Method and device for eliminating white smoke of wet-containing flue gas

A wet flue gas, white smoke technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of poor adjustability, high operation and maintenance costs, large floor space, etc., and achieve the unit consumption of cooling water. Low, good water quality, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

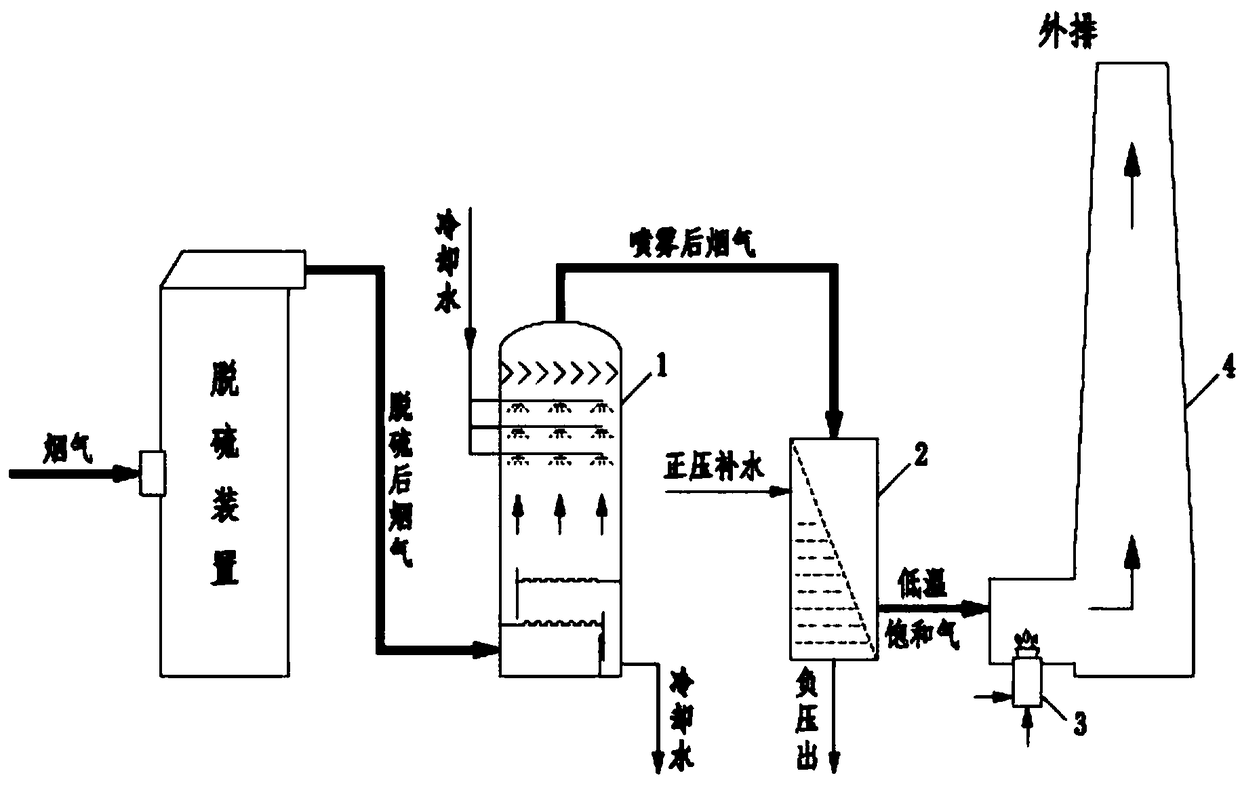

[0052] Such as figure 1 As shown, the wet flue gas elimination white smoke device of the refinery, the flue gas temperature after desulfurization is 65°C, the dew point is 55°C, and the flow rate is 3.0×10 5 Am 3 / h; after desulfurization, the flue gas enters the spray tower 1, the inner and lower trays in the spray tower 1 are bubble-cap trays, and the inner upper part of the spray tower 1 is provided with a cooling spray device, which is connected with the membrane eliminator 2, The flue gas first passes through the lower bubble tray, the gas flow rate is 3.5m / s, and the spray water volume is 354m 3 / h, the droplet size is 200-500μm, and the flue gas is cooled to 38°C by the cooling spray device.

[0053] After spraying, the flue gas enters the membrane eliminator 2 for liquid suction and demisting. The membrane eliminator 2 is installed outside the spray tower 1. The membrane eliminator 2 is connected in two stages. The membrane eliminator 2 is equipped with a 50nm hydrop...

