A vocs waste gas adsorbent regeneration pyrolysis furnace

An adsorbent regeneration, pyrolysis furnace technology, applied in filter regeneration, combustible gas purification, combustible gas purification/reconstruction, etc., can solve problems such as leakage, VOCs exhaust gas sealing failure, no solution for electrothermal purification filter elements, etc. achieve the effect of reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

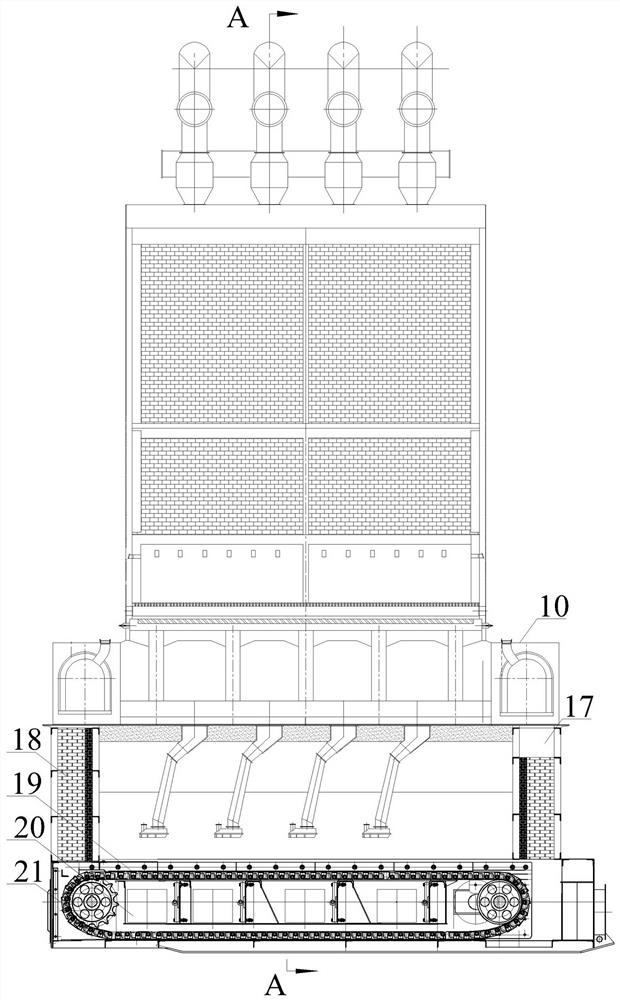

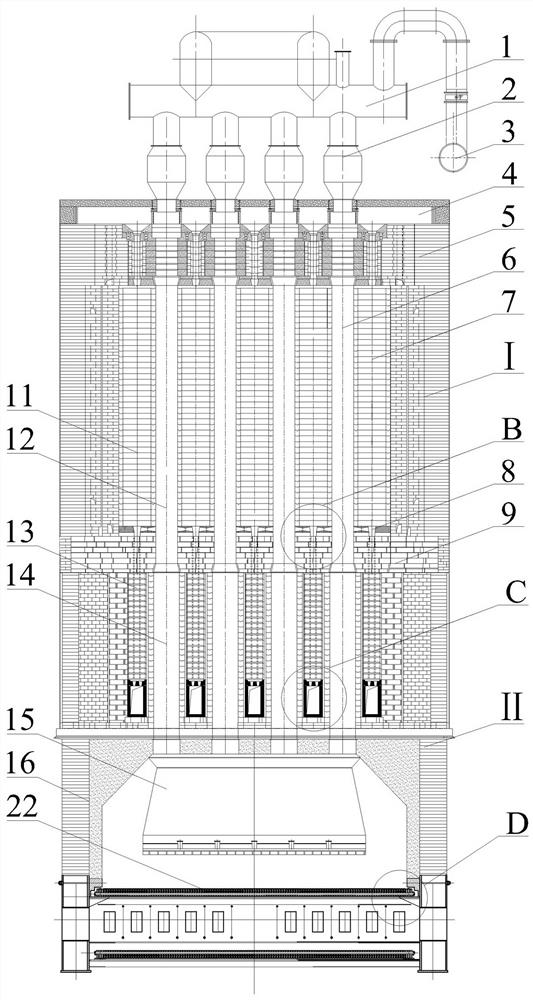

[0034] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a VOCs exhaust gas adsorbent regeneration pyrolysis furnace is characterized in that it includes a desorption pyrolysis furnace I and a chain drive grate bed II.

