White smoke eliminating chimney

A chimney and white smoke technology, applied in the field of white smoke elimination chimney, can solve the problems of limited condensation and can not effectively solve the white smoke in the chimney, and achieve the effect of reducing the proportion of saturated water, eliminating white smoke and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

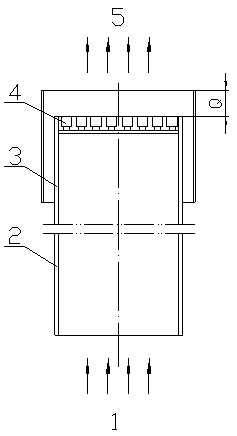

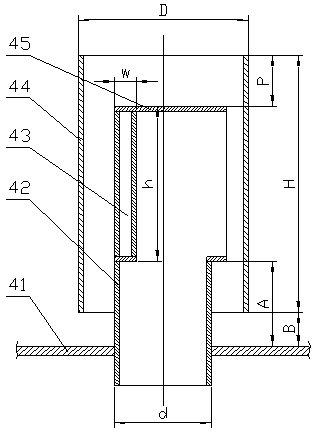

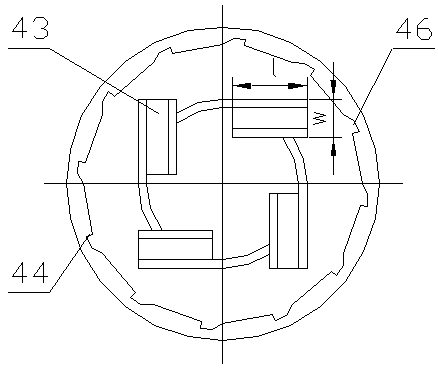

Embodiment 1

[0058] There is a chimney used in the wet desulfurization process, the diameter of the chimney is 3000mm, and a large amount of white smoke is found at the mouth of the chimney during use, which seriously affects the appearance of the environment. On the basis of the original chimney, a demister and an outer sleeve were added on the top of the chimney. The diameter of the outer sleeve was 3050mm. The demister used 200 demist components. The white smoke at the outlet of the white smoke chimney is obviously eliminated, and the surrounding environment is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com