Treatment process for improving high-temperature, salt and corrosion resisting performance of hot spraying coating

A processing method, thermal spraying technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of low overall laser energy conversion efficiency, small laser energy penetration depth, workpiece surface oxidation, etc., to achieve High degree of automation, stable quality, and clean processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with the examples.

[0022] The HOPE-I high-current pulsed electron beam device is used to irradiate the thermal spray coating to improve its high temperature salt corrosion resistance. Specific steps are as follows:

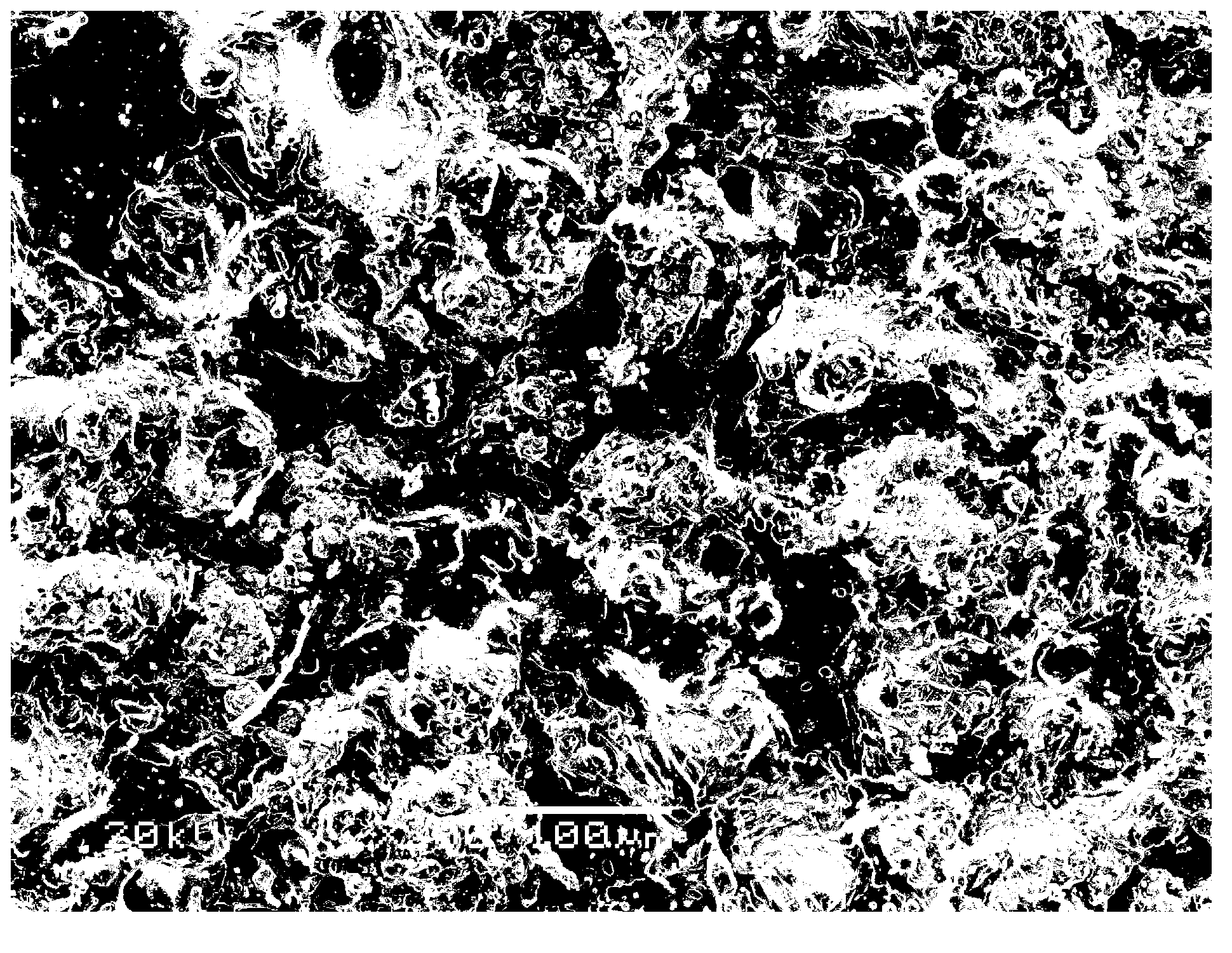

[0023] (1) Sandblasting and roughening the surface of the 45# steel base material;

