Feed water control method for supercritical concurrent boiler without boiler-water circulating pump

A boiler water circulating pump and once-through boiler technology, applied in the control of water supply, preheating, steam generation, etc., can solve the problems of increased energy consumption of the water supply pump and high temperature of superheated steam, reducing heat loss, reducing the amount of desuperheating water, and ensuring safety running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution will be described in detail below in conjunction with the drawings.

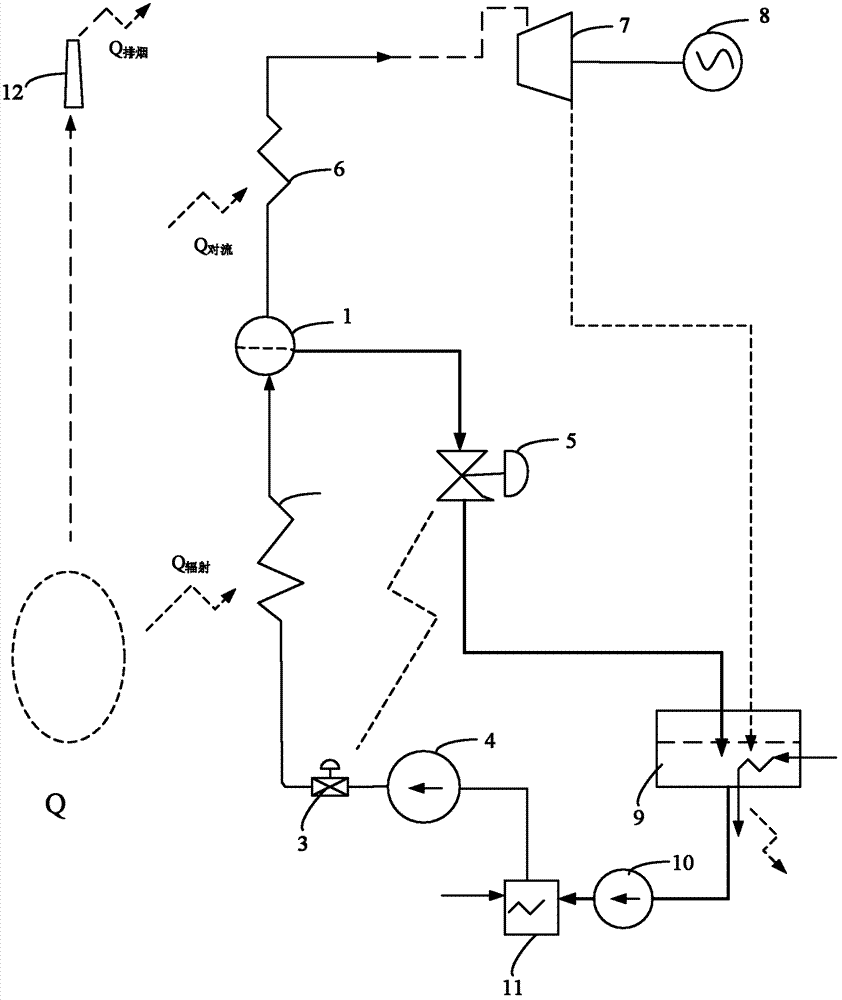

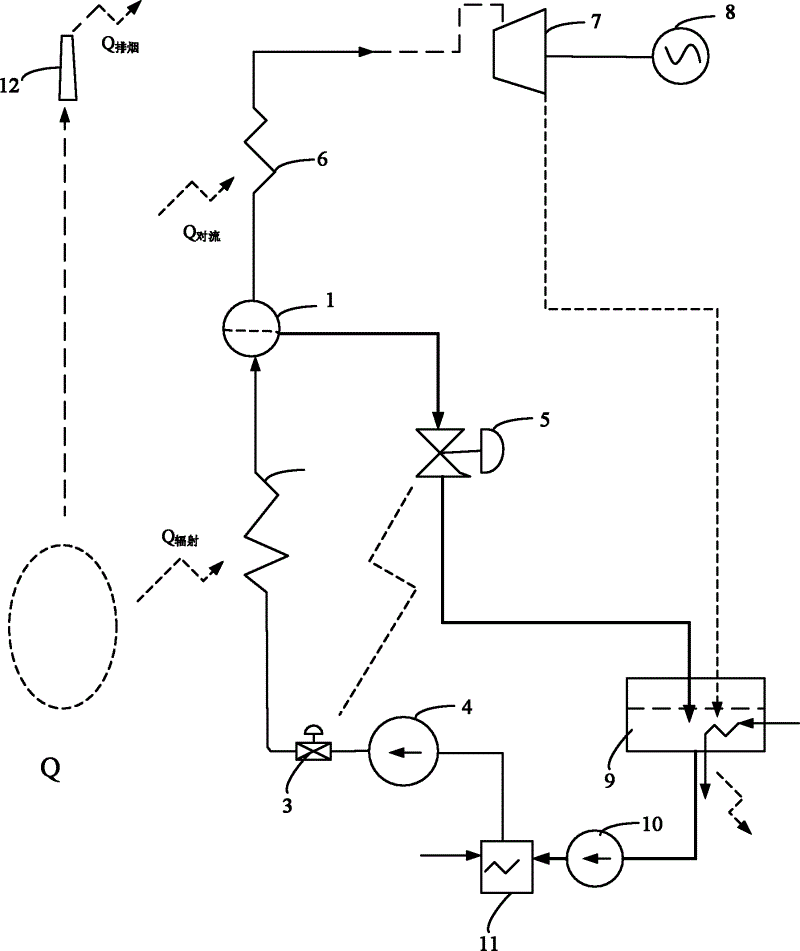

[0022] Refer to figure 1 , A schematic diagram of the principle structure of a boiler-less water circulating pump supercritical once-through boiler device, in which coal is burned in the furnace, the boiler is equipped with a water wall 2 and a superheater 6, and the flue gas after heat absorption is discharged from the chimney 12. After the feed water is heated by the deaeration heater 11, it is fed into the water wall 2 by the feed water pump 4 and heated, and the amount of feed water entering the water wall 2 is controlled by the feed water flow valve 3, and the steam-water mixture heated by the water wall 2 in the furnace It enters the steam-water separator 1 for separation, the saturated steam enters the superheater 6 to continue heating, and the superheated steam is sent to the steam turbine 7 to perform work, driving the generator 8 to work; the boiler water in the steam-wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com