A wet flue gas self-returning integrated flue gas purification device and its application

A flue gas purification and self-heating technology, which is applied in combination devices, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of forming large droplets, falling near chimneys, affecting local climate, chimney precipitation, etc. Achieving good design concepts and promotion prospects, eliminating chimney rain problems, and saving construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

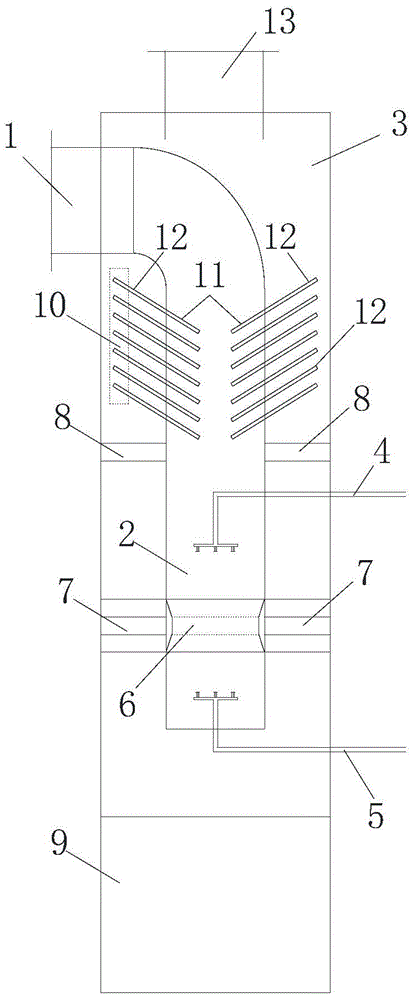

[0031] A wet flue gas self-returning type integrated flue gas purification device, its structure is as follows figure 1 As shown, it includes the washing tower outer cylinder 3, the flue gas outlet 13 arranged on the top of the washing tower outer cylinder 3, the absorption liquid storage chamber 9 arranged under the washing tower outer cylinder, connected to the side of the washing tower outer cylinder 3 and extending To the air intake flue extension cylinder 2 in the outer cylinder 3 of the washing tower, the front end of the air intake flue extension cylinder 2 is provided with a flue gas inlet 1, the flue gas inlet 1, the air intake flue extension cylinder 2 and the washing tower outer cylinder 3 It can be transformed by using the original flue and scrubber device.

[0032] In the intake flue extension tube 2, there are co-direction downstream nozzles 4 and reverse nozzles 5, wherein the liquid droplets sprayed by the same direction downstream nozzles 4 are in the same dir...

Embodiment 2

[0043] The present invention takes the actual coal-fired flue gas as the research object to carry out experimental research. 1000m from the coal-fired boiler flue 3 / h of actual coal-fired flue gas, and a set of wet flue gas self-returning integrated flue gas purification device has been established. Inlet flue gas temperature is 150°C, SO 2 The concentration is 1200mg / m 3 , the dust concentration is 5g / m 3 . The test system adopts the limestone-gypsum wet desulfurization process to desulfurize the flue gas, and the liquid-gas ratio is 10L / m 3 , the superficial gas velocity is 3m / s, the calcium-sulfur ratio is 1.1, and the gas-liquid contact time is 10s. After 100 hours of operation, SO 2 The outlet concentration is controlled at 100mg / m 3 Within the limit, the outlet dust concentration is controlled at 0.4g / m 3 Below, the outlet flue gas temperature is above 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com