Patents

Literature

39results about How to "Eliminate "white smoke"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

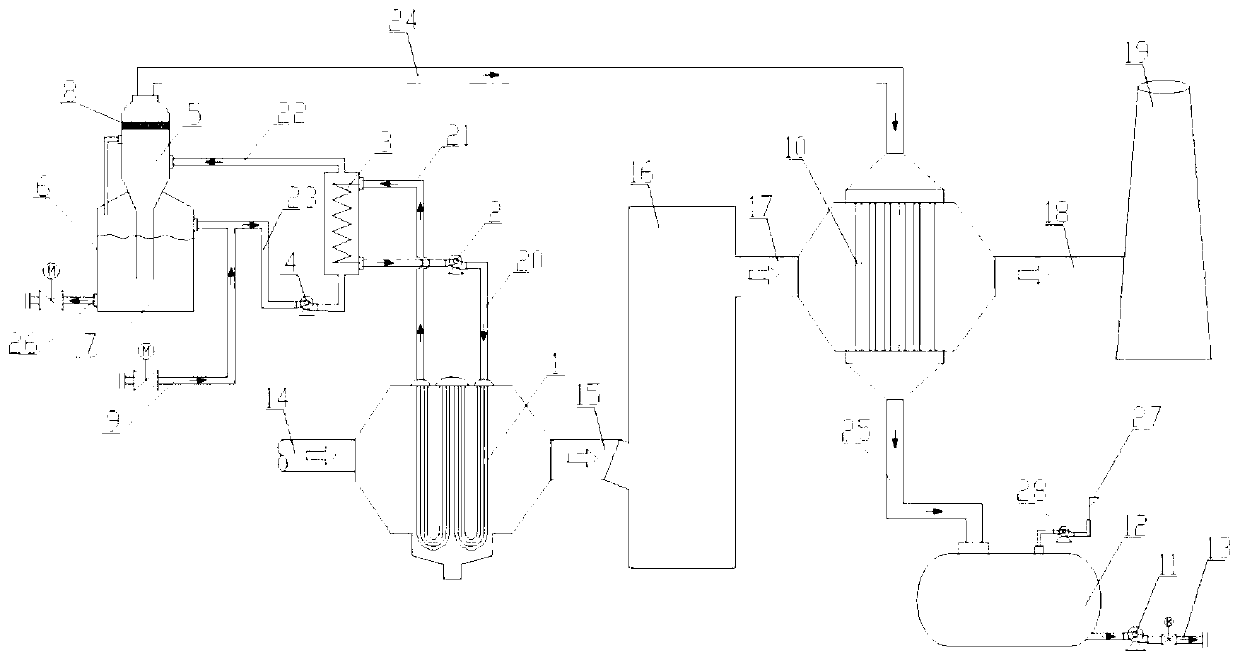

Integrated system for efficiently and synergistically removing multiple pollutants

ActiveCN103994456AImprove removal efficiencyImprove compatibilityLighting and heating apparatusAtmospheric pollutionDust collector

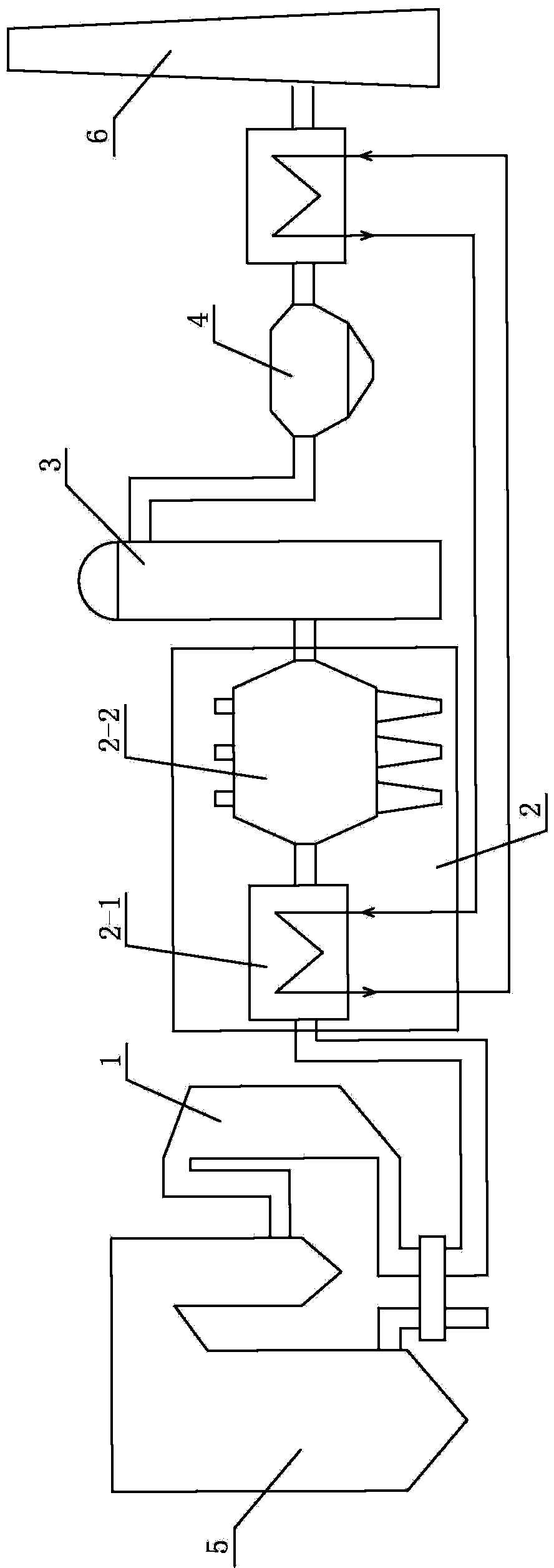

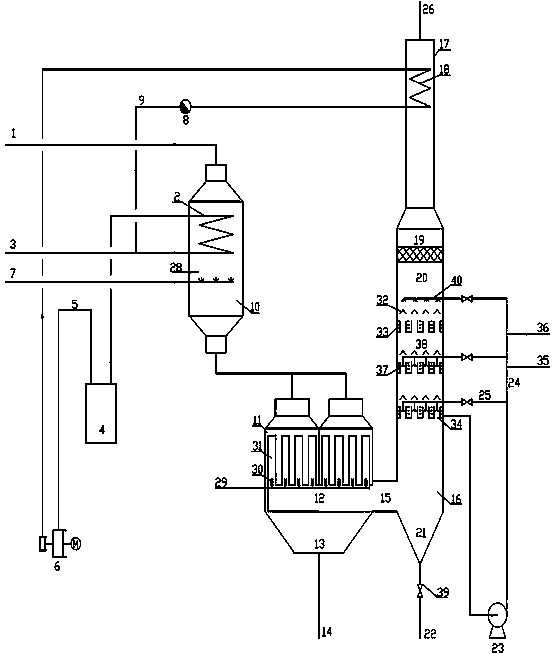

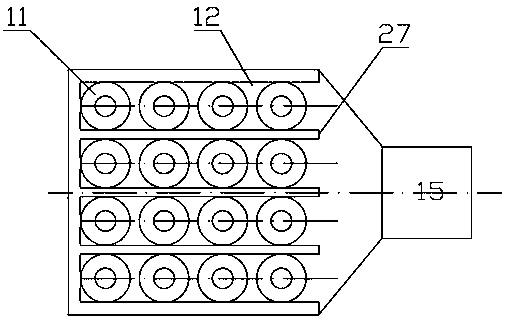

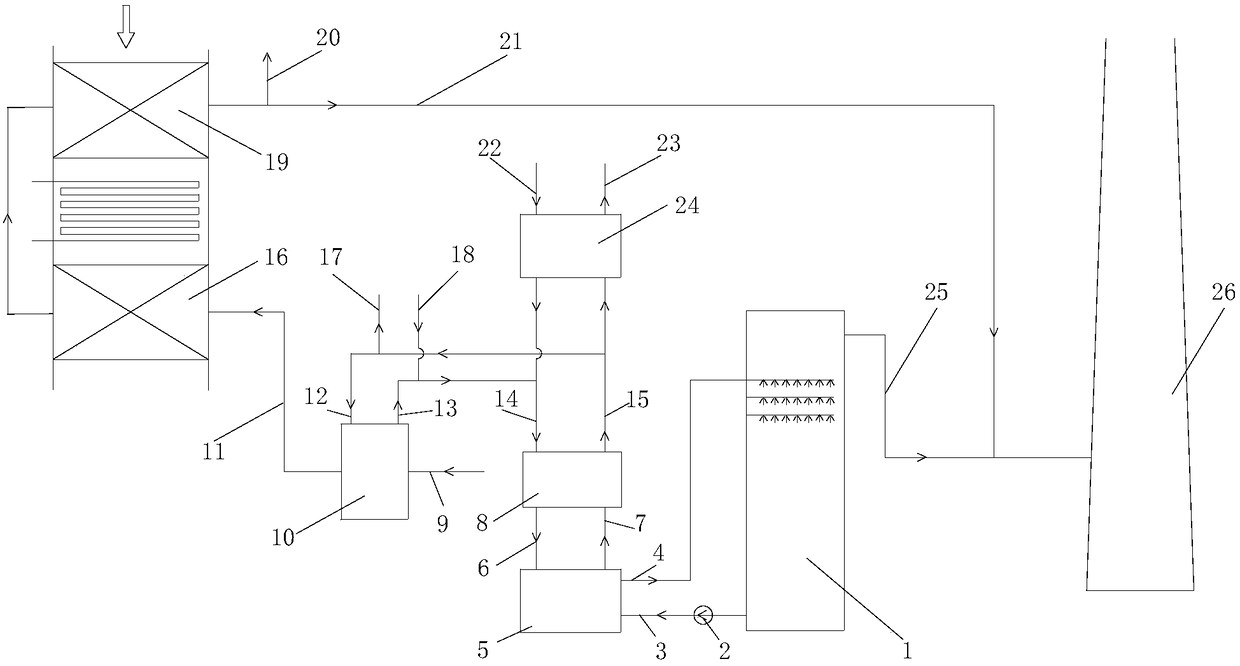

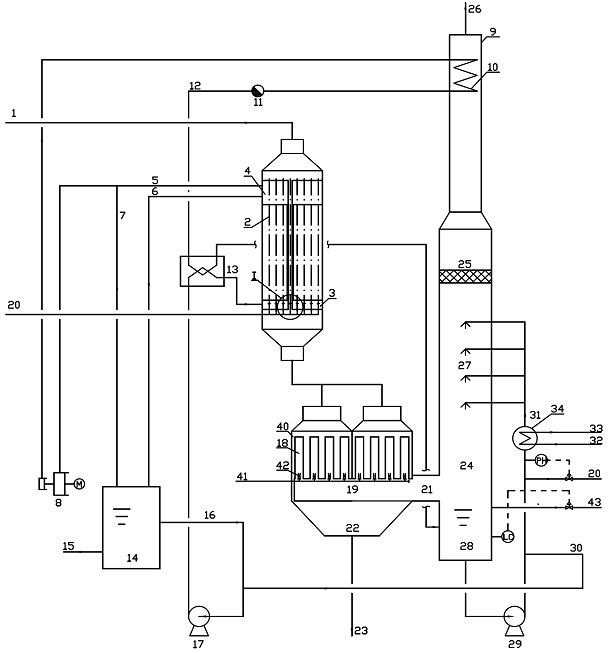

The invention relates to an integrated system for efficiently and synergistically removing multiple pollutants. The integrated system reduces discharge values of smoke, SO2, NOx, mercury, SO3 and other main smoke pollutants to achieve the discharge standard of a fuel gas unit. According to the technical scheme, the system comprises an SCR reactor, low-temperature dust removing equipment, a desulfurizing absorption tower and a wet-type electrostatic dust collector, wherein the inlet of the SCR reactor is connected with a smoke outlet through a tail smoke channel of a boiler improved through low-nitrogen combustion, and SCR denitration catalysts are modified catalysts capable of improving oxidation susceptibility of zero-valent mercury; the inlet of the low-temperature dust removing equipment is connected with the outlet of the SCR reactor to be used for removing dust and SO3; the inlet of the desulfurizing absorption tower is connected with the outlet of the low-temperature dust removing equipment to be used for desulfuration and dust removal; the inlet of the wet-type electrostatic dust collector is connected with the outlet of the desulfurizing absorption tower, and the outlet of the wet-type electrostatic dust collector is connected to a chimney through warming equipment to be used for removing the dust, gypsum fogdrops, the mercury and SO3. The integrated system is used for the technical field of atmospheric pollution prevention.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD +1

