Recirculation type semidry process reaction tower for purifying flue gas and technique thereof

A technology for cleaning flue gas and reaction towers, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

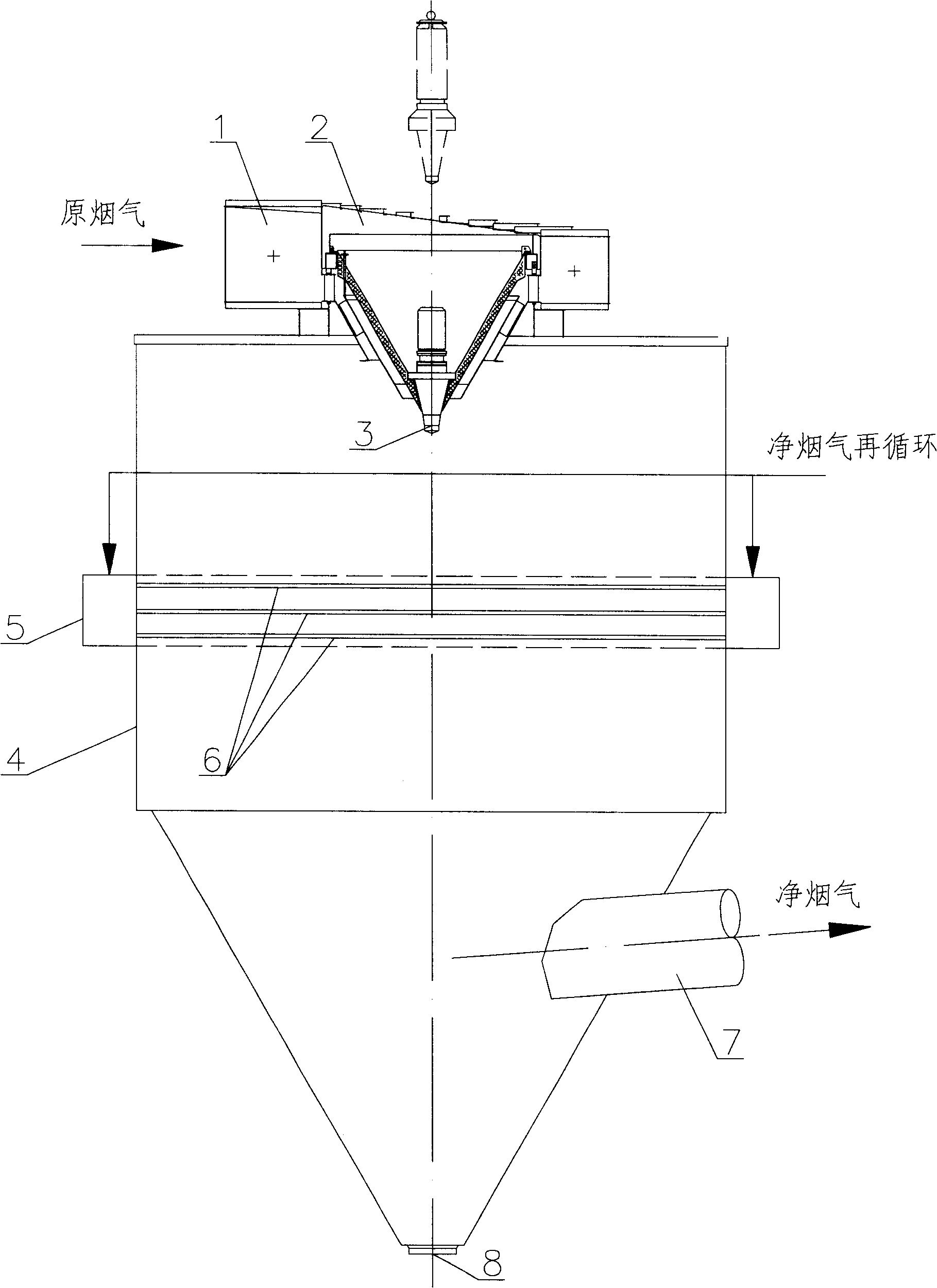

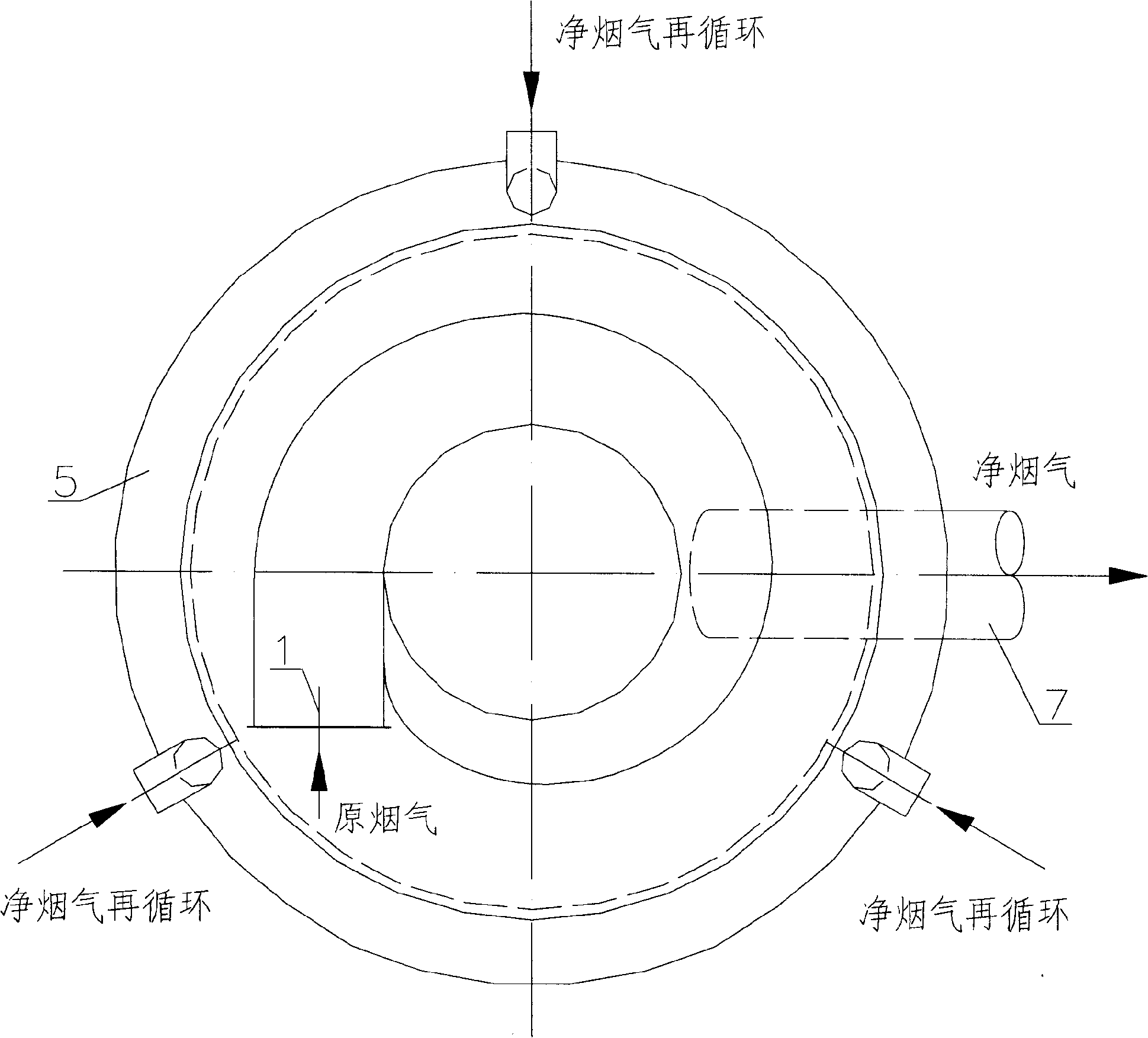

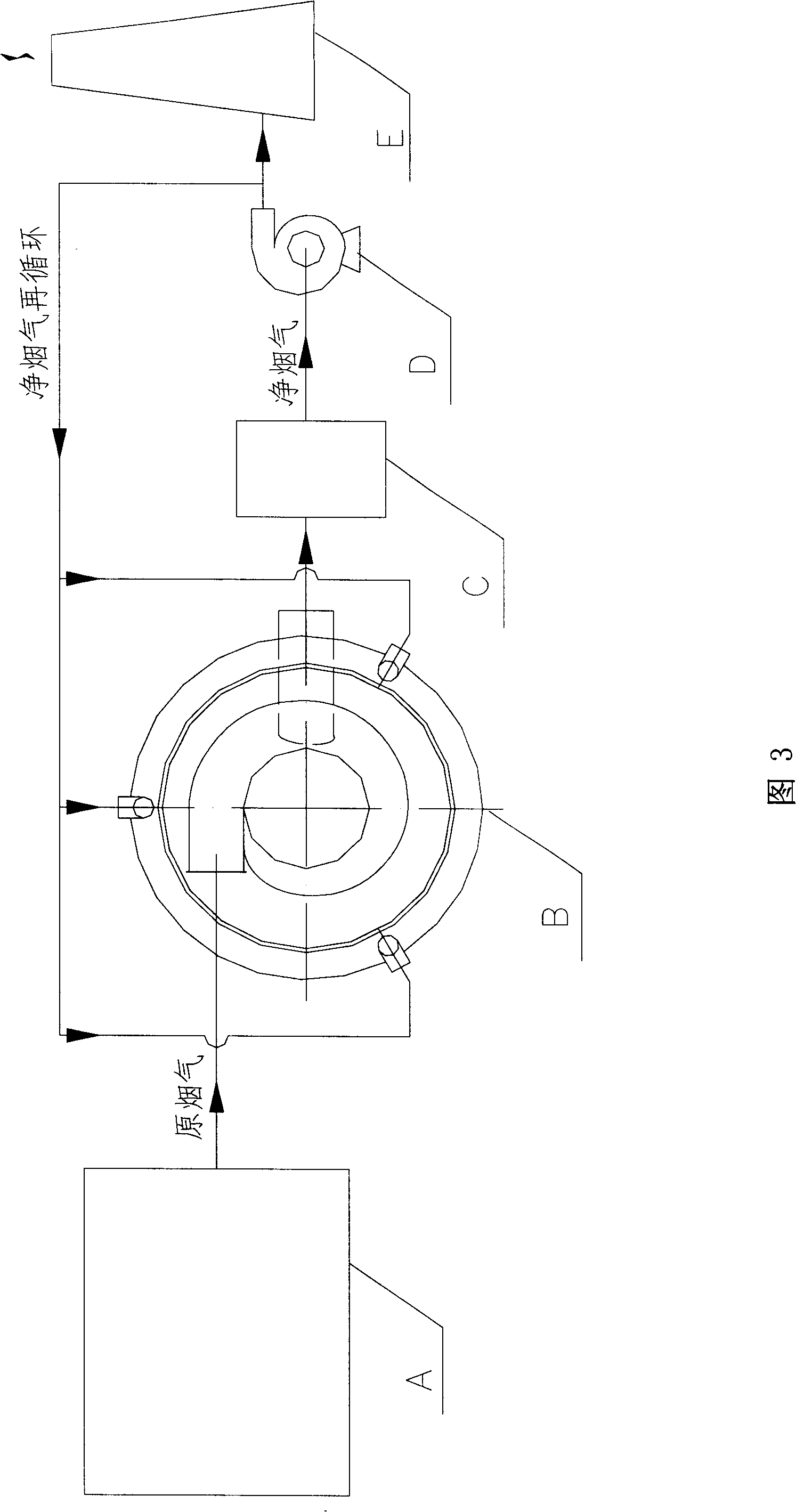

[0019] Such as figure 1 As shown, the clean flue gas recirculation type semi-dry reaction tower of the present invention includes the original flue gas inlet 1, the original flue gas rectification deflector 2, the rotary sprayer 3, the reaction tower tower body 4, and the recirculation net flue gas header 5 , Annular net flue gas nozzle 6, net flue gas outlet 7 and ash outlet 8. The original flue gas inlet 1 and the original flue gas rectifying deflector 2 are located at the top of the reaction tower, and a rotary sprayer 3 is installed at the center of the top of the reaction tower, the net flue gas outlet 7 is located at the bottom of the reaction tower, and the ash discharge port 8 is located at the bottom of the reaction tower . Three circles of annular net flue gas nozzles 6 are arranged on the wall surface of the approximately middle height position of the reaction tower body 4, and the annular net flue gas nozzles 6 are distributed on the circumferential wall surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com