A device for preparing insoluble sulfur evaporation process

A sulfur and process technology, which is applied in the field of devices for preparing insoluble sulfur evaporation processes, can solve the problems of difficulty in ensuring the normal operation of the atomizer and the particle size requirements of sulfur droplets, and the details of the production device are not disclosed, and reduce energy consumption. , The effect of improving production efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

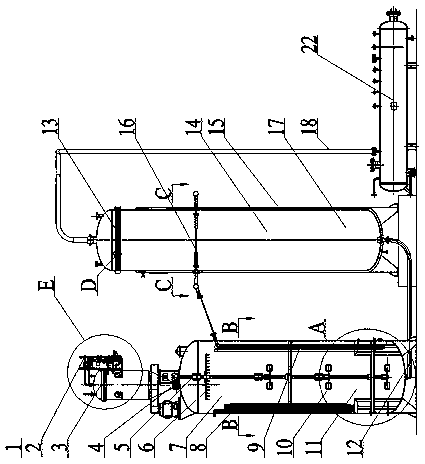

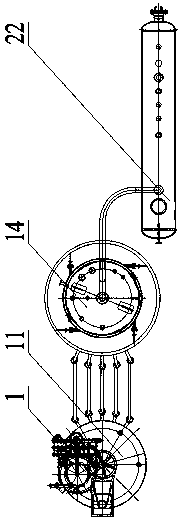

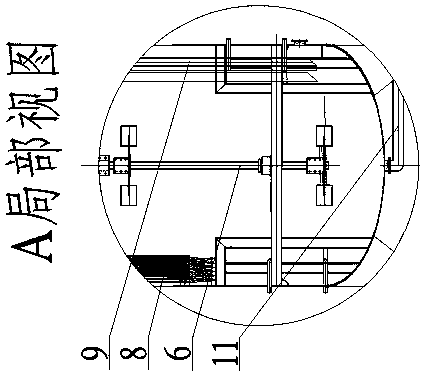

[0030] The device will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] The invention is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a device for preparing insoluble sulfur evaporation process is characterized in that it includes a saturated steam heating kettle assembly 11, a superheater 14, a superheated sulfur steam intermediate tank 22, and a sulfur powder storage tank 1.

[0032] The saturated steam heating kettle assembly 11 includes a feed port 5, a stirring assembly 6, a saturated steam heating kettle body 7, a saturated steam heating coil 8, a transpiration convection pipe 9, and a circulation convection pipe 12. The stirring assembly 6 is designed with a stirring Paddle 10, spreader 6.

[0033] The superheater 14 includes a gas-liquid separator 13 , a hot air heating jacket 15 , a distributor assembly 16 , and a hot air heating furnace body 17 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com