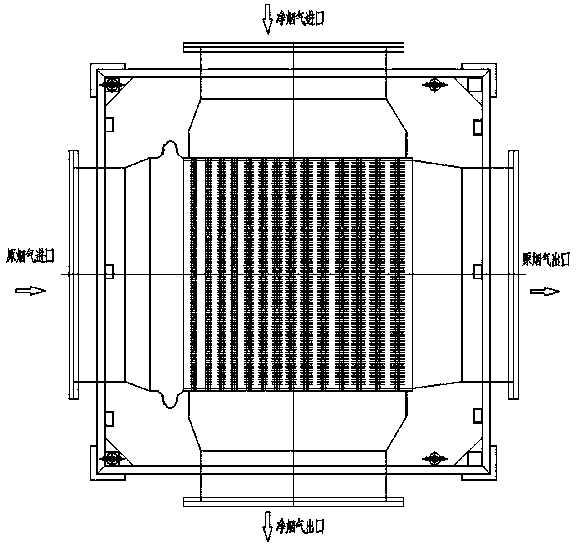

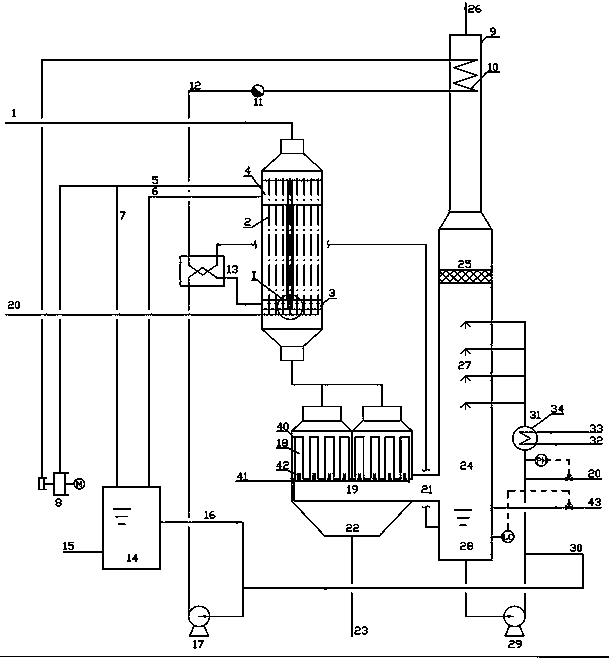

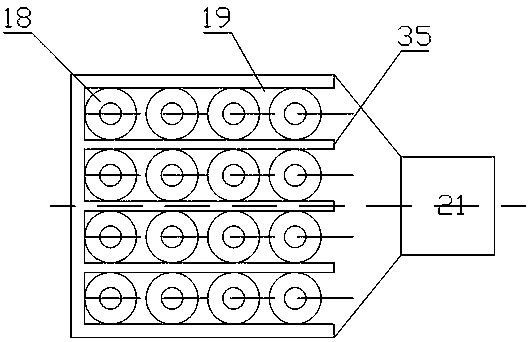

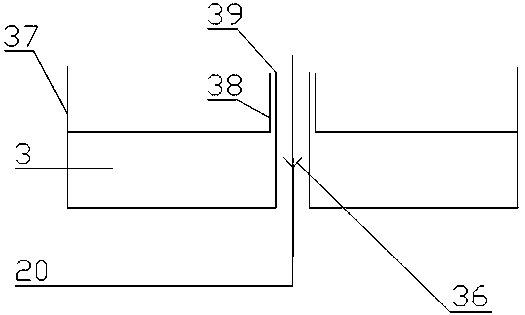

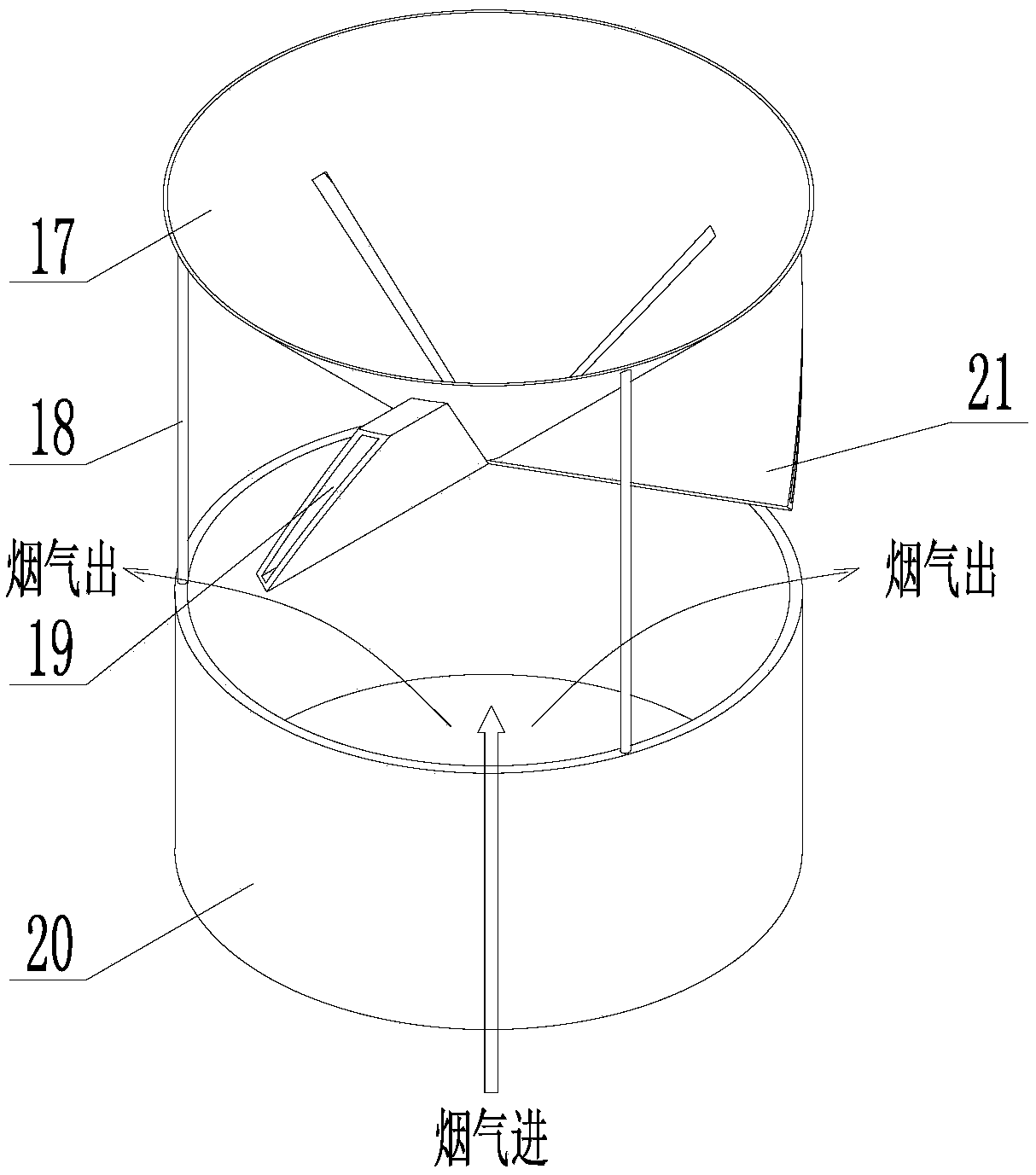

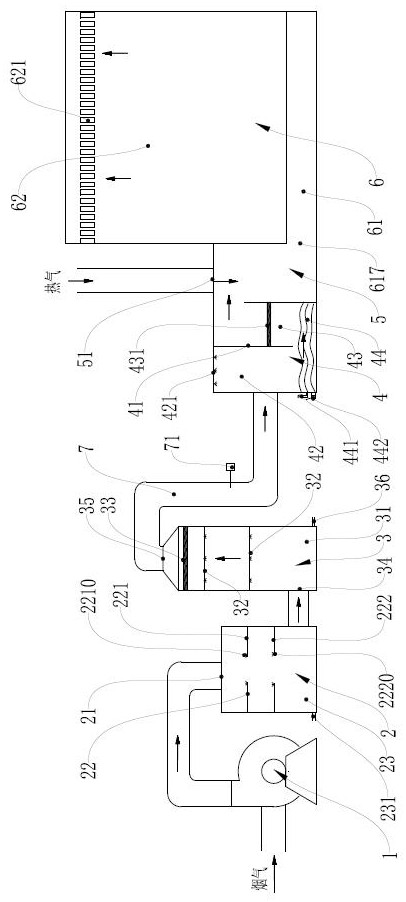

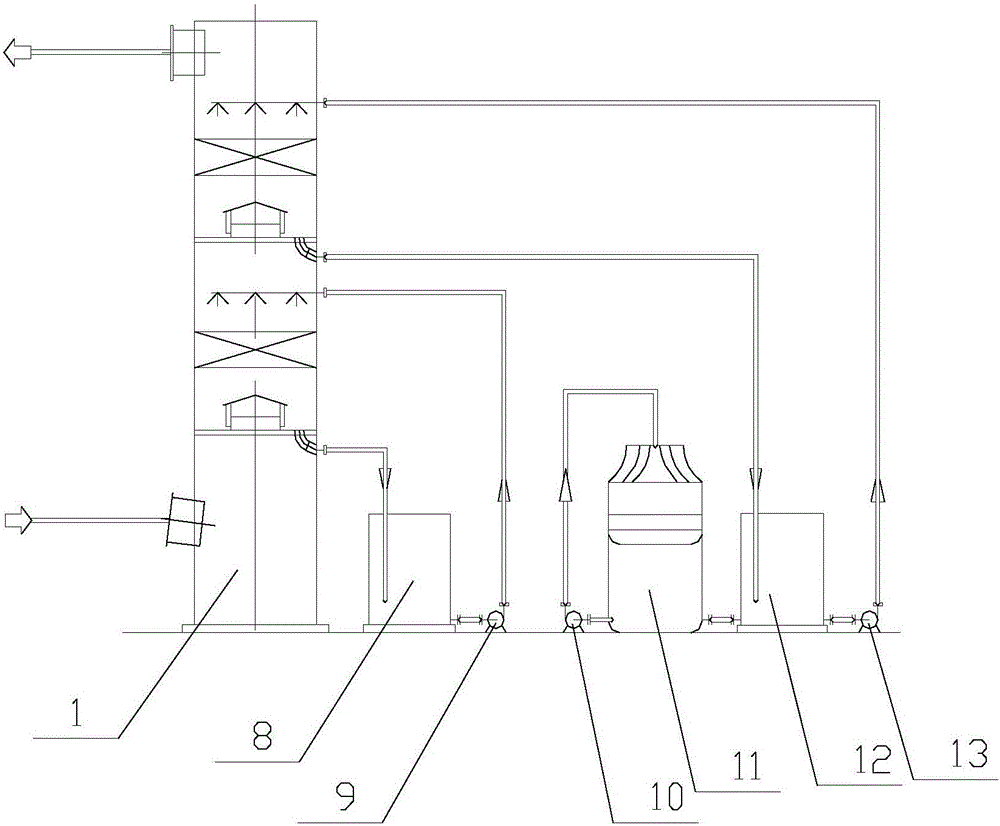

Ultralow-emission, water-saving and smoke suppression synergistic advanced purification system and method thereof

InactiveCN105920967ATo achieve the purpose of dust removal and fog removalHelp removeCombination devicesGas treatmentWater savingMulti pollutant

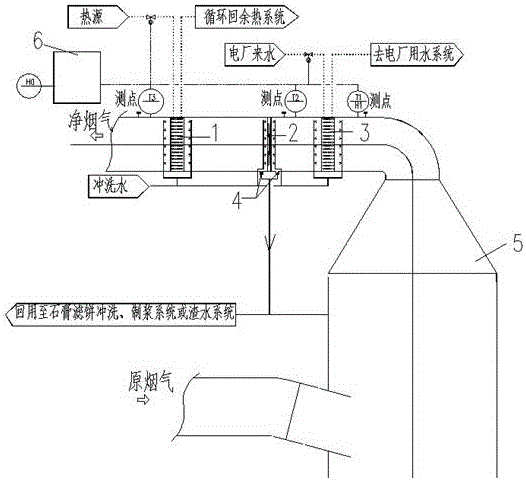

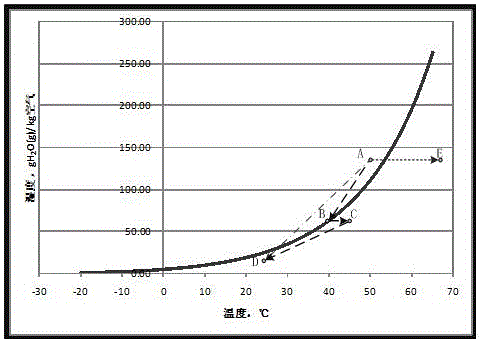

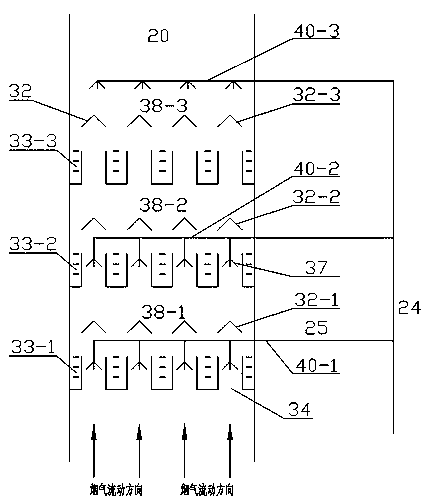

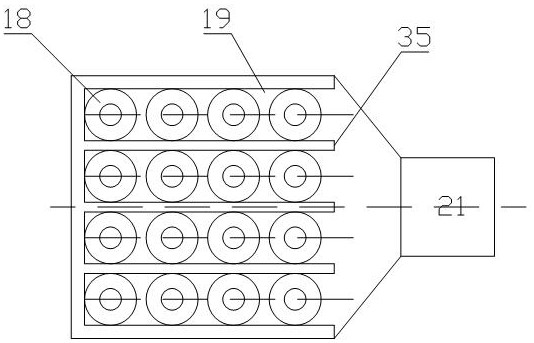

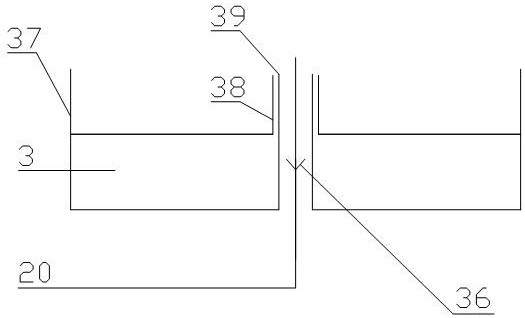

The invention provides an ultralow-emission, water-saving and smoke suppression synergistic advanced purification system and a method thereof. The system and the method are used for further processing outlet smoke in order to meet ultralow emission, smoke suppression and water saving synergistic advanced purification requirements. The system mainly includes a slight cooling phase change aggregation promoter, a multi-pollutant trap and a gentle heating smoke eliminator which are sequentially arranged in the outlet flue of a desulfurization tower, smoke discharged from the desulfurization tower is sequentially processed through the slight cooling phase change aggregation promoter, the multi-pollutant trap and the gentle heating smoke eliminator, and the processed smoke is discharged through a chimney. Compared with present routine methods with large energy consumed in direct heating of saturated or supersaturated smoke containing a large amount of water vapor to an unsaturated state through directly heating the smoke and alleviating white smoke escaping of the chimney, the method adopting slight cooling and gentle heating to suppress smoke purification, adopted in the smoke suppression synergistic purification system in the invention has the advantages of promotion of removal of fine particles, droplets, soluble salts and other pollutants, recovery of water in the smoke, obvious energy saving and consumption reduction, and true realization of smoke suppression.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

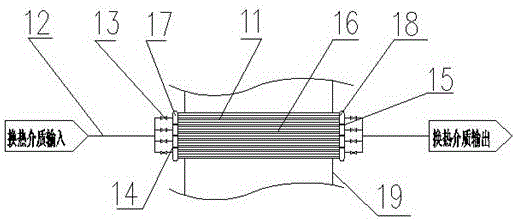

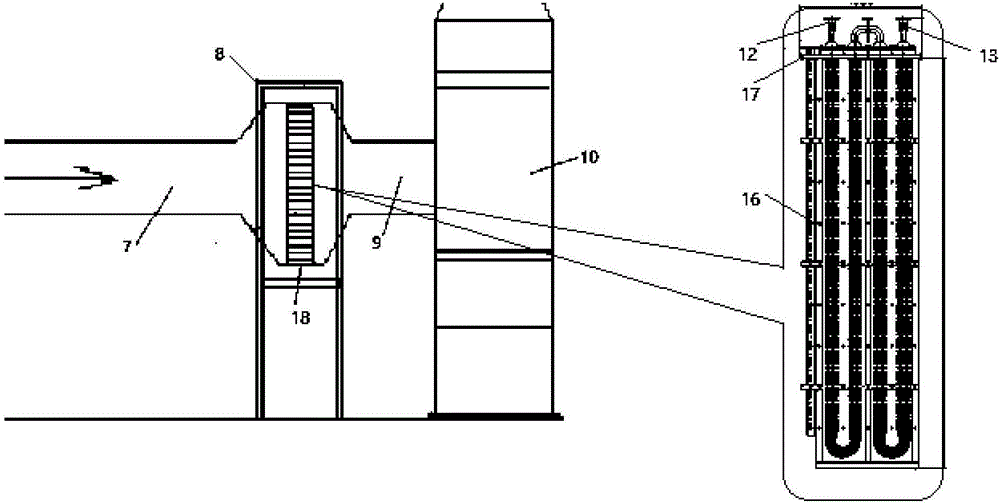

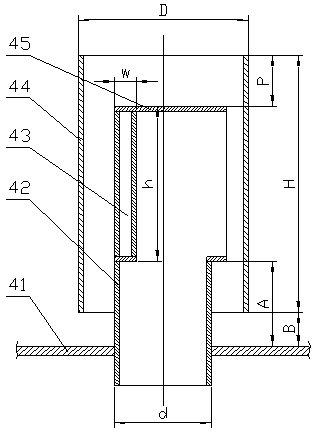

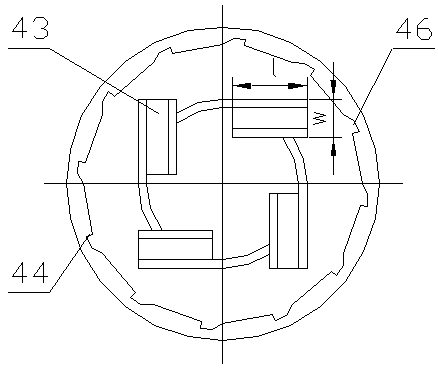

White smoke removing system and technology capable of accurately controlling corrosion

PendingCN108479289AReduce material requirementsReduce acid dew point corrosionDispersed particle separationCombustion technology mitigationThermal energyFin height

The invention discloses a white smoke removing system and a technology capable of accurately controlling corrosion. The system comprises a gradient fin temperature control type heat exchanger, a cooling washer, a sewage treating device and a defogger, wherein the gradient fin temperature control type heat exchanger can continuously enhance heat transfer on the high-temperature untreated gas side in a cooling process through pipe bundle distribution and an external-pipe fin height step type design to control a wall surface temperature to be larger than an acid dew point. Therefore, an anticorrosion design can be achieved through lower material cost; meanwhile, spraying is utilized to enhance condensation and dehumidification, and thermal energy of untreated gas is recycled to heat clean flue gas; by means of the two measures, an absolution moisture content and a relative moisture content are both remarkably reduced, and the white smoke phenomenon can be completely removed without an extra heat source and under low water consumption.

Owner:南京宜热纵联节能科技有限公司

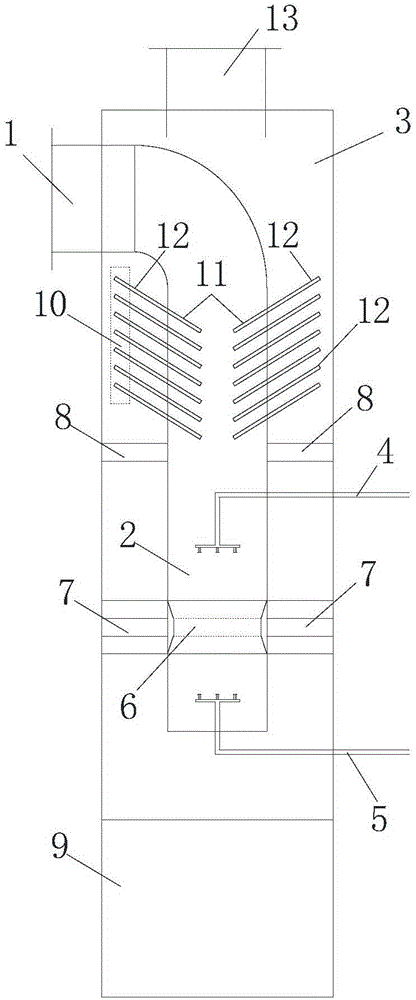

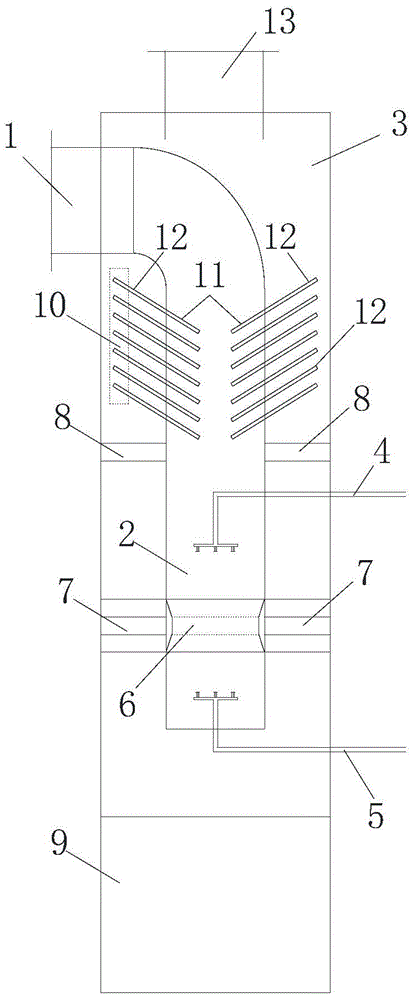

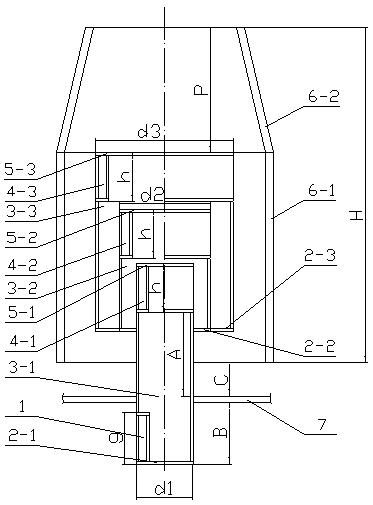

Wet smoke self-temperature returning integrated smoke purification device and application thereof

The invention relates to a wet smoke self-temperature returning integrated smoke purification device and an application thereof. The device comprises a washing tower outer barrel, a smoke outlet, an absorbing liquid storing cavity and a gas inlet flue extending barrel, the smoke outlet is disposed at the top of the washing tower outer barrel, the absorbing liquid storing cavity is arranged below the washing tower outer barrel, the gas inlet flue extending barrel is connected with the side of the washing tower outer barrel and extends to inside of the washing tower outer barrel, a smoke inlet is arranged at the front end of the gas inlet flue extending barrel, a same-direction fair current spraying head and a reverse spraying head are arranged inside the gas inlet flue extending barrel, directions of liquid drop sprayed by the same-direction fair current spraying heads and smoke flowing direction are the same, vertical opposite spraying is formed with the reverse spraying heads, and foam induction rings are arranged between the same-direction fair current spraying heads and the reverse spraying heads. According to the wet smoke self-temperature returning integrated smoke purification device and the application thereof, multiple functions such as dust removing, desulfuration, defogging and smoke heat exchange are integrated, device structure is compact, the floor space is small, the problems of 'white smoke' or chimney rain of wet purification smoke can be remarkably eliminated, and influence of smoke discharging on surroundings or vision can be reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