[0035] The desorption pyrolysis furnace I includes a desorption pyrolysis furnace body 5 and a feeding system 1 .

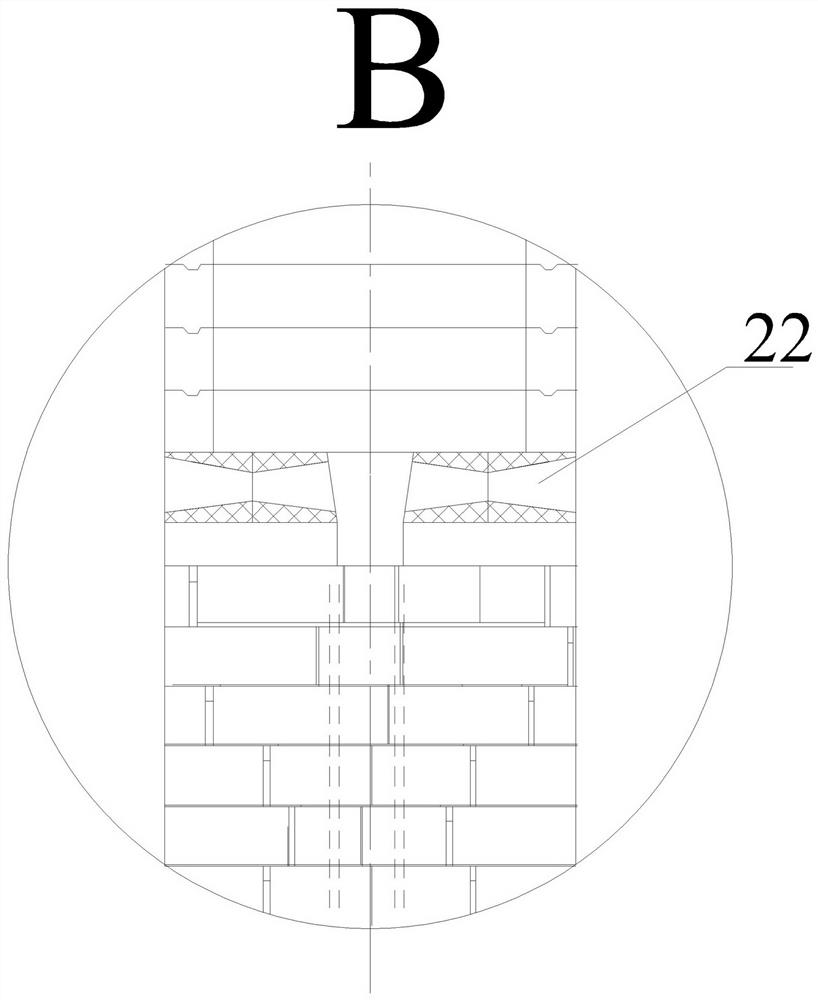

[0036] The desorption pyrolysis furnace body 5 is designed with a fire path 7 and a vertical path 6, the fire path 7 is for the circulation of high-temperature flue gas, the vertical path 6 is for the adsorbent to move and fall, and the fire path 7 and the vertical path 6 are adjacently built. The middle partition arch 9 divides the desorption pyrolysis furnace body 5 into upper and lower areas, that is, the upper area desorption pyrolysis area and the lower area heat storage area.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com