Low-vanadium-content wide-active-temperature-window denitration catalyst and preparation method thereof

A technology of active temperature window and denitrification catalyst, applied in the field of denitrification catalyst, can solve the problems of insufficient low-temperature activity, poor anti-sulfur poisoning performance, low oxidation rate, etc., and achieve the effect of widening the low-temperature activity window, improving performance and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below through specific examples, but the present invention is not limited only to the following examples. Example:

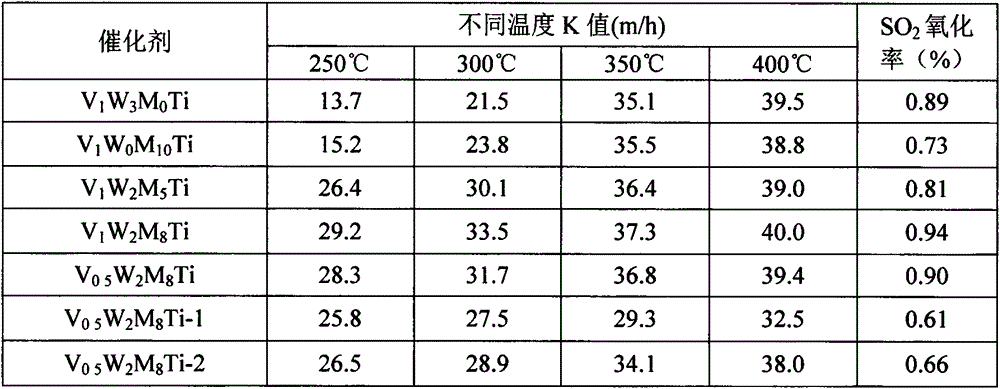

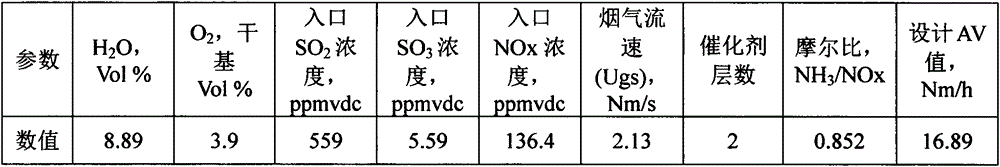

[0027] Table 1 Denitrification performance test data

[0028]

[0029] Note: SO 2 Oxidation rate test value at 400°C; V 0 5 W 2 m 8 Ti-1 samples calcined at 300℃; V 0.5 W 2 m 8 The Ti-2 sample is calcined at 650°C; if it is made into a honeycomb catalyst, its wall thickness is 1.1mm.

[0030] in,

[0031] (1) The prepared catalyst is V 2 o 5 -WO 3 -MoO 3 / TiO 2 , a series of catalysts prepared in the experiment are denoted as VxWyMzTi, where x, y, z represent the V in the catalyst 2 o 5 、WO 3 、MoO 3 mass percent content.

[0032] (2) Effect of catalyst preparation method on catalyst performance

[0033] Catalyst V 1 W 3 m 0 Ti, V 1 W 0 m 10 Ti, V 1 W 2 m 5 Ti, V1 W 2 m 8 Ti, V 0.5 W 2 m 8 The preparation methods of Ti all have aging time of 32 hours; drying temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com