Desulfuration wastewater zero discharge coupling smoke white removal integration system

A desulfurization wastewater and zero-discharge technology, which is applied in the fields of gaseous effluent wastewater treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of wasting water resources, unbalanced water balance of desulfurization towers, and increasing operating costs of enterprises, etc. , achieve significant economic and environmental benefits, eliminate chimney gypsum rain and white smoke, and protect the tail flue and chimney

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

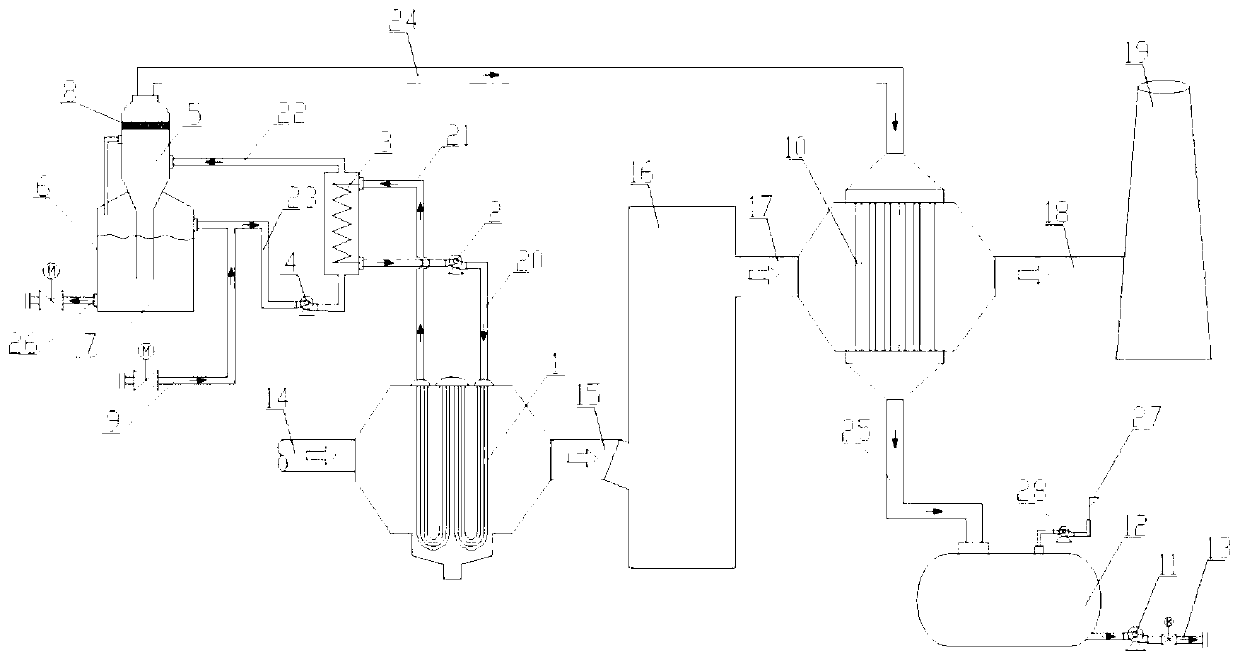

[0044] Such as figure 1 As shown, an integrated system for zero discharge of desulfurization wastewater coupled with flue gas dewhitening, including air-water heat exchanger 1, water-water heat exchanger 3, evaporation crystallizer 6, steam-gas heat exchanger 10 and hydrophobic expansion Box 12.

[0045] The air-water heat exchanger 1 is a shell-and-tube heat exchanger, including a shell and heat exchange tubes arranged inside the shell, and the shell of the air-water heat exchanger 1 has a heat exchanger flue gas inlet 14 and the flue gas outlet 15 of the heat exchanger; the gas-water heat exchanger 1 is arranged between the desulfurization tower 16 and the original flue gas flue, and the flue gas inlet 14 of the heat exchanger communicates with the original flue gas flue for heat exchange The flue gas outlet 15 of the device communicates with the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com