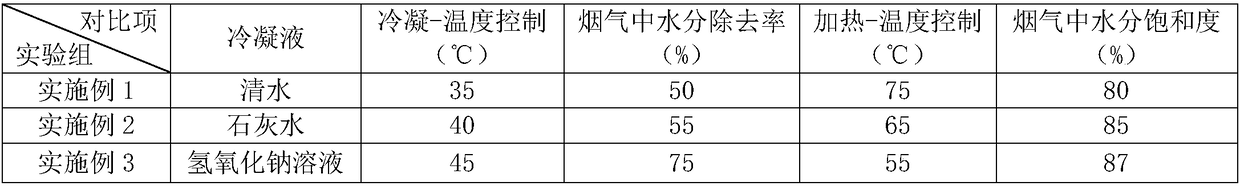

Method used for eliminating white mist water vapour at flue gas discharge outlets

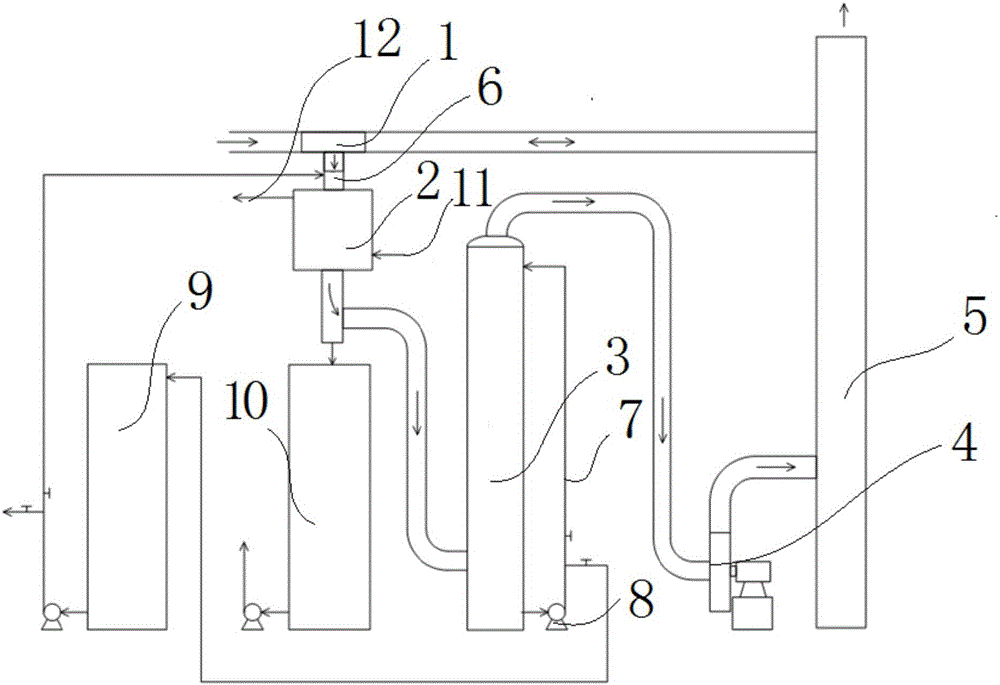

InactiveCN108310794AReduce moisture contentLower dew point temperatureCombination devicesGas treatmentFlue gasSlurry

The invention discloses a method used for eliminating white mist water vapour at flue gas discharge outlets, and belongs to the technical field of low temperature wet flue gas treatment. According tothe method, condensation is carried out firstly, and then heating is carried out; wet method desulphurization flue gas is introduced into a condensing tower, a condensate liquid is adopted for spraying of the flue gas for condensation, so that the temperature of the flue gas is reduced, precipitation of condensed water is realized, and water in the flue gas is removed; the flue gas after removingof condensed water is introduced into a demister to remove mist granules and slurry droplets in flue gas; the flue gas is introduced into a heating device for heating and temperature increasing, so that the moisture saturation degree of the flue gas is reduced, the hypersaturated states of the flue gas are converted into unsaturated states, and flue gas is discharged. The method is capable of preventing generation of white mist effectively; investment cost and operation cost are low; economical benefit and environment benefit are excellent; white mist elimination effect is excellent; and the efficiency is relatively high.

Owner:红河绿地环保科技发展有限公司

Flue gas desulfurization and desulfurization wastewater treatment method and flue gas desulfurization and desulfurization wastewater treatment apparatus

ActiveCN108686478AIncrease unsaturationDissipate in timeGas treatmentDispersed particle filtrationGas phaseTreatment costs

The invention relates to a flue gas desulfurization and desulfurization wastewater treatment method. According to the flue gas desulfurization and desulfurization wastewater treatment method, a flue gas pre-treatment tower comprises a flue gas / desalted water heat exchanger and a spraying unit; liquid-state desalted water is converted into gas-state desalted water by using flue gas in the flue gas / desalted water heat exchanger, and the gas-state desalted water enters a gas-liquid separator and is separated; the gas phase is compressed, the compressed gas phase enters the gas discharge cylinderon the top of a desulfurization tower to heat and purify the flue gas; the spraying unit is used for spraying a NaOH solution to reduce the flue gas temperature to below the dew point temperature of an acid, the cooled flue gas enters a bag type dust removing device and is treated, and the treated flue gas enters the desulfurization tower; and on the bottom of the desulfurization tower, a proper amount of desulfurization wastewater is subjected to spraying drying by using the flue gas, and the flue gas enters a desulfurization zone and is subjected to desulfurization purification. The invention further relates to a treatment apparatus of the treatment method. With the method and the apparatus of the present invention, the purified flue gas meets the discharge requirement, and the zero discharge of the flue gas desulfurization wastewater is achieved, the white smoke and the blue smoke are simultaneously eliminated, and the flue gas desulfurization and desulfurization wastewater comprehensive treatment cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

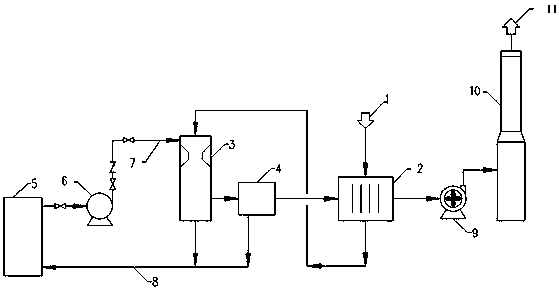

Comprehensive smoke treatment device and method

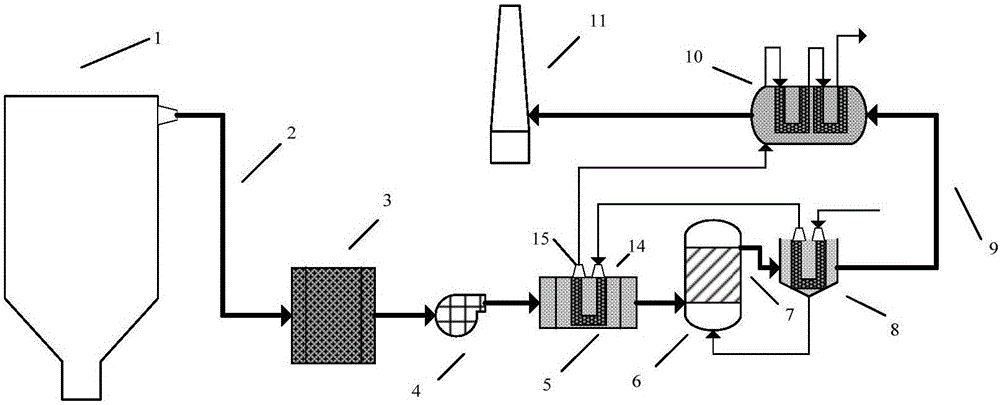

InactiveCN106801884AEasy to captureImprove cohesionEmission preventionCombustion technology mitigationTowerPhase change

The invention discloses a comprehensive smoke treatment device. The comprehensive smoke treatment device comprises a boiler, a tail flue, a dry dust collector, an induced draft fan, a waste heat recycling heat exchanger, a desulfurizing absorption tower, a desulfurizing tower outlet flue, a phase change cohesion dust remover, a phase change cohesion dust remover outlet flue, an intermediate heat medium smoke heat exchanger and a chimney, all of which are sequentially connected. The phase change cohesion dust remover comprises a heat exchange pipe, a pipe plate and a water collecting device. The heat exchange pipe is arranged on the pipe plate. The heat exchange pipe is further provided with a phase change device demineralized water inlet and a phase change device demineralized water outlet. The phase change device demineralized water outlet is connected with a waste heat recycling heat exchanger demineralized water inlet. A waste heat recycling heat exchanger demineralized water outlet is connected with an intermediate heat medium smoke heat exchanger demineralized water inlet. The water collecting device is connected with the desulfurizing absorption tower through a water pipe. The invention further discloses a method using the device for smoke treatment. The comprehensive smoke treatment device and method have the beneficial effects that the structure is simple, energy saving, emission reducing and environment friendliness are achieved, and waste heat is circularly utilized.

Owner:浙江巨化热电有限公司

Flue gas and flue gas desulfurization wastewater treatment method and device

ActiveCN108619871AIncrease water vapor contentRaise the acid dew pointCombination devicesGas treatmentLiquid wasteSteam condensation

The invention relates to a flue gas and flue gas desulfurization wastewater treatment method and device. The flue gas is used to exchange heat and raise the temperature of desulfurization wastewater in a flue gas / desulfurization wastewater heat exchanger, a spray nozzle is arranged in a flue gas outlet to spray an NaOH solution, the temperature of the flue gas is reduced to the temperature of theacid dew point, then the flue gas enters a bag filter to remove dust and a sulfate / sulfuric acid liquid drop and then falls into a desulfurizing tower; the flue gas is desulfurized, purified and heated and the temperature is raised in the desulfurizing tower, the wastewater part at the bottom part of the desulfurizing tower serves as a circulating absorption liquid, other wastewater enters a plateheat exchanger in the form of desulfurization wastewater; and the plate heat exchanger uses steam condensation water produced in a heating coil in an exhaust funnel to preheat the desulfurization wastewater, and the preheated wastewater enters the flue gas / desulfurization wastewater heat exchanger. The double purposes of purifying the flue gas and meeting the emission requirement and achieving zero emission of the flue gas desulfurization waste liquid are achieved on the basis that the waste heat of the flue gas is fully used, meanwhile, the white smoke and the blue smoke are eliminated, andthe comprehensive treatment costs for the flue gas desulfurization and the desulfurization waste liquid are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

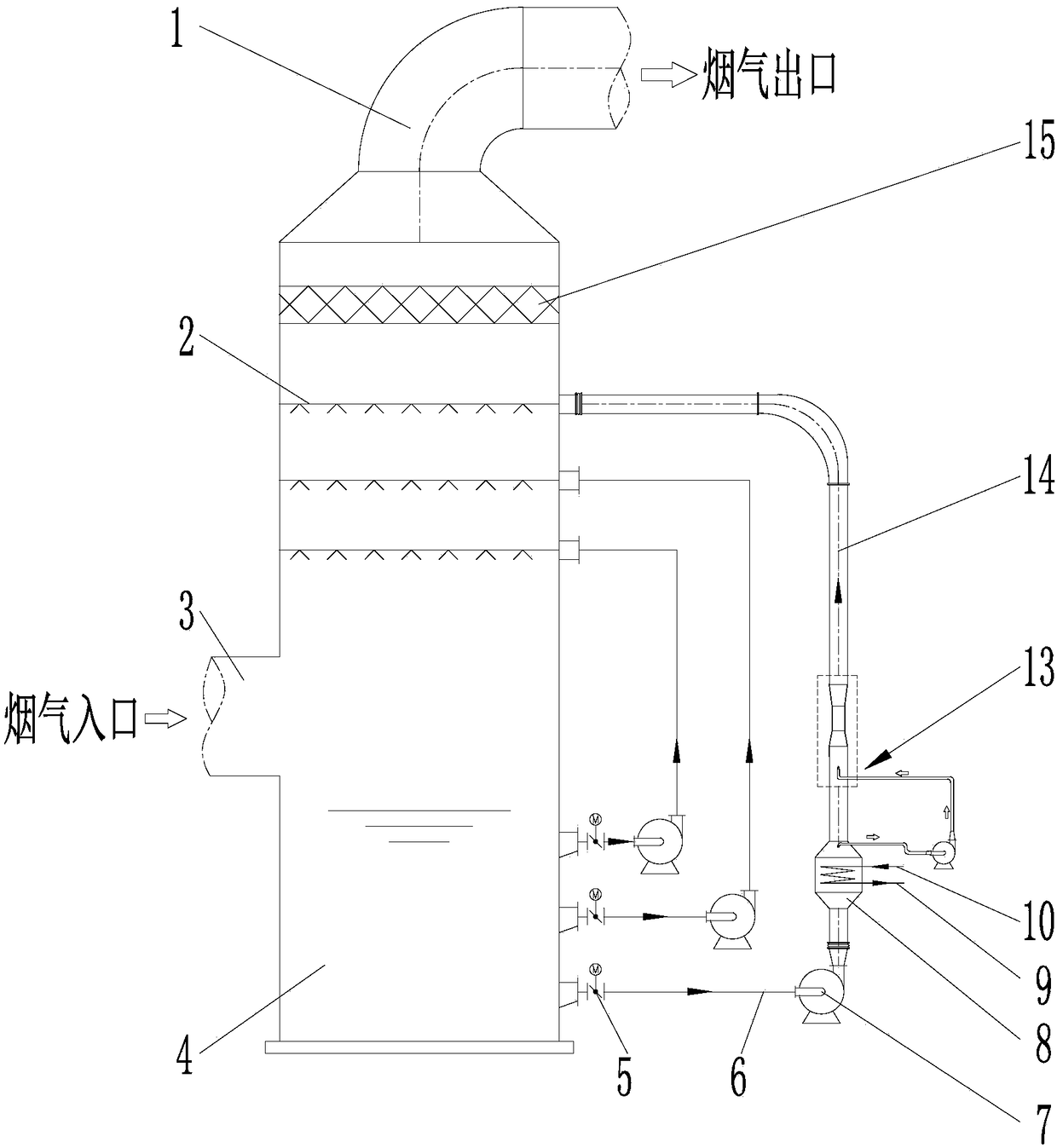

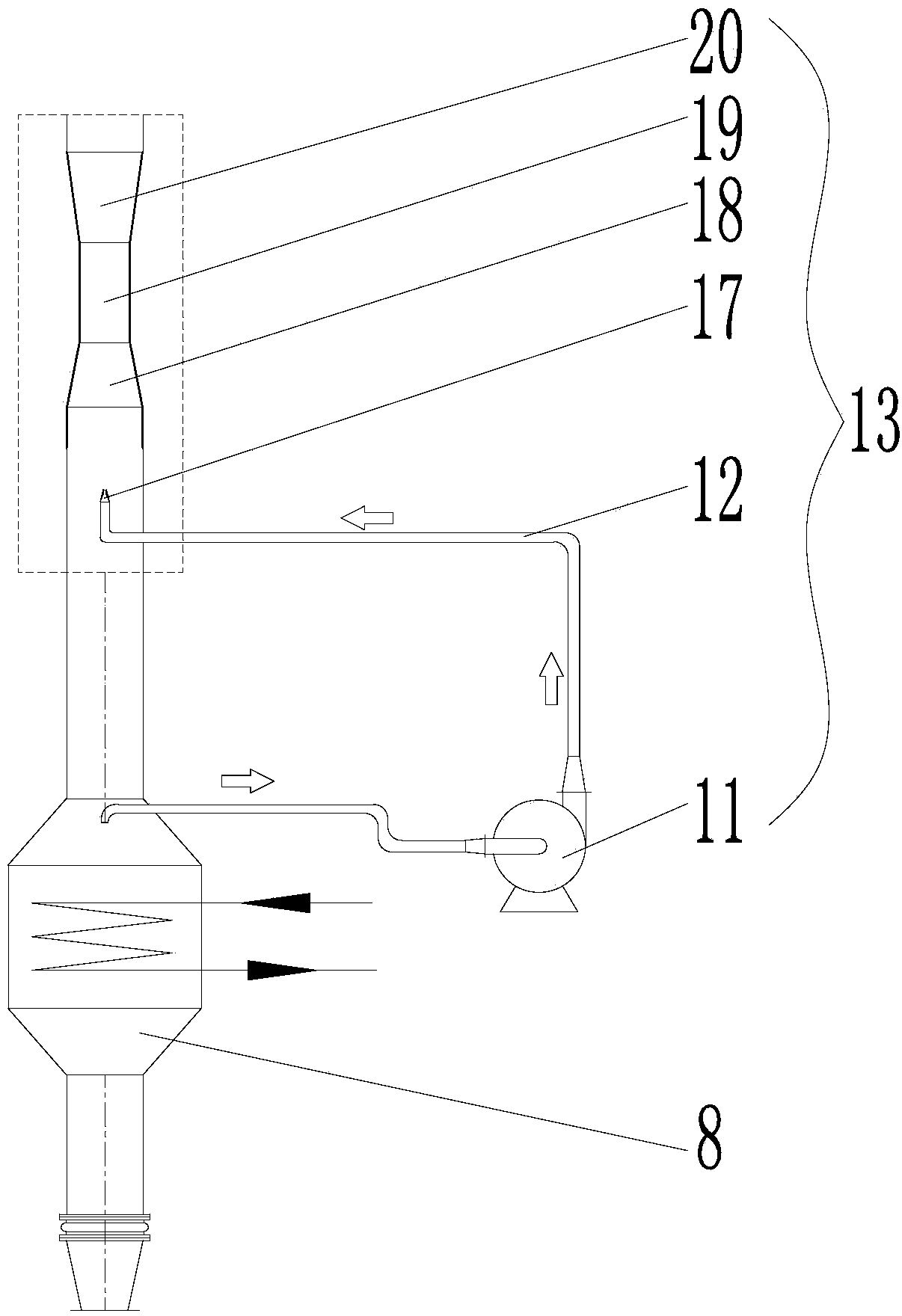

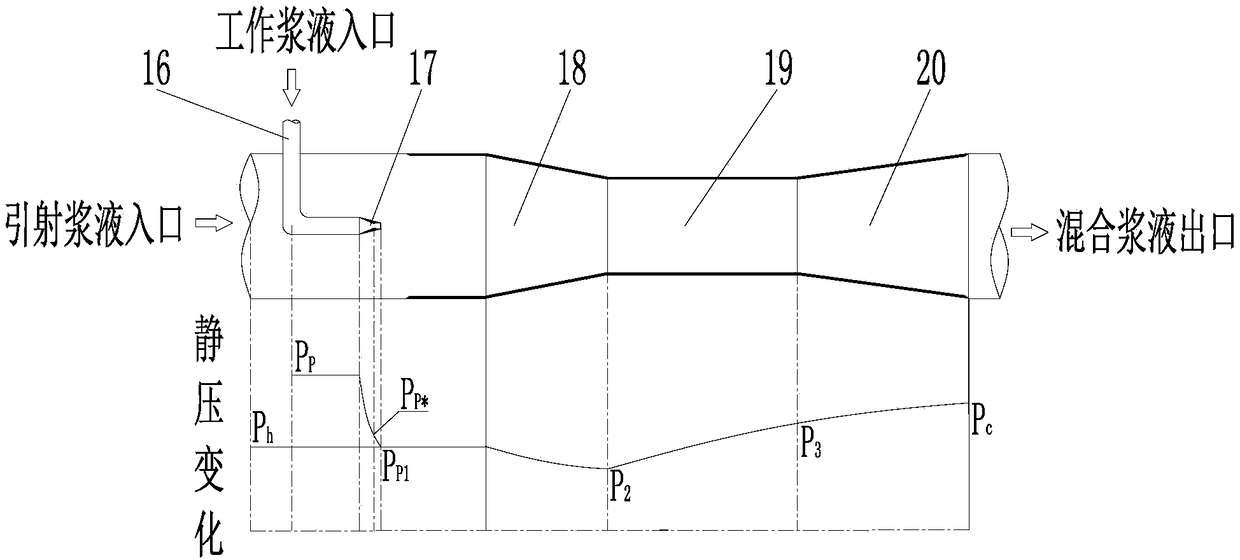

Cooling and white smoke eliminating device and method for circulating slurry for desulfurizing tower of thermal power plant