Embodiment 2

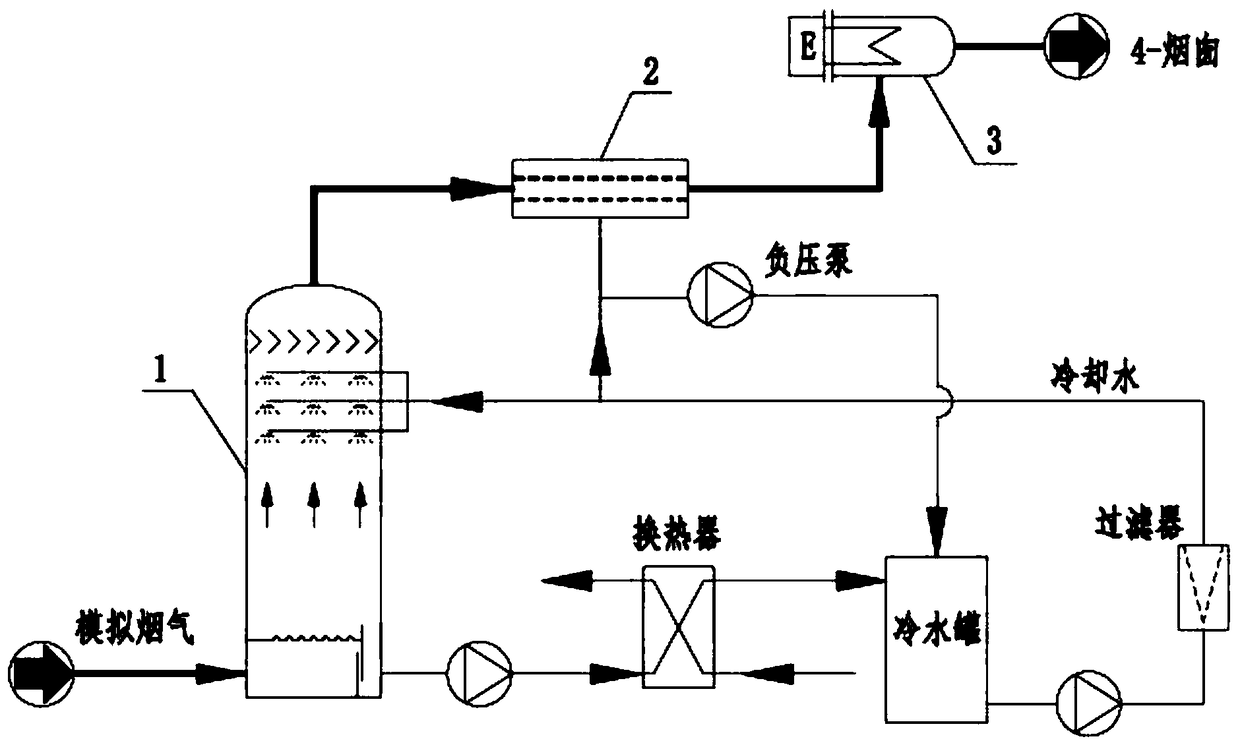

[0055] Such as figure 2 As shown, the flue gas dehumidification production side line experimental device, the simulated flue gas is 1000Am 3 / h Dusty saturated humid air treatment unit, 1000Am 3 The flue gas after desulfurization of / h enters the spray tower 1, the lower tray in the spray tower 1 is a floating valve tray, and the inner upper part of the spray tower 1 is equipped with a cooling spray device, which is connected with the membrane demister 2, and the dust The saturated humid air first passes through the lower valve tray, the gas flow rate is 3m / s, and the spray water volume is 1.4m 3 / h, the droplet size is 400-800μm, after desulfurization at 55℃, the flue gas is cooled to 45℃ by the cooling spray device, and the partial pressure of water vapor is reduced from 15.8kPa to 9.6kPa;

[0056] After spraying, the flue gas enters the membrane demister 2 for liquid suction and demisting. The membrane demister 2 is arranged outside the spray tower 1. The membrane demist...

Embodiment 3

[0058] Such as figure 1 As shown, this embodiment is a 330MW unit of a coal-fired power plant. After desulfurization, the flue gas temperature is 50°C and the flow rate is 1.30×10 6 Am 3 / h, water volume content 11.80%; after desulfurization, the flue gas enters the spray tower 1, the lower tray of the spray tower 1 is a bubble tray, and the upper inner part of the spray tower 1 is equipped with a cooling spray device, and the cooling spray device and the film demist Connected to device 2, the flue gas first passes through the lower bubble-cap tray, the gas flow rate is 2.5m / s, and the spray water volume is 1139m 3 / h, the droplet size is 100-300μm, and the flue gas is cooled to 45°C by the cooling spray device.