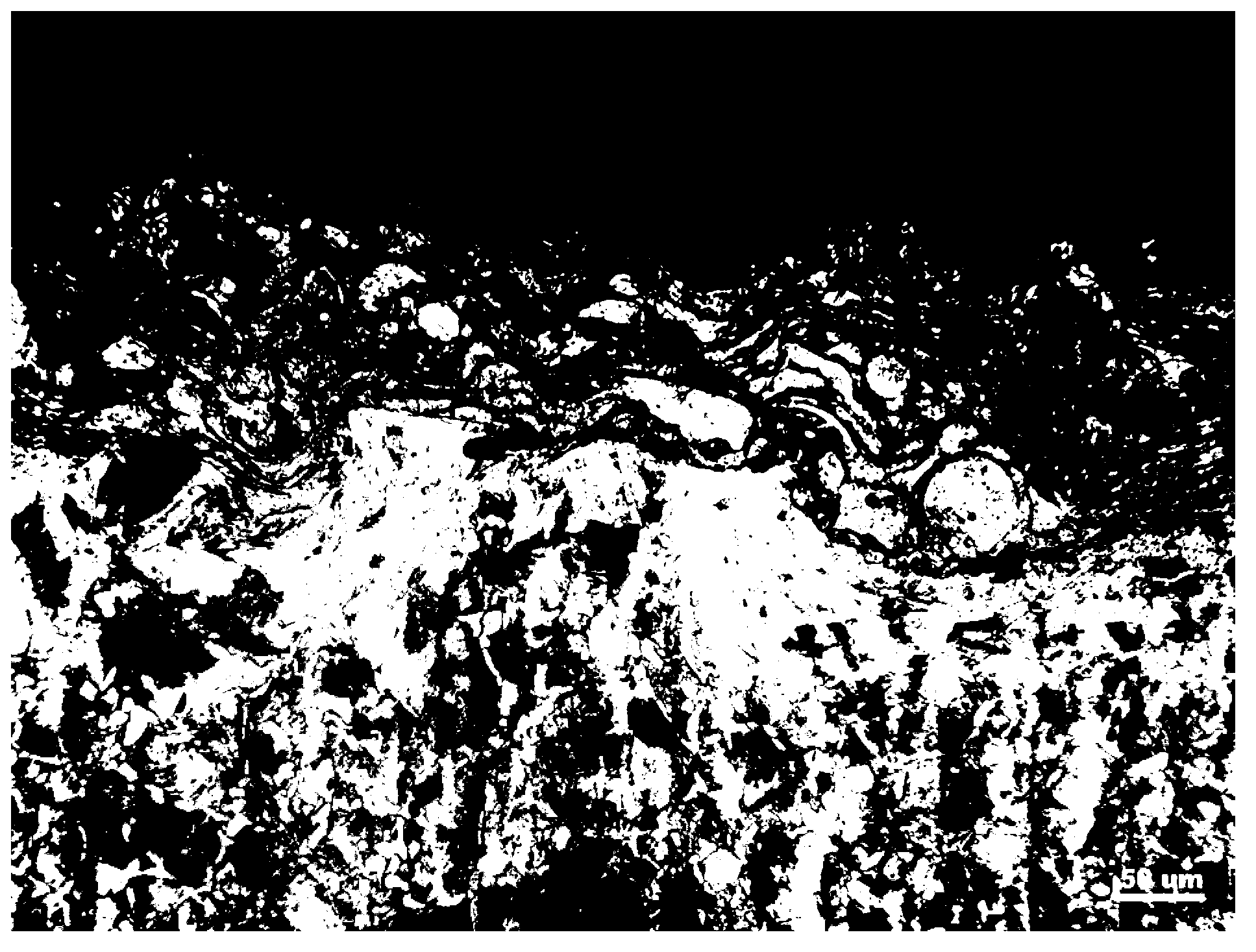

[0024] (2) Use the ZPG-400B arc spraying system, QDⅢ-250 spray gun to spray NiCrAl (10.5 Cr, 4.5 Al, Ni balance) coating with a thickness of about 50 μm, the spraying distance is 20 cm, the gun moving speed is 100 mm / s, and the air supply pressure is 0.5 MPa;