ActiveCN108295633ASimple crafting systemShort transformation periodUsing liquid separation agentCombustion technology mitigationSlurryButterfly valve

The invention discloses cooling and white smoke eliminating device and method for circulating slurry for a desulfurizing tower of a thermal power plant, and belongs the fields of the flue gas purification and the white smoke elimination of utility boilers and metallurgical coking and relevant industrial boilers, and the like. The side surface of the bottom of the desulfurizing tower in the deviceis provided with electric butterfly valves; the electric butterfly valves, slurry circulating pump inlet pipes, slurry circulating pumps, a slurry cooler, a slurry jetting and boosting device, a slurry circulating pump outlet pipe and top-layer spray layers are connected in sequence. The device can be used for reducing the water replenishing amount of the desulfurizing tower, is used for decreasing the moisture content of flue gas, and is used for further eliminating white smoke. Meanwhile, the invention also provides the cooling and white smoke eliminating method for the circulating slurry for the desulfurizing tower of the thermal power plant. The latent heat of vaporization in the flue gas is recovered; the heat loss of the smoke exhausted from a boiler is further decreased; the moisture carried in the flue gas is reduced; the water resource is saved, and the white smoke from a chimney outlet is eliminated.

Owner:CHINA HUADIAN ENG +1

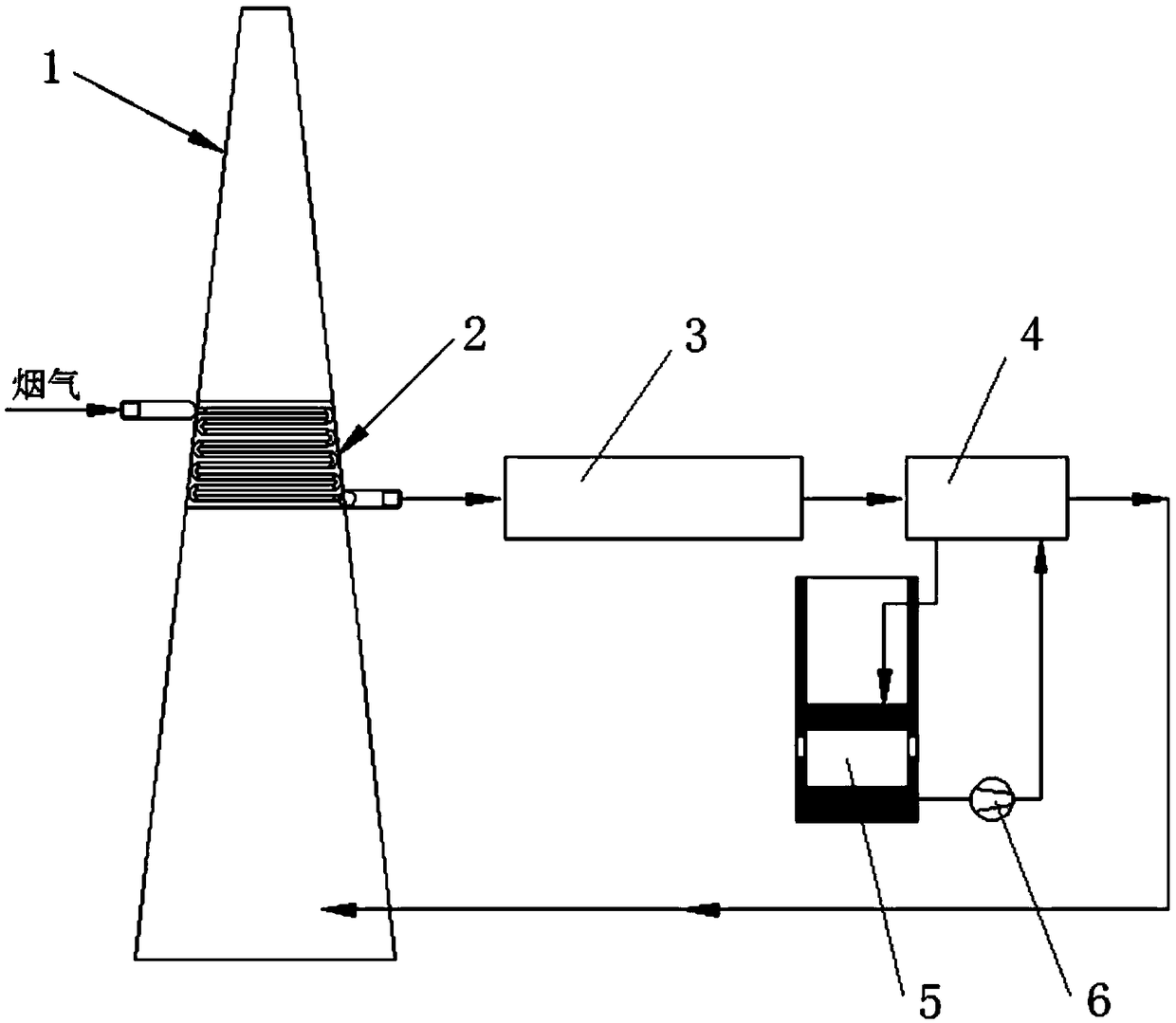

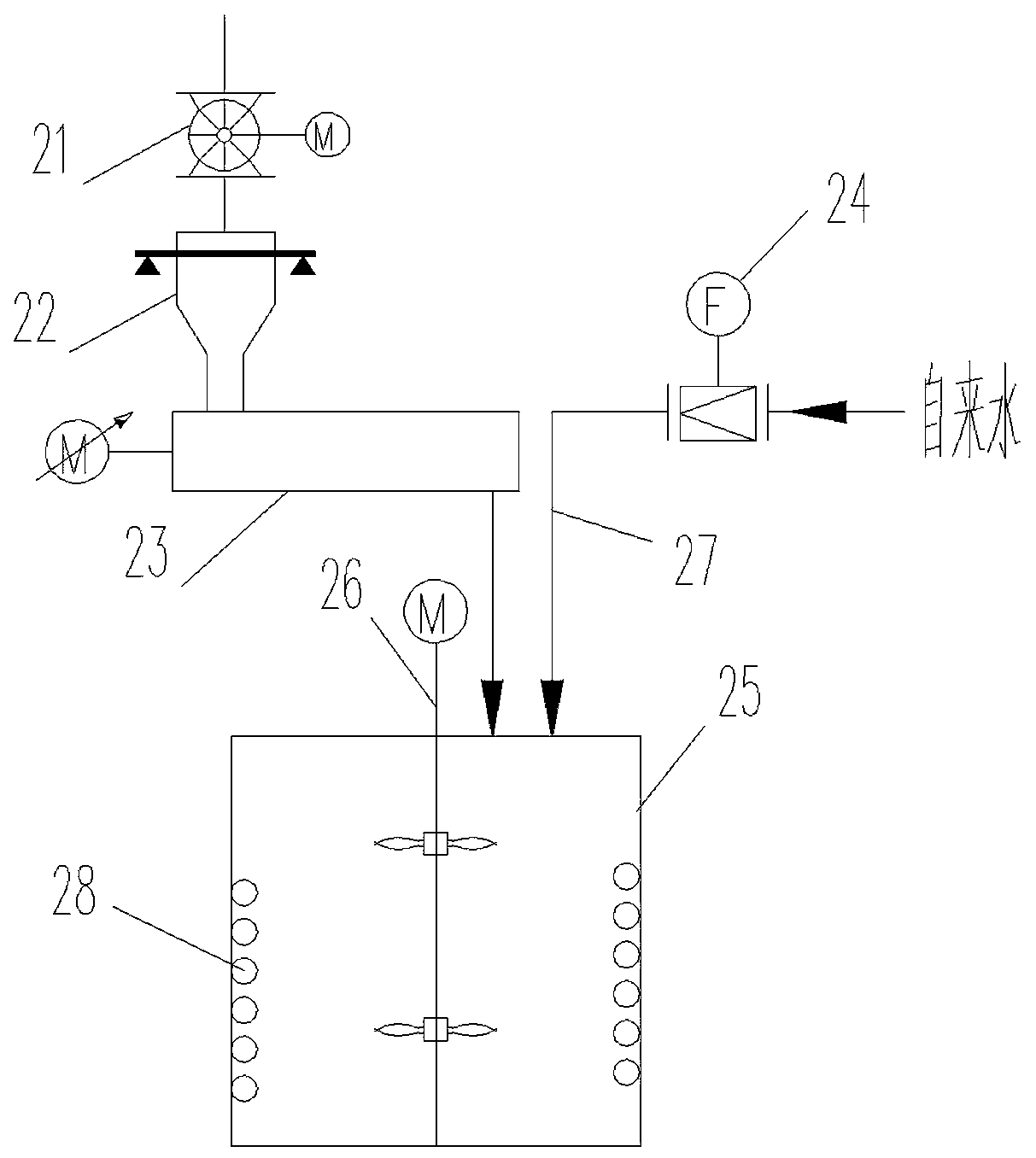

Method and device for reduction absorption treatment of pollutants in natural gas boiler smoke

InactiveCN105056741AEliminate white smokeLow running costDispersed particle separationAir quality improvementPollutantNOx

The invention discloses a method and device for reduction absorption treatment of pollutants in natural gas boiler smoke. The method comprises the following steps: S10 of cooling and dewatering the smoke; S20 of adopting Na2S solution to serve as an absorption solution to perform reduction absorption of NOx and SO2 in the smoke; and S30 of treating and absorbing spent solution. The method and device for reduction absorption treatment of pollutants in natural gas boiler smoke is suitable for smoke emission treatment of all gas boilers and particularly suitable for small and medium boilers. Through the reduction absorption of the Na2S solution, the emission of NOx can be reduced by over 80%, the emission of SO2 is reduced by over 90%, and the running cost is lower than that of an ozone oxidation absorption method by over 50%. In addition, white smoke in the smoke is eliminated by reducing the smoke temperature, and smoke waste heat is recycled.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

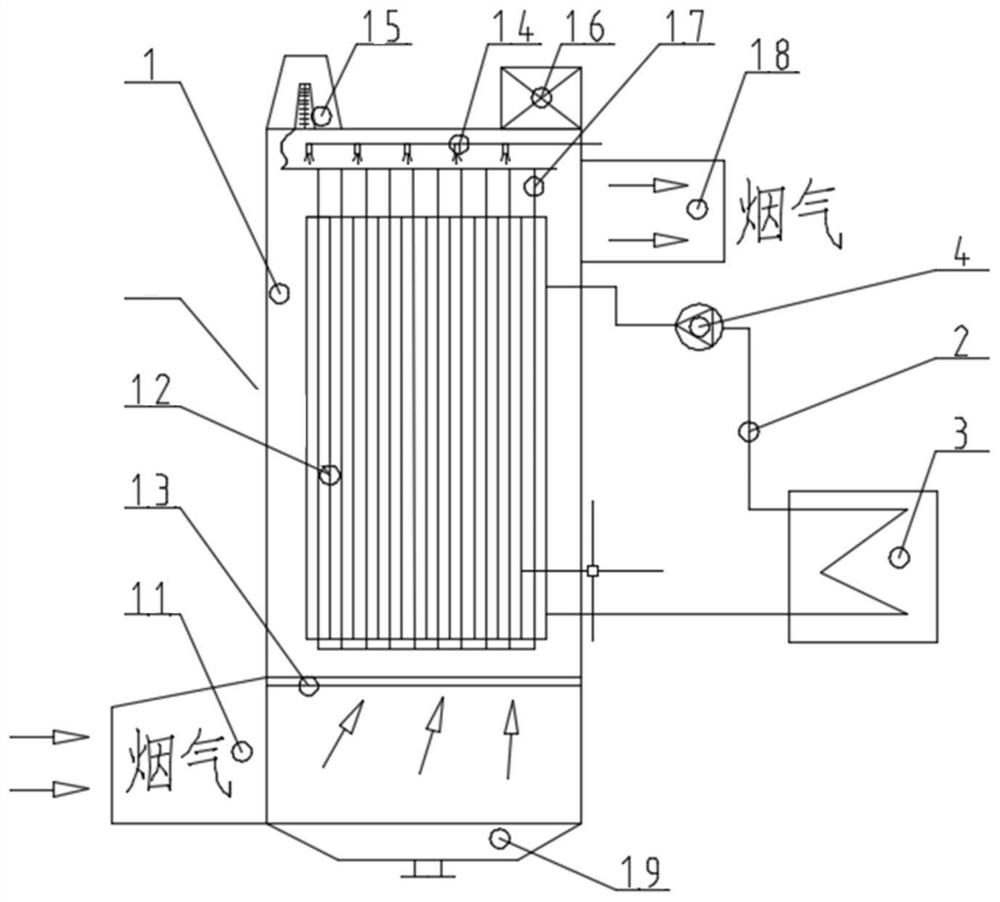

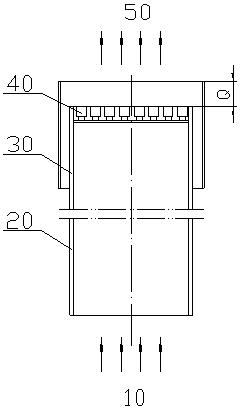

Phase change-based flue gas end dehydration fine dust removal device

PendingCN110090519AReduce dust contentReduce moisture contentHuman health protectionCombination devicesEvaporationEngineering

The invention discloses a phase change-based flue gas tail end dehydration fine dust removal device and relates to the field of air pollution control. The phase change-based flue gas tail end dehydration fine dust removal device comprises a horizontally arranged dedusting box body and a sedimentation tank, wherein a phase change cooling area, a spray cooling area and a filter screen dedusting areaare sequentially arranged in the dedusting box body from the flue gas inlet flue direction to the flue gas outlet flue direction. The phase change cooling area comprises a plurality of layers of heatpipe heat exchange layers, each layer of heat pipe heat exchange layer comprises a plurality of heat pipes which are arranged in parallel with each other, the evaporation sections of the heat pipes are positioned inside the dedusting box body, and the condensation sections of the heat pipes are positioned outside the dedusting box body. The spray cooling area comprises a plurality of atomizing nozzles. The filter screen dedusting area comprises a plurality of vertically arranged filter screen dust removal units, wherein each filter screen dust removal unit comprise a support frame, and the support frame is paved with a filter screen. The sedimentation tank is positioned below the opening on the bottom surface of the dedusting box body. The phase change-based flue gas tail end dehydrationfine dust removal device aims at further dedusting industrial flue gas under the conditions of low cost and low energy consumption to achieve near zero emission and eliminate white smoke.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

White smoke eliminating chimney

InactiveCN108692324AReduce the percentage of saturated waterEliminate white smokeDispersed particle separationChimneysEngineeringSmoke

The invention discloses a white smoke eliminating chimney. A demister and an outer sleeve are installed on the top of a traditional chimney. The outer sleeve is arranged on the outer side of the chimney. The outer sleeve and the chimney are arranged coaxially. The outer sleeve is in a cylindrical structure opened up and down and can be of a cylinder shape or a conical cylinder shape. The upper edge of the outer sleeve is higher than the upper edge of the chimney by a certain distance, and the lower edge of the outer sleeve is lower than the upper edge of the chimney. A ring-shaped space is arranged between the outer sleeve and the chimney. The demister is arranged in the chimney. The top of the demister is flush with the upper edge of the chimney. According to the white smoke eliminating chimney, white smoke is eliminated remarkably, pollution to surroundings is reduced, and the problem of the white smoke is solved effectively.

