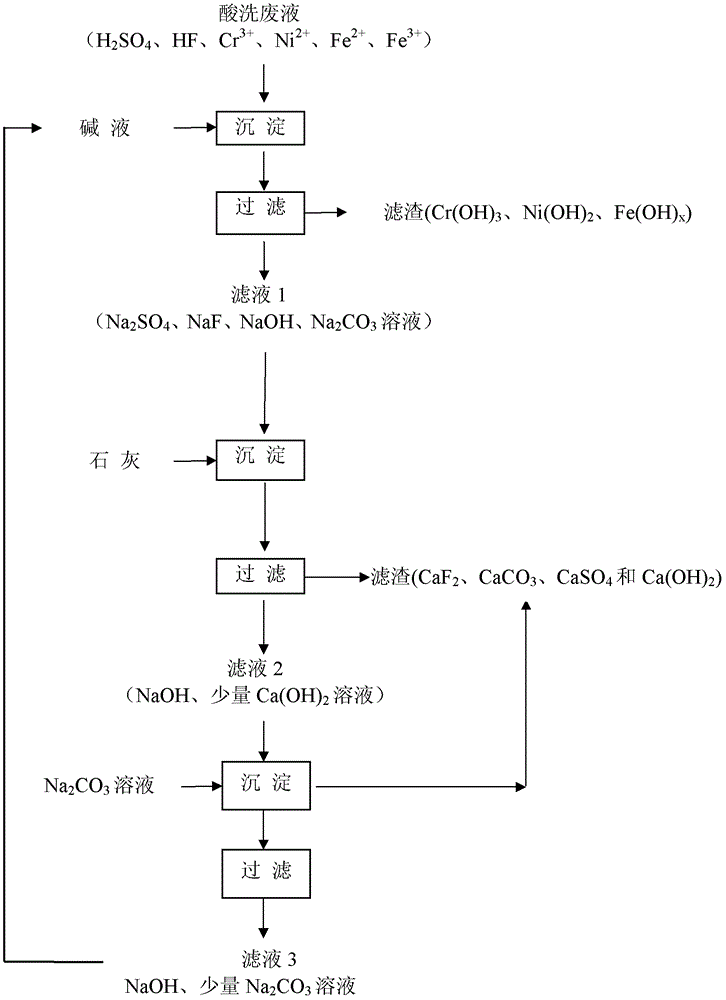

Circular processing method of stainless steel acid washing waste liquid

InactiveCN102603098BLow costEmission reductionWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteWaste processing

The invention belongs to the technical field of waste processing and circular economy, in particular to a circular processing method of stainless steel acid washing waste liquid. The circular processing method comprises the steps of: in allusion to various acid radical ions and metal ions (SO4<2->, F<->, Cr<3+>, Ni<2+>, Fe<2+>, Fe<3+>) in the stainless steel acid washing waste liquid, firstly regulating the pH value of the acid washing waste liquid to 7-10 by using alkaline liquid, and precipitating and drying the metal ions Cr<3+>, Ni<2+>, Fe<2+> and Fe<3+> to form a metallurgical raw material; then adding lime to a filtrate to precipitate F<->, CO3<2-> and SO4<2-> in the forms of CaF2, CaCO3 and CaSO4; and finally adding Na2CO3 to the filtrate to obtain CACO3 precipitation, wherein the filtrate is the mixed solution of NaOH and Na2CO3 and directly returns the filtrate to the stainless steel acid washing waste liquid to precipitate the metal ions. The circular processing method realizes ultralow emission of the stainless steel acid washing waste liquid, danger-free solid waste emission, harmless reutilization of heavy metal ions and recycling of tail liquid, and has obvious economic, environmental and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

Double wet method flue gas desulphurization and dust removal treatment process

ActiveCN106422730AReduce the moisture content of flue gasAchieve ultra-low emissionsGas treatmentUsing liquid separation agentWater contentChemistry

The invention relates to a double wet method flue gas desulphurization and dust removal treatment process. The double wet method flue gas desulphurization and dust removal treatment process is characterized in that calcium carbonate and ammonia water or urea are matched in a furnace to remove NO and NO2, then particulate matters and solute carried by first-stage dust removal and desulphurization are cleaned by using second-stage dust removing water through an n-shaped two-stage wet method desulphurization and dust removal process; second-stage water is desulfurized and denitrified by using the characteristics that ammonia is harmless and is low in gaseous conversion temperature; formed ammonium sulfite refluxes for secondary utilization, and a double-alkali method desulphurization process is formed in first-stage dust removing water. The water content in flue gas at the tail end is reduced by adopting a cyclone centrifugal force, and main pollutants such as SO2, NOX and soot in flue gas emission in a boiler can be discharged at ultra-low emission.

Owner:张明鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com