Chimney structure capable of effectively eliminating white smoke

A chimney and white smoke technology, applied in the direction of climate sustainability, greenhouse gas reduction, combustion methods, etc., can solve the problems of long heat exchange process, complex equipment structure, low heat exchange efficiency, etc., to achieve safe and reliable operation, increase Small heat transfer area and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

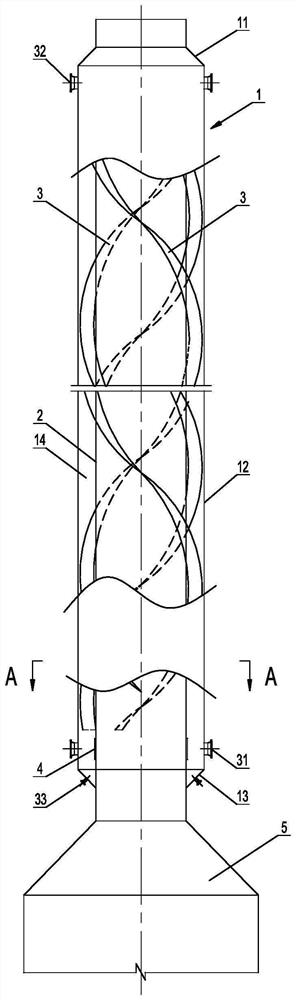

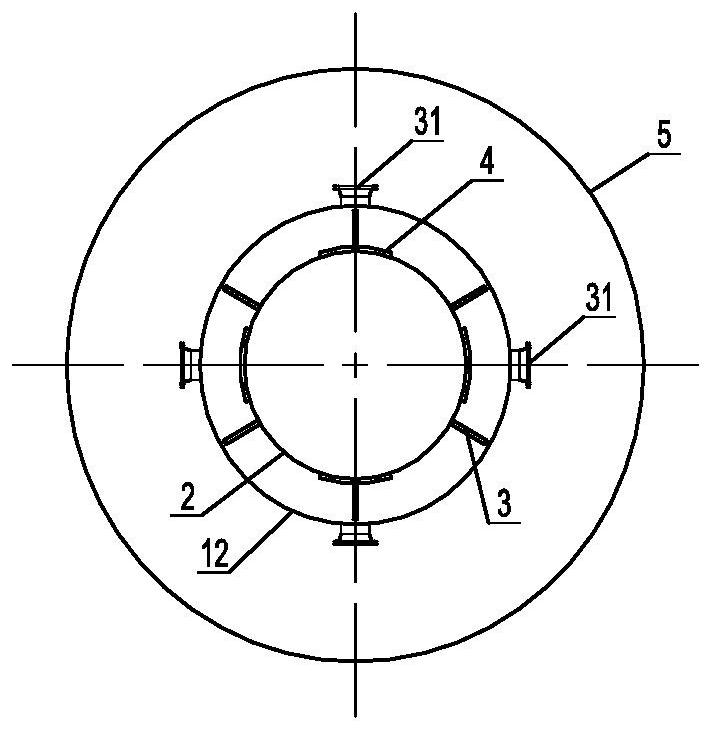

[0017] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0018] The chimney structure of the embodiment can effectively eliminate white smoke, such as figure 1 and figure 2 As shown, it includes an outer sleeve 1, a chimney 2 and a spiral fin plate 3. The outer sleeve 1 is sleeved on the outside of the chimney 2. The chimney 2 is a traditional chimney 2. The outer sleeve 1 consists of an upper cone section 11, a barrel section 12 It is composed of the lower cone section 13, the barrel section 12 is welded with the upper cone section 11 and the lower cone section 13 respectively, the upper cone section 11 and the lower cone section 13 are respectively welded with the chimney 2, and the outer wall of the chimney 2 is surrounded by the inner wall of the outer sleeve 1. The annular cavity 14 is formed, the tube section 12 is welded with a steam inlet pipe 31 and a steam outlet pipe 32, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com