Optimization method for ammonia escape of coal slime fluidized bed boiler denitration system

A fluidized bed boiler and optimization method technology, applied in chemical instruments and methods, separation methods, design optimization/simulation, etc., can solve problems such as large ammonia escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention will be further analyzed below in conjunction with the accompanying drawings and specific embodiments.

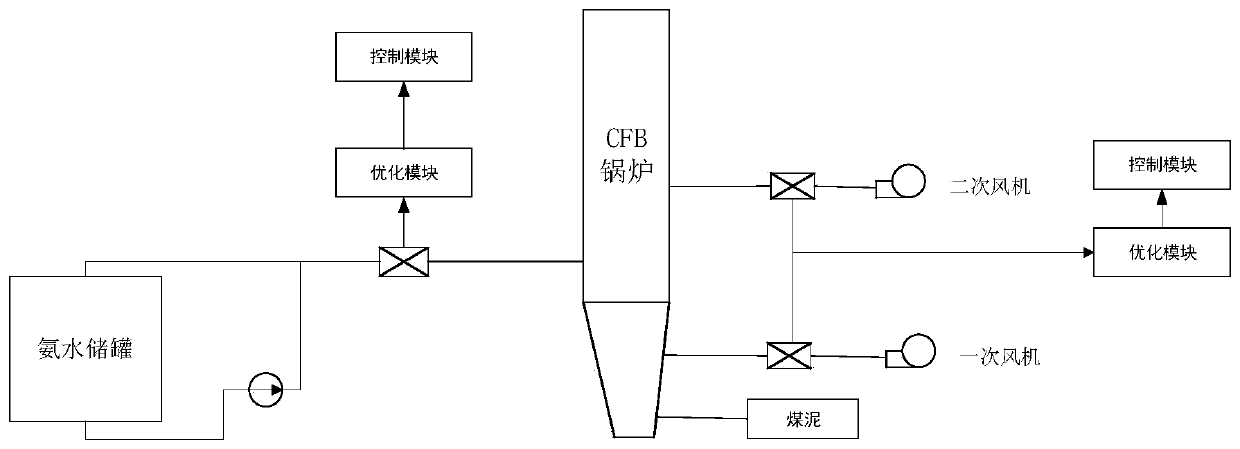

[0093] like figure 1 As shown, a block diagram of the overall control of ammonia escape in the denitrification of a fluidized bed of coal slime, which optimizes and controls the NOx before and after ammonia injection.

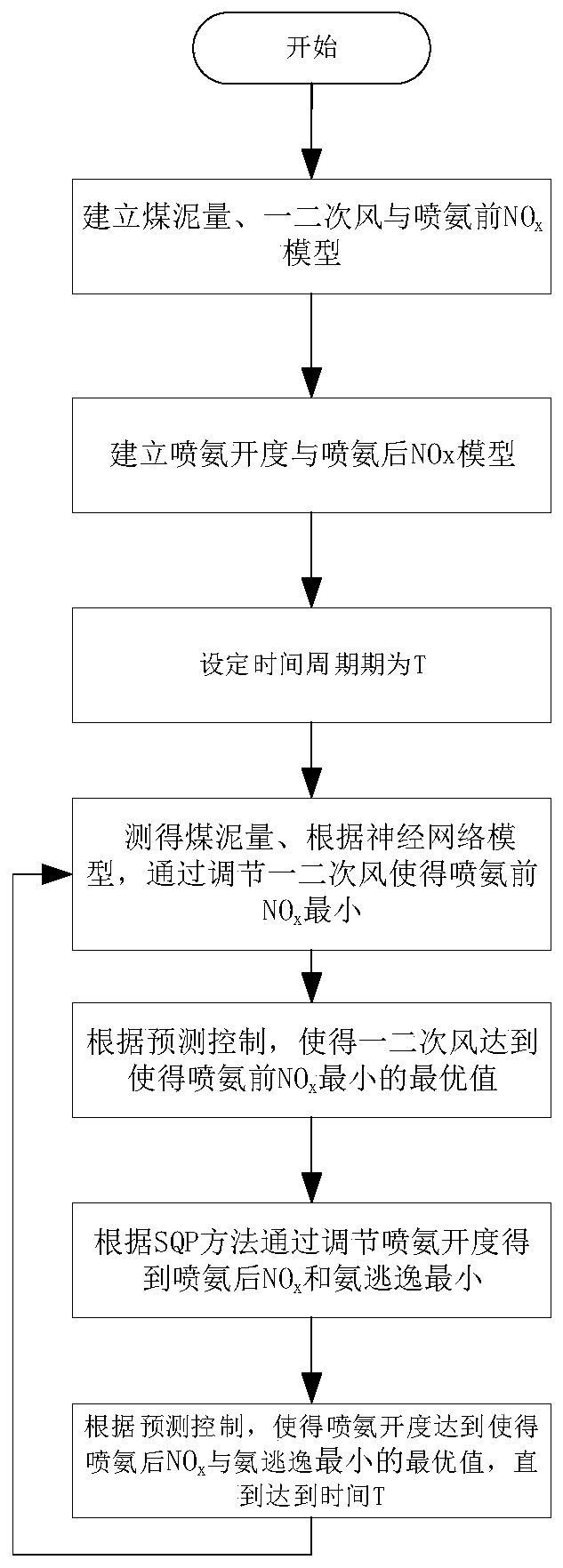

[0094] like figure 2 As shown, an optimization method for ammonia escape in the denitrification of a coal slime fluidized bed, the specific implementation adopts the following steps:

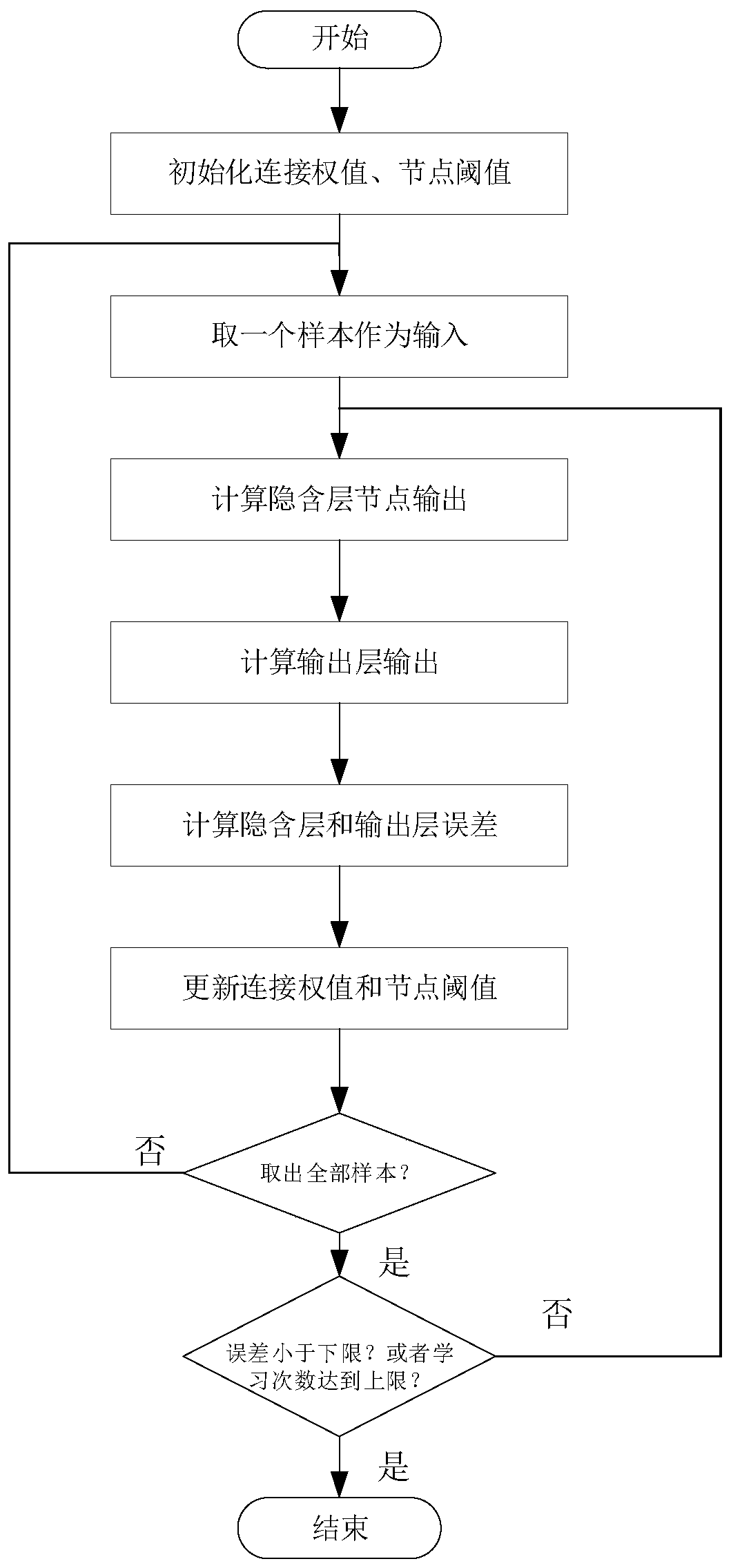

[0095] Step 1. Use the neural network learning method to establish a model of the relationship between the amount of coal slime, primary and secondary air, and NOx production before ammonia injection, and then enter step 2;

[0096] Step 2, establish the model of ammonia injection opening and NOx generation after ammonia injection, then enter step 3;

[0097] Step 3. Set a time period T, optimize NOx before ammonia injection, obtain the optimal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com