Liquid blast furnace slag heat recovering apparatus and method

A technology of heat recovery device and blast furnace slag, which is applied in the direction of heating device, recycling technology, process efficiency improvement, etc., and can solve the problems of liquid slag granulation and high heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

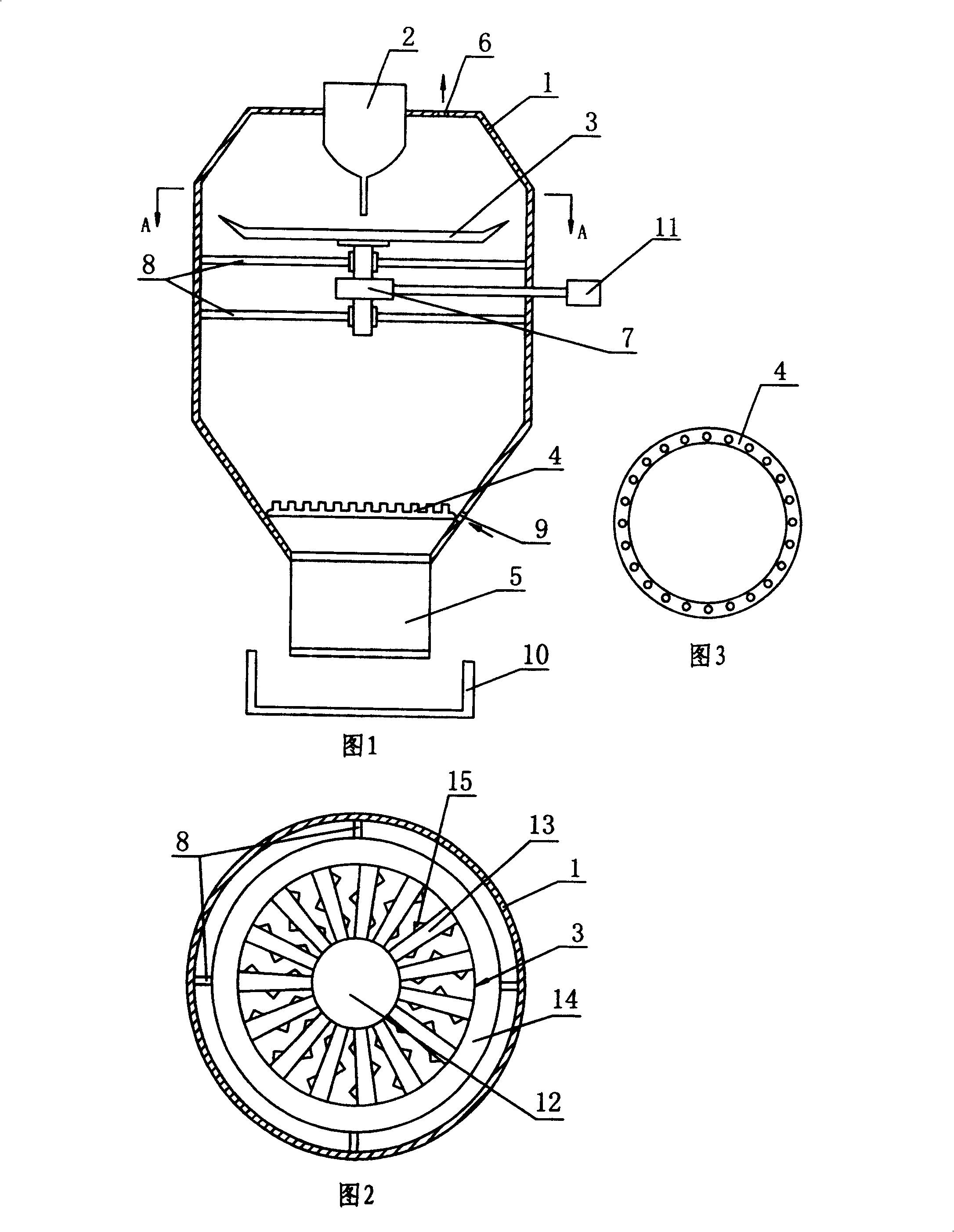

[0031] As shown in Figure 1, the liquid blast furnace slag heat recovery device is mainly composed of a cylindrical airtight container 1, a liquid slag gate 2, a granulation device 3, a cooling gas injection device 4, and a slag sealing and slag cleaning device 5 ;

[0032] The liquid slag gate 2 is set on the top of the cylindrical airtight container 1, and the outer edge of the gate is sealed with the airtight container; in the cylindrical airtight container 1, the lower part of the liquid slag gate 2 is provided with a motor and a transmission system 7. The granulation device 3; the top of the cylindrical airtight container 1 is provided with an air outlet 6, and the lower side wall is provided with an air inlet 9.

[0033] In the figure, 8 is the mounting frame for setting the granulation device 3 and the transmission system 7, 10 is the slag collection tank, and 11 is the motor.

[0034] The granulation device 3 can be a spoke-type granulation device or a cup-type granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com