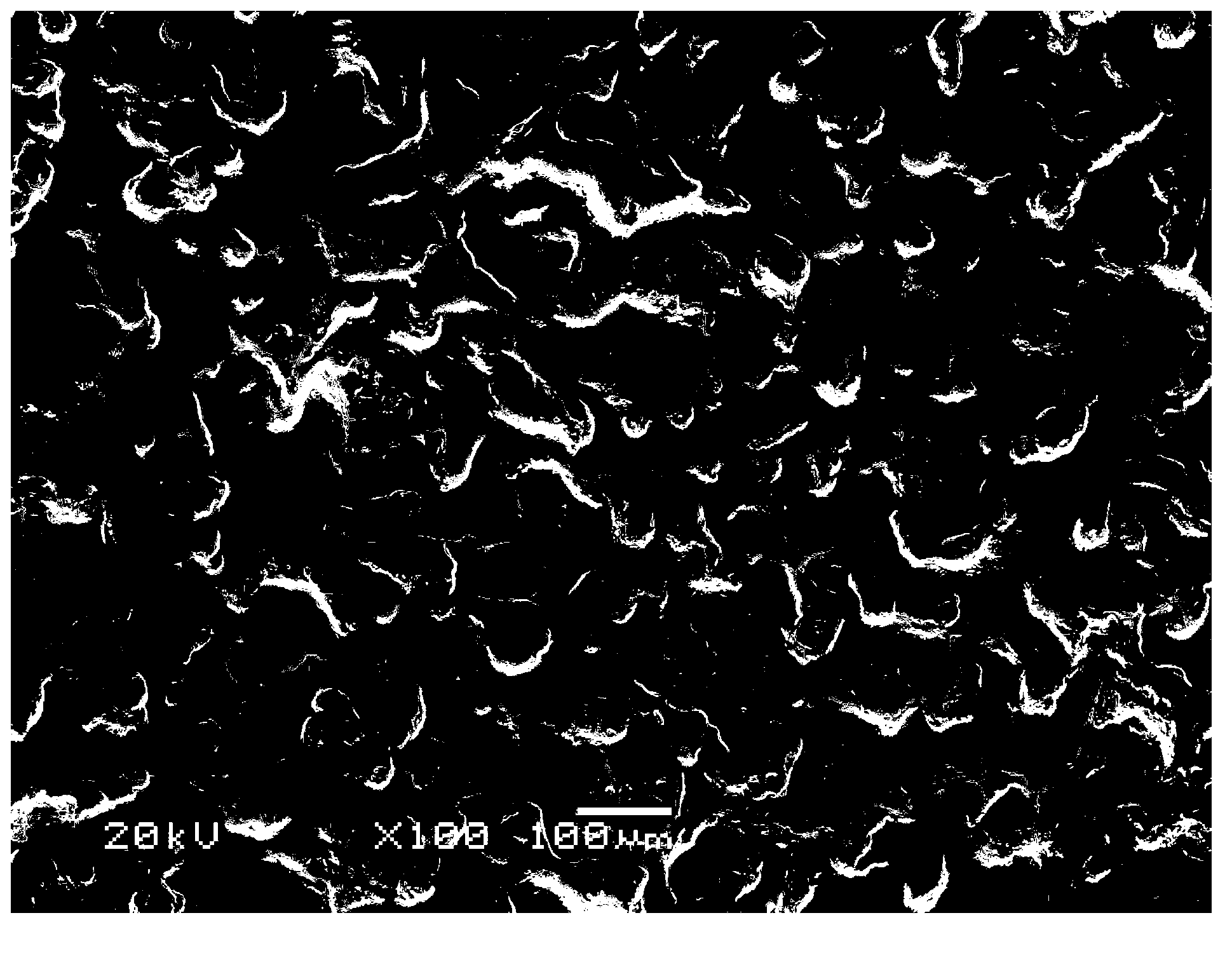

[0025] (3) Use an electric grinder at 1000r / min to repeatedly grind the surface of the coating, control the compaction force, remove loose deposits on the surface of the thermal spray coating, and clean it by blowing dry compressed air;

[0026] (4) Put the coated workpiece with the surface cleaned into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com