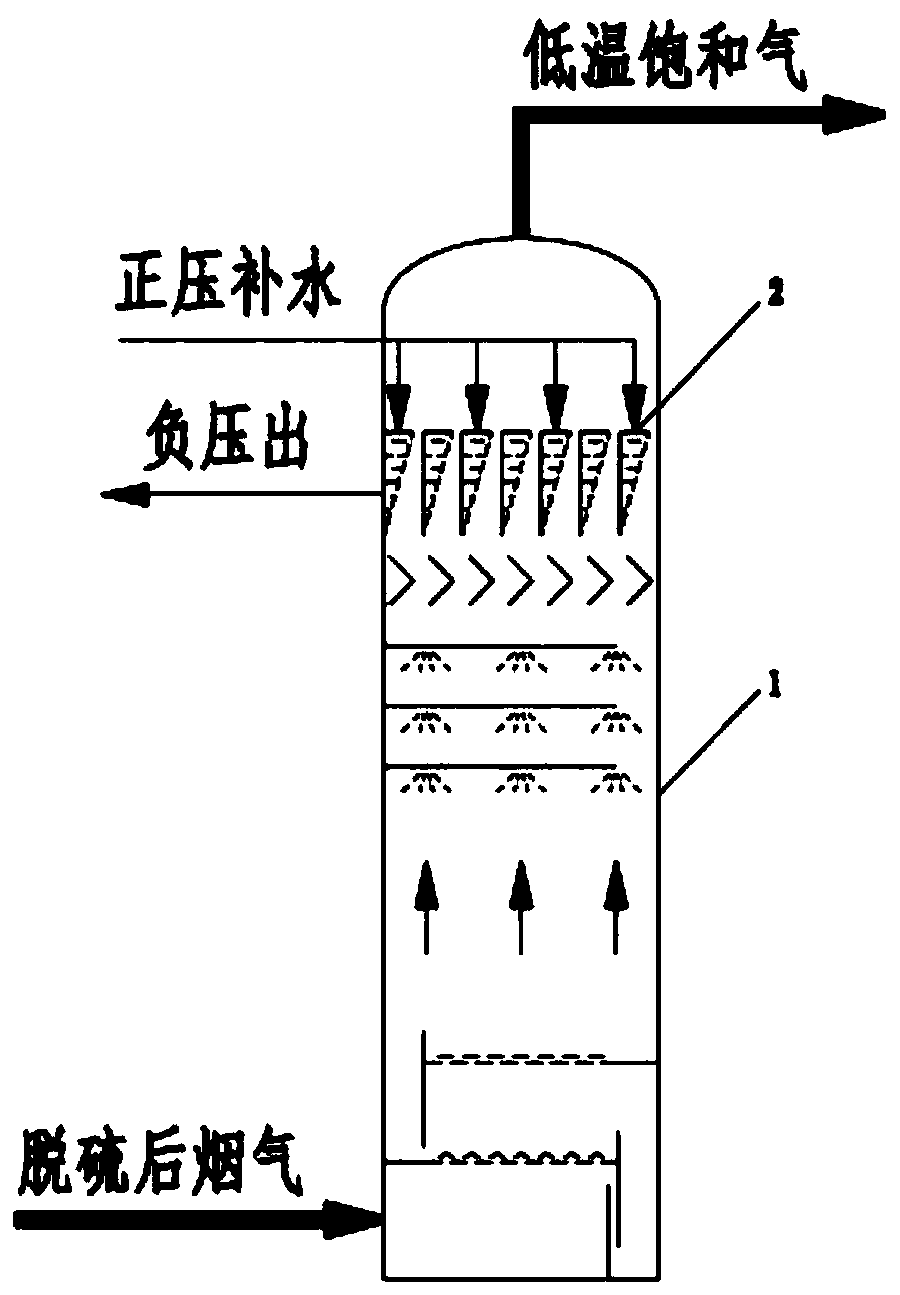

[0059] After spraying, the flue gas then enters the membrane eliminator 2 for suction and demisting. The membrane eliminator 2 is set inside the spray tower 1 to become a single device such as image 3 As shown, a buffer baffle is set between the membrane eliminat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com