Owner:CHINA PETROLEUM & CHEM CORP +2

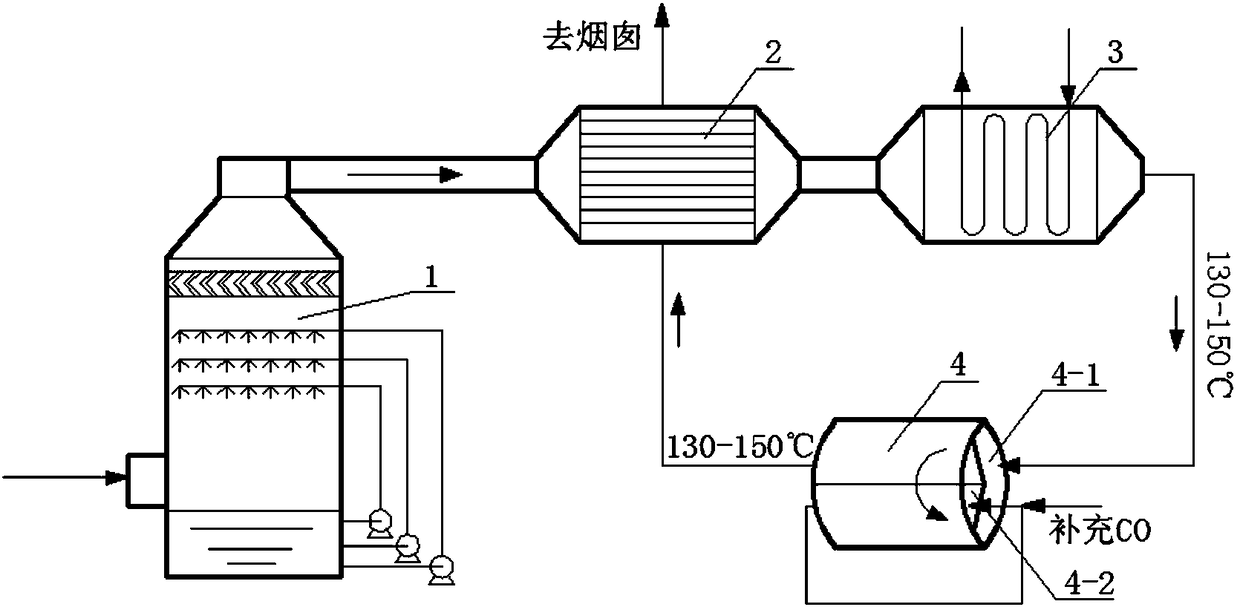

A process and method for eliminating smoke plume through flue gas reheating in combination with CO low-temperature denitration

InactiveCN108568210AAvoid inactivationExtend your lifeGas treatmentDispersed particle separationFlue gasSulfur

A process and method for eliminating smoke plume through flue gas reheating in combination with CO low-temperature denitration are disclosed. On a flue of a wet desulphurization column, a gas-gas plate-type heat exchanger, a flue gas heater and a low-temperature denitration reactor are connected in order. The low-temperature denitration reactor is a rotary low-temperature denitration reactor or acirculating fluidized bed reactor. The flue after the low-temperature denitration reactor is connected to the gas-gas plate-type heat exchanger. Large smoke fume at an outlet of a chimney is eliminated through reheating of the flue gas after the desulphurization column, nitrogen oxides in the flue gas are removed at a low temperature (130-150 DEG C) and an ultra-clean emission standard for nitrogen oxides is met. The whole process is carried out after the wet desulphurization column, thus avoiding sulfur deactivation of a catalyst. The process and the method have characteristics of simple steps, convenient operation and high practicability.

Owner:SHANDONG UNIV

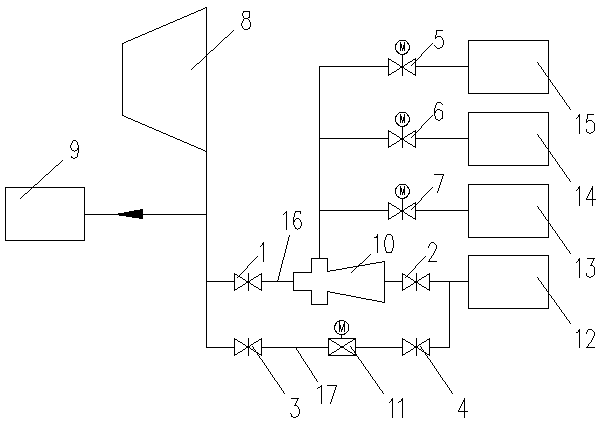

Recovery system and recovery method of residual pressure and residual heat in backpressure heat supply unit

PendingCN111520205AReduce water and heat lossEliminate white smokeHeat recovery systemsRecuperative heat exchangersProcess engineeringInjection pump

The invention provides a recovery system and a recovery method of residual pressure and residual heat in a backpressure heat supply unit. The system and the method can reduce loss if water, heat and pressure energy, increase heat supply of the backpressure heat supply unit and eliminate a phenomenon of 'generating white smoke'. The system comprises a backpressure steam turbine, a deaerator, a drain tank, a drain flash tank, periodic blowdown flash tank, valves from No.1 to No.7, a steam jet pump, a main pipeline and a bypass pipeline. In normal operation, the No.3 valve and the No.4 valve areclosed, and other valves are opened; discharged steam of the backpressure steam turbine is conveyed into the steam jet pump to be used as working steam, thus, after the steam jet pump extracts the discharged steam in the periodic blowdown flash tank, the drain flash tank and the drain tank, pressure is reduced and the steam becomes medium pressure steam usable for the deaerator, and the medium pressure steam enters into the deaerator; if the steam jet pump goes wrong, the No.3 valve and the No.4 valve of a bypass line are opened, and the No.1 valve and the No.2 valve are closed, the system cancontinue working, and thus continuous running of the system is guaranteed.

Owner:CHINA UNITED ENG

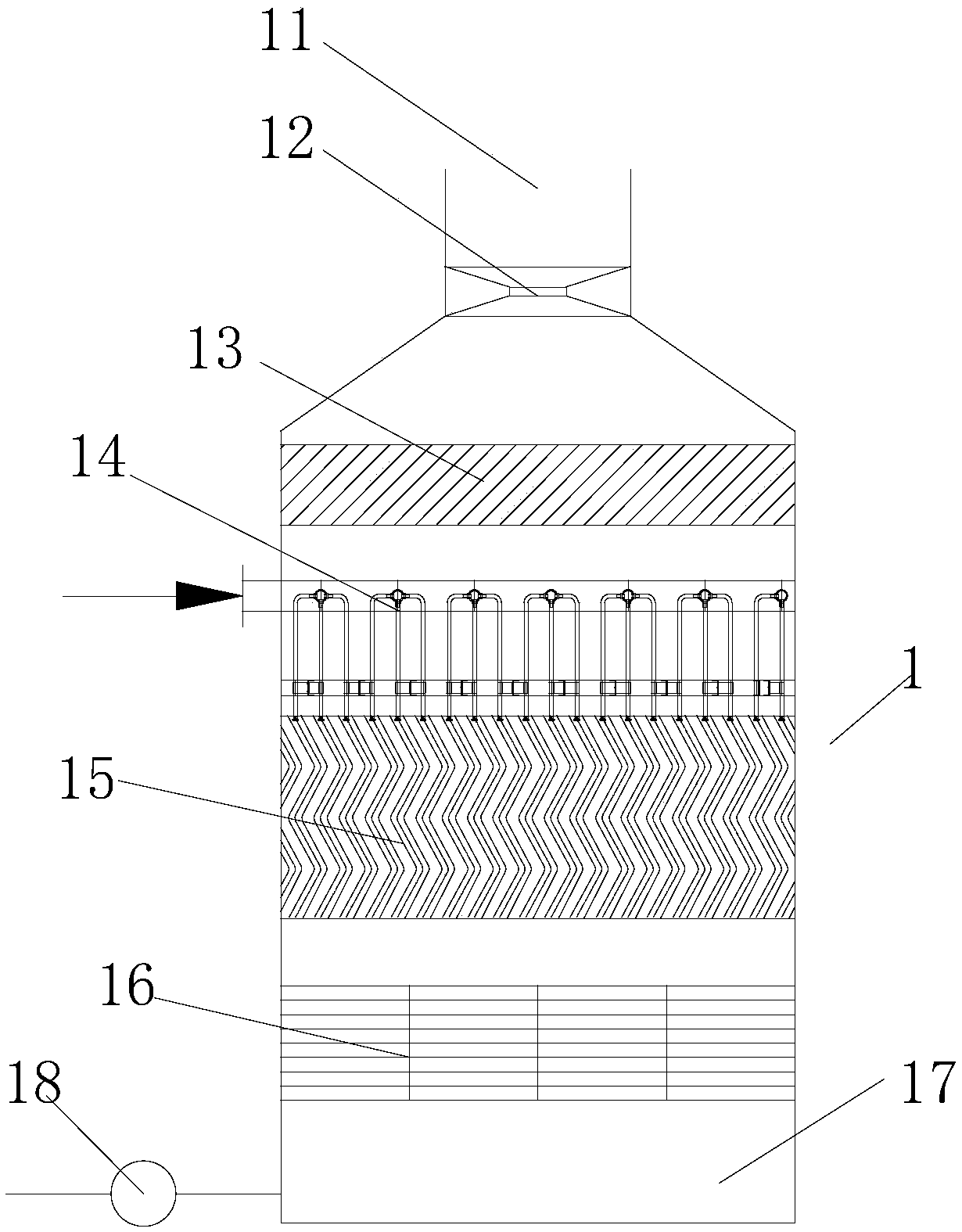

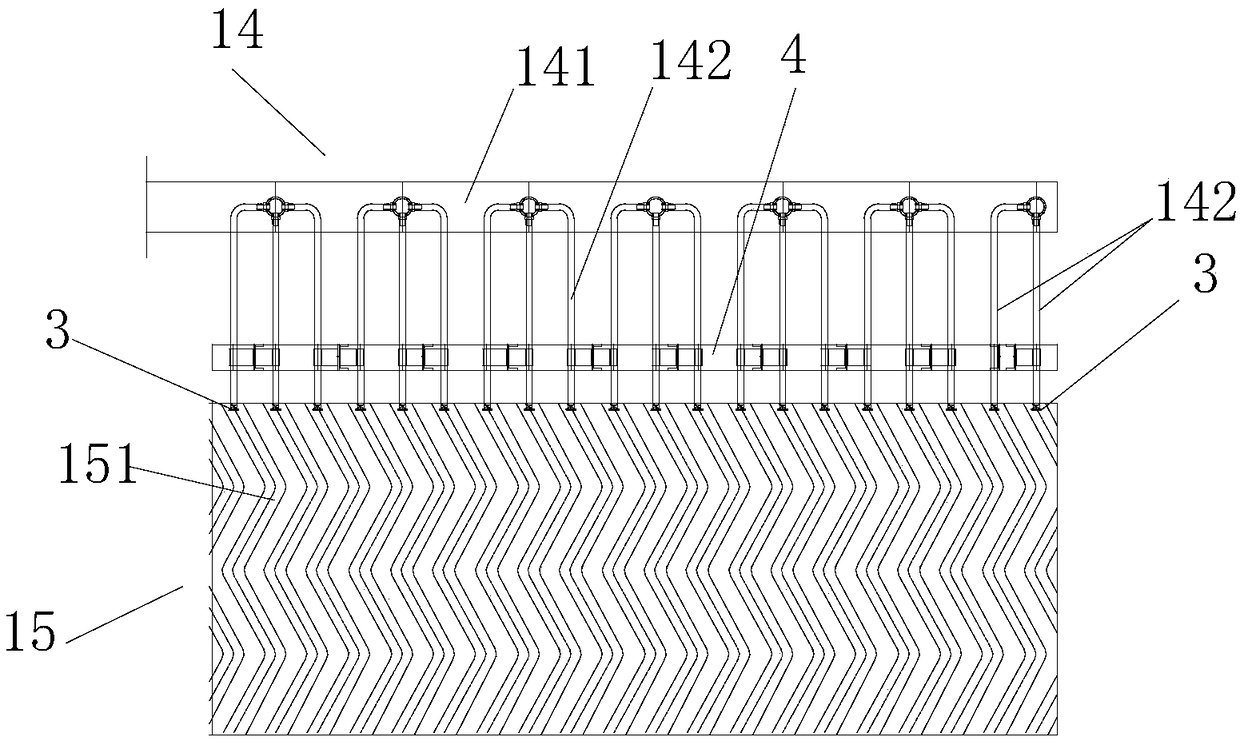

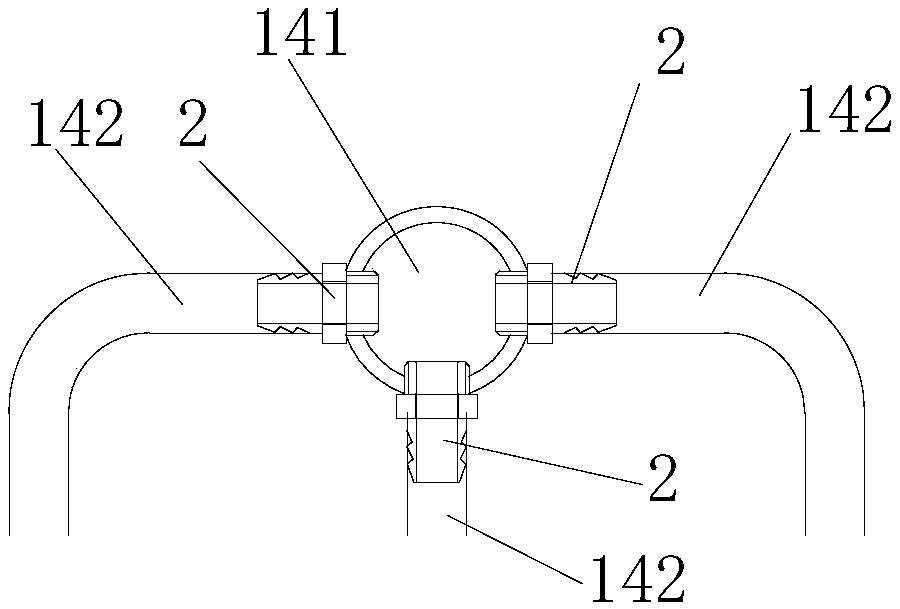

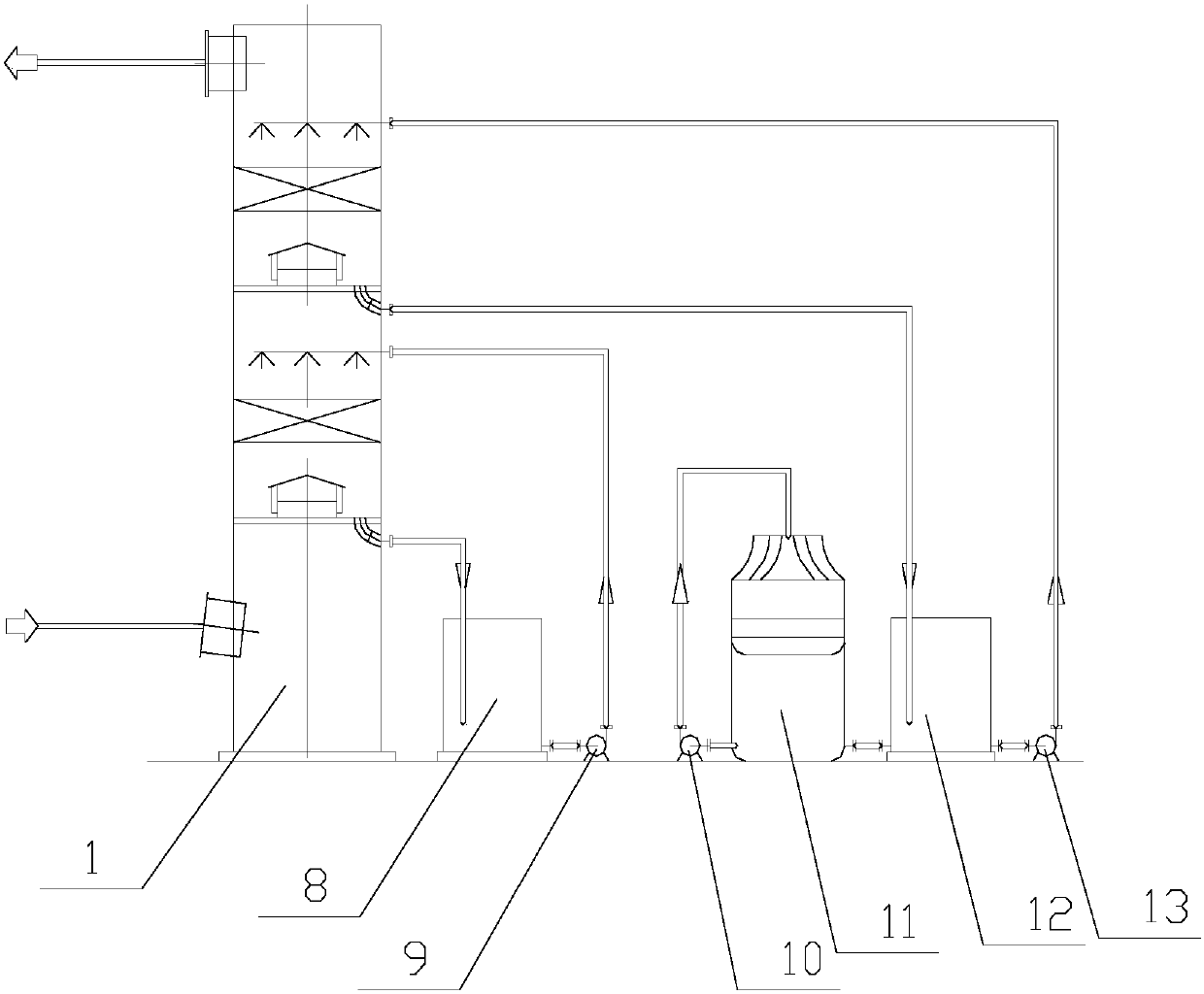

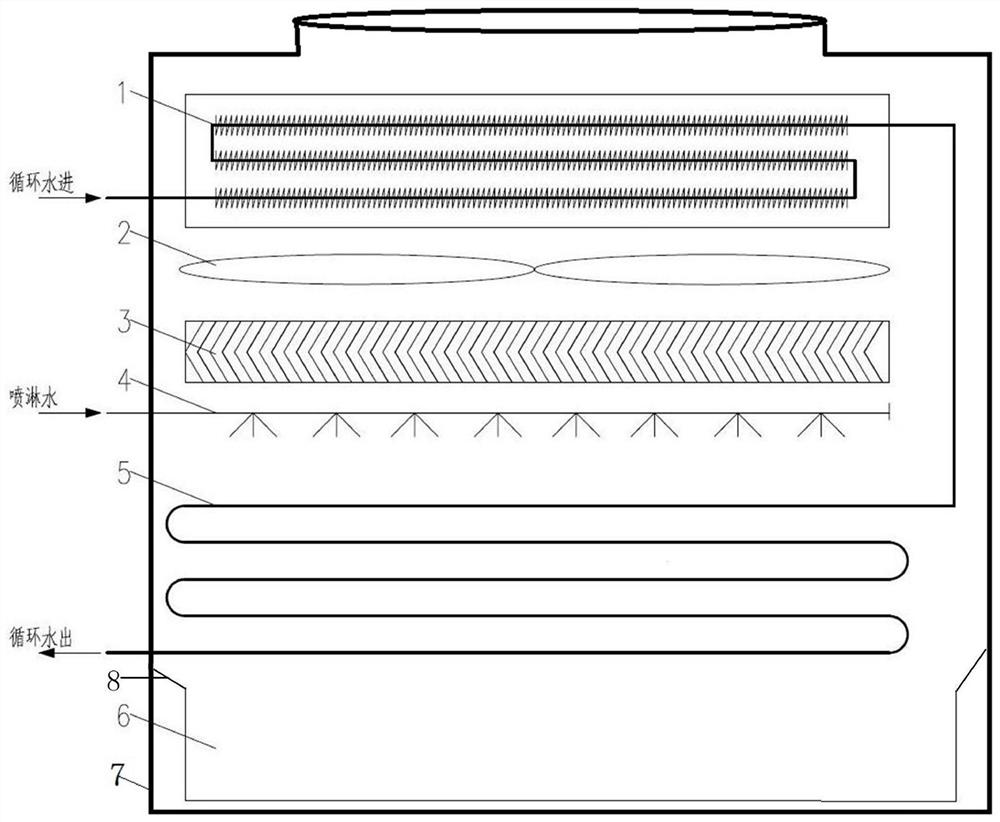

Mechanical cooling tower white smoke removing device

InactiveCN109443039AIncrease the heat exchange areaImprove heat transfer efficiencyTrickle coolersLiquid temperatureCooling tower

The invention discloses a mechanical cooling tower white smoke removing device comprising a tower body. An exhaust port is arranged at the upper end of the tower body, a fan is arranged in the exhaustport, a defogger, a water distributing system, a heat exchange filler and an air intake grille are sequentially arranged on the portion, below the fan, in the tower body, the lower portion, below theair intake grille, at the bottom of the tower body is used as a circulating water tank, a plurality of water flow passages and a plurality of air flow passages adjacent to the plurality of water flowpassages are distributed inside the heat exchange filler alternately, the water distributing system includes a water distributing main pipe and a plurality of water distributing branch pipes, the water distributing main pipe is located at the position, above a packing layer and below the defogger, inside the tower body, and the water distributing main pipe communicates with and is connected witha minor water distributing machine arranged inside each water flow passage through the corresponding water distributing branch pipe. The mechanical cooling tower white smoke removing device has the advantages that heat of high-temperature circulating water is transferred and the circulating water is cooled by adopting an air-liquid indirect heat exchange mode, and only the air-liquid temperature changes during the heat exchange process, so that the water vapor evaporation amount of the high-temperature circulating water is greatly reduced during the heat exchange process, high temperature andlow humidity unsaturation emission of the air subjected to heat exchange is realized, the white smoke phenomenon of a mechanical cooling tower in winter is eliminated, and water resources are saved.

Owner:杭州蕴泽环境科技有限公司

Device capable of eliminating white smoke

PendingCN109173557AEliminate white smokeSave energyGas treatmentDispersed particle separationWater vaporProcess engineering

The invention discloses a device capable of eliminating white smoke. The device comprises a heat exchanger, a desulphurization wet-type electrostatic deduster, and a condensation device; the heat exchanger is used for cooling high temperature smoke introduced into the heat exchanger, and heating smoke discharged from the condensation device; the heat exchanger is arranged in a chimney; the desulphurization wet-type electrostatic deduster is connected with the heat exchanger, and is used for desulphurization dedusting and humidity reducing temperature reducing treatment of smoke discharged fromthe heat exchanger; the condensation device is connected with the desulphurization wet-type electrostatic deduster, and is used for humidity reducing temperature reducing treatment of smoke discharged from the desulphurization wet-type electrostatic deduster; the heat exchanger is arranged in the chimney, so that temperature reduction of high temperature smoke is realized, and drying of smoke tobe discharged is realized, and energy is saved; and in addition, the desulphurization wet-type electrostatic deduster and the condensation device are used for temperature reducing and humidity reducing, so that water steam content of smoke is reduced effectively, and white smoke elimination effect is achieved.

Owner:SHANGHAI SHENGJIAN ENVIRONMENTAL SYST TECH

System and technology for removing white smoke exhausted from boiler and industrial kiln chimneys

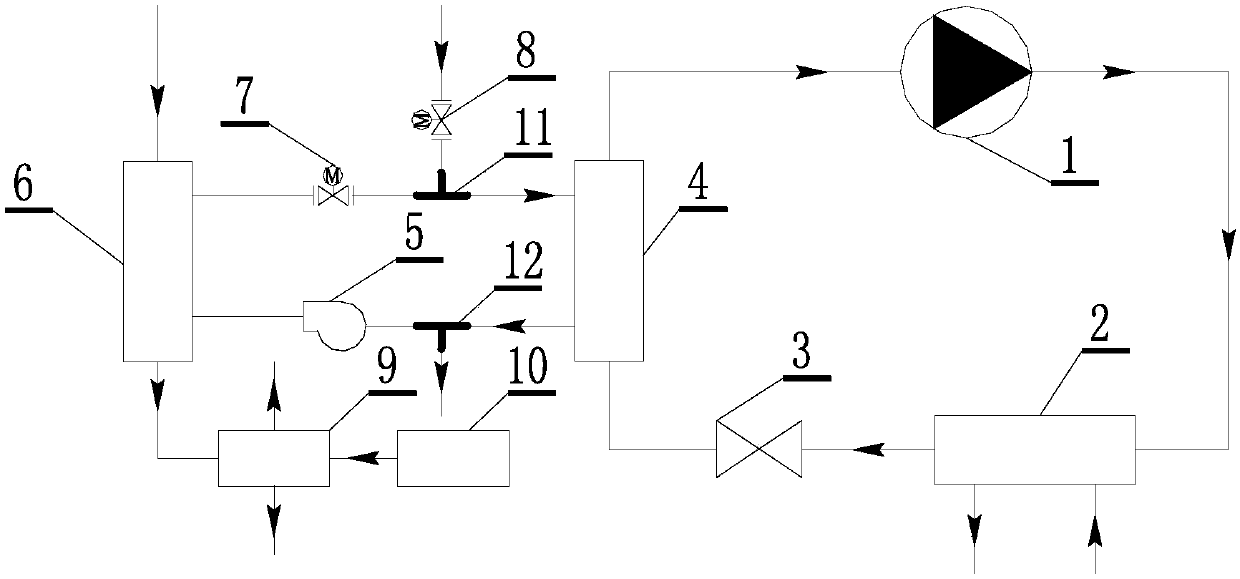

InactiveCN108518700AReduce the temperatureIncrease temperatureHeat pumpsEmission preventionHeating seasonHeat pump

The invention discloses a system and technology for removing white smoke exhausted from boiler and industrial kiln chimneys. The system comprises a heat pump, a desulfurization process water heat exchanger, an air heater, a supplemental water heater, a plurality of water feeding and discharging pipelines and a plurality of smoke ducts, wherein the heat pump is used for generating low-temperature water and absorbing heat from low-temperature heat source desulfurization process water, accordingly, the temperature of smoke exhausted from an outlet of a desulfurization tower is lowered, and the amount of water contained in the smoke exhausted from the outlet of the desulfurization tower is decreased; meanwhile, the heat pump can generate high-temperature water which is used for serving as a heat source of the air heater to heat cold air, and surplus heat can be recovered, used for outside heating in winter and used for heating supplemental water in non-heating seasons; and the dual functions of smoke waste heat recovery and white smoke removing are achieved, and under the condition that operation of a boiler is not influenced, zero-cost operation of the white smoke removal process is achieved.

Owner:ZIBO INNOVATION ENERGY TECH CO LTD

Electric drive heat pump unit with smoke comprehensive treatment function

PendingCN108106044AEmission reductionImprove economyMechanical apparatusEmission preventionElectricityPlate heat exchanger

The invention discloses an electric drive heat pump unit with a smoke comprehensive treatment function. The electric drive heat pump unit comprises a refrigerant circulation loop formed by a compressor, a condenser, a throttle valve and an evaporator, the water side of the condenser and the water side of the evaporator are connected with a user air-conditioning system, the water side of the evaporator and the water side of a smoke-water heat exchanger are connected to form a circulated water waste heat recovering loop, a first electric two-way valve and a circulation pump are arranged on the water side of the evaporator, a second electric two-way valve is arranged on a water return main pipe of the user air-conditioning system, a smoke side inlet of the smoke-water heat exchanger is connected with an outlet of a chimney of a boiler, a smoke side outlet of the smoke-water heat exchanger is connected with an air inlet of an air-liquid separator, an exhaust opening is formed in the top ofthe air-liquid separator, a water discharging opening is formed in the bottom of the air-liquid separator, an agent adding opening is formed in the side portion, and an agent adding device is connected to the agent adding opening. By means of the electric drive heat pump unit, waste heat in smoke can be recovered, and contaminant in the smoke is treated.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING

Device and method for spraying, cooling and eliminating white smoke in desulfurization tower of thermal power plant

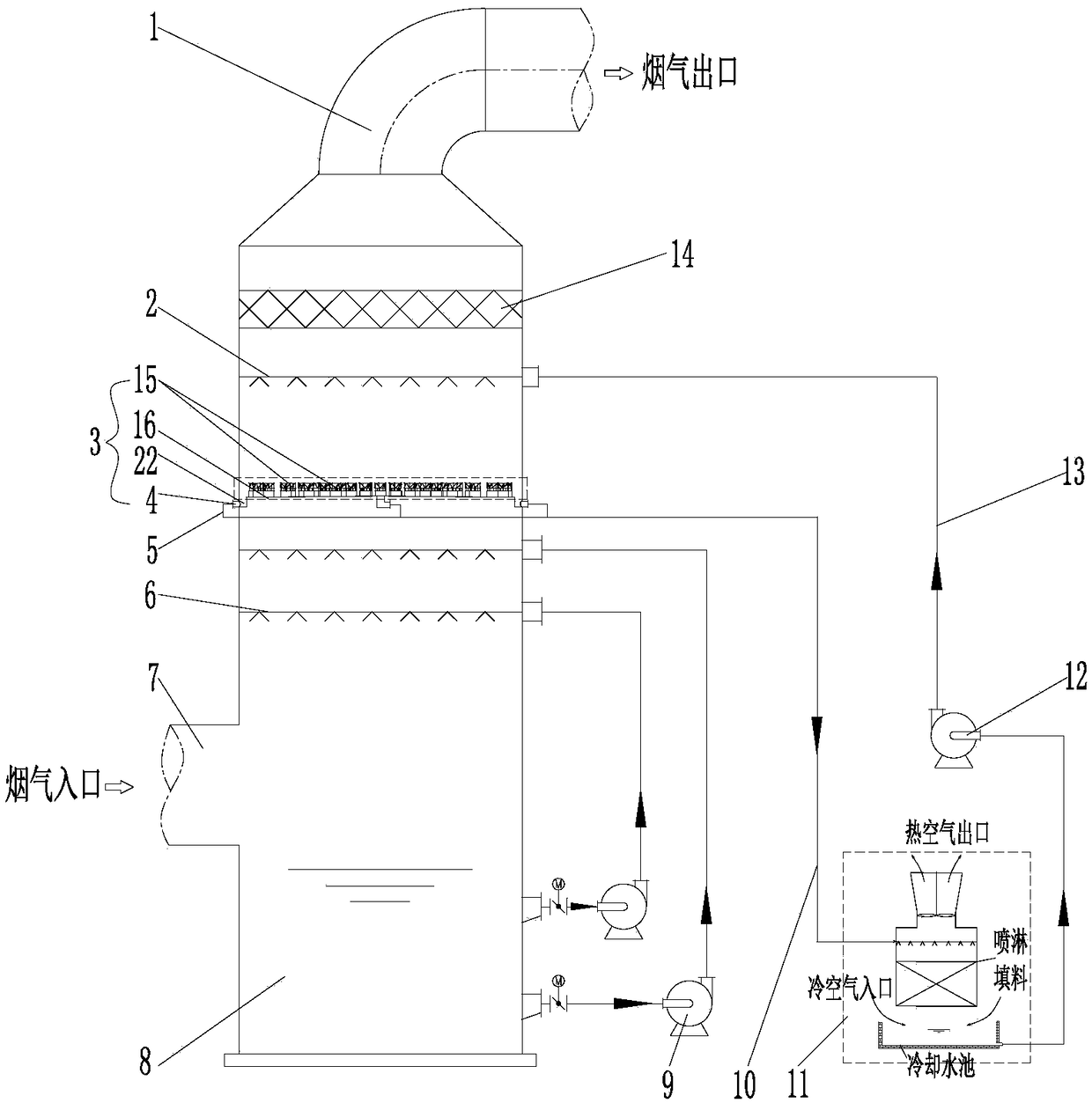

PendingCN109289228ASimple structureShort transformation periodGas treatmentDispersed particle separationSlurryEngineering

The invention relates to a device and method for spraying, cooling and eliminating white smoke in a desulfurization tower of a thermal power plant. The desulfurization tower is internally horizontallyequipped with a demister, a top water spray layer, a liquid holding device and a slurry spray layer from top to bottom successively. The slurry spray layer is located above an inlet of the desulfurization tower. The liquid holding device comprises a drainage port, a concave drainage tank, flue gas through-flow devices and a liquid holding layer; the peripheral edge of the liquid holding layer issurrounded by the concave drainage tank, and a number of liquid drainage outlets are arranged on the concave drainage tank; the upper surface of the liquid holding layer is surrounded by a number of flue gas through-flow devices. The device has the advantages of high device integration, simple operation, reliable operation, no damage to water balance of an absorption tower and no heat exchanger. Therefore, no risk of corrosion leakage of the heat exchanger exists, and the safety is high. By use of the method for eliminating white smoke, the latent heat of vaporization in flue gas is recovered,the heat loss of boiler exhaust gas is further reduced, the moisture carried in the flue gas is reduced, and white smoke plume at a chimney outlet is eliminated.

Owner:CHINA HUADIAN ENG +1

Desulfuration wastewater zero discharge coupling smoke white removal integration system

PendingCN110272081AHandle cleanEliminate Chimney Plaster RainDispersed particle separationWaste water treatment from gaseous effluentsExpansion tankEvaporation

The invention belongs to the technical field of industrial energy saving and environment protection and relates to a desulfuration wastewater zero discharge coupling smoke white removal integration system in a wet-process desulfuration technology. The system comprises a gas-water heat exchanger, a water-water heat exchanger, an evaporation crystallizer, a steam-gas heat exchanger and a hydrophobic expansion tank; heat in high-temperature non-desulfuration smoke is transferred into hot medium water through the gas-water heat exchanger, heat in the hot medium water is transferred into desulfuration wastewater through the water-water heat exchanger, heat in the desulfuration wastewater is transferred into steam after vaporization through the evaporation crystallizer, heat in the steam is transferred into purified smoke through the steam-gas heat exchanger, and liquid-state water generated after the steam is condensed is stored through the hydrophobic expansion tank and can be reused by other technologies in a factory. According to the system, the aims of clean treatment of the desulfuration wastewater and removal of chimney gypsum rain and white smoke are achieved, the problem of water unbalance during operation of a desulfuration tower is solved, safe and reliable operation of the desulfuration tower under the variable working condition is guaranteed, and the operation cost of enterprises is lowered.

Owner:北京新世翼节能环保科技股份有限公司

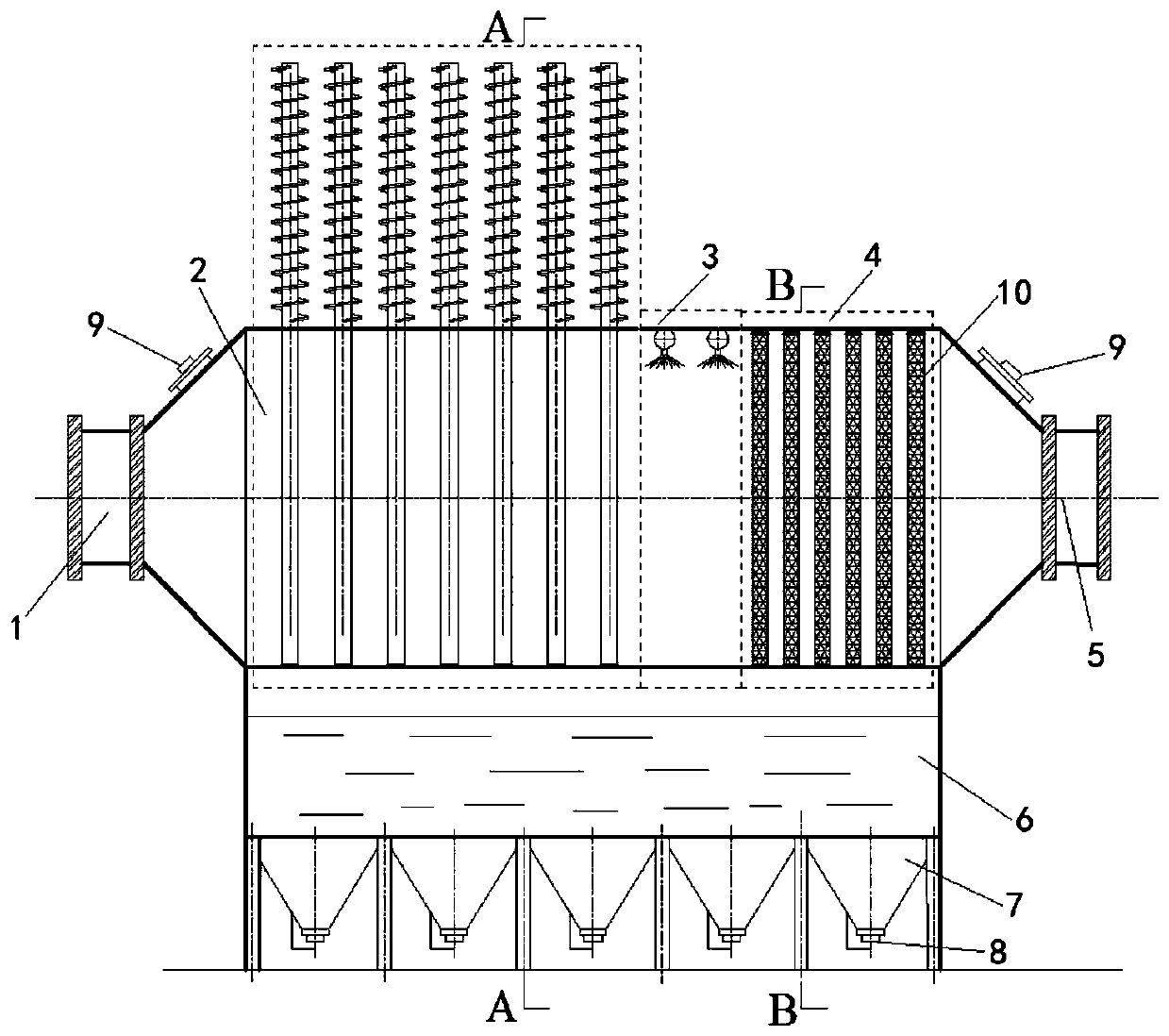

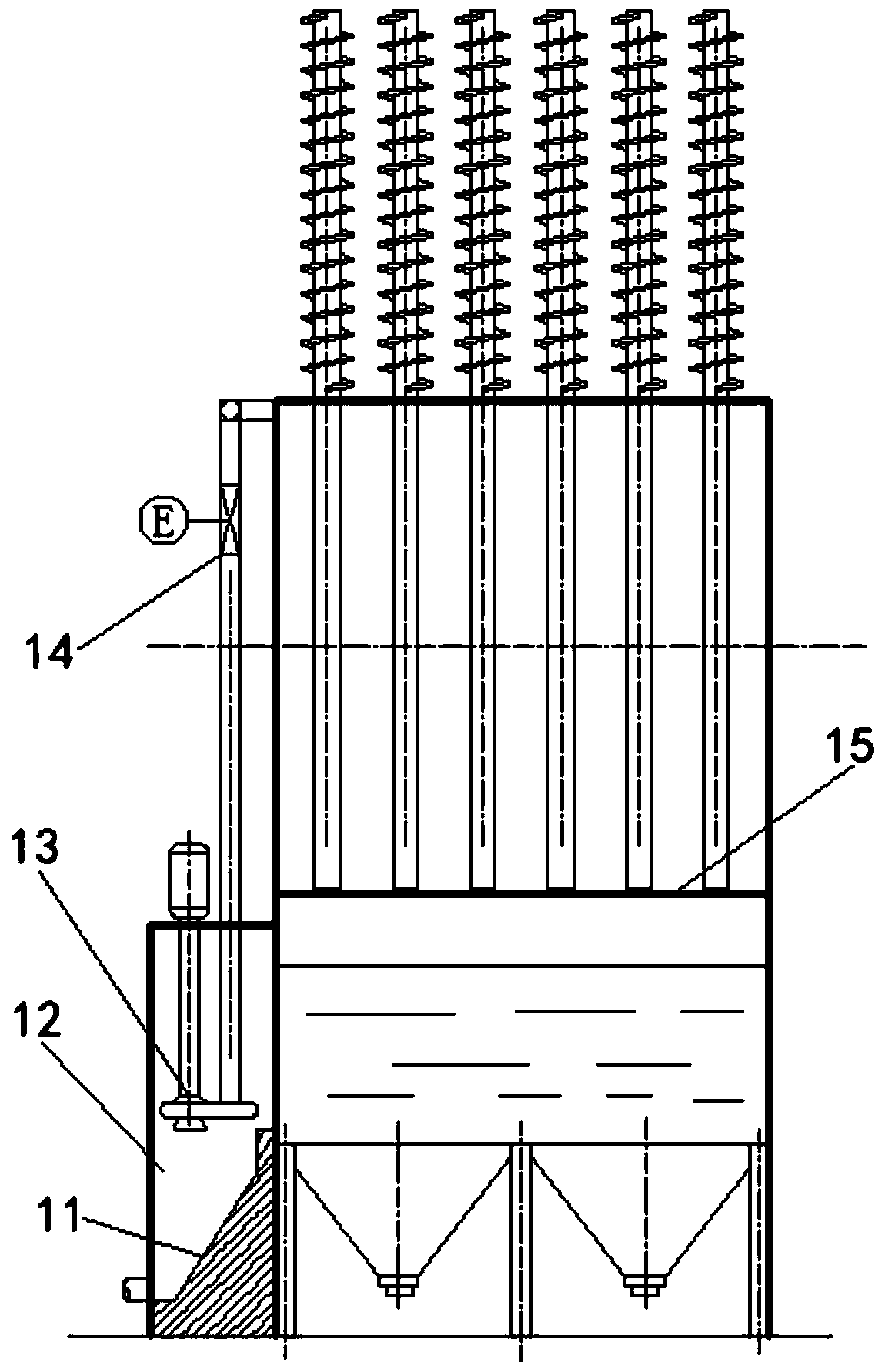

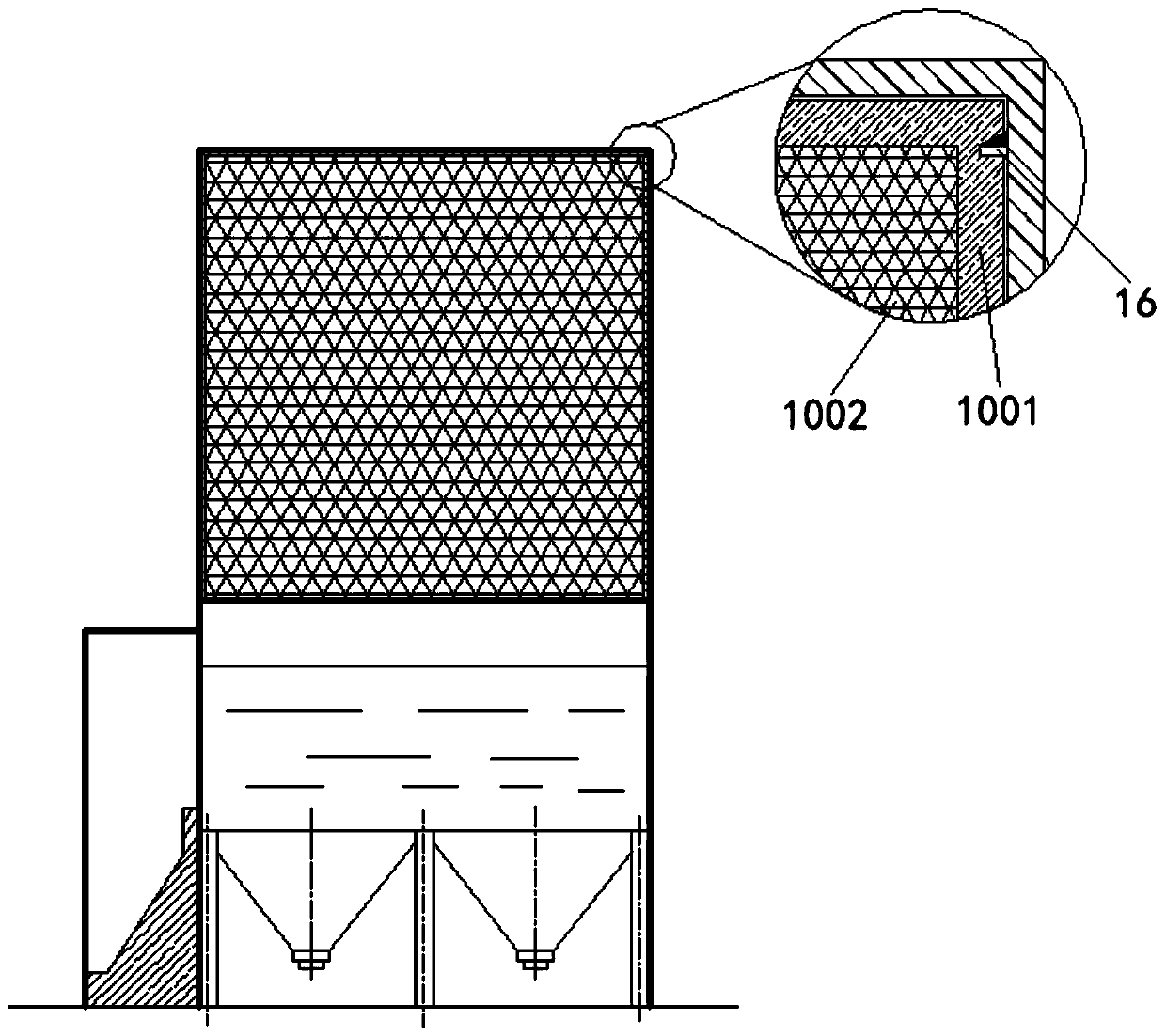

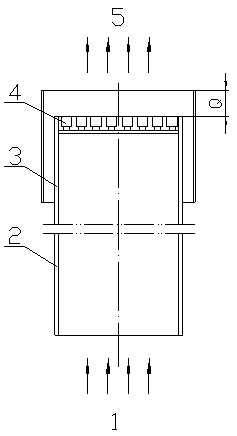

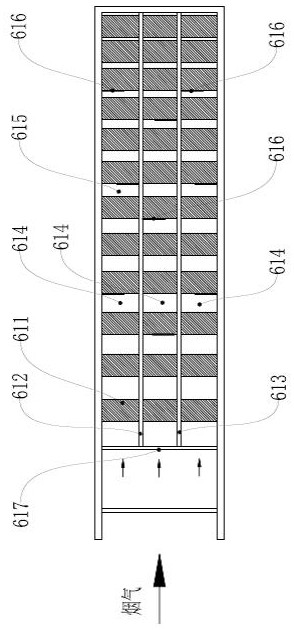

Enhanced white smoke elimination system based on wet electric precipitator ofcoal-fired power plant

PendingCN112264188AEliminate white smoke from chimneysLow energy consumptionIndirect heat exchangersExternal electric electrostatic seperatorHoneycombAtmospheric sciences

The invention discloses an enhanced white smoke elimination system based on a wet electric precipitator of a coal-fired power plant. The system comprises a vertical honeycomb wet electric precipitatorbody, a condensation pipe and an external cooling water tank, a condensation anode plate is arranged in the vertical honeycomb wet electric precipitator body, the condensation anode plate is of a hollow structure, the condensation pipe is inserted into the condensation anode plate, the external cooling water tank is arranged in the condensation anode plate, the outlet of the external cooling water tank is communicated with the inlet of the condensation pipe, and the inlet of the external cooling water tank is communicated with the outlet of the condensation pipe. According to the system, thephenomenon of white smoke and rain can be avoided, the operation effect of the dust remover is improved, and the energy consumption of a power plant is reduced.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

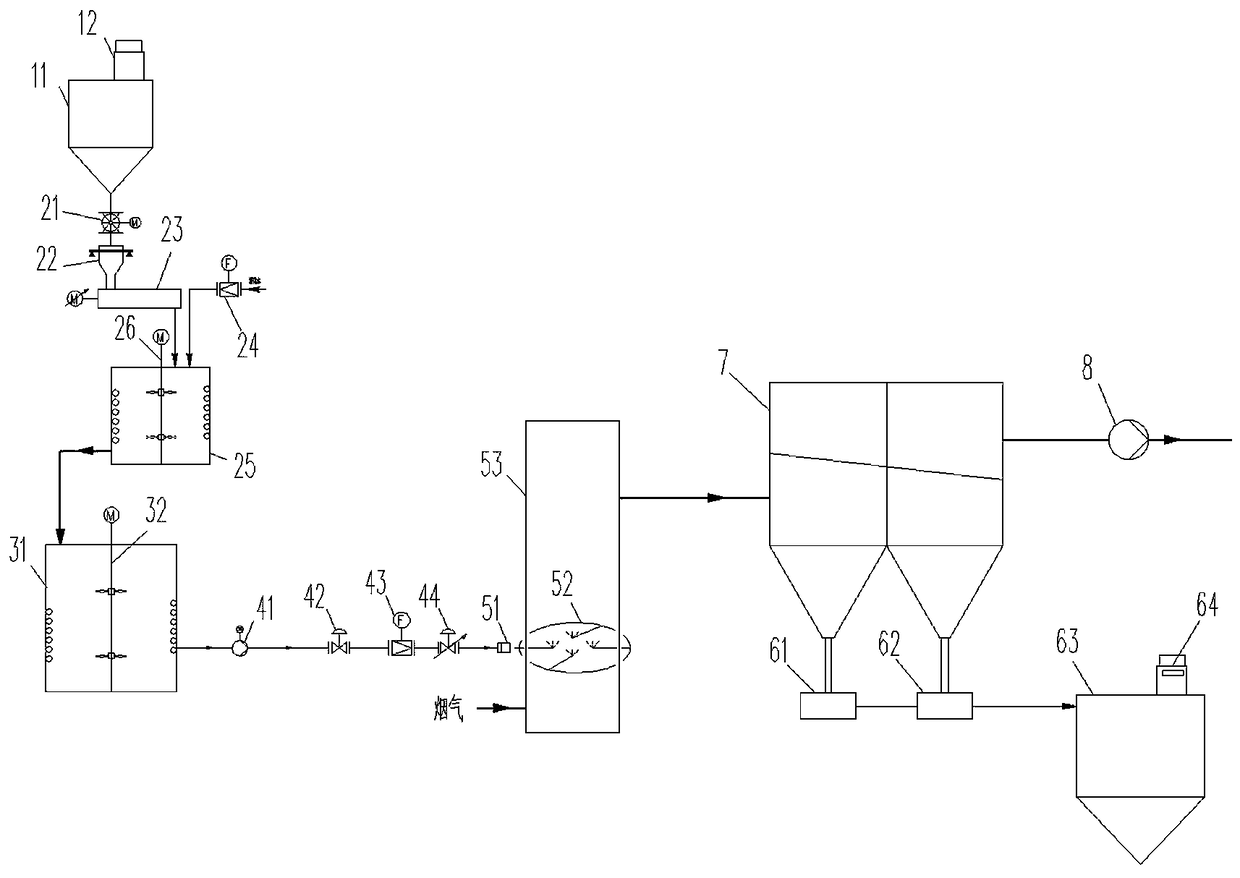

Flue gas desulfurization system for sheet glass industry melting furnace

InactiveCN108837687AMeet emission standardsGuaranteed stabilityGas treatmentDispersed particle separationFlat glassFlue gas

The invention discloses a flue gas desulfurization system for a sheet glass industry melting furnace. The system comprises a sodium carbonate storage part, wherein the sodium carbonate storage part comprises a sodium carbonate storage bin, a sodium carbonate dissolving part, a sodium carbonate solution storage part, a sodium carbonate solution conveying part, a spraying desulfurization part and adust removal collecting part; sodium carbonate raw materials pass through the sodium carbonate storage part, the sodium carbonate dissolving part, the sodium carbonate solution storage part and the spraying desulfurization part; a sodium carbonate solution is sprayed to flue gas in a desulfurization tower for desulfurization, the desulfurized flue gas is discharged by a bag filter, and byproductsare collected through a byproduct storage bin. Desulfurization efficiency of the desulfurization system can reach 90% or higher, and emission standards are met.

Owner:SHENZHEN TRIUMPH TECH ENG +1

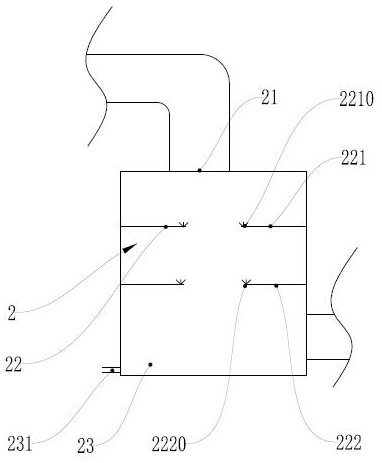

A wet flue gas self-returning integrated flue gas purification device and its application

The invention relates to a wet smoke self-temperature returning integrated smoke purification device and an application thereof. The device comprises a washing tower outer barrel, a smoke outlet, an absorbing liquid storing cavity and a gas inlet flue extending barrel, the smoke outlet is disposed at the top of the washing tower outer barrel, the absorbing liquid storing cavity is arranged below the washing tower outer barrel, the gas inlet flue extending barrel is connected with the side of the washing tower outer barrel and extends to inside of the washing tower outer barrel, a smoke inlet is arranged at the front end of the gas inlet flue extending barrel, a same-direction fair current spraying head and a reverse spraying head are arranged inside the gas inlet flue extending barrel, directions of liquid drop sprayed by the same-direction fair current spraying heads and smoke flowing direction are the same, vertical opposite spraying is formed with the reverse spraying heads, and foam induction rings are arranged between the same-direction fair current spraying heads and the reverse spraying heads. According to the wet smoke self-temperature returning integrated smoke purification device and the application thereof, multiple functions such as dust removing, desulfuration, defogging and smoke heat exchange are integrated, device structure is compact, the floor space is small, the problems of 'white smoke' or chimney rain of wet purification smoke can be remarkably eliminated, and influence of smoke discharging on surroundings or vision can be reduced.

Owner:SHANGHAI JIAOTONG UNIV +1

Chimney

ActiveCN108692322ASolve the "white smoke" problemReduce the ratioDispersed particle separationChimneysFlue gasEngineering

The invention discloses a chimney. The chimney is provided with a demister and an outer sleeve which are arranged on the top of a traditional chimney, the outer sleeve is arranged on the outer side ofthe chimney, the outer sleeve is of a cylindrical structure with an upper opening and a lower opening, and can be cylindrical or cone-shaped; and the upper edge of the outer sleeve is higher than theupper edge of the chimney along a certain distance, the lower edge of the outer sleeve is lower than the upper edge of the chimney, an annular space is formed between the outer sleeve and the chimney, and the demister is arranged inside the chimney, the top of the demister is flush with the upper edge of the chimney. According to the chimney, the proportion of saturated water in a flue gas is greatly reduced, white smoke is remarkably eliminated, so that pollution to the surrounding environment is reduced, and the problem of "the white smoke" of the chimney is effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A white smoke desulfurization and dust removal system

ActiveCN111729484BImprove desulfurizationImprove dust removal effectCombination devicesGas treatmentThermodynamicsSmoke Emission

The invention discloses a desulfurization and dust removal system for white smoke, which comprises an induced draft fan, a pretreatment chamber, a desulfurization and dust removal tower, a cooling and whitening chamber, a temperature-rising whitening chamber and a diffusion and whitening chamber connected in sequence. The top of the pretreatment chamber A first flue gas inlet is provided, and the induced air pipe of the induced draft fan communicates with the first flue gas inlet of the pretreatment chamber, and the pretreatment chamber is provided with a first spray device; the cooling The top of the de-whitening chamber is provided with a first partition, and the first partition divides the cooling and de-whitening chamber into successively connected spraying parts and demisting parts, and the top of the spraying part is provided with a second spraying part. A shower device, the demisting part is provided with a first demister. The white smoke elimination, desulfurization and dust removal system has good effects of white smoke elimination, desulfurization and dust removal, simple structure, convenient maintenance, low maintenance and operation costs, and solves the problems of serious white smoke emission and heavy smoke odor in the production of ceramic factories. question.

Owner:FOSHAN DONGHUA SHENGCHANG NEW MATERIAL CO LTD

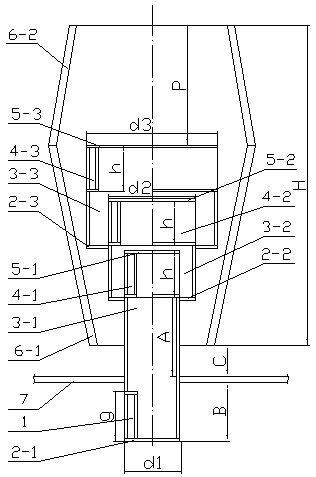

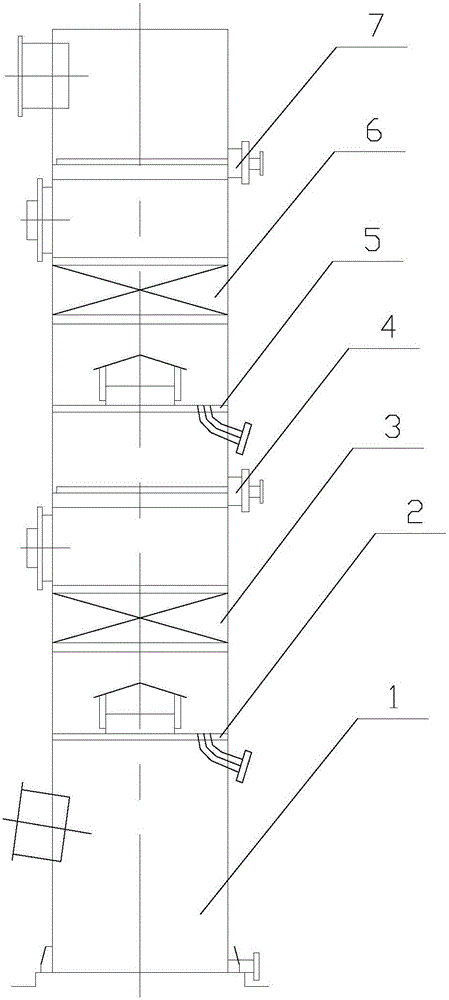

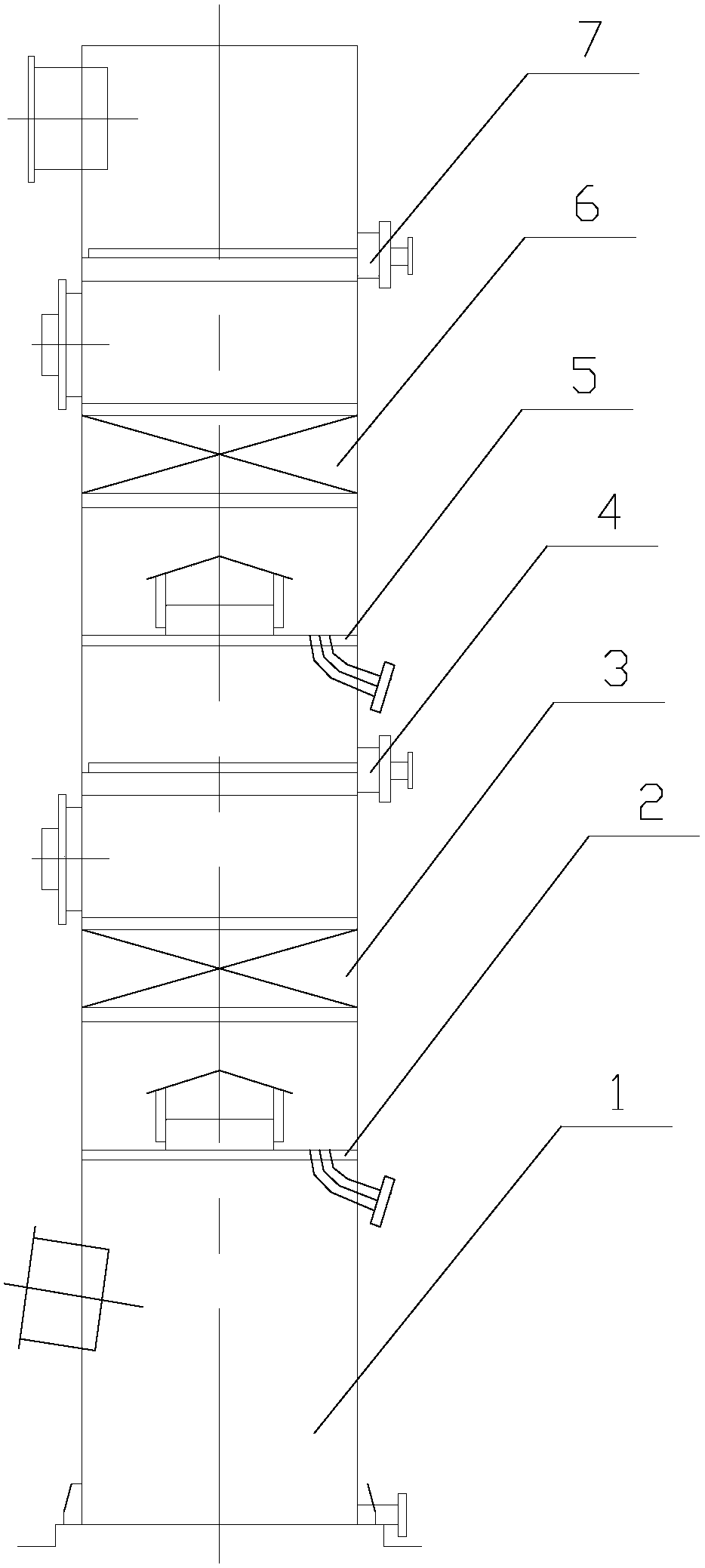

Double-membrane microelectrostatic precipitator

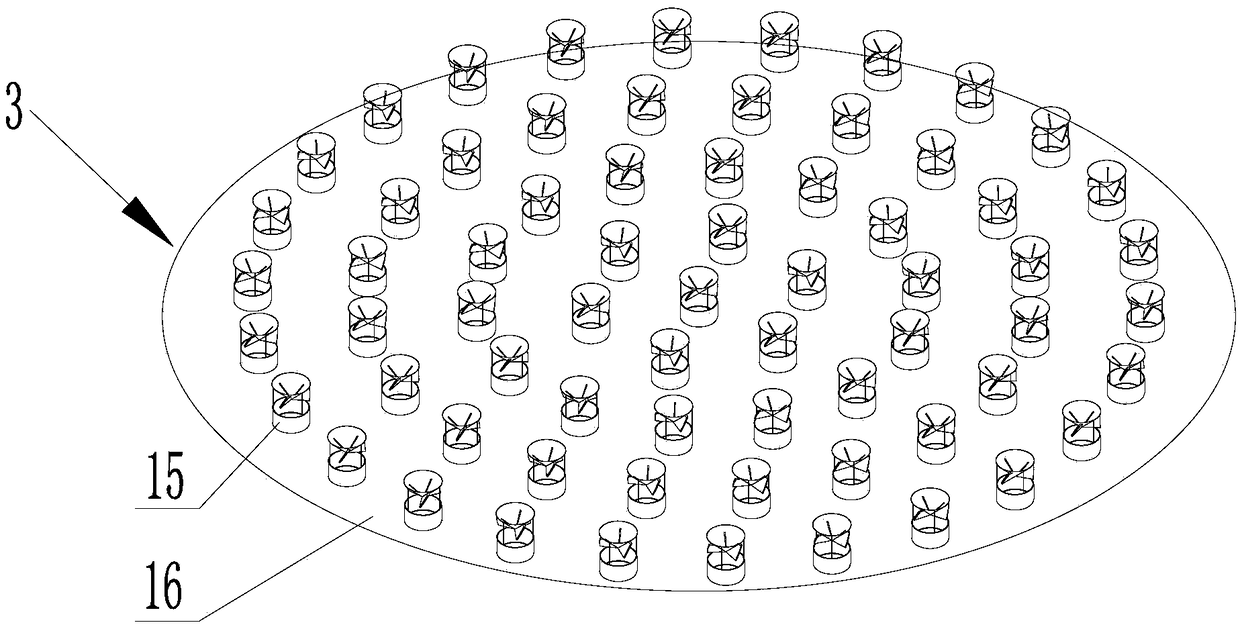

ActiveCN106110806AMeeting ultra-low emission requirementsSolve the phenomenon of gypsum rainCombination devicesParticulatesCyclone

The invention relates to a double-membrane microelectrostatic precipitator, and relates to the field of special equipment for ultra-low-emission of particulate matter. A primary dust capturing section comprises a primary three-dimensional mass transfer liquid collecting disc, a primary membrane micro-electrocoagulation layer and a primary membrane distributor, and the primary membrane micro-electrocoagulation layer is arranged above the primary three-dimensional mass transfer liquid collecting disc; the primary membrane distributor is arranged above the primary membrane micro-electrocoagulation layer, and a secondary dust capturing section is arranged above the primary membrane distributor; the secondary dust capturing section comprises a secondary three-dimensional mass transfer liquid collecting disc, a secondary membrane micro-electrocoagulation layer and a secondary membrane distributor, and the secondary membrane micro-electrocoagulation layer is arranged above the secondary three-dimensional mass transfer liquid collecting disc; the secondary membrane distributor is arranged above the secondary membrane micro-electrocoagulation layer. By adopting a combination structure of special fillings and special three-dimensional mass transfer liquid collecting discs, and special spraying, and a simple combination with dehumidification equipment, the comprehensive environmental protection and emission reduction effects of gravity dust removal, inertial dust removal, cyclone dust removal and the like, which cannot be achieved by the traditional dust removal process, can be achieved.

Owner:HE BEI NEWTHREETALENT ENVIRONMENTAL TECH CO LTD

A double-membrane micro-electrostatic precipitator

ActiveCN106110806BMeeting ultra-low emission requirementsSolve the phenomenon of gypsum rainCombination devicesCycloneParticulates

The invention relates to a double-membrane microelectrostatic precipitator, and relates to the field of special equipment for ultra-low-emission of particulate matter. A primary dust capturing section comprises a primary three-dimensional mass transfer liquid collecting disc, a primary membrane micro-electrocoagulation layer and a primary membrane distributor, and the primary membrane micro-electrocoagulation layer is arranged above the primary three-dimensional mass transfer liquid collecting disc; the primary membrane distributor is arranged above the primary membrane micro-electrocoagulation layer, and a secondary dust capturing section is arranged above the primary membrane distributor; the secondary dust capturing section comprises a secondary three-dimensional mass transfer liquid collecting disc, a secondary membrane micro-electrocoagulation layer and a secondary membrane distributor, and the secondary membrane micro-electrocoagulation layer is arranged above the secondary three-dimensional mass transfer liquid collecting disc; the secondary membrane distributor is arranged above the secondary membrane micro-electrocoagulation layer. By adopting a combination structure of special fillings and special three-dimensional mass transfer liquid collecting discs, and special spraying, and a simple combination with dehumidification equipment, the comprehensive environmental protection and emission reduction effects of gravity dust removal, inertial dust removal, cyclone dust removal and the like, which cannot be achieved by the traditional dust removal process, can be achieved.

Owner:河北纽思泰伦科技发展有限公司

Closed cooling tower and method for eliminating saturated air at air outlet

PendingCN111750697AEliminate "white smoke"Reduce energy consumptionTrickle coolersThermodynamicsCooling tower

The invention belongs to the technical field of cooling towers, and particularly relates to a closed cooling tower and a method for eliminating saturated air at an air outlet. The cooling device comprises cooling fins, a blowing type fan, a water collector, a spraying pipeline, a cooling pipe, a water collecting tank and a shell. The radiating fins, the blowing type fan, the water collector, the spraying pipeline, the cooling pipe and the water collecting tank are sequentially and horizontally arranged in the shell from top to bottom, and the cooling fins communicate with the cooling pipe. According to the closed cooling tower, the fan layout of a traditional closed cooling tower is changed, the blowing type fan serves as the cooling tower fan, the water collector is arranged at the bottomof the fan, primary condensation separation is conducted on saturated air, the cooling fins are arranged at the top of the fan, secondary absorption is conducted on heat in the saturated air, the saturated air is not saturated any more, and therefore the purpose of eliminating the saturated air is achieved. The blowing type fan is arranged below the cooling fins, cold energy generated by the blowing type fan is secondarily utilized, and energy consumption is reduced.

Owner:XIAN CHANGQING TECH ENG +1

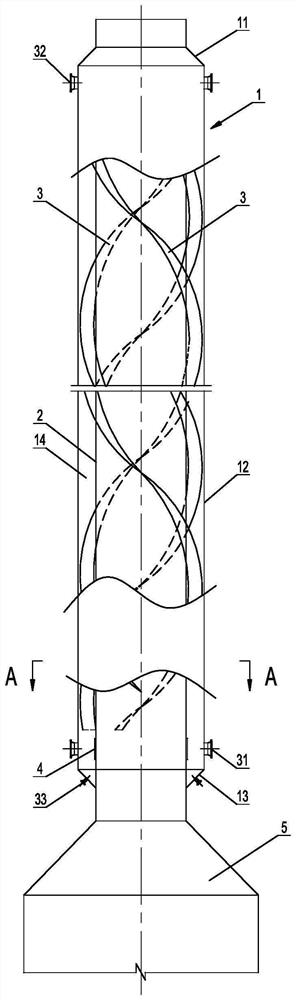

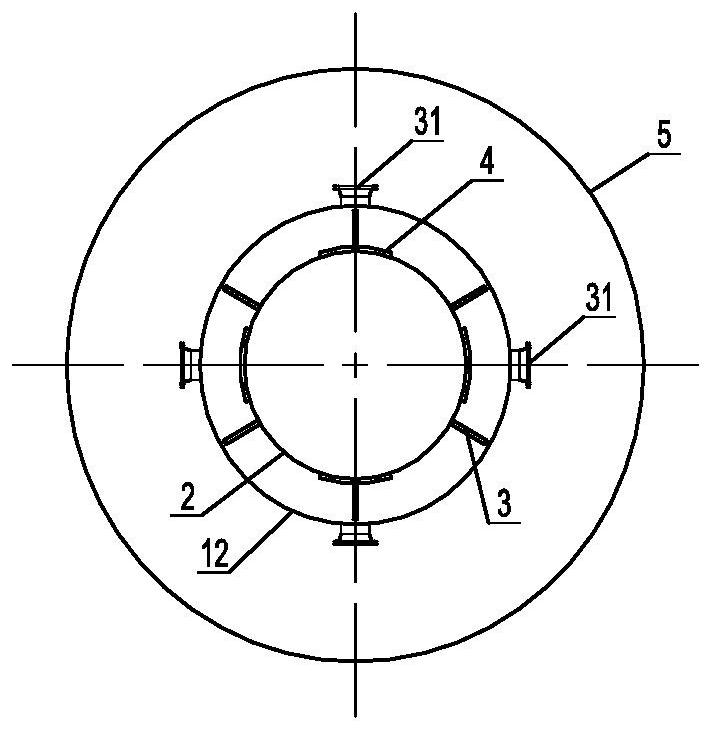

Chimney structure capable of effectively eliminating white smoke

PendingCN114857607ARealize heat exchangeIncrease temperatureCombustion technology mitigationChimneysFlue gasEmission standard

The chimney structure capable of effectively eliminating the white smoke comprises an outer sleeve, a chimney and a spiral fin plate, the outer sleeve is arranged on the outer side of the chimney in a sleeving mode, the outer sleeve is composed of an upper conical section, a shell ring and a lower conical section, the shell ring is welded to the upper conical section and the lower conical section, and the upper conical section and the lower conical section are welded to the chimney. An annular cavity is defined by the outer wall of the chimney and the inner wall of the outer sleeve, a steam inlet connecting pipe and a steam outlet connecting pipe are welded to the shell ring, a condensate outlet connecting pipe is welded to the lower conical section, and the steam inlet connecting pipe, the steam outlet connecting pipe and the condensate outlet connecting pipe are communicated with the annular cavity. The spiral fin plate is wound and welded to the outer wall of the chimney and located in the annular cavity, the lower end opening of the chimney is used for introducing low-temperature flue gas which is treated and reaches the emission standard into the chimney, and the steam inlet connecting pipe is used for introducing high-temperature steam into the annular cavity. The heat exchanger is simple in structure, convenient to disassemble and assemble, safe and reliable in operation, capable of shortening the heat exchange technological process, small in occupied area and wide in application prospect.

Owner:SINOPEC NINGBO ENG +2

A treatment method and device for flue gas and flue gas desulfurization wastewater

ActiveCN108619871BIncrease water vapor contentRaise the acid dew pointCombination devicesGas treatmentPlate heat exchangerBaghouse

The invention relates to a treatment method for flue gas and flue gas desulfurization wastewater. In the flue gas / desulfurization wastewater heat exchanger, the flue gas is used to exchange heat for the desulfurization wastewater, and a nozzle is set at the outlet of the flue gas to spray NaOH solution to make the flue gas At this time, the flue gas enters the bag filter to remove dust and sulfate / sulfuric acid droplets, and then enters the desulfurization tower; desulfurization purification and heating are carried out in the desulfurization tower, and the waste water at the bottom of the tower is used as The absorption liquid is circulated, and the others enter the plate heat exchanger in the form of desulfurization wastewater; the plate heat exchanger uses the steam condensed water generated by the heating coil in the exhaust cylinder to preheat the desulfurization wastewater, and after preheating, the wastewater enters the flue gas / desulfurization wastewater exchange heater. On the basis of making full use of the waste heat of the flue gas, the present invention realizes the dual purpose of purifying the flue gas to meet the emission requirements and zero discharge of flue gas desulfurization waste liquid, and simultaneously eliminates "white smoke" and "blue smoke", and reduces the cost of flue gas desulfurization. and the comprehensive treatment cost of desulfurization